104.09 Lines, Grades, and Elevations

General

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

To ensure uniformity and to reduce errors the procedures, methods and policies presented in this section should be followed.

A large portion of engineering costs is represented by construction staking. If errors occur in staking, the cost can be considerable to MDOT. The survey crew is to stake according to the standards stated at the end of each section and to build in independent checks to eliminate errors. For example: an operation involving a level should never be terminated without checking into a known elevation; alignment operations, such as bridge layout or sewer staking, are not to be left before checking into known control points.

Construction survey notes generated by hand are to be recorded in bound field books. If data has been developed by computer, three-ring binders are acceptable. Data generated with data collectors and total stations or GPS units must be downloaded and a hard copy provided. It must be provided in a format that can be checked for accuracy and content by manual computations. Field books/binders should be identified on the cover with control section number, job number, subject (alignment, slope stake, bench marks, etc.) and each book numbered for cross-referencing. The Engineer's name, address and phone number are to be placed on the first page in case the book is misplaced. An index must be placed in the front of each field book. Pages are to be numbered.

Computations, such as grade sheets and bridge underclearances, are to be included. All notes are to be neat, clean, legible, complete and information is to be clear so another crew can continue the work or make computation checks.

The date, weather, crew, instrument type and crew chief’s signature are to be listed with each day's notes. Errors should have a line drawn through them, or the word "void" printed across a page, and a note referring to the location where the correct notes are to be found. Erasures are not to be used.

All computations and field notes are to be included in the files at the end of the project and are a matter of record. MDOT reserves the right to check anytime. Various examples of field notes are included throughout this section.

MDOT will determine how the project is to be staked depending upon staff availability. All consultant and Contractor staking projects require quality assurance checks at the frequency shown under Consultant/Contractor Quality Assurance Guidelines later in this section. Responsibilities and standards for specific types of staking operations are listed with the discussion of these activities.

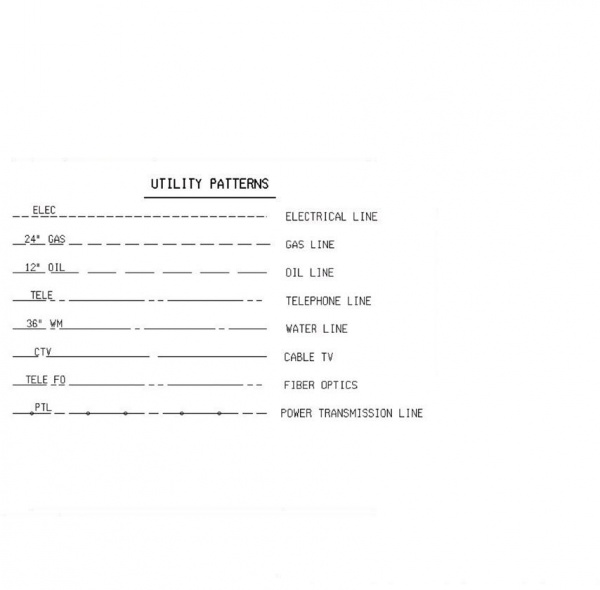

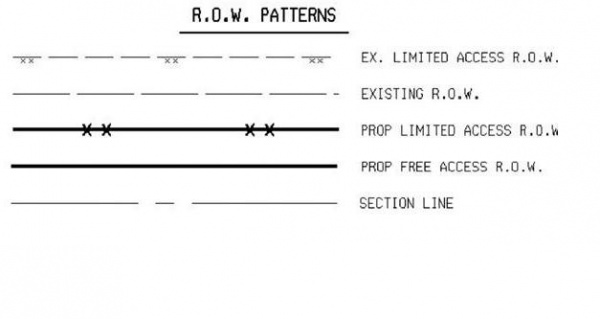

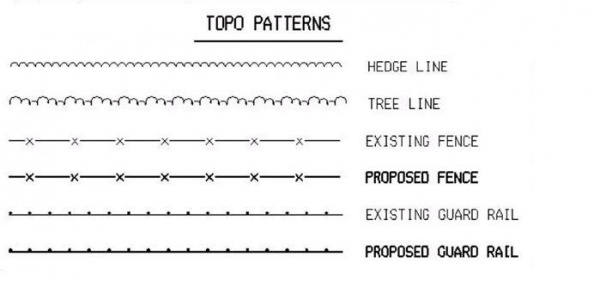

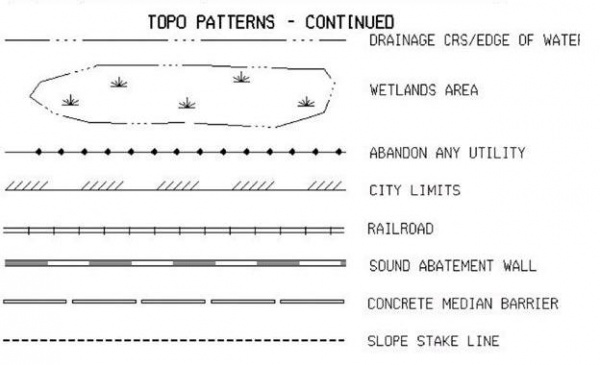

Topographic Symbols

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

The topographic symbols shown here are to be used for all survey drawings and notes. Additional symbols are available from Design.

Checking Plans

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Plans must be checked for errors and omissions of detailed information needed for the layout.

- Horizontal alignment needs to be checked. Bearings with delta angles, curve data, spiral data, coordinates with bearings and distances need to be verified. Care should be taken to distinguish construction centerline, which is the basis for proposed work, from survey centerline which is established to depict the existing roadway. Legal centerline, if used, should be distinguished from either design or survey centerline. Assistance in interpretation can be obtained from Design Surveys and the Real Estate Support Area. If coordinates have not been included on the plans, they are generally available from the design unit (except bridges). If they are not available, they can be generated through Simplicity software, or other similar packages (if you need help contact the Construction and Technology Field Engineering Unit). Before using IGRDS-generated coordinates with Simplicity software, Y and X need to be substituted for North and East (Y is always North/South and X is always East/West).

- The vertical alignment must be computed from PVI to PVI and to the connection at each end to ensure proper grade percentages are used. Plan typicals are to be checked before completing grade sheets. Superelevation lengths transition and location should be checked to be sure the proper standard plan has been used. Curb and gutter and gore grades should be checked to ensure proper fit along roadway for positive drainage. Grades for projects generated through the computer need to be checked. Contact the Construction and Technology Field Engineering Unit for assistance.

- Sewer and utility grades are to be computed for possible conflicts with each other and conflicts with ditches, pavement and bridges. Catch basins should be checked to be sure they are at the low points. Some field work may have to be done to avoid conflicts.

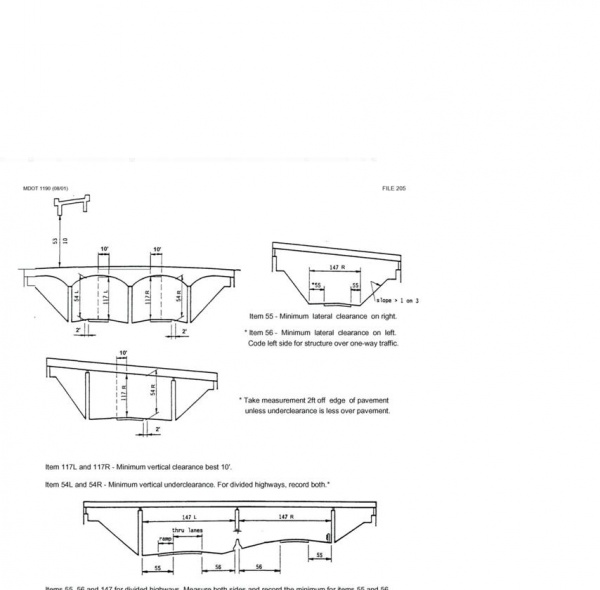

- Bridges need to be checked for proper alignment with the roadways and for proper clearance. Be sure to check for proper orientation of structure units when staking bridges. All dimensions of footings, piers, caps, rockers, beams and decks must be checked before staking. Reference points and lines for bridge work should be established and witnessed before any work begins at the site. Pile driving data is available though the Construction and Technology Field Engineering Unit. Profile grades at the road and bridge connections need to be checked, as well as the cross section and the bulkhead elevations. Deck grades also will need to be checked after obtaining the actual beam elevations. (See Division 7 of this manual for more on structure elevations.)

