Difference between revisions of "602 - Concrete Pavement Construction"

| (106 intermediate revisions by 7 users not shown) | |||

| Line 4: | Line 4: | ||

<center><span STYLE="font: 40pt arial;">'''Concrete Pavement Construction'''</span></center> | <center><span STYLE="font: 40pt arial;">'''Concrete Pavement Construction'''</span></center> | ||

| − | |||

| − | ==GENERAL== | + | ==[[#GENERAL|GENERAL]]== |

<span style="color: red"> -Reserved- </span> | <span style="color: red"> -Reserved- </span> | ||

| + | {{top}} | ||

| − | ==MATERIALS== | + | ==[[#MATERIALS|MATERIALS]]== |

| − | === | + | ===[[#Acceptance of Materials|Acceptance of Materials]]=== |

| − | + | Before paving operations start, the paving Inspector should verify that the Contractor’s proposed materials to be incorporated in the pavement have been approved for use through testing or via pre-approved products lists as required for the contract. Most materials will be stockpiled in the Contractor’s yard on the project site. Also, this is often the location of the batching plant. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | Before paving operations start, the paving | ||

{| class="wikitable" | {| class="wikitable" | ||

| Line 53: | Line 26: | ||

<center>1</center> | <center>1</center> | ||

| | | | ||

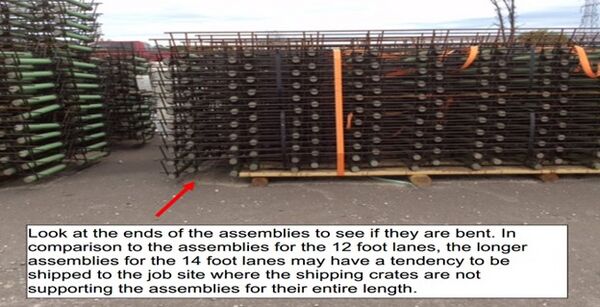

| − | When the load transfer assemblies arrive on the project site, call Region materials personnel so they can verify that the assemblies were built | + | When the load transfer assemblies arrive on the project site, call Region materials personnel so they can verify that the assemblies were built in accordance with the standard plans. Documentation of Acceptance by Region materials personnel is required. Figures 602-1 and 602-2 show load transfer assemblies stored on the job site. |

|- | |- | ||

| | | | ||

| Line 65: | Line 38: | ||

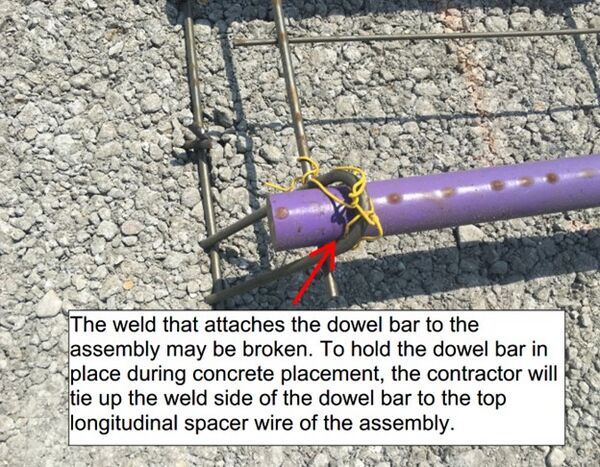

After the Contractor starts to set the load transfer assemblies on the grade, they must be visually inspected for: | After the Contractor starts to set the load transfer assemblies on the grade, they must be visually inspected for: | ||

| − | * Broken or missing welds. | + | * Broken or missing welds as shown in Figure 602-3. |

* Damage in handling or shipping. | * Damage in handling or shipping. | ||

* Proper height of dowel bars in the assembly. | * Proper height of dowel bars in the assembly. | ||

| Line 75: | Line 48: | ||

<center>4</center> | <center>4</center> | ||

| | | | ||

| − | The entire bar is to be coated with an approved | + | The entire bar is to be coated with an approved epoxy coating to prevent corrosion, and the entire bar’s length is to be coated with an approved material to prevent concrete from adhering to the bar (typically beeswax). |

|- | |- | ||

| | | | ||

| Line 86: | Line 59: | ||

| | | | ||

Visually inspect the handling and storage of all materials used in the concrete paving operation. | Visually inspect the handling and storage of all materials used in the concrete paving operation. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

| | | | ||

| − | <center> | + | <center>7</center> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| | | | ||

| − | + | Contractor must cover load transfer assemblies when they are to be stored on site for extended periods (more than 6 months). | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|} | |} | ||

| + | [[File:602-1.jpg|600px|thumb|center|'''Figure 602-1 Load transfer assemblies stored on the jobsite.''']] | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | [[File:602-2.jpg|600px|thumb|center|'''Figure 602-2 Load transfer assemblies stored on the jobsite.''']] | ||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-3.jpg|600px|thumb|center|'''Figure 602-3 Load transfer assembly with a broken weld.''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | {{top}} | |

| − | + | ====[[#Straight and Bent Tie Bars |Straight and Bent Tie Bars ]]==== | |

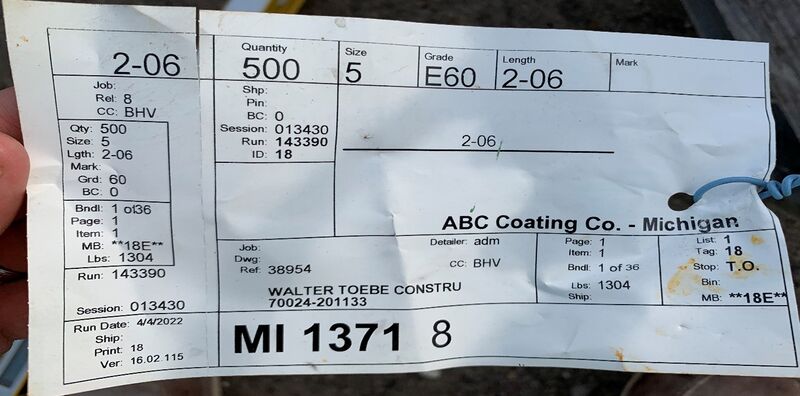

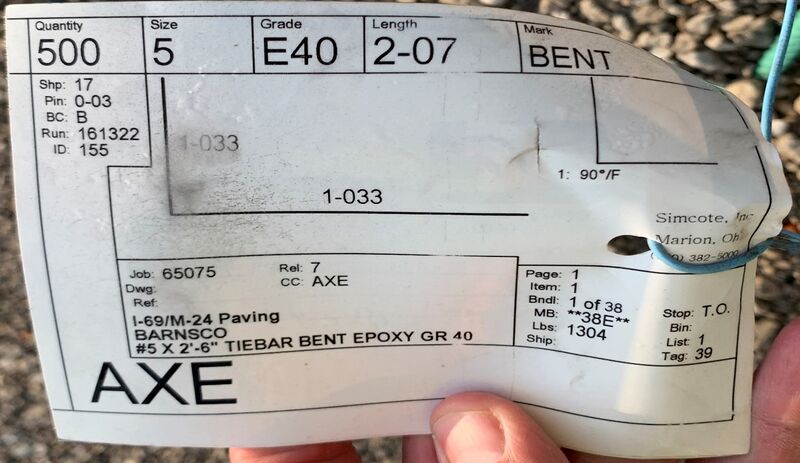

| − | + | Tie bars should be checked for certification or sampled and tested when they arrive on a project. Straight Tie Bar examples (See Figure 602-4, 602-5, 602-6, 602-7). Bent Tie Bar examples (See Figures 602-8, 602-9, 602-10, 602-11, 602-12, and 602-13). | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | {{top}} | ||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-4.jpg|800px|thumb|center|'''Figure 602-4 Straight Tie Bar (Stored on the job site)''']] | |

| − | | | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | [[ | + | [[File:602-5.jpg|800px|thumb|center|'''Figure 602-5 Straight Tie Bar (Tag)''']] |

