102.02 Contents of Proposal - Progress Clause

Progress Clause

The progress clause is intended to specify the construction timing and schedule requirements to the contractor. The progress clause is provided by the Construction Engineer at the Omissions and Errors Check (OEC) meeting. This document provides the project start and completion dates as well as any interim dates (e.g. open to traffic, staging, milestone) The contractor is required to prepare a progress schedule for submittal that incorporates the project dates as noted in the progress clause. Traffic requirements and liquidated damages are not to be described in detail in the progress clause. However, the progress clause must mention that failure to meet the specified date(s) will result in the assessment of liquidated damages as specified in other contract documents.

If the project involves an expedited schedule, the progress clause is to include the language referenced in the Boilerplate Progress Clause.

The Special Provision for High-Tension Cable Barrier, 12SP807(F), requires corrective action for end terminal foundation movement exceeding one inch within 12 months of final cable tensioning. This requirement dictates that high-tension cable barrier projects must have delayed final acceptance. The final acceptance date must occur after the 12 month acceptance period for the barrier and after any corrective work required of the contractor. This will ensure specification compliance and allow the completion of any corrective actions.

Progress clause documentation must also take this 12 month acceptance period into account for final project completion dates. The contractor must have time to complete the required measurements and perform any corrective action that is required. It is suggested that an additional 60 days be included on these projects in addition to the 12 month period to allow for completion of corrective action.

The table below details the recommended timelines for delivery and procurement of typical long-lead items. When developing the Progress Clause dates, consider these timelines as they can have a significant impact on the constructability of a project. Considerations should also be made for any procurement times associated with unique special provisions where certain manufacturers or products are specified. More information regarding steel superstructure is provided here.

|

| |

|---|---|

|

|

(includes typical timeframes for development and review of procurement, shop drawings, fabrication, and delivery) |

|

Steel Plate Girders and Rolled Beams – with flange thicknesses less than three inches |

26 weeks |

|

Bascule, Arch, Tub Girder, High Performance Steel, Plate Girders and Rolled Beams – with flange thicknesses three inches or greater |

Consult Structural Fabrication Unit |

|

Steel Pipe pile in excess of 14 inches diameter, and HP shapes greater than 14 inches in depth. |

12 weeks |

|

Concrete Beams |

8 to 12 weeks |

|

Mast Arms / Strain Poles |

25 weeks |

|

Concrete Spun Poles |

14 weeks |

|

Lighting Towers |

25 weeks |

|

Intelligent Transportation Systems (ITS) projects and components |

Consult ITS Program Office |

|

Delineator and 3# U-Channel Posts |

21 to 34 weeks |

|

Barrier Gates |

5 to 10 weeks - Consult Work Zone Delivery Engineer |

|

Work Zone Speed Trailers |

5 to 10 weeks - Consult Work Zone Delivery Engineer |

Boilerplate Progress Clause

The file link provided below is intended to serve as a boilerplate document for creating a progress clause. Text is to be reviewed, deleted, modified, or added before incorporation into the proposal document.

File:Boilerplate Progress Clause Template 5-23-19 .docx

The link will take you to a separate page to download the file.

Progress Clauses with Incentive or A+B Schedules

Incentive special provisions provide monetary amounts for completion of work before specified contract dates. These special provisions, if applicable, are to be referenced in the progress clause for successfully meeting dates or times, but the specific incentive requirements and monetary amounts are to be included in a unique special provision. The special provision is to be titled Special Provision for Incentive, (Route (Structure Number)), (Incentive Type). The structure number is only to be included on bridge projects and if the bridge has an associated incentive. Incentive types are: Completion of Work; Interim Completion of Work; and Open to Traffic. Incentive projects are to include the Special Provision for Extension of Time and Increased Costs for Incentive Projects.

MDOT is phasing out the disincentive terminology. This language simply references failure to meet the contract incentive requirements. The disincentive language is not to be used on construction oversight documentation. Not meeting the incentive requirements will result in the application of liquidated damages and the associated pay item “Liquidated Damages, Other”.

The calculation of incentive values based on user delay costs must be documented and placed in the appropriate project folder in the ProjectWise directory.

Progress Clause for Steel Superstructure Projects

This document provides guidance to the TSC construction/project engineer in determining contract milestones for the progress clause in projects requiring steel beams or steel girders, and large format steel foundation piling. This formation is to be used to estimate timeframes for the progress clause for the order and delivery of steel piling, and beams/girders after the project award.

Once a bridge project is awarded, the contractor will place an order with a structural steel fabricator. The structural steel fabricator will then need to place an order with a steel mill for the required plates and shapes. The steel mills produce heats of different types and sizes of steel. For example, a mill may produce 36-inch rolled beams one week and piling the following week, and other mills may exclusively produce plates, but only roll certain thicknesses once or twice a month. Structural steel rolled in a given heat is typically already devoted to an already placed order, and the mill rolling typically occurs between four to twelve weeks after the order has been placed. Many factors influence when a fabricator can take delivery from a mill, including demand from other states’ bridge programs, demand from other domestic and international industries, cost, availability, and stockpiles of raw material; and production status of mills around the country. Fabricators do not stockpile most types of beams or plate steel. This is consistent with the just-in-time concept of manufacturing common in industry today.

For some small orders or certain types of steel, such as pin and hangers (link plates and pins), fabricators can purchase the needed steel through warehouses or they may have their own supply. For emergencies, such as from a high load impact, fabricators can purchase the needed steel items from national warehouses. However, the cost of this steel may be much higher, and is not economically feasible (to the fabricator or the state) for large orders.