- ROW plans need to be checked for proper ties needed for layout, adequate room for construction, utility conflicts and potential sight distance problems. Coordinates are frequently not given unless the ROW is to be monumented. However, the various computer programs used for design can usually generate coordinates close enough for construction layout (construction is to pull any fence 1.0 foot inside of the actual line). Descriptions, ROW plans and old data is available through the Real Estate Support Area.

Preliminary Staking

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Before work can begin, project control must be established. MDOT or their representative is responsible for establishing horizontal control, ROW, vertical control and bridge stakeouts unless covered by a special contract. Cross sections are to be taken by the Contractor on Contractor staking projects but still must be monitored by MDOT. On projects without Contractor staking, MDOT will take all cross sections. If plan quantity for earthwork is agreed upon, only enough cross sections to verify the design sections are required.

Horizontal Controls

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Horizontal control begins with locating the control points, traverse points, mapping points, section corners, etc., set by Design surveys. These points will be noted on the plans along with respective witnesses. From these, all PC, PI, PT, TS, SC, PIS, CS, ST and POT points are established. Supplying these points is not necessary if coordinate points are given and correlation between the end points is established. If points are not found, they must be established by traversing, or the use of coordinates with total stations or GPS units. Contact the Construction and Technology Support Area, Field Engineering Unit for assistance with traversing or coordinate work.

From these control points, the horizontal alignment, conforming to the centerline shown on the plans, is established. Deflection angles at PIs and tangent distances, or long chord distances, must be checked and recorded. Distances between control points on the tangent should not exceed 1000 feet and should be closer on rolling terrain. Coordinate points may be established by MDOT instead of PC, PI, PT, etc., if agreed upon by the Contractor and the Engineer and provided that MDOT has checked alignments, etc. and has provided notes to the Contractor to tie these together.

All control points should be either witnessed or backed up by traverse points outside the construction influence area, unless GPS or total station with roadway staking software or radial staking will be used during the life of the contract. When possible, witness alignment points outside the construction limits. Consideration must be given to future use of the control points. Vertical difference between final position of the control point and its witnesses must be considered along with location of control points offset for construction staking. When deflections occur in the ROW, establishing control points and witnesses at these locations is advised.

One method of witnessing alignment points is by measuring a minimum of three bearings and distances to permanent and prominent objects as shown in Figure 104-1. Generally, reference caps will be attached to these objects. Witnesses should be less than 100 feet away. Avoid small acute angles between witnesses, and witnesses 180° from one another.

Applications: Used on resurfacing projects, etc., where witnesses will remain undisturbed and an offset line will not be needed.

A second method of witnessing alignment points is by establishing the angle and distance to tacked hubs set at convenient distances. The hubs should be set where they will not be disturbed during construction and are accessible enough for a transit, or total station to be set over them. (Figure 104-2).

Applications: Often used when witnessing PIs. If the interior angle is bisected, the midpoint can easily be established.

A third method is similar to the second but has two sets of witnesses (tacked hubs) at known angles and distances from the centerline. Having the two lines approximately 90° from one another is desirable. (Figure 104-3)

Applications: Frequently used for control points that fall within an intersection. A very accurate method, because two transits, or total stations, can be used thereby eliminating chaining.

A fourth method again uses tacked hubs, but the witnesses are set 90o to the construction centerline (Figure 104-4). This allows the survey crew to establish any offset lines with minimal transit setups. This is probably the most desirable method.

Applications: Commonly used on widening and relocation projects where offset lines will be run parallel to the construction centerline. When POCs on long curves are to be witnessed, this method should be used. To witness a POC at right angles to the curve, the transit or total station is set on the point. After taking a backsight, the deflection angle for the transit station is turned and 90o is added or subtracted to the vernier, depending on which way the witnesses are to be established.

A fifth method can now be used since total stations have become so accurate and coordinates are readily available. This method establishes an independent baseline with coordinates tied in with the centerline points. Then, when centerline, or offset points, are to be established, they can be done radially. This method saves time witnessing but requires more time on the computer generating offset coordinates, (Figure 104-5).

Applications: Saves much of the witnessing time, particularly when many witnesses will not be preserved. Once the control points have been set, the baseline points are established anywhere that they will be safe (preferably on high ground with good visibility). Then, angles and distances

from a control point to the baseline points are measured. The baseline points can now be tied to the centerline coordinate system by traversing. Contact the Construction and Technology Field Engineering Unit for assistance. Simplicity software works very well. When GPS is used, witnessing will not be necessary. However, traverse points may be needed if future construction operations will not be using GPS.

Horizontal Control Responsibilities

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

MDOT Staking Projects:

- MDOT will establish POB, POE, POT, PI, PC, PT, TS, PIS, SC, CS and ST for each alignment and run line when needed. Points are to be no more than 1000 feet apart and visible from adjacent points.

Consultant Staking for MDOT (project control):

- Consultant will set all the above-mentioned control points and run line as needed.

- MDOT will make random QA field checks, at the frequency required and record findings.

- MDOT will make random computation checks of alignment notes and record findings.

- Alignment notes are to be made available on request and become part of the project records upon completion of the project.

Contractor Staking Projects:

- MDOT will set the control points as previously noted.

- Contractor will witness and preserve the control points and then run line as needed to construct the project.

- MDOT will make random QA field checks as required and record findings.

- MDOT will make random computation checks of alignment notes and record findings.

When a consultant monitors for MDOT:

- MDOT will check consultant documentation to assure the QA checks have been made as required and record findings.

- MDOT will make random field checks, of the same points the consultant checked, as needed and record findings. Alignment notes are to be made available on request and become part of the project records upon completion of the project.

Design Build Projects:

- Details are to be spelled out in the scope of the project. When no detailed information is given, the responsibilities will revert back to the standard specifications and current special provisions.

Horizontal Control Standards

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

All distances are to be measured and recorded to the nearest 0.01 foot.

When setting control points, angles need to be turned and recorded to the nearest 5 seconds.

When setting witness points, angles need to be turned and recorded to the nearest 10 seconds, unless method 5 is used. Then angles need to be turned to the nearest 5 seconds.

Horizontal Curves

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Before running horizontal curves or spirals, the data should be checked and deflection angles and chord lengths computed. If coordinates are going to be used, they can be generated by various software packages and then staked radially (checks must be made to assure all points are on the curve). Stakeout can also be performed with data collectors using their road packages. Highway curves are generally done by arc definition and railroad curves by chord definition (some older road projects were done using chord definition). Projects using English units of measure are usually keyed on the degree of curve. With metric curves, the key becomes the radius (no longer use D), (Figure 104-6.)

Terminology and formulas used in horizontal curve computations are shown below.

|

|

|

|---|---|

|

Δ = External Angle (Delta). |

Will be provided by Design. |

|

R = Radius |

Will be provided by Design. |

|

T = Length of Tangent |

R Tan Δ/2. |

|

LC = Long Chord |

2 R sin Δ/2. |

|

E = External Distance |

T Tan Δ/4. |

|

M = Middle Ordinate Distance |

R(1-cos Δ/2). |

|

L = Length of Curve |

100 Δ/D, or 100ΔR/5729.578 |

|

PC = Point of Curvature |

Stationing = PI Station - T. |

|

PI = Point of Intersection |

Will be provided by Design. |

|

POC = Point on Curve |

PC + Arc Length |

|

POCT = Point of Curve Tangent |

Back Tangent : PC + Tangent Distance Forward Tangent : Represented with the PI Station + Tangent Distance |

|

PT = Point of Tangent |

Stationing = PC station + L. |

|

MP = Midpoint of Curve |

Stationing = PC station + L/2. |

|

Deflection Angle per foot |

360°F 4R TT (English curves) or D/200 |

|

Any Chord Length |

2R(Sin Deflection Angle). |

Another common curve parameter is the degree of curve (D) which defines the sharpness of the curve in terms of the radius.