| − | |||

| − | + | [[File:602-6.jpg|800px|thumb|center|'''Figure 602-6 Straight Tie Bar Coating (Tag)''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | [[File:602-7.jpg|800px|thumb|center|'''Figure 602-7 Straight Tie Bar installation''']] | ||

| − | |||

| − | |||

| − | + | [[File:602-8.jpg|600px|thumb|center|'''Figure 602-8 Bent Tie Bar''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | ''' | + | [[File:602-9.jpg|800px|thumb|center|'''Figure 602-9 Bent Tie Bar (Tag)''']] |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-10.jpg|800px|thumb|center|'''Figure 602-10 Bent Tie Bar installation''']] | |

| − | |||

| − | |||

| − | + | [[File:602-11.jpg|800px|thumb|center|'''Figure 602-10 Straightening Bent Tie Bars''' (wait to straighten tie bars until after concrete has gained the required strength or you may damage weak young concrete around the bar. Note how tie bars are not to be installed close to the transverse saw cut and load transfer assemblies)]] | |

| − | |||

| − | + | [[File:602-12.jpg|800px|thumb|center|'''Figure 602-12 Bent Tie Bar''' After the bent tie bar is straightened, use straight-edge to make sure the tie-bar depth is set at half the pavement thickness for its entire length +/- ¾”). If pavement thickness = 12” then 6” to center of bar (acceptable range = 5 ¼” to 6 ¾”).]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | [[File:602-13.jpg|800px|thumb|center|'''Figure 602-13 Bent Tie Bar''' The far end of this bar was set too high when initially straightened and needs to be bent further down to within tolerances. Measurements show 2-10/16” to the top of bar from the top of pavement + 5/16” = 2-15/16” to center of bar (allowable range = 5-1/4” to 6-3/4").]] | ||

| − | |||

| − | + | {{top}} | |

| − | + | ====[[#Curing_Compound|Curing Compound]]==== | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | *Check certification or sample and test each batch or lot. | ||

| + | *Material may be in drums or in a large tank. Inspection consists of seeing that the material is not contaminated or diluted and that it is mixed according to the manufacturer’s recommendations (See Figure 602-14). | ||

| + | *A curing compound should not be used when stored from one construction season to the next without resampling and testing. | ||

| + | *Check yield of material to confirm correct coverage. Proper coverage as soon as practical is important for reducing evaporation of the concrete mixture water from the top of the fresh concrete and for reducing/reflecting solar heat input into the pavement as the concrete sets and gains strength. Very high concrete temperatures at set and shortly after are generally not good in terms of expected long term performance for the concrete pavement due to potential for increased slab shrinkage and warping. For white membrane type curing compounds, coverage should result in a full white color without grey spots from underlying concrete reflecting through due to inadequate thickness or poor spray pattern or nozzles. During cold weather conditions, protect the curing compound from freezing as shown in Figure 602-15. | ||

| − | |||

| − | |||

| − | |||

| + | [[File:602-14.jpg|800px|thumb|center|'''Figure 602-14 14 Tote of Curing Compound''']] | ||

| − | |||

| − | |||

| + | [[File:602-15.jpg|800px|thumb|center|'''Figure 602-15 Protecting the Curing Compound from Freezing''']] | ||

| − | + | {{top}} | |

| − | + | ==[[#EQUIPMENT|EQUIPMENT]]== | |

| − | + | Subsection 602.03 of the Standard Specifications for Construction sets forth the equipment requirements for the concrete paving operations. The specific equipment requirements described in the Standard Specifications have been reduced in the 2020 version of the Standard Specifications. Because equipment used today has become more precise and sophisticated, the Department is less concerned about the specific type or piece of equipment the Contractor uses and more focused on measuring and quantifying the results. | |

| − | + | Equipment capacity and capability arriving at the job site will likely not be the same for a small urban widening project versus a high production rural interstate freeway project. For example, a small old paver may not be able to meet high initial smoothness specifications for an interstate freeway final pavement surface, and a new modern paver may be necessary to achieve a very smooth condition. If there are questions about the equipment condition and/or suitability, contact the Engineer or the MDOT State-Wide Concrete Paving Specialist. | |

| + | {{top}} | ||

| − | |||

| − | + | ==[[#PRECONSTRUCTION|PRECONSTRUCTION]]== | |

| − | + | Early in the construction project, at the pre-construction meeting, the Contractor will submit a formal proposed Materials Source List. This list may identify some of the proposed suppliers of products to be used in the pavement and offer an initial review. A minimum of 14 days prior to paving operations, the Contractor is to submit the official Quality Control Plan for Concrete. This document will include the proposed concrete mixture designs Job Mix Formulas (JMF’s) and information on proposed pavement placement and consolidation methods and procedures for verification of as-placed dowel and tie bar locations. It is best for the field engineer or technician to review the paving QC plan before construction begins as part of job planning. It is best to gather the internal project paving control team together for a project briefing to go over the proposed materials and procedures and required testing plans before the start of the paving. | |

| − | |||

| − | |||

| − | |||

| − | + | {{top}} | |

| − | |||

| − | + | ==[[#CONSTRUCTION|CONSTRUCTION]]== | |

| − | === | + | ===[[#PLACING AND FINISHING CONCRETE|Placing and Finishing Concrete]]=== |

| − | + | The Lansing Office concrete paving staff specialist will typically visit the project when paving starts to assist in verifying equipment suitability and troubleshooting related issues to get the project properly started. The daily paving inspector should note the trimming, placing, spreading, consolidation, finishing, texturing, and curing equipment the Contractor uses each day within the daily work reports, along with any unusual issues encountered with equipment or paving operations. The paving inspector must coordinate with the project and region materials control staff for quality assurance testing needed for the paving materials | |

| + | {{top}} | ||

| + | ====[[#Minimum Project Requirements|Minimum Project Requirements]]==== | ||

| − | + | The Contractor will have determined how, using equipment or hand work, they will do the following: | |

| + | *Trim the base to the required elevation grade. | ||

| + | *Deliver and place the concrete on the grade in a timely manner and without contamination or segregation as shown in Figure 602-16, 602-17, 602-18, 602-19, 602-20, 602-21, 602-22, 602-23, and 602-24. | ||

| + | *Install lane ties and dowel bars for joints, and other reinforcement as required. | ||

| + | *Consolidate and finish the concrete including straight edging and floating. | ||

| + | *Apply the required texturing and edge treatments to the fresh concrete surface. | ||

| + | *Apply the required curing procedures and products for the pavement, and | ||

| + | *Saw clean and seal the required joints. | ||

| − | + | Smaller concrete pour areas are often placed by hand and within stationary forms, rather than using formless ‘slip-form’ type paving techniques. More specialized concrete forms can serve the dual purpose of containing the plastic concrete and supporting a trackway for lightweight concrete placing and finishing equipment, such as roller screeds, to ride on. | |

| − | + | [[File:602-16.jpg|800px|thumb|center|'''Figure 602-16 Contractor placing concrete directly on the grade with the concrete hauling units.''']] | |

| − | |||

| − | |||

| − | + | [[File:602-17.jpg|800px|thumb|center|'''Figure 602-17 Contractor placing concrete directly on the grade with the concrete hauling units.''']] | |

| − | |||

| − | + | [[File:602-18.jpg|800px|thumb|center|'''Figure 602-18 Make sure hardened concrete gets cleaned out of concrete haul units at the plant and not mixed in the fresh concrete (keep a close eye on the bottom corners of the dump trucks for hardened concrete). ''']] | |

| − | |||

| − | + | [[File:602-19.jpg|800px|thumb|center|'''Figure 602-19 Removing hardened concrete that got mixed in the fresh concrete. The hardened concrete could have come from a concrete haul units previous loads or fallen from a piece of equipment (e.g. paver, roller screed, and loader bucket). ''']] | |

| − | |||

| − | |||

| − | + | [[File:602-20.jpg|800px|thumb|center|'''Figure 602-20 Make sure the clay from the haul road doesn’t get tracked on the concrete haul unit tires and mixed in the fresh concrete. The vibrators on the paver will move the clay chunks upward to the surface of the pavement (resulting in popouts). ''']] | |