The table below details the recommended timelines in which steel delivery to the project site can be expected.

| Work Item – Order and Delivery of Steel Beams | Time |

|---|---|

| Plate Girders and Rolled Beams – with flange thicknesses less than three inches | 26 weeks after award |

| Bascule, Arch, Tub Girder, High Performance Steel (HPS Grade 70 or 100), Plate Girders and Rolled Beams – with flange thicknesses three inches or greater | Consult Structural Fabrication Unit(*) |

| Pipe pile in excess of 14 inches nominal diameter, and HP shapes greater than 14 inches in depth. | 12 weeks after award |

- Contact the Operations Field Services Division’s Structural Fabrication Unit (MDOT-StructuralFabrication@michigan.gov) for assistance in developing the timeframes for order and delivery of steel in preparing the progress clause.

For plate girders and rolled beams with flange thicknesses less than three inches, the recommended time from award to delivery at the project site is based on the following:

- Up to three months for steel delivery from mill to fabricator,

- Up to two months for fabrication,

- Up to one month for submittal and approval of requests for information (RFI’s) and shop drawings, and shipping of the fabricated product to the project site.

Smaller diameter pipe pile and pile shapes such as HP12 and HP14 are rolled by multiple steel mills on a regular basis and should be readily available. For pile sections greater than 14 inches in diameter or depth, such as HP16 and HP18 shapes, and 16 inch diameter pipe pile, there are fewer mills to choose from and the rolling schedules are less frequent. Therefore, the recommended time frame for those shapes is 12 weeks after award. This is based only on delivery since fabrication time and shop drawings are not required.

While in many cases for structural steel, delivery can occur before the 26 week time frame, there are many variables which can influence steel delivery and frequently they cannot be determined at the time the progress clause is written. In addition to the factors influencing delivery of steel from the mill to the fabricator, the contractor that is awarded the contract and the fabricator they choose can affect the timeline. The fabricator chosen by the contractor may have less work or greater production capabilities than another fabricator. Some fabricators may try to book their production schedules such that by late winter or early spring they are fully booked through the summer or into fall. For this reason jobs let in the spring may have fewer fabricators available to complete the work and the jobs can be difficult to complete in one season especially if designed for part-width construction. In addition, the timeline to deliver steel beams for stage one of a part-width project may take the majority of the recommended timeline for delivery of both stages as the fabricator may elect to apply some aspects of fabrication to both stages instead of completing stage one in total before starting on stage two. The mill order and other milestones may take equal time whether they include one or both stages.

For the reasons outlined above, it is recommended that the table above be used when developing progress clauses for projects with steel superstructures or large format piling. Careful consideration is to be made on projects with staged construction, or interim completion or interim open to traffic dates.

If you have any questions please contact the Structural Fabrication Unit at MDOT-StructuralFabrication@michigan.gov.

Determination of Work Days/Completion Date

Work Day/Completion Date Determination, Figure 102-2, shows the worksheet to be used for calculating the estimated time to complete major work items and arrive at the total work days/completion date for completion of all work items. Anticipated start dates should consider letting date and earliest possible award dates to avoid an unrealistic completion date on calendar day date projects. This worksheet should remain on file at the project office and become part of the permanently retained project files for audit purposes.

Critical Path Networks

Critical Path Networks are often needed to develop the Progress Clause for a project. With MDOT-designed projects, the project manager is required to develop a Critical Path Network on any project that includes an Incentive or Special Liquidated Damages clause. It is recommended that the project manager develop a Critical Path Network for projects with the following characteristics:

|

| |

|---|---|

|

|

New construction. |

|

|

Major reconstruction or rehabilitation on an existing roadway that will severely disrupt traffic. |

|

|

Unique or experimental work. |

|

|

More than one construction season. |

|

|

Complex staging (multiple stages with traffic shifts). |

There may be other projects that do not meet these criteria which should have a Critical Path Network. The project manager will need to evaluate each project separately. The appropriate construction staff Engineer from the Construction Section and the Engineer assigned to the project should be consulted when determining the need for and when developing a Critical Path Network.

Preparation of a Critical Path Network is a requirement on all consultant-designed projects, regardless of the project type or complexity. The Engineer should contact the Design Consultant Coordination Unit for the project's critical path, if they have not received it, to prepare the Progress Clause.

Construction Time Estimates - Production Rates

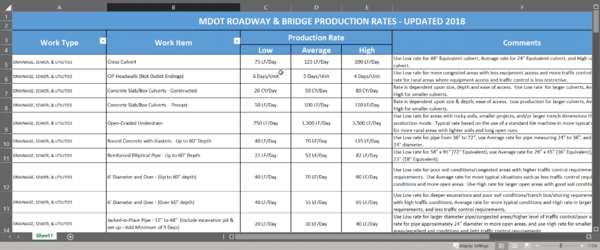

The file link provided below contains production rates for major work items. The link will prompt you to download the file.

These rates should be used as guides and adjusted as necessary to reflect project specific conditions (accessibility, site, traffic, region, quantities, etc.) and previous work history in the area. The rates include a low, average, and high production rate estimate which should serve as helpful guidance to both Design & Construction Engineers when developing and administering the project (evaluating schedules, progress clauses, force accounts, extra work, etc.). The rate range is intended to reflect & capture around 80% of typical projects, with the allowance that some outliers will exist due to extenuating project circumstances.