For highways, degree of curve is defined as the central angle subtended by 100 feet of arc and is calculated in terms of the radius as :

R = 5729.578/D or D = 5729.578/R

For railroads, degree of curve is defined as the central angle subtended by 100 feet of chord and is calculated in terms of the radius as :

R = 50 sin D/2

EXAMPLE PROBLEM NO. 1 - HORIZONTAL CURVE

Given:

Δ = 87° 00' 00" Rt (87.0 decimal degrees)

R = 1000 feet

PI = Sta. 11+17.48

Staking interval of 50 feet

Offset of 22 feet to inside of curve

Compute:

Curve Parameters, Deflection Angles, Short Chords, Offset Chords

D = 5729.578 / 1000 = 5° 43' 46.5"

T = 1000 x tan (87°) / 2 = 948.96 feet

LC = 2 x 1000 x sin (27°) / 2 = 1,376.71 feet

E = 948.96 x tan (87°) / 4 = 378.60 feet

M = 1000 (1 - cos 87° /2) = 274.63 feet

L = (100 x 87°) / 5° 43' 46.5" = 1,518.44

PC = (11 + 17.48) - 948.96 = Sta 1 + 68.52

MP = (9 + 072.779) + 455.531/2 = Sta 9 + 27.74

PT = (9 + 072.799) + 455.531 = Sta 16 + 86.96

Compute Deflection Angles

Deflection Angle = distance x deflection angle per foot

Deflection angle per foot = D / 200 (convert D to decimals of degrees first) 0.028648

(Note: when computing by hand, do not round this value too soon)

Deflection angle from PC to the MP, PT and to each 50 foot stake are tabulated here.

| Dist.(ft) | Defl. Angle per Foot | Decimal Degrees | Defl. Angle | |

|---|---|---|---|---|

| From PC to Sta 2+00 | 31.48 | 0.028648 | 0.90187 | 0° 54' 06.6" |

| Between any 50 foot stakes | 50.00 | 0.028648 | 1.43245 | 1° 25' 56.6" |

| From Sta 9+00 to MP (9+27.74) | 27.74 | 0.028648 | 0.79472 | 0° 47' 40.9" |

| From MP to Sta 9+27.74 to 9+50 | 22.26 | 0.028648 | 0.63773 | 0° 38' 15.7" |

| From Sta 16+50 to PT (16+86.96) | 36.96 | 0.028648 | 1.05887 | 1° 03' 31.8" |

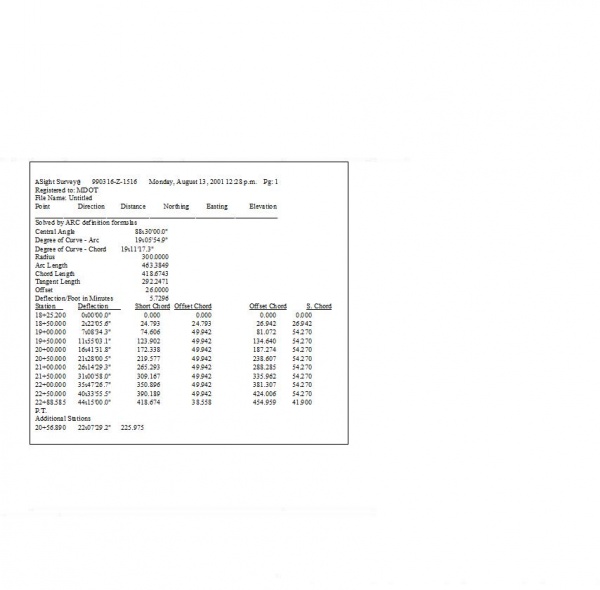

The deflection angles are tabulated in Figure 104-7 along with the cumulative total deflection angles. The total deflection angle should equal Δ/2 providing a good check. (Rounding of decimals of seconds may result in a slight difference).

If a curve is being computed by hand, this is a convenient method because it provides a check on your math computations. See Figure 104-7 for sample field notes.

Software packages such as Sight Survey by Simplicity Systems do a good job with this type of computation. They will also generate a chord from the PC to each station which is a method for staking a curve using the total station.

Compute short chords

Short Cord = 2R (sine of the deflection angle)

From PC to Sta 2 + 00.00 2(1000) (sin 0deg 54' 06.7") = 31.48 feet

Between any two 50 foot stakes 2(1000) (sin 1deg 25' 56.6") = 50.00 feet

From Sta 9 + 00.00 to MP 2(1000) (sin 0deg 47' 41") = 27.74 feet

From MP to Sta 9 + 50.00 2(1000) (sin 0deg 38' 15.6") = 22.26 feet

From Sta 16 + 50.00 to PT 2(1000) (sin 1deg 03' 31.9") = 36.96 feet

Compute offset chords using the following ratios

New Radius/ Original Radius = New Chord/ Original Chord

For an offset of 22 feet to the inside of the actual curve the new Radius is 78 feet

1000 - 22 / 1000 = New Chord / 31.48 or 30.79 feet

1000 - 22 / 1000 = New Chord / 50.00 or 48.90 feet

1000 - 22 / 1000 = New Chord / 27.74 or 27.13 feet

1000 - 22 / 1000 = New Chord / 22.26 or 21.77 feet

1000 - 22 / 1000 = New Chord / 36.96 or 36.15 feet

Chords can also be computed radiating from the PC. This procedure requires only two people for the field work. Deflection angles remain the same but new chords must be computed using the total deflection angles tabulated on the next page. For this example the following centerline chord can be computed from the PC to the MP.

Chord = 2 R (sine of the total deflection angle)

Chord = 2(1000) (sin 21° 45' 01.2") = 741.12

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*Error due to Rounding of Factor and Stationing

Alignment Books

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

When bound books are used, they are generally set up so that the control points and witnesses are shown for a curve, followed by the curve data.

Computer Printouts

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

When computer generated data is used, the printouts should be placed in a three-ring binder. A bound book showing witnesses will still be needed.

Figure 104-8 shows a typical format for a Sight Survey Simplicity Systems example.

When running horizontal curves, it is often necessary to set up somewhere on the curve, or on the PT. The procedure used for running a curve while setting anywhere on the curve other than the PC is as follows:

- Set the angle on the vernier for the point being sighted. Plunge the telescope and turn the angle for the next station; if setting on the PT, or backing the curve in, do not plunge - just turn directly.

Coordinate Method

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

With data collectors, total stations, and GPS units, curves and offsets can also be staked out from remote locations by use of coordinates generated from various software packages; or from data collectors using internal software routines.

Spirals

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Spirals are being used frequently on new alignment projects. Standard Plan R-107 explains when spirals are to be used. When spirals are used, the spiral leading into the curve and the spiral leaving the curve will normally be the same (Figure 104-9). Table XII must be used to compute the spiral parameters. Deflection angle and chord data are computed using the formulas shown on the following pages.

Terminology used in spiral computations is shown below. Many of these parameters are computed as shown in example problem #2 using factors from spiral tables given later in this section.

Figures 104-10 through 104-12 show examples of spiral curve field notes.

|

TS Tangent to spiral |

|

|

SC Spiral to curve. |

Stationing = TS Station + Length of Spiral |

|

CS Curve to spiral. |

Stationing = SC Station + Length of Curve. |

|

ST Spiral to tangent. |

Stationing = CS Station + Length of Spiral. |

|

PIS Point of Intersection for the spiral. |

Stationing = TS Station + Long Tangent or Stationing = ST Station - Long Tangent |

|

PICC Point of Intersection for the Curve. |

|

|

PI Point of Intersection before adding spirals. |

|

|

Ls Length of spiral. |

200ΔsR/5729.578 (English). |

|

P Amount of Shift for the Curve. |

(Use spiral tables) |

|

K Distance from the relocated PC to TS. |

(Use spiral tables) |

|

LT Long Tangent for the spiral. |

(Use spiral tables) |

|

ST Short Tangent for the spiral. |

(Use spiral tables) |

|

Δs Spiral External Angle. |

|

|

Δc Curve External Angle. |

|

|

Δ External Angle before adding spirals. |

(Δs + Δc + Δs) or (2Δs + Δc). |

|

X Distances along the Long Tangent from the TS or ST to a point opposite the SC or CS. |

(Use spiral tables) |

|

Y Offsets from Long Tangent to the spiral TS or ST. |

(Use spiral tables) |

|

LCs Long Chord for the spiral. |

|

|

Ts Distances from TS or ST to Original PI. |

(R + P) (tanΔ/2) + k. |

|

Spiral Deflection Angle |

[(sta. dist/Ls)2]/3 x Δs |

|

Short Chords |

Difference in deflection angles, times 3, multiplied by a factor from the spiral tables. |

Given:

Δ = 110° 25' 30"Rt.