| − | |||

| − | |||

| − | + | [[File:602-21.jpg|800px|thumb|center|'''Figure 602-21 Make sure the clay from the haul road doesn’t get tracked on the concrete haul unit tires and mixed in the fresh concrete ''']] | |

| − | |||

| − | |||

| − | + | [[File:602-22.jpg|800px|thumb|center|'''Figure 602-22 Clay may get mixed into the concrete at the plant, due to the bottom of the stockpile not being on a paved surface, and loader operator gathering aggregates in the bottom 12 inches of the stockpile. ''']] | |

| − | |||

| − | |||

| − | + | [[File:602-23.jpg|800px|thumb|center|'''Figure 602-23 Segregation in the concrete mix with the use of a material transfer machine (notice the separation of the larger aggregates in the concrete mix). ''']] | |

| − | |||

| − | + | [[File:602-24.jpg|800px|thumb|center|'''Figure 602-24 Putting down the guard in front of the material transfer machine prevented the concrete mix from being excessively segregated. ''']] | |

| − | + | {{top}} | |

| − | + | ====[[#Grade Condition|Grade Condition]]==== | |

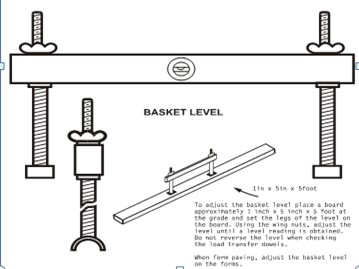

| − | The | + | Proper subgrade preparation and high-quality subbase and base design and construction is the foundation to long lasting concrete pavements. The exposed subgrade area for the entire project needs to be evaluated and repaired/improved as necessary prior to placement of subbase and base layers or final pavements. When the stability of the subgrade is in question, the Engineer should consult with the region soils personnel for the proper solution. The Engineer will promptly inspect the grade to decide whether drying and re-compacting in place, undercutting and replacement of weak soil, or in-place lime/cement type subgrade improvement is necessary and determine the limits of subgrade stabilization (refer to subsection 205.03.E.). An effective method for determining the limits of undercutting is by test-rolling (proof rolling) the subgrade using a suitable heavy loaded vehicle. Test-rolling is a good procedure for visually determining the subgrades uniformity and stability. Refer to MDOT Wiki Division 2 - Section 205 for the procedure of test-rolling. Once weak areas are identified, the geotechnical evaluation team may use various procedures including test holes, test pits/excavations and probing devices such as the U.S. Army style dynamic cone penetrometer to determine the depth of weak soils requiring treatment or removal. |

| − | The | + | After the aggregate base or open-graded drainage course (OGDC) is placed shaped and compacted, it is brought to final grade, usually by an automatic trimmer machine. The automatic trimmer operates off a string line or by automated machine guidance (3D controls) to control the vertical and horizontal alignment. The automated machine obtains its position with an onboard computer communicating to the global positioning systems (GPS), total stations, lasers, or combinations of similar methods while referencing the Contractor’s model developed for the project. Control string lines, if used, must be tight and checked for excessive sag between securing posts and corrected as necessary before the final trimming of the aggregate base surface elevation, as most slipform paving equipment will travel on the aggregate base or OGDC for final grade (See Figure 602-25). |

| − | + | Contractors are supposed to use appropriate haul routes that are built strong enough to support the needed heavy traffic without significantly damaging or yielding the subgrade beneath the final pavement areas. It is critical for jobs that have weaker clayey subgrades and/or thinner base designs, that the prepared base is not used as a haul road in areas that have not been designed as and/or approved as a haul route. If the prepared aggregate base is damaged by construction equipment prior to placing concrete, refer to subsection 602.03.B. | |

| − | + | In the past, the Department required the Contractor to use a concrete spreader and material transfer machine to place the concrete on the grade in front of the paver. Recently, the Department granted the Contractors the general privilege of driving the concrete hauling units directly on the grade to place the concrete in front of the paver. A heavy-duty base and subbase system placed on hard/dense natural soils will likely survive this traffic. However, a low-traffic road type design with thin base and subbase at a site having marginal to weak subgrades may not survive much traffic or weight moving around on top of the base layer material. With this privilege, subsection 602.03.D. of the Standard Specifications for Construction states, “When the Engineer determines that damage occurs to the base course from hauling units, discontinue production until the cause of the damage has been evaluated and corrected” (e.g. excessive rutting and looking for geotextile separator coming to the surface of the base course), (See Figure 602-26). When there is large rutting or yielding damage to the base course, that damage is typically being reflected from damaged/displaced subgrade below the base (rutting in the subgrade reduces the strength of the subgrade and compaction effects and increases moisture susceptibility). | |

| − | + | To prevent damaging the foundation support with the concrete hauling units, the Contractor needs to minimize the hauling time on the base course by properly using the designated haul road and setting up truck access points in front of the paver as necessary to get on and off the grade. Also, at these truck access points the base course may become more disturbed due to the frequent concrete hauling units turning on the grade. If the Inspector notices the base is being damaged by the concrete hauling units, then the Contractor needs to implement a corrective action to their process of placing concrete. For projects having weak subgrade and/or thin base layers experiencing excessive damage, it may be necessary for the Contractor to place less concrete in each hauling unit or completely stay off the grade and use a material transfer machine to place the concrete into the paver. The Contractor will typically use a roller too smooth out minor deflections in the base course, which is required to provide a level surface to place the load transfer assemblies on). | |

| + | [[File:602-25.jpg|800px|thumb|center|'''Figure 602-25 Automatic Grade Trimmer ''']] | ||

| − | |||

| − | |||

| − | + | [[File:602-26.jpg|800px|thumb|center|'''Figure 602-26 Concrete Hauling Units Damaging the Base Course. ''']] | |

| − | + | {{top}} | |

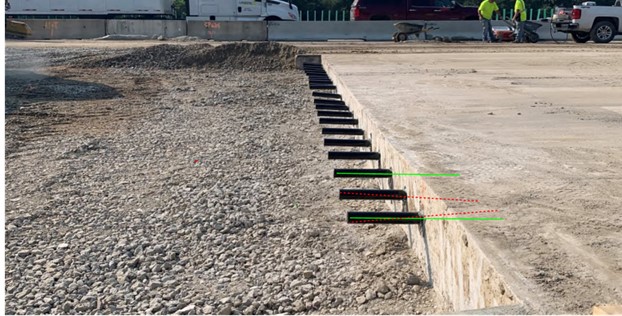

| − | [[ | + | ====[[#Load Transfer Assemblies|Load Transfer Assemblies]]==== |

| − | + | After the base is properly compacted and fine trimmed, dowel bar type load transfer assemblies are placed at planned transverse joint locations. The Inspector should work closely with the Contractor’s crew while they are setting these assemblies. Make sure the joint layouts are in accordance with R-43 Series of the Standard Plans (e.g. match mainline joints to the 22 foot point and 2 foot point of the gores, mainline joints matching the ramps joints, and expansion joints). Custom joint layout patterns are typically used for roundabouts and unusually shaped placement areas. It is preferred that joints line up with drainage structures that are in the curb and gutter or valley gutter castings and manholes to help prevent random cracking in the concrete panels (See Figure 602-27) that tends to emanate from odd shaped inclusions such as manholes and drainage structures. | |

| + | The load transfer assembly is anchored to the grade and holds the dowel bars in position so they will not move during concrete placement and consolidation. | ||

| + | *The typical distance between joints must match the Standard Plans policy, or custom joint layout drawings that are a part of the contract and plans. | ||

| + | *It will be necessary for the Contractor to mark the centerline of the as-installed assemblies so that future joint saw cuts can be made directly over the center of the dowel bars after the concrete has hardened sufficiently. Usually, this location marking is accomplished by setting a long nail or stake in the grade, matching the centerline of the dowels, set just outside the pavement limits (ribbon attached to the nail or stake), or by setting a nail-marker inside the vertical face of the fresh concrete pavement right over the load transfer assembly centerline (See Figure 602-27A). It is critical to get the saw cut lines to be close to the middle of the dowel bars. | ||

| + | *The load transfer assemblies must be positioned at right angles to the centerline as shown in Figure 602-28. | ||

| + | *After they are properly positioned, they must be secured to the base using six pins or stakes per basket assembly or as directed by the Engineer. | ||

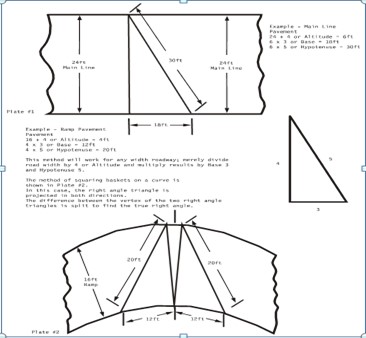

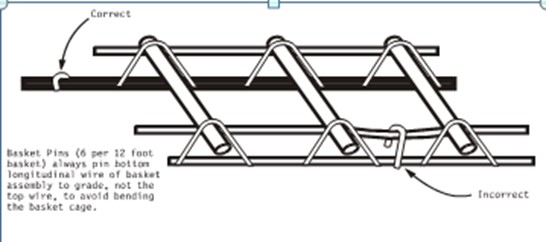

| − | + | The assembly pins must be in contact, snug, with the lower horizontal spacer wire to function properly. The location of the assembly pins is also critical to prevent the basket from shifting or overturning from the concrete paver pushing the concrete into the assembly as shown in Figure 602-29, 602-30, 602-31, and 602-32. | |

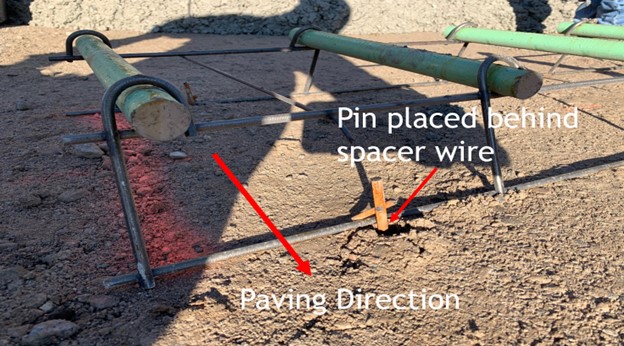

| − | + | After the contractor completes staking the assembly, the inspector should check vertical alignment with the basket level to ensure that dowels are parallel with the pavement surface and not tilted left-right or up-down significantly (See Figure 602-33). Any apparent misalignment can usually be corrected by the contractor (e.g. by tapping the frame to realign the bars, etc.). The dowel bars should also be inspected for completeness of coating | |

| − | |||

| − | |||

| − | + | [[File:602-27.jpg|800px|thumb|center|'''Figure 602-27 Transverse joint in the roadway matching a corner of the drainage structure in the valley gutter. ''']] | |

| − | |||

| − | + | [[File:602-27A.jpg|800px|thumb|center|'''Figure 602-27A Marking out the location of the future saw cut with a nail. ''']] | |

| − | |||

| − | |||

| − | + | [[File:602-28.jpg|800px|thumb|center|'''Figure 602-28 Positioning Dowel Basket Assemblies.''']] | |

| − | |||

| − | |||

| + | [[File:602-29.jpg|800px|thumb|center|'''Figure 602-29 Location of Basket Pins and Basket Level. ''']] | ||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-30.jpg|800px|thumb|center|'''Figure 602-30 Location of Basket Pins. ''']] | |

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-31.jpg|800px|thumb|center|'''Figure 602-31 To prevent the assembly from shifting or overturing due to the concrete being pushed by the paver, the contractor will first place concrete over the assemblies. ''']] | |

| − | |||

| − | |||

| − | + | [[File:602-32.jpg|800px|thumb|center|'''Figure 602-32 The inspector will wet check the dowel bar location behind the paver to ensure the assembly did not shift or overturn. ''']] | |

| − | |||

| − | + | [[File:602-33.jpg|800px|thumb|center|'''Figure 602-33 Basket Level Tool. ''']] | |

| − | |||

| − | + | {{top}} | |

| − | + | ====[[#Dowel Bar Inserter (DBI)|Dowel Bar Inserter (DBI)]]==== | |

| − | + | The DBI is an approved mechanical device that automatically installs load transfer bars into the full depth fresh concrete at the required depth and location, and properly consolidates the surrounding concrete. The device must install the bars in a slow and fluid manner and be capable of consolidating the concrete around the dowel bars such that no air voids are created or remain around the bars, without the supplemental use of hand-held vibrators. These modern automated devices may be used in lieu of stationary load transfer assemblies (See Figures 602-34, 602-35, 602-36, 602-37, 602-38, 602-39, and 602-40). | |

| + | When a dowel bar inserter (DBI) is used to install load transfer bars, the bars shall be placed at the same spacing as detailed for dowel bar assemblies in the Standard Plan R-40 series. The pavement shall be placed and consolidated full depth prior to insertion of the dowel bars. | ||

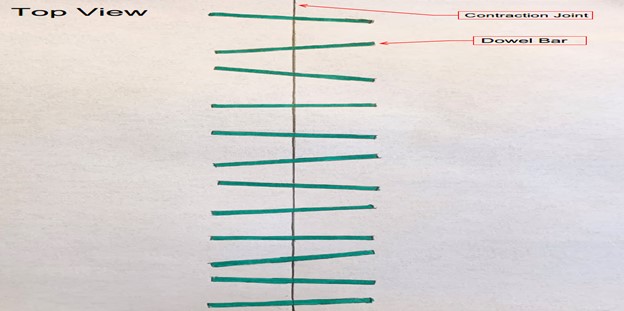

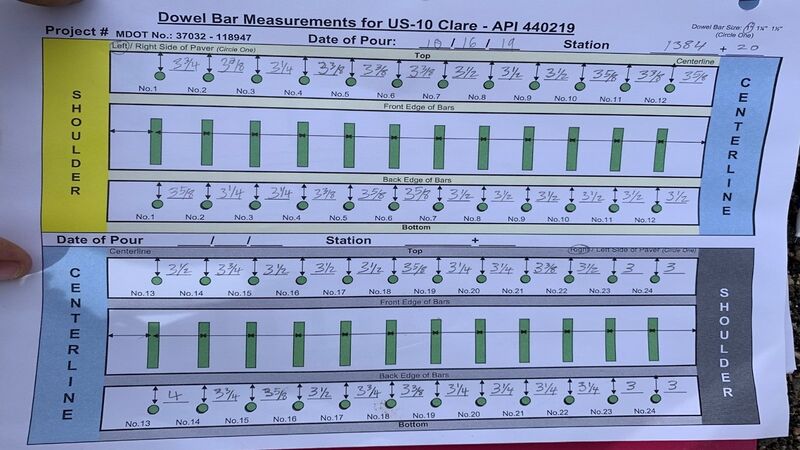

| − | + | Proper alignment of the dowel bars is crucial to proper joint opening and closing behavior in response to summer to winter expansion and contraction (See Figures 602-41, 602-42, and 602-43). Premature pavement distress such as medium to high severity spalling can develop if a dowel or group of dowels is not properly aligned. The Contractor is required to perform wet checks to verify the dowel bars are at the proper depth and position alignment (vertically and horizontally) in accordance with MDOT Specifications and Standard Plans. The Contractor will also verify the location of the nail to the center of the dowel bar (tolerance +/- 2 inches of side shift, See Figure 602-27A). These wet checks measurements will be made every 500 feet and as required by the Contractors Quality Control Plan. The Engineer will witness these measurements and may request documentation of these measurements (See Figures 602-44, 602-45, and 602-46 for wet checks). | |

| − | The | + | The following are forms to document the wet checks at different pavement widths: |

| + | *Download a copy of the [https://mdotwiki.state.mi.us/images_construction/5/58/12_ft_Wet_Checks.pdf 12 ft Wet Checks]. | ||