Δs = 15° 16' 44"

R = 300 feet

TS = 34 + 65.72

Staking interval of 25 feet

Compute:

Curve Parameters, Deflection Angles, Short Chords using factors from spiral tables.

|

Δc = |

(110° 25' 30") - 2(15° 16' 44") = 79° 52' 02". |

|

Ls = |

[200 (15° 16' 44") R] / 5729.578 = 160.00 feet. |

|

P = |

0.02216 x 160.00 = 3.55 feet. (0.02216 is found in Table XII under °/Da) |

|

K = |

0.49881 x 160.00 = 79.81 feet. (0.49881 is found in Table XII under Xo/Da) |

|

LT = |

0.66917 x 160.00 = 107.07 feet. (0.66917 is found in Table XII under LT) |

|

ST = |

0.33561 x 160.00 = 53.70 feet. (0.33561 is found in Table XII under ST) |

|

X = |

0.99291 x 160.00 = 158.87 feet. (0.99291 is found in Table XII under X) |

|

Y = |

0.08844 x 160.00 = 14.15 feet. (0.08844 is found in Table XII under Y) |

|

LCs = |

0.99684 x 160.00 = 159.49 feet. (0.99684 is found in Table XII under LC) |

|

Ts = |

(300 + 3.55) tan 110° 25' 30"/2 + 79.81 = 516.76. |

|

PIs = |

(in spiral) = (34 + 65.72) + 107.07 = 35 + 72.79 |

|

SC = |

(34 + 65.72) + 160.00 = 36 + 25.72. |

|

CS = |

(36 + 25.72) + length of curve or (length of curve = 100 Δ/D = 418.18) Therefore, the CS = (36 + 25.72) + 418.18 = 40 + 43.90 |

|

ST = |

(40 + 43.90) + 160.00 = 42 + 03.90. |

|

PIS = |

(out spiral) = (42 + 03.90) - 107.07 = 40 + 96.83. |

Compute deflection angles - because a spiral is an arc with a continually changing radius, each defection angle must be computed starting from the tangent points, TS or ST, using the equation:

Deflection Angle = [(Dist / Ls)2 / 3] x (Δs)

From TS to Sta 34 + 75.00 is 9.28 feet.

[(9.28 / 160)2 / 3] x (15°16'44") = 00°01'01.2"

From TS to Sta 3.5 + 00.00 is 34.28

[(34.28 / 160)2 / 3] x (15°16'44") = 00°14'01.6"

Each deflection angle is calculated in this manner.

Compute short chords - The short chord lengths are also continually changing and are computed from point to point as follows.

- Compute the difference in deflection angles (in decimal degrees) from TS or ST to station and multiply by 3.

- Compute the distance from TS or ST to station.

- Go to spiral table for Δ° and read LC Factor.

- Multiply distance by the LC Factor from spiral table.

3 times the difference in deflection angles TS to Sta 34+75.00=0.05

The distance is 9.28 feet

In Table XII for Δ° = 0.05 the LC Factor is 1.0000

Therefore the short chord = 9.28 (1.0000) = 9.28 feet

Between any two stakes 3 times the difference in deflection angles to compute Δ.

Difference, in stations, from 34 + 75.00 to 35 + 00.00 = 0.21678 x 3 = 0.65

In Table XII for Δ° = 0.65 the LC Factor is 0.999995

Therefore the short chord = 25.000 (0.999995) = 24.9999 or 25.00 feet

The chords can also be computed radiating from the TS to any station.

3 times the difference in deflection angle TS to 35 + 00.00 = (0.0° 14' 01.6" - 0° 00' 00") / (0° 14' 01.6" x 3) = 0.7

The distance is 34.28

In Table XII for Δ° = 0.7 the LC Factor is 0.99999

Therefore, the short chord is 34.28 (0.99999) = 34.28 feet

The previous example is the way to compute spiral data by hand. Sight Survey will also compute spirals. However, it will not do offsets. The computer programs will vary from the hand computed version due to approximations in the tables.

See Figure 104-13 for sample printout for this example generated using Sight Survey by Simplicity Systems.

Note: This program generates data from the TS to the midpoint of the curve; then starts at the ST and works back to the midpoint of the curve.

The data below works only when setting on the TS for In Spiral and on the ST for the Out Spiral. If it becomes necessary to set up anywhere else, new deflection angles and chords must be computed. These computations require a different set of formulas. If this needs to be done, contact the Construction and Technology Field Engineering Unit.

Another thing unique to a spiral is that the deflection angles from the PIS to the TS to the SC is always equal to Δs/3. The angle formed by PIS and SC to TS is 2 Δs/3. (Figure 104-14).

Use of Tables XII & XIII - Spiral Tables - General Explanation

D Degree of central circular curve (Da = arc definition of D; Dc = chord definition of D).

Ls Length of spiral curve.

Δ Central angle of the spiral, or spiral angle.

X, Y Coordinates (abscissa and ordinate) of the SC referred to the TS as origin and to the initial tangent as X-axis.

Xo, Yo Coordinates (abscissa and ordinate) of the offset TC, which is the point where a tangent to the circular curve produced backward becomes parallel to the tangent at the TS.

LT Long tangent of the spiral.

ST Short tangent of the spiral.

LC Long chord of the spiral.

EXAMPLE PROBLEM for USE of SPIRAL CURVE TABLES

when solving for P & K

For arc definition

Ls = 200 feet and Δs = 9 30 >

P = 0.01381 x 200 = 2.76 '

K = 0.49954 x 200 = 99.91 >

For chord definition

Ls = 200 feet and Δs = 9 30 >

P = (0.01381-0.0010) x 200 = 2.56 >

K = (0.49954-0.0120) x 200 = 97.508 >

* Multiply functions (except * values) by the given value of Ls. When chord definition of degree of curve (Dc) is used, correct the calculated values of o or Xo by subtracting the product of Dc and the * values.

* Multiply functions (except * values) by the given value of Ls. When chord definition of degree of curve (Dc) is used, correct the calculated values of o or Xo by subtracting the product of Dc and the * values.

* Multiply functions (except * values) by the given value of Ls. When chord definition of degree of curve (Dc) is used, correct the calculated values of o or Xo by subtracting the product of Dc and the * values.

* Multiply functions (except * values) by the given value of Ls. When chord definition of degree of curve (Dc) is used, correct the calculated values of o or Xo by subtracting the product of Dc and the * values.

* Multiply functions (except * values) by the given value of Ls. When chord definition of degree of curve (Dc) is used, correct the calculated values of o or Xo by subtracting the product of Dc and the * values.

* Multiply functions (except * values) by the given value of Ls. When chord definition of degree of curve (Dc) is used, correct the calculated values of o or Xo by subtracting the product of Dc and the * values.

- Multiply functions (except * values) by the given value of Ls. When chord definition of degree of curve (Dc) is used, correct the calculated values of o or Xo by subtracting the product of Dc and the * values.

* Multiply functions (except * values) by the given value of Ls. When chord definition of degree of curve (Dc) is used, correct the calculated values of o or Xo by subtracting the product of Dc and the * values.

* Multiply functions (except * values) by the given value of Ls. When chord definition of degree of curve (Dc) is used, correct the calculated values of o or Xo by subtracting the product of Dc and the * values.

Right-of-Way

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

ROW limits should be established before construction begins. Stakes marking the ROW line should be set on both sides of the construction centerline at 100 foot intervals (50 foot intervals should be used on sharp curves), including all corners marking a change in width or direction. A 1 inch x 4 inch x 36 inch stake marked with “ROW” is used to designate ROW limits. The plans may call for the ROW line to be fenced. When fencing is required, the fence will be placed 1 foot inside the ROW limits. Accuracy is extremely important. ROW plans, along with description of each parcel, are available through the TSC office or Lansing Real Estate Support Area. ROW monumentation will be set by Design Survey Section, region surveyor, or by contract.

Preservation of Land and U.S. Survey Monuments

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

During construction, extreme care must be taken to preserve all section and quarter corner monuments. When construction operations require the obliteration of an existing monument, it is to be witnessed and replaced as soon as the construction operations have progressed to where it will not be disturbed. This work shall be performed under direct supervision of a professional surveyor licensed in the State of Michigan. If a corner can be reestablished in its original location without disturbing the existing witnesses, no further action needs to be taken. However, if any witnesses are disturbed and have to be replaced, or if the existing corner is significantly changed, the changes will have to be recorded.

Monument boxes are to be placed over all section corners where the existing monument falls in a hard surfaced highway. Even though a monument box is placed, witnessing the monument is still necessary. When a section or quarter corner is not in a public highway, the monument will be set not more than six inches above the surface of the surrounding ground, nor more than six inches below the surface. When a corner occurs in a public highway that is not hard surfaced, the monument is to be placed at least six inches below the surface as stated in Act 74 of 1970 as amended by Act No. 313 P.A. of 1975:

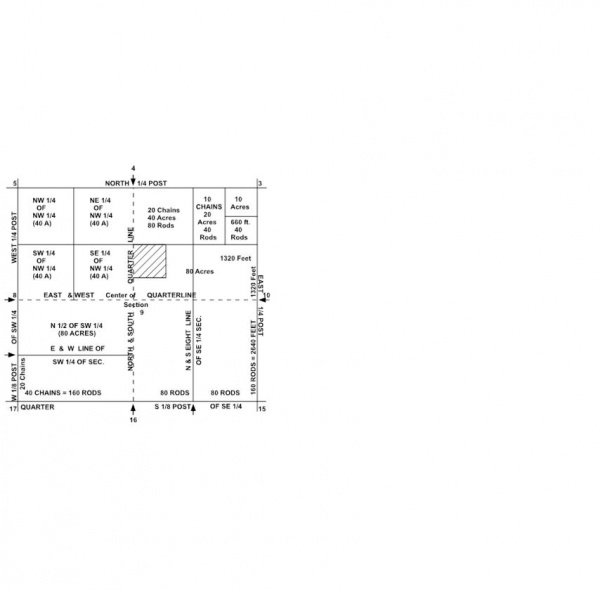

The Contractor is responsible for preserving, witnessing and reestablishing section corners and quarter corners. This work is to be done as soon as possible and must be performed by a registered land surveyor. See Figure 104-15 for divisions of a section.