| + | *Download a copy of the [https://mdotwiki.state.mi.us/images_construction/e/e8/14_ft_Wet_Checks.pdf 14 ft Wet Checks]. | ||

| + | *Download a copy of the [https://mdotwiki.state.mi.us/images_construction/9/96/24_ft_Wet_Checks.pdf 24 ft Wet Checks]. | ||

| + | *Download a copy of the [https://mdotwiki.state.mi.us/images_construction/2/2c/26_ft_Wet_Checks.pdf 26 ft Wet Checks]. | ||

| + | |||

| + | Any out of tolerance joints shall be marked and replaced at the Contractor’s expense. If the dowels are consistently out of tolerance with respect to alignment and/or depth, the Contractor must stop production paving and take steps to correct the alignment problems. Dowel alignment problems can be created when too much concrete height or thickness, commonly referred to as head, develops in front of the paver that has the DBI mounted to it. The amount of head maintained in front of the paver must be in accordance with the DBI and paver manufacturer’s recommendations to provide consistent proper dowel alignment. | ||

| − | + | Many other factors can contribute to dowel alignment and depth problems when using a DBI. The important thing to remember is to be sure the DBI is consistent when placing dowels throughout each day’s production. Periodic wet and dry alignment/depth checks are necessary to confirm consistency. The Inspector should also make sure the Contractor is following all the DBI manufacturer’s recommendations for this equipment. | |

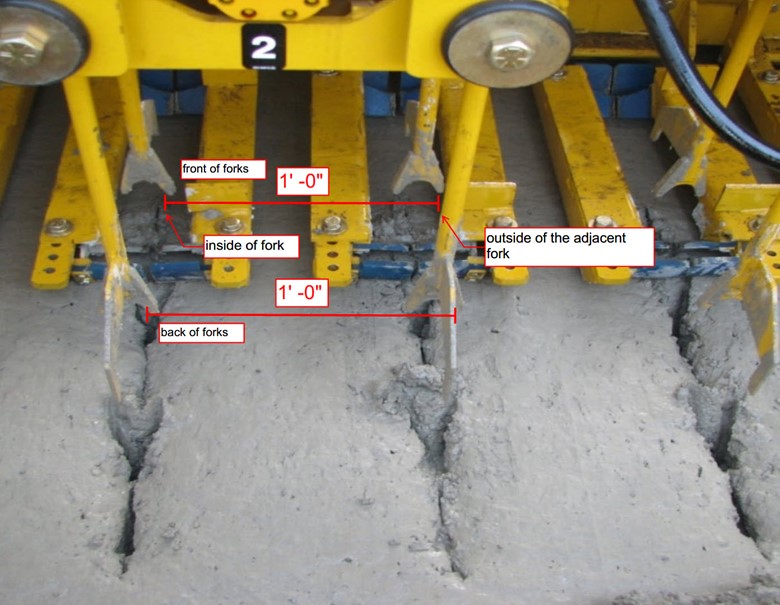

| − | + | The insertion forks of the DBI may get bent during production, and this may occur from too much concrete in the dowel bar trays (See Figures 602-47 and 602-48). If an insertion fork bends on the DBI, the Contractor will either bend it back into position or replace it. Then, the Contractor needs to verify the depth and position of the insertion fork on the DBI. The best initial check for horizontal alignment of the dowel bars is for the Contractor to measure the spacing between the front and back of the insertion forks as shown in Figure 602-49. Then, the Contractor needs to wet check the joints where the dowel bars were inserted with the bent forks and then where the forks were corrected to confirm consistency. The Contractor will need to use two chaining pins to wet check the horizonal alignment of the dowel bars. | |

| + | |||

| + | Also, as the Contractor is correcting the DBI, the Inspector needs to keep track of any concrete haul units waiting to place concrete and the concrete placed on the grade in front of the paver (the spec book states in subsection 602.03.D, “Place a transverse end-of-pour joint when unavoidable interruptions of concrete placement occur that are longer than 60 minutes from the time the concrete is batched until final finishing of the concrete surface). The Inspector needs to visually inspect the concrete sitting on the grade to see if it appears to be setting up (especially on days where there is a high evaporation rate), as this could impact the consolidation ability around the dowel bars. The Inspector should identify this area in their daily work report and the Engineer may require a core to be taken to verify consolidation. | ||

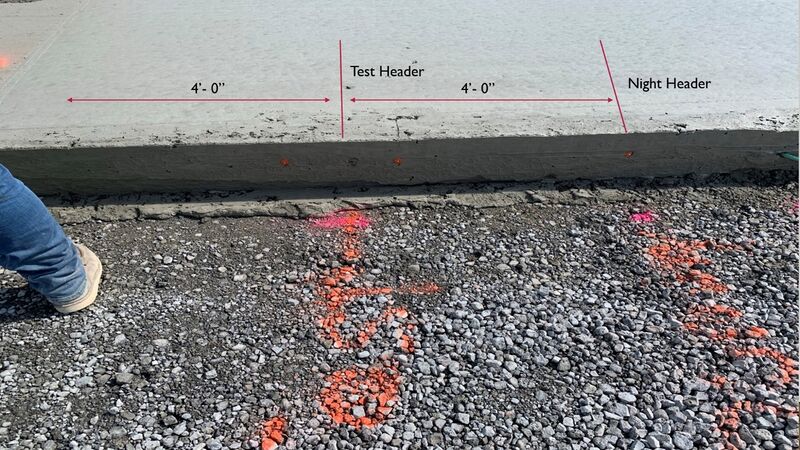

| − | + | The Contractor must construct and evaluate DBI test headers throughout the project to verify proper consolidation of concrete around the dowel bars and alignment of dowel bars in hardened concrete. Three test headers are required in each direction of travel, but the Engineer may request more depending on if the Contractor uses more than one paver with the DBI setup and the contractor quality control measurements. See Figures 602-50, 602-51, 602-52, 602-53, 602-54, 602-55, 602-56, and 602-57. | |

| − | + | Also, if there are issues with the DBI, a test header needs to be made at the end of the days production and the Contractor needs to remove the test header for inspection of the dowel bar placement before restarting the concrete paving operation. Based on the test header results, the Contractor may need to recheck and adjust the DBI forks before restarting the concrete paving operations. | |

| − | The | + | The following is a spreadsheet for documenting the test header results into the office file. There is an example filled out in the spreadsheet. The Inspector can record the test header results in the field onto the wet check form and then input the information into the spreadsheet. |

| − | |||

| − | + | *Download a copy of the [https://mdotwiki.state.mi.us/images_construction/f/f4/Test_Header_Spreadsheet_2020.xlsx Test Header Spreadsheet 2020]. | |

| + | |||

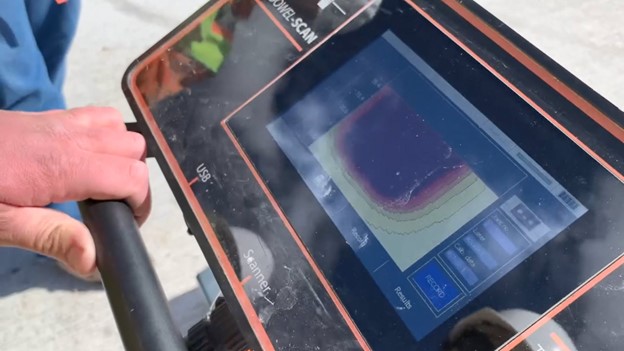

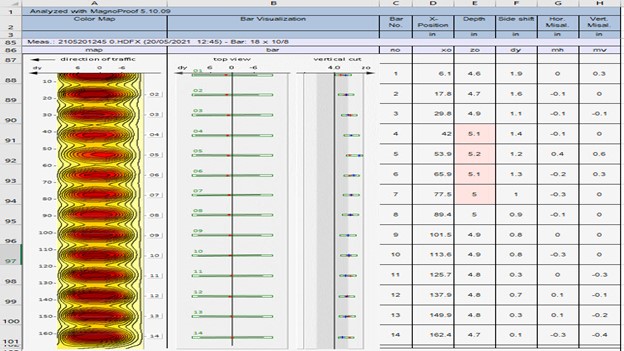

| + | When the DBI is being used, MDOT Lansing Construction Field Services (CFS) will provide the project office the service of the MIT-Dowel Scan non-destructive dowel scanning device. CFS highly recommends the Engineer to have the transverse joints scanned throughout the duration of the project, especially when the contractor starts paving, when changes the paver setup occur, if more than one paver is used with the DBI setup, and when issues arise with the DBI in general. | ||

| − | + | The MIT-Dowel Scan device has 10 sensors (magnets) that pick up the magnetic properties of the dowel bars, which create magnetic fields, and then the data is processed to predict embedded depths and alignments (See Figure 602-58). The MIT-Dowel Scan gives you real time imaging and results (See Figure 602-59). The MIT-Dowel Scan data will be shown on an excel spreadsheet identifying the dowel bar spacing, depth, side shift, horizontal misalignment, and vertical misalignment (See Figure 602-60). The MIT-Dowel Scan is extremely accurate for evaluating the DBI paving operations (the dowel bars near the longitudinal joints may have influence of the lane ties so that data can’t be used). The MIT-Dowel Scan accuracy has been confirmed by being compared to test headers and cover meters. Currently, the MIT-Dowel Scan technology is relatively new and is used for information purposes only and not as part of formal quality assurance procedures. There are other DOTs that use the MIT-Dowel Scan in their specifications. The typical process CFS uses to MIT-Dowel Scan the transverse joints, is by scanning about 10 joints every 700 feet to 1000 feet to identify any patterns of potential issues with the dowel bar placement. Then, CFS will give the project office an excel spreadsheet and interpretation of the results. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | The | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-34.jpg|800px|thumb|center|'''Figure 602-34 Independent DBI unit to the concrete paver. ''']] | |

| − | | | ||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-35.jpg|800px|thumb|center|'''Figure 602-35 Inside view of DBI unit (DBI forks and dowel bar trays). ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-36.jpg|800px|thumb|center|'''Figure 602-36 DBI unit. Gomaco is the manufacture of this machine, and they recommend the concrete roll size inside the DBI unit not to exceed 12 inches. ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-37.jpg|800px|thumb|center|'''Figure 602-37 When the concrete roll is too large, the excess concrete will get inside the bar trays. This may occur if there is too much concrete in front of the paver. The concrete needs to be cleaned out of the bar trays to prevent misaligning the dowel bars. Then, the contractor needs to decrease the concrete roll size by adjusting the paver. ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-38.jpg|800px|thumb|center|'''Figure 602-38 DBI unit. ''']] | |

| − | |||

| − | |||

| − | + | [[File:602-39.jpg|800px|thumb|center|'''Figure 602-39 Replacing the worn out forks for the DBI. ''']] | |

| − | | | ||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-40.jpg|800px|thumb|center|'''Figure 602-40 Replacing the worn out forks for the DBI. ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-41.jpg|800px|thumb|center|'''Figure 602-41 The two of the most significant factors in joint performance is dowel bar vertical and horizontal skew. Excessive skew in any direction creates potential for locked joints during normal expansion and contraction of the slabs that occur naturally from temperature and moisture changes. In this picture, it shows the vertical alignment of the dowel bars. The dowel bars should be parallel to the surface and centerline of the harden slab. The green line indicates a level dowel bar and the red dash indicates a dowel bar that is skewed and misaligned. Studies have shown that joints have a higher chance of locking up when the dowel bars are oppositely misaligned (where one dowel bar is tipped up and the other is tipped down). ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-42.jpg|800px|thumb|center|'''Figure 602-42 Dowel bar horizontal alignment. Joints have a higher chance of locking up when the dowel bars are oppositely misaligned (the dowel bars creating a “V’ shape). ''']] | |

| − | |||

| − | |||

| − | + | [[File:602-43.jpg|800px|thumb|center|'''Figure 602-43 Corner cracking that can be caused from dowel bar misalignment. ''']] | |

| − | | | ||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-44.jpg|800px|thumb|center|'''Figure 602-44 Helpful tools to do wet checks is a chaining pin and flat edge to match top of pavement (the top of the pavement has a tendency to drop down, so placing a flat edge next to the chaining pin is the best practice to getting an accurate measurement). ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-45.jpg|800px|thumb|center|'''Figure 602-45 Wet check. ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-46.jpg|800px|thumb|center|'''Figure 602-46 Wet check documentation. ''']] | |

| − | |||

| − | |||

| − | + | [[File:602-47.jpg|800px|thumb|center|'''Figure 602-47 Bent forks on the DBI. ''']] | |

| − | |- | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-48.jpg|800px|thumb|center|'''Figure 602-48 The contractor bending the insertion forks for the DBI back into the proper position. ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-49.jpg|800px|thumb|center|'''Figure 602-49 Verifying the horizontal alignment of the insertion forks.''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-50.jpg|800px|thumb|center|'''Figure 602-50 Test Header. ''']] | |

| − | |||

| − | |||

| − | + | [[File:602-51.jpg|800px|thumb|center|'''Figure 602-51 Locate the end of the dowel bar with the chaining pin, then measure 2 inches from the end of the dowel bar and place a nail on the vertical face of the concrete slab. Then, measure 14 inches and put another nail in the vertical face of the concrete slab. Marking out the test header is important to ensure the dowel bar is not missed when saw cutting. ''']] | |

| − | | | ||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-52.jpg|800px|thumb|center|'''Figure 602-52 Label test header (dowel bar number, direction of paving, front and back of dowel bar). ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-53.jpg|800px|thumb|center|'''Figure 602-53 Test header cut in two sections. ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-54.jpg|800px|thumb|center|'''Figure 602-54 Don’t cut test header in 4ft sections. Not able to get accurate measurements with saw cuts. ''']] | |

| − | |||

| − | |||

| − | + | [[File:602-55.jpg|800px|thumb|center|'''Figure 602-55 It would be best practice for the Contractor to cover the test header with insulated blankets (helping the concrete gain strength) when the test header is planned to be removed in less than 12 hours (especially when the ambient temperature is less than 60 degrees Fahrenheit), so adjustments on the DBI Unit can be made before the next day of production. Care needs to be taken when removing test headers. The Contractor will generally remove the test header with the forks on a loader. Also note, if the test header is too green and lifted too high with the loader forks, it will likely break around the dowel bars (the Contractor should just drag back the test header on the grade and leave enough clearance to measure the test header). ''']] | |

| − | | | ||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-56.jpg|800px|thumb|center|'''Figure 602-56 Measuring horizontal alignment. ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-57.jpg|800px|thumb|center|'''Figure 602-57 Measuring vertical alignment. ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-58.jpg|800px|thumb|center|'''Figure 602-58 MIT-Dowel Scan. ''']] | |

| − | |||

| − | |||

| − | + | [[File:602-59.jpg|800px|thumb|center|'''Figure 602-59 MIT-Dowel Scan real time imaging and results.''']] | |

| − | | | ||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-60.jpg|800px|thumb|center|'''Figure 602-60 MIT-Dowel Scan data shown on an excel spreadsheet. ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | {{top}} | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ====[[#Expansion Caps|Expansion Caps]]==== | |

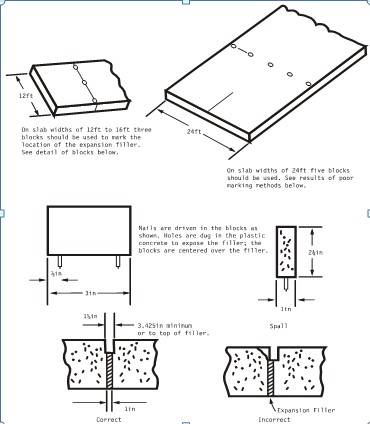

| − | + | In general sawed contraction joints will slowly open over time as silt and fine sand infiltrate the joints and cracks and prevent them from fully closing. Therefore, expansion joints are installed intermittently and at strategic locations to absorb this movement. Special caps are used on ends of dowels at expansion joints to accommodate future joint closing or compression over time. Expansion caps must be securely placed on opposite unwelded ends of the bars, with 1 inch space left between the end of the bar and the inside of the cap. Most expansion caps have inverted dimples 1 inch from end of cap as an indicator (See Figure 602-61). When using the slipform paving method, the outside 4 inches of the expansion felt will be removed and replaced after the paver goes. | |