Policy Regarding Geodetic Markers

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

All geodetic bench marks, GPS monuments and triangulation points found on a construction project should be preserved. When any of these markers are located within construction limits, the area supervising land surveyor should be notified immediately. Triangulation points require a high order survey to relocate, and the services of the National Geodetic Surveyor (NGS) are usually secured to do the work. The area supervising land surveyor will institute the action necessary in this case. Bench marks are often reset by MDOT. Again, the area supervising land surveyor is notified so that proper forms and a new bronze marker can be secured from the Construction Field Engineering Unit.

Applicable Excerpts from Surveying Acts

(Refer to Design Survey Manual for more complete citations). -Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

- (a) “Property corner” means a geographic point on the surface of the earth, which is on, is a part of, and controls a property line.

- (b) “Property controlling corner” for a property means a public land survey corner or any property corner which does not lie on a property line of the property in questions but which controls the location of 1 or more of the property corners of the property in question.

- (c) “Public land survey corner” means any corner actually established and monumented in an original survey or resurvey used as a basis of legal description for issuing a patent for the land to a private person from the United States government.

- (d) “Corner” unless otherwise qualified, means a property corner, a property controlling corner, a public land survey corner or any combination of these.

- (e) “Accessory to a corner” means any exclusively identifiable physical object whose spatial relationship to the corner is recorded. Accessories may be bearing trees, bearing objects, monuments, reference monuments, line trees, pits, mounds, charcoal-filled bottles, steel or wooden stakes or other objects.

- (f) “Monument” means an accessory that is presumed to occupy the exact position of a corner.

- (g) “Reference monument” means a special monument that does not occupy the same geographical position as the corner itself but whose spatial relationship to the corner is recorded and which serves to witness the corner."

- (h) “Licensed surveyor” means a surveyor who is licensed to practice land surveying under the occupational code, Act No. 299 of the Public Acts of 1980, being sections 339.101 to 339.2721 of the Michigan Compiled Laws, and has a paid-up license for the calendar year, or who is authorized under that act to practice land surveying.

- (i) “Board” means the board of land surveyors, as established by section 2002 of the occupational code, Act No. 299 of the Public Acts of 1980, being section 339.2002 of the Michigan Compiled Laws.

- History: 1970, Act. 74, Imd. Eff. July 16, 1970; Am. 1975, Act 313, Eff. Mar. 31, 1976; Am 1988, Act 26, Eff. May 1, 1988.

- Sec. 3. A surveyor shall complete, sign, stamp with his seal and file with the register of deeds of the county where the corner is situated, a written record of corner establishment or restoration to be known as a "corner record" for every public land survey corner and accessory to such corner that is established, reestablished, monumented, remonumented, restored, rehabilitated, perpetuated, or used as control in any survey by such surveyor, and within 90-days thereafter, unless the corner and its accessories are substantially as described in an existing corner record filed in accordance with the provisions of this act.

- Sec. 7. In every case where a corner record of a public land survey corner is required to be filed under the provisions of this act, the surveyor shall reconstruct or rehabilitate the monument of such corner and accessories to such corner, so that it shall be left by him in such physical condition that it remains as permanent a monument as is reasonably possible and so that the same may be reasonably expected to be located with facility at all times in the future.

- History: 1970, Act 74, Imd. Eff. July 16, 1970.

- Sec. 8. A corner record shall not be filed unless it is signed by a licensed surveyor and stamped with the surveyor’s seal, or in the case of an agency of the United States government or the state, the certificate may be signed by the chief of the survey party making the survey, and approved, signed and sealed by the licensed surveyor in responsible charge of the agency.

- History: 1970, Act 74, Imd. Eff. July 16, 1970; Am 1988, Act 26, Eff. May 1, 1988.

- Sec. 10. When a monument is set and it is not in a public highway, the monument shall be set not more than 6 inches above the surface of the surrounding ground nor more than 6 inches below the surface of the ground. When a corner occurs in a public highway which is not hard-surfaced, the monument shall be placed at least 6 inches below the surface of such highway. When a highway is hard-surfaced at the corner, whether by concrete, tarvia, or otherwise, a circular opening at least 6 inches in diameter shall be left at the corner and properly covered with a metal cover. The monument shall be placed in the opening beneath the cover.

- History: Add. 1975, Act 313, Eff. Mar. 31, 1976.

- Sec. 14. (1) A person who defaces, destroys, alters, or removes a corner is guilty of a misdemeanor and shall be punished by a fine of not more than $500.00, or imprisonment for not more than 60 days, or both, and shall be responsible for the costs or reestablishment, replacement, and filing of the corner by a licensed land surveyor. A corner may be temporarily removed for construction purposes if the corner is properly witnessed by a licensed land surveyor prior to removal. The corner shall be reset, re-witnessed, and re-filed by a licensed land surveyor within 30days after the completion of construction. A corner shall not be temporarily removed for more than 1 year. A person who knows that a corner has been defaced, destroyed, altered, or removed shall report that fact to the county surveyor of the county in which the corner is located.

- (2) As used in this section, "person" means an individual, or any public or private legal entity.

- History: Add. 1975, Act 313, Eff. Mar. 31, 1976; Am. 1988, Act 26, Eff. May 1, 1988.

Divisions of a One Mile Section

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

ROW Staking Responsibilities

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Staking Projects:

MDOT will establish ROW for all projects (those requiring fence and those not requiring fence). Stakes will be set every 100 feet on tangent sections and every 50 feet on curves when necessary. Stakes will also be set anytime there is a deflection in the ROW line. ROW easements will also need to be staked.

Consultant Staking Projects:

Consultant will stake ROW as outlined above.

MDOT will make random QA field checks at the frequency required and record findings.

MDOT will make random checks for compliance with ROW plans and record findings.

Any computations or field notes are to be made available on request and become part of the project records upon completion of the project.

Contractor Staking Projects:

Contractor is to preserve the ROW stakes and to stay inside the ROW. When it becomes necessary to remove section corners, they are to be witnessed, reset and recorded (by a registered land surveyor, licensed in the State of Michigan) as soon as construction activities will no longer disturb them.

Design/Build Projects:

Details are to be spelled out in the scope of the project. When no detailed information is given, the project responsibilities will revert to the standard specifications and current special provisions.

ROW Staking Standards

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

All distances are to measured and recorded to nearest 0.01 feet.

All angles are to be turned to the nearest 5 seconds or better.

After setting the ROW line, any fencing is to be pulled inside 1.00 feet.

Any time the project calls for ROW Monumentation, or Monumentation Preservation, the work must be done by a registered land surveyor, licensed in the State of Michigan.

Vertical Control

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Before any level work is done on a project, the bench marks shown on the plans must be checked for elevation and location. It is the policy of the department to use National Geodetic Surveys (NGS) datum when possible. A complete record of all known NGS bench marks is maintained in the Lansing design office. Municipal surveys shall be on the datum used by the municipality and must be compared with the datum used by MDOT.

Bench marks should be established at locations that will be convenient for future work. It is also convenient to alternate on left and right side of the roadway, particularly when work is to be done under traffic. Good bench marks are placed on permanent or semipermanent objects. Examples are a stamped brass disk, spike and nut in exposed tree roots; a steel post driven in the ground; or a chiseled A+@ in foundation walls, headwalls or on the top of fire hydrants. Bench mark number and elevations are to be painted on the bench or guard stake.

Locating Bench Marks

- At each end of large structures.

- At points of change from cut to fill.

- At high and low points.

- Locations that are handy for cross sectioning of side hills.

- Any time there is a difference of 25 feet in elevation in rolling terrain.

Bench Loops

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

In order to verify or establish elevation for bench marks, they must be looped with a minimum of three bench marks in the loop. Readings are to be recorded to the nearest 0.01 foot and the loop must check within 0.01 foot when checking into any bench mark. Before starting a bench loop operation the level must be checked. Check level vials and make a two peg test. The tapes and shoes on the rods along with the tripod head & shoes also need to be checked.

Several methods of looping bench marks are used. Examples of field notes for each method are shown. Level books are usually set up with descriptions and elevations in the front and loop notes and computations in the back.

One method of looping bench marks is to use a single rod system as shown in Figure 104-16. For convenience and accuracy, distance between the instrument and the rod should not exceed 250 feet and should be balanced within each setup.

Another method for looping between bench marks is the three-wire method. This requires the operator to record all three cross hair readings, total the readings, divide by three then compare the average with the middle reading (should be within 0.01 foot) before moving the instrument. This method seems slower but will generally catch wrong readings and eliminate the need to redo the loop. Distances between the instrument and the rod should not exceed 250 feet and distances from instrument to the rod need to be balanced. (Figure 104-17).

A third method is to use a laser level. The instrument needs to be checked out before starting. Lasers are generally tight enough for construction staking, but may not be tight enough for bench looping. They are normally used to check the difference between two benches, but not for looping because the instrument may be off in an X or Y direction, or the band may be too wide. When lasers are used for looping, two readings need to be taken and averaged. To take the readings, come from the top down until reading is stable and then come up from the bottom until the reading is stable. (Figure 104-18)

A fourth method, and the one which is probably the most accurate, is to use the digital level and let the instrument take the readings. Readings can be recorded as in the single rod method or can be recorded internally and dumped to a computer when completed. The computer can process the data, adjust the net, if proper software is loaded, and print out the bench mark elevations. Instruments can be set to average readings and to display to 0.001 foot.

Bench loops can also be done with total stations depending upon the vertical angle accuracy. When this method is used, the prism needs to be read with the scope in the direct and in the inverted positions. Both readings are recorded and then averaged. Care must be taken when sighting the prism - a target on the prism is recommended. When processing the notes be mindful of algebraic signs (you always add BS and subtract FS but the way you handle the readings vary. This method is not generally used for looping, but is used to transfer a bench to the top or bottom of a hill. (Figure 104-19)

Vertical Control Responsibilities

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

MDOT Staking Projects:

MDOT will establish bench marks approximately every 1000 feet along the project. MDOT will also set at least two near each bridge site. These will be looped and an elevation established for each one. The bench mark elevations and looping notes will be in a bound book, or on an electronic printout. This data will be supplied to the Contractor.

Consultant Staking for MDOT (project control):

Consultant will set the bench marks at the frequency noted above.

MDOT will make random QA field checks at the frequency required and record findings.

MDOT will make random computation checks of bench loop closures and record findings.

Bench mark notes will be made available on request and become part of the project records upon completion of the project.

Contractor Staking Projects:

MDOT will set bench marks at the frequency noted above.

Contractor will preserve or move the bench marks to safe locations. If others are needed, the Contractor will be responsible for establishing locations and determining the elevations. Any new bench marks, elevations and looping notes will be supplied to MDOT.

Contractor is expected to check into each bench mark (every 1000 feet ).

MDOT will make random QA field checks, at the required frequency, of any new bench loops and will record findings.

When a consultant monitors for MDOT (Consultant CE projects):

MDOT will check consultant documentation to assure the QA checks have been made and record findings.

MDOT will make random field checks as needed and record findings.

Bench mark notes are to be made available on request and become part of the project records upon completion of the project.

Design/Build Projects:

Details are to be spelled out in the scope of the project. When no detailed information is given, the project responsibilities will revert to the standard specifications and current special provisions.

Vertical Control Standards

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Checks for bench mark to loops must be within 0.01 foot. When checking into a bench mark after grading stakes, the tolerance is 0.03 foot.

Vertical Curves

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

MDOT generally uses equal tangent vertical curves. An equal tangent vertical curve sketch is shown in Figure 104-20.

Terminology and formulas used in vertical curve computations are shown below.

|

|

| |

|---|---|---|

|

|

See Plans | |

|

|

See Plans | |

|

|

Half the horizontal distance between the PVC and the PVT. | |

|

|

Computed horizontally along stations. | |

|

|

Distance from Curve to PVI | |

|

|

Distance from PVC to any station up to the PVI and then figured from the PVT back toward the PVI. | |

|

|

Offset from curve to tangent (t2 / T2) x E. | |

|

|

High or Low point (G1 x L) / (G1 - G2) = distance from PVC | |

|

|

Point of vertical curve (curve starts). | |

|

|

Point of vertical intersection. | |

|

|

Point of vertical tangent (curve ends). |

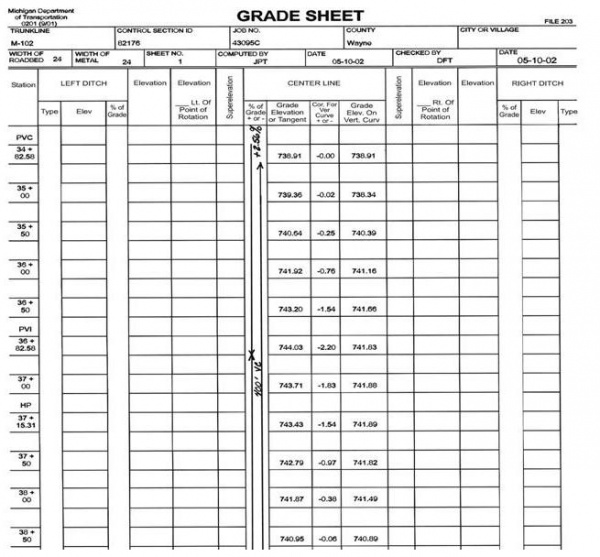

EXAMPLE PROBLEM NO. 3 - VERTICAL CURVE:

Given: L = 400 feet Find: Vertical Curve Parameters

G1 = +2.56% Tangent Elevations

G2 = - 1.84% Offsets

PVI (Station) = 36 + 82.58 Curve Elevations

PVI elevation = 744.03 High Point of Curve

Calculate the vertical curve parameters

E = [(G2 - G1) / 8] x L/100 = [(-1.84 - 2.56) / 8] x (400/100) = -2.20

Tangent elevations are calculated using the elevations of the PVC or PVT and subtangent distances and grades.

PVC 34 + 82.58 = 738.91

35+ 00 = 739.36

35 + 50 = 740.64

36 + 00 = 741.92

36 + 50 = 743.20

PVI 36 + 82.58 = 744.03

37 + 00 = 743.71

37 + 50 = 742.79

38 + 00 = 741.87

38 + 50 = 740.95

PVT 38 + 82.58 = 740.35

Offsets are computed from the PVC or PVT.

Y = (t2 / T2) x E (computed from the PVC)

34 + 82.58 = 0.000

35 + 00 becomes: (17.422 2002) x -2.20 = -0.02

35 + 50 becomes: (67.422 2002) x -2.20 = -0.25

36 + 00 becomes: (117.422 2002) x -2.20 = -0.76

36 + 50 becomes: (167.422 2002) x -2.20 = -1.54

36+ 82.58 becomes: (2002 2002) x -2.20 = -2.20

Y = (t2 / T2) x E (computed from the PVT)

37 + 00 becomes: (182.582 2002) x -2.20 = -1.83

37 + 50 becomes: (132.582 2002) x -2.20 = -0.87

38 + 00 becomes: (82.582 2002) x -2.20 = -0.38

38 + 50 becomes: (32.582 2002) x -2.20 = -0.06

38 + 82.58 = 0.000

Curve Elevations are computed from the tangent elevations and offsets.

34 + 82.58 = 738.91 - 0.00 = 738.91

35 + 00 = 739.36 - 0.02 = 738.34

35 + 50 = 740.64 - 0.25 = 740.39

36 + 00 = 741.92 - 0.76 = 741.16

36 + 50 = 743.20 - 1.54 = 741.66

36 + 82.58 = 744.03 - 2.20 = 741.83

37 + 00 = 743.71 - 1.83 = 741.88

37 + 50 = 742.79 - 0.97 = 741.82

38 + 00 = 741.87 - 0.38 = 741.49

38 + 50 = 740.95 - 0.06 = 740.89

38 + 82.58 = 740.35 - 0.00 = 740.35

High Point

HP = (G1 x L) / (G1 - G2)

HP = (2.560 x 400) (2.560 - (-)1.840 = 232.73

HP = 232.73 feet from the PVC or at station 37 + 15.31

Tangent elevation at 37 + 15.31 = 743.43

Offset elevation at 37 + 15.31 = -1.54

Curve elevation at the HP = 741.89

The same procedure is used for finding the low point of a vertical curve where the back tangent is a minus grade and the front tangent is a plus grade.

|

| |

|

|

|

|---|---|

|

36 + 82.580 34 + 82.580 35 + 00.000 35 + 50.000 36 + 00.000 36 + 50.000 37 + 00.000 37 + 15.307 37 + 50.000 38 + 00.000 38 + 50.000 38 + 82.580 36 + 82.580 (PVI) |

744.030 P.I. 738.910 P.C. 739.339 740.386 741.158 741.654 741.876 741.889 HIGH POINT 741.823 741.494 740.891 740.350 (P.T.) 741.830 |

Cross Sections

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

The purpose of cross sectioning is to determine accurate information from which to compute earthwork quantities. Before starting, the crew chief should instruct the members of the level party on the method to be used and the purpose for cross sectioning. Cross sections will be taken every 50 feet along centerline and at sufficient intermediate stations to provide a true representation of the ground surface.