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-61.jpg|800px|thumb|center|'''Figure 602-61 Expansion Cap. ''']] | |

| − | |||

| − | + | {{top}} | |

| − | |||

| − | |||

| − | + | ====[[#Expansion Joint Filler|Expansion Joint Filler]]==== | |

| − | + | During final finishing operations. The previously removed 4-inch end section of the expansion filler material should be replaced and the concrete consolidated around the joint filler. The expansion joint filler location should also be marked for sawing at a later date. The best method of doing this is by working from a bridge spanning the pavement. The expansion filler top is exposed in about five locations across a 24-ft pavement by using a small trowel to remove the concrete. A small block is then placed on top of the expansion filler. The block should extend to the surface and be held in place by nails extending into the filler. Later the joint is sawed out from block to block (See Figure 602-62). | |

| − | |||

| − | + | [[File:602-62.jpg|800px|thumb|center|'''Figure 602-62 Transverse Expansion Joints. ''']] | |

| − | | | ||

| − | |||

| − | |||

| − | + | {{top}} | |

| − | + | ===[[#Production Paving Projects|Production Paving Projects]]=== | |

| − | + | Concrete will be produced in a central mix plant. Production paving projects will typically be set up with a portable concrete batch plant (See Figure 602-63). Concrete will be transported to the job site in concrete hauling units (dump trucks or agitator trucks) (See Figures 602-64 and 602-65). The allowable haul time will depend on the type of hauling unit and the concrete temperature, as stated in subsection 1001.03.E.3. | |

| − | |||

| − | |||

| − | |||

| − | + | The contractor will provide a ticket system to record the batch numbers with information required by subsection 1001.03.A.3. The inspector collecting the concrete tickets from the concrete hauling units needs to verify the batch weights of the materials are within the required tolerances of subsection 1001.03.A.2 and match the weights of the Job Mix Formula and Optimized Gradations. | |

| − | |||

| − | + | [[File:602-63.jpg|800px|thumb|center|'''Figure 602-63 Portable Concrete Batch Plant. ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-64.jpg|800px|thumb|center|'''Figure 602-64 Concrete Open Trucks (Dump Truck). ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-65.jpg|800px|thumb|center|'''Figure 602-65 Open Top Agitating Units. ''']] | |

| − | + | {{top}} | |

| − | + | ====[[#Dual Lane Operation|Dual Lane Operation]]==== | |

| − | |||

| − | |||

| − | |||

| − | + | The concrete spreading operation should be kept reasonably close to the pavers so no more than 30 minutes elapse between layers of concrete, or between placing and finishing the concrete (See subsection 602.03.D). | |

| − | + | Tie bars are placed at the center longitudinal joint. A lane tie bar installer is often mounted on the rear and in the center of the paver. It will place reinforcement bars of proper length and diameter according to Standard Plan R-41 Series. | |

| − | + | An Inspector should check the spacing of bars as soon as possible after paving starts. Check the bar depth after finishing operations are complete, as they have a tendency to settle due to the vibration of paving equipment. This is done by using the work bridge to access the longitudinal joint between lanes. | |

| − | + | {{top}} | |

| − | |||

| − | |||

| − | |||

| − | + | ====[[#Slipform Pavers/Riding Finishing Machine|Slipform Pavers/Riding Finishing Machine]]==== | |

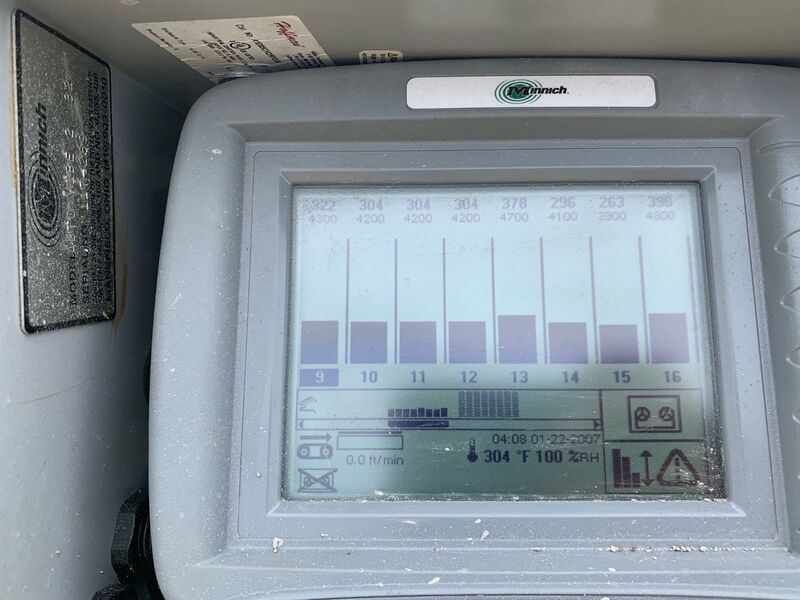

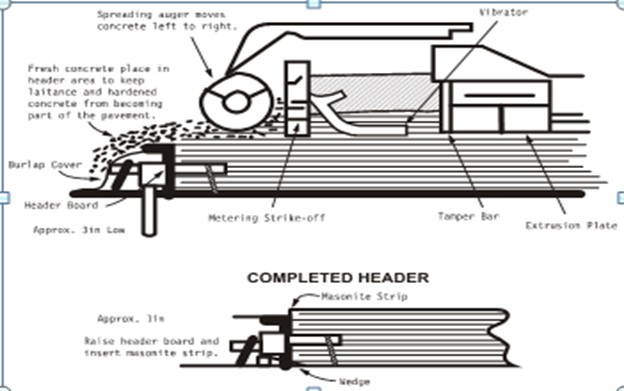

| − | + | The slipform paver uses a lower slump concrete to minimize edge slump. Therefore, full width vibrators are necessary to eliminate all internal honeycombs. Contractors should have a vibrator monitor system as required by subsection 602.03.A.7 (See Figure 602-66 and 602-67). | |

| − | + | It is important that the slipform paver, or finishing machine, has the correct recommended concrete amount in the screed, or strike-off plates, to prevent overloading that can cause slipping of the track or drive wheels. Drive train slippage will typically result in chatter bump type irregularities on the pavement surface. Also, an inadequate amount of concrete placed in front of the pavers screed will result in low-spot type irregularities on the pavement surface (See Figure 602-68 and 602-69). | |

| − | |||

| − | |||

| − | + | Form riding finishing machines, and some slipform pavers, have two oscillating screeds that shape the surface of the concrete. For the best results, the front screeds should have about an 8 inch roll of concrete in front of it. The second should have a smaller roll, about 4 inches. A slow, steady forward movement with a uniform supply of concrete in front of the type of finisher will produce the best surface finish. Slipform pavers are equipped with extrusion plates to form and finish the concrete. Slipform pavers are equipped with spray bars to add water as an aid to finishing but the addition of water should be kept to a minimum. Adding too much water to the surface is to be avoided as it can result in a low strength high shrinkage thin surface zone that can be subject to thin delamination and scaling distress. The contractor should attach burlap to the slipform paver and spray water on the burlap, rather than directly on the fresh concrete surface (See Figure 602-70). | |

| − | + | If a pan float, or other mechanical float, is used behind the slipform paver or the finishing machine, it should leave the concrete surface in a substantially finished condition (See Figure 602-71) | |

| − | + | Some slipform paving machines are equipped with transverse screeds for additional floating. Tears or open areas indicate improper screed adjustments, inadequate vibration or perhaps a harsh mix. Attempts to correct the equipment should be made before changing the mix. | |