Original Cross Sections

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Cross sections may be taken with some form of level, total station, GPS unit or from aerials. Cross section notes are a permanent record and will be kept in a bound level book or in an electronic file. If an electronic file is used, a hard copy must be provided also or a disk. Cross sections will be needed for original ground, undercuts, muck holes, etc. and for the final section. (Figure 104-23)

|

| |

|

|

Taken at right angles to the construction centerline or baseline. |

|

|

Taken right and left of construction centerline with zero distance reading on the centerline and readings progressing outward. |

|

|

Taken at least every 25 feet outward from centerline and more often when needed. |

|

|

Extend outward to the ROW line or beyond. In the case of a grading permit, cross sections should extend to include limits of permit. |

|

|

Readings on ground surfaces are taken to the nearest 0.1 foot. |

|

|

Readings on hard surfaces, such as pavement, curb, or railroad tracks are taken to the nearest 0.01 foot. |

Cross sections may be taken radially with a total station, GPS unit and data collectors, but end area plots will still be required for computing earthwork volumes. The Average End Area Method will generally be used to compute earthwork volumes and to provide a check on the slopes (final section). Even when staked section method, station grading, or Contractor staking is used, enough original and final sections are needed to verify the situation a minimum of every 500 feet. If the field checks suggest changes have occurred, the entire job will need to be sectioned.

In the case of ordinary ramps or circular ramps where minimal excavation is involved, it is more practical to use some sort of prismoidal correction. This is generally done by adjusting the distance between end areas based on the center of the end area. In the case of computer computations, this correction can be made by using the computer end areas and adjusting the distances between sections in the field.

Cross sections or depth measurements (when used in lieu of cross sections) of topsoil should be recorded and placed in the file. This data will be needed to determine quantities for earth excavation and embankment.

Taking cross sections throughout the project may be required for topsoil removal, subgrade undercutting, shallow muck areas, etc. Sometimes other means may be used, such as depth checks, hand level shots from preset grade stakes, etc. When surcharges are used, they will need to be cross sectioned. The sections should extend down the sides of the charge to original ground.

The Contractor is required to furnish a boat to help in obtaining the sections in shallow muck holes or borrow areas under water. Attempting to get sections with a man suspended in a drag line bucket is dangerous and not allowed. When the area cannot be sectioned using a boat, borings may be required.

Borrow/Wetland Sections

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

In the occasional instance where it is necessary to measure borrow or wetland site volume, it is to be measured in the same manner as roadway excavation. If the site is adjacent to the road under construction, the regular road cross sections can be extended to include the area involved. Sections should be taken at such intervals necessary to establish the ground profile (generally every 25 feet along the baseline and every 25 feet or less, perpendicular to the baseline).

If the borrow or wetland site is separate from the construction area, the limits must be clearly staked as a guide to the Contractor. ROW stakes, with the legend “borrow limits,” are to be placed around the perimeter of the borrow site after first verifying the limits of excavation. An entire quarter section may be indicated on the permit, when the owner simply intended a knob or hill to be removed. Because of a condition in the agreement, grade stakes may be necessary to limit the depth of the excavation. In most cases, the borrow should be taken to a location best suited for drainage and appearance. Borrow areas shall be properly drained, unless otherwise provided as in wetland situations.

When borrow or wetland area cross sections are needed, baselines should be staked and witnessed to establish a reference for necessary sections. The witnesses should fall outside of any possible operation of the Contractor, and end points should be set so they can easily be extended if necessary. Cross sections are generally taken on a 25 feet grid and at intermediate pluses as necessary. Readings will be taken to the nearest 0.1 foot. If possible, the road datum should be used. If this is not practical, at least two bench marks are to be established outside the construction operations and referenced to an assumed datum.

A sketch of the borrow location should be shown on the first page of the notes. The sketch should include fences, baseline location and stationing, witnesses, bench marks, buildings or landmarks, and borrow limits. Also, include a description giving section, township, range, north arrow and any other information that will help those unfamiliar with the project to reestablish and carry on the work.

In most new borrow sites the topsoil overburden must be removed before suitable borrow can be obtained. In these instances, the site will need to be sectioned before and after topsoil removal unless the topsoil depth is uniform and the deduction from the borrow quantity can be accurately determined.

Original Cross Section Responsibilities

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Staking Projects:

MDOT will take original sections - enough to verify existing sections. If check sections indicate a problem, or if plan quantity is not agreed to, the entire project will need to be sectioned.

Consultant Staking for MDOT (project staking):

Consultant will take the sections as noted above.

MDOT will take random QA field checks at the frequency required and compare to design plots and record findings.

Cross section notes, plots and computations are to be made available on request and become part of the project records upon completion of the project.

Contractor Staking Projects:

MDOT will take sections (one per 500 feet) to verify design sections.

Contractor will take sections for entire project, if plan quantity has not been agreed to, and make plots along with earthwork computations by the average end area method.

MDOT will take random QA field checks at the frequency required and record findings.

MDOT will make random checks of the plotted sections and earthwork computations and record the findings.

When a consultant monitors for MDOT:

MDOT will check consultant documentation to assure the QA checks have been made and record findings.

MDOT will make random field checks as needed and record findings.

Cross section notes, plots and computations are to be made available on request and become part of the project records upon completion of the project.

Design/Build Projects:

Details are to be spelled out in the scope of the project. When no detailed information is given, the project responsibilities will revert to the standard specifications and current special provisions.

Original Cross Section Standards

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Taken every 50 feet along centerline when taken for quantity determination. Taken every 500 feet along centerline in open areas and every 50 feet in wooded areas when used to verify.

Maximum distance between shots is not to exceed 25 feet (left and right) and is recorded to the nearest 0.1 foot when readings are taken on the ground and 0.01 foot when taking readings on hard surfaces.

Borrow areas, or wetland replacement sites, are to be sectioned at 25 feet along centerline and at least every 25 feet left and right. If data is taken radially (with data collectors), software must be capable of generating plots every 25 feet. No matter how sections are taken, cross section plots are required.

Elevation readings are taken to the nearest 0.10 foot on ground surfaces and to nearest 0.01 foot on hard surfaces.

Intermediate & Final Cross Section Responsibilities

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

MDOT Staking Projects:

MDOT will take all cross sections, make all necessary plots and compute end areas and volumes.

When plan quantity has been agreed to, final sections need to be taken every 500 feet to verify slopes.

Consultant Staking Projects:

Consultant will take all sections, make plots and compute end areas and volumes as noted.

MDOT will take random QA sections as required and record findings.MDOT will also make random QA checks on plots, end areas, volume computations and record findings.

Cross section notes, plots and computations are to be available on request and become part of the project records upon completion of the project.

Contractor Staking Projects:

Contractor will take all cross sections, make plots and compute end areas and volumes.

MDOT will take random QA sections at the frequency required and record findings.

MDOT will make random checks on plots, end area; volume computations and then record findings.

When a consultant monitors for MDOT:

MDOT will check consultant documentation to assure the QA checks have been and record findings.

MDOT will make random field checks as needed and record findings.

Cross section notes, plots and computations are to be made available on request and become part of the project records upon completion of the project.

Design/Build Projects:

Details are to be spelled out in the scope of the project. When no detailed information is given, the project responsibilities will revert to the standard specifications and current special provisions.

Intermediate & Final Cross Section Standards

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Take a maximum of every 50 feet plus odd locations along centerline when needed to determine limits or breaks.

Maximum distance between shots perpendicular to the baseline is not to exceed 25 feet and will be recorded to the nearest 0.1 foot.

When data is taken radially (with data collectors), software must be capable of generating plots at any interval not to exceed 50 feet.

Cross section plots will be required.

Readings will be taken to the nearest 0.1 foot.

CONSTRUCTION STAKING

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

All construction staking and information given to the Contractor shall be properly documented. The crew chief or Engineer shall advise the Contractor and grade inspector of all information contained on the stakes. However, it is the Contractor's responsibility to understand all information on the stakes.

Each day's notes must include the date, weather conditions and members of the crew. Replacement of stakes, due to the careless operation of the Contractor, should be recorded in the notes showing time and crew members used in replacement of the stakes.

The following staking is required for construction. Each type of staking operation is discussed in this section.

Refer to Figure 104-24 for a roadway sketch and terminology used in this section.

|

|

Staking Requirements |

|---|---|

|

|

Clearing and grubbing stakes. |

|

|

Slope stakes. |

|

|

Subgrade stakes. |

|

|

Pavement stakes. |

|

|

Drainage stakes. |

|

|

Utility stakes. |

|

|

Tunnel stakes. |

|

|

Sewer stakes. |

|

|

Structure stakes. |

|

|

Miscellaneous stakes. |

Clearing Stakes

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

After the existing alignment has been re-established and the proposed alignment set and witnessed, the areas to be cleared are staked. Care must be taken to ensure adequate distance behind the slope stake for the vertical curve as required. An effort should be made to save trees when possible, while still meeting safety requirements. Sight distances must be taken into account, particularly at intersections. This will ensure a roadway that is both safe and pleasing to the motorist.

The stakes are set at right angles to the roadway centerline using a cloth tape. Measurements must be taken every 50 feet along centerline and at breaks. The stakes are marked "clear" or "C&G." Caution must be used to stay within the ROW limits. Field notes should show stationing, distance left and right, date and names of persons doing the staking. Sufficient information must be shown in the notes so that an accurate determination of clearing quantities can be made.

If slope stake data is not available, distances can be obtained from the computation output sheet for the preliminary earthwork computations or the original cross-section plots. These are available from the Design Support Area.

When individual tree or stump removal is required, the notes must be set up to indicate the station, distance left or right, and size. The date and names of individuals making measurements must also be documented. (Figure 104-26)

Clearing Staking Responsibilities

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Staking Projects:

MDOT will take measurements, set stakes every 50 feet and make sketches along with area computations.

Consultant Staking for MDOT (project staking):

Consultant will take all measurements and set stakes every 50 feet. They will also make all sketches and area computations.

MDOT will make random QA field checks at the frequency required. They will also make random QA checks on the computations and record findings.

Field notes and computations are to be made available on request and become part of the project records upon completion of the project.

Contractor Staking Projects (project staking):

Contractor will take all measurements, set stakes, make area computations and document with sketch and dimensions.

MDOT will make random QA checks on field measurements as required and a thorough check on computations used to determine pay item quantities and record findings.

When a Consultant Monitors for MDOT:

MDOT will check consultant documentation to assure the QA checks have been made and record findings.

MDOT will make random field checks as needed and record findings.

Field notes and computations are to be made available on request and become part of the project records upon completion of the project.

Design/Build Projects:

Details are to be spelled out in the scope of the project. When no detailed information is given, the responsibilities revert to the standard specifications and current special provisions.

Selective Thinning and Individual Tree/Stump Removal:

All locations, stakes and measurements will be taken by MDOT.

MDOT will also make plots and do the computations for determining pay quantity.

Clearing Staking Standards

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Clearing distances will be measured to the nearest 1 foot.

Tree and stump diameters will be measured to the nearest inch at a point 4.5 feet above the base of the tree.

W/2

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Before any slope staking can be performed, the distance from the centerline to the subgrade shoulder point must be computed. This distance is commonly referred to as W/2.

- Y - Vertical distance between the finished shoulder point and a point on the subgrade directly below the finished shoulder point.

- X - Horizontal distance between the finished shoulder point and the subgrade shoulder point.

The methods most commonly used to compute the subgrade shoulder point when there is no super elevation is illustrated in the following examples. Refer to Figure 104-27.

EXAMPLE PROBLEM NO. 4 - W/2 NO SUPERELEVATION

Given:

Y = (2.44) - (0.64) = 1.80

Subgrade slope = 2% or 0.02

Front slope = 1 on 6 or 0.1667

Other distances and elevations as shown in Figure 104-27

Compute the distance X

- X = Rate of front slope (Y) +/- [Rate of front slope [subgrade slope (X)]]

- X = 6 (1.80) + [6(0.02) (X)]

Note: use front slope rate not decimal

- X = 10.8 + 0.120 X

- X - 0.120 X = 10.8

- X = 10.8/0.88

- X = 12.27 feet

Distance (W/2) from centerline to the subgrade shoulder point is

- 12.0 + 10.0 + 12.27 = 34.27 feet from centerline.

The drop becomes:

- 12.27 x 0.02 = -0.25 or -0.25 + -2.44 = -2.69 feet from Plan Grade.

The distance X can also be computed by adding, (or subtracting, depending on whether the front slope is a cut or fill) the subgrade slope to the front slope (in decimal form) and dividing the result into the vertical distance Y.

- X = Y/(front slope - subgrade slope)

- X = 1.8/(0.1667 - 0.02)

- X = 1.8/0.14667

- X = 12.27

The total distance (W/2) from centerline to subgrade shoulder point is

- 12.0 + 10.0 + 12.27 = 34.27 feet.

A sketch for a superelevation section is shown in Figure 104-28 and example problem #5 illustrates the calculations.

EXAMPLE PROBLEM NO. 5 - W/2 WITH SUPERELEVATION

Given:

Subgrade slope = 6% or 0.06

Front slope = 1 on 4 or 0.25

Y = 2.00

X = 4(2.00) - 4(0.06X)

X = 8.00 - 0.24X

1.24X= 8.00

X = 6.45 feet from finish shoulder point to subgrade shoulder point

or

X = 2.00/(0.25 + 0.06) =2.00/0.31

X = 6.45 feet

Once the subgrade shoulder distances have been computed, the W/2 distances can be determined. The W/2 is merely a point of reference from which slope stakes are established.

In a section without ditches, W/2 is measured to the subgrade shoulder point. In a section with ditches, W/2 is normally measured to the point of intersection of the ditch bottom and the back slope. (Figure 104-29).

Occasionally, a swamp ditch is encountered. This is a ditch outside of the toe of slope and is independent. It will usually have its own W/2 and will be staked separately.

Slope Stakes

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

Slope stakes are set at the intersection of proposed front slope with original ground in fill sections and at the intersection of back slope with original ground in ditch sections. See Figure 104-29 for slope stake locations. They mark the limits of excavations and embankments. Stakes should be set left and right of centerline every 50 feet. The slope stake should be set to the nearest 0.1 foot for distance and the ground elevations read to the nearest 0.1 foot.

Information is to appear on slope stakes for various types of grading sections, as shown in Figure 104-30. The stations are marked on the back, along with the W/2. On the front is the distance to centerline or reference line, ditch cut, cut or fill, ditch type and size, along with front and back slope ratios. Place stationing on the front side if space allows.

The reference point to which the cut or fill on the slope stake refers is generally the intersection of the subgrade and the fore slope. Some-times, the sand subbase and the fore slope intersection are used, or the finish shoulder point may be used. Whatever is used needs to be discussed with the Contractor. The purpose of the slope stake is to allow the grade checker to build the correct elevations and slopes from the slope stake back to the subgrade shoulder point. Situations may dictate a variable back slope to stay inside ROW, or to give a pleasing appearance. Modifying back slopes is generally easier and does not have a significant impact on safety standards. Normal slopes will be 1 on 2, 1 on 4, 1 on 6, etc.

Sometimes offsetting slope stakes from the true location is necessary; the offset shown on the stake is the distance from the offset location to the true location. The cut or fill shall be shown in reference to the ground at the location of the stake as set.

Figure 104-31 shows an example of slope stake and cross section field notes. The slope stake information is shown on the left page and the cross section data on the right. Another acceptable format is to use the right page for both cross sections and slope stake information.

Slope Staking Responsibilities

-Reserved-

-File Currently Under Review-

-Previous file left in for place holding and informational purposes only.-

MDOT Staking Projects:

MDOT will develop all grades and dimensions.

MDOT will set slope stakes every 50 feet.

Stakes will indicate cut or fill, slopes, ditch information and distance from centerline.

Consultant Staking for MDOT (project staking):

Consultant will compute all grades, including ditches, and present to the MDOT Engineer prior to staking.

Consultant will set slope stakes every 50 feet, or agreed upon interval (with MDOT Engineer).

MDOT will make random QA field checks at the frequency required and record findings.

MDOT will make random computation checks of grades, distances, transitions and W/2s, then record findings.