| − | + | The slab edge condition being created should be evaluated immediately behind the slipform paver. The edge forming equipment (edgers) used on the paver can be adjusted to minimize edge slump. When the concrete leaves the trailing edge of the edgers, it should slump down and out to the proper width and elevation. Because concrete does move or slump in this way, it is essential to maintain a uniform slump from load to load to match the edger settings. Conventional edgers should be used to round the top corner. It should be left with a radius not exceeding 1/4-inch. Edge slump should be rechecked with the 5-ft straightedge behind all finishing operations. Any edge slump exceeding 3/8 inch should be corrected before the concrete sets. If continuing slumps of up to 1/4-inch occur, the Contractor should adjust the edgers on the trailing end of the side forms to eliminate the slump. | |

| − | |||

| − | |||

| − | + | After machine finishing, the slab surface should be checked by the Contractor’s finisher using a 10-ft straightedge and the 5-ft lap method of straight edging. Any high or low areas indicated by the straightedges are to be corrected. The areas needing correction may be hand floated, if necessary, to seal the surface. On slipform paving, the finisher should stop the straightedge about 4 to 6 inches from the edge to keep the edge from slumping due to the added weight of the straightedge. | |

| − | + | [[File:602-66.jpg|800px|thumb|center|'''Figure 602-66 Vibration Monitor System (Minnich). ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-67.jpg|800px|thumb|center|'''Figure 602-67 Vibration Monitor System (TOPCON). ''']] | |

| − | |||

| − | |||

| − | + | [[File:602-68.jpg|1000px|thumb|center|'''Figure 602-68 Placing concrete in front of the paver. ''']] | |

| − | | | ||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-69.jpg|1000px|thumb|center|'''Figure 602-69 Location of the augers on the paver. ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-70.jpg|1000px|thumb|center|'''Figure 602-70 Float Pan. ''']] | |

| − | |||

| − | + | {{top}} | |

| − | |||

| − | |||

| − | + | ====[[#Concrete Overlay|Concrete Overlay]]==== | |

| − | + | Concrete overlays can be used over existing asphalt or concrete pavements. MDOT uses what are referred to as bonded and un-bonded overlay designs. Unbonded designs use bond breaker layers to allow the new concrete slabs to detach from the layer below, while bonded designs may use cementitious bonding layers to develop a long-term bond between the new and old pavements. In recent years mostly un-bonded type designs have been used. The design thickness values for overlays typically range from about 4 to 10 inches. Thin overlays, less than about 6 inches, typically do not use steel bars or dowels, but use special fiber reinforcements in the slabs along with short slabs with saw cut spacings less than about 6 feet. Overlays greater than about 6 inches typically do use dowel and tie bars for joints in the design and often use longer slabs with saw cut spacings up to about 12 feet. | |

| − | + | The existing pavement typically undergoes surface preparation and repairs that could include milling/abrading of the surface, cleaning, HMA or concrete joint repairs. The prepared surface is then overlaid with a bituminous/asphalt or wax type bond breaker layer, or a layer of separation geotextile fabric before the new concrete surface is paved (See Figure 602-71 and 602-72). In some cases, where grades permit, a layer of HMA, 1 to 3 inches in thickness is placed as what is called a stress relieving interlayer (SRI) over the original pavement to develop stronger and more uniform support for the new overlay. | |

| − | + | Random unscheduled daily yield checks, using the random number sheet, on the volume produced by the batch plant should be performed to verify the amount of concrete produced per batch by comparing the apparent yield thickness or distance to actual thickness or distance measurements. This volumetric yield check can then be applied to all batches leaving the plant and compared to the computed total volume placed during the day’s production. The yield check can provide a simple verification of the batch ticket volume printed by the batch plant. This procedure should be part of the Contractor’s quality control plan and periodically verified through MDOT quality assurance testing where appropriate. This method of checking the volume of concrete should be used wherever concrete is being paid for by volume. | |

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-71.jpg|1000px|thumb|center|'''Figure 602-71 Concrete overlay with HMA bond breaker layer. ''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:602-72.jpg|1000px|thumb|center|'''Figure 602-72 Concrete overlay with HMA bond breaker layer. ''']] | |

| − | |||

| − | + | {{top}} | |

| − | + | ====[[#Grade Control|Grade Control]]==== | |

| − | | | ||

| − | |||

| − | + | Grade control is critical when paving a concrete overlay. Overruns can be controlled by monitoring the grade of the surface the overlay is to be placed on prior to paving the bond breaker layer and the overlay. Recorded string line depth checks on the grade control prior to paving the overlay are important to monitor the volume of concrete to be placed and keep it close to the actual plan quantity. | |

| − | + | Grade control is again the critical item for controlling Contractor material quantities, and final profiles when paving miscellaneous concrete. Smaller miscellaneous areas are typically formed prior to paving miscellaneous concrete. The forms can benefit the grade control process. However, matching the grades in approaches, and ramp gore areas can lead to pavements that do not drain properly or have a rough initial ride quality for the public. | |

| − | + | If not included in the plans, a set of detailed grades should be computed and plotted prior to the beginning of the project to attempt to alleviate grade problems. The detailed grades should be computed from the plan profiles for the adjacent pavement. After the grades are computed, they should be plotted to determine the proposed gore/approach cross sections prior to beginning the project. If the detailed grades are determined prior to paving, the Inspector and Project Engineer can typically fine tune adjust the mainline and/or ramp grades to tie-in better and provide smoother transitions for gores and approach pavement. | |

| − | |||

| − | |||

| − | |||

| − | + | {{top}} | |

| − | + | ====[[#Concrete Texturing|Concrete Texturing]]==== | |

| − | + | Following floating, the surface is to be textured longitudinally with a burlap drag (see subsection 602.03.K). Even though the final grooving (tining) will be created by metal tine rakes, it is important that the slab be properly textured initially with burlap to give the surface a slightly roughened micro-texture, gritty texture with exposed sand grains, to better interact with tire rubber for friction. | |

| − | + | About 36 to 60 inches of burlap width should be in contact with the pavement surface as it is dragged. Two layers of burlap may be required to impart a suitable gritty surface. The burlap should be cleaned of built-up mortar intermittently as needed, at least daily, and replaced when it is no longer effective. It should be kept moist to avoid dry burlap from absorbing water from the concrete surface. | |

| − | |||

| − | |||

| − | |||

| − | + | When slipform paving, it is better not to have the burlap drag extend over the edges, as it may cause the concrete to edge-slump or tear the edges. The outer 4 inches of the surface near the edges should be hand dragged by the finishers doing the edging. | |

| − | + | A strip of artificial turf grass mat may be used as an alternate to burlap and in some low-speed traffic areas a turf drag is the final texturing used for the surface. After the burlap/turf drag process, concrete surface in higher speed traffic areas are typically grooved transversely or longitudinally with a steering controlled texturing machine to achieve better high speed hydroplaning resistance. A manual texturing device, often a hand-held tinning rake, may be used for small area miscellaneous pavement. The Contractor must place grooves with a width and depth of ⅛-inch, with a tolerance of 1⁄32-inch, spaced ¾-inch on center with a tolerance of 1⁄16-inch. Do not groove the pavement surface within 1½ inches of longitudinal joints. Grooves should not be overlapped. Overlapping decreases the spacing, which results in tearing and dragging of fresh concrete along the surface during texturing. The grooves should be installed in one continuous pass across the entire pavement surface. Do not allow grooves to dig too deep as this can start to move coarse aggregates present near the top of the fresh concrete and cause tearing/dragging of the fresh concrete surface resulting in reduced ride quality numbers and unnecessary tire-pavement noise and damage to the concrete surface. Grooves that are too shallow can have reduced tire hydroplaning resistance during heavy rain events. | |

| − | + | Texturing operations shall not delay curing. Timely application of curing compound is critical to the final strength and durability of the concrete pavement. Proper and timely application of the curing compound must take precedence over texturing the surface with the texture machines or rakes. If texturing has to be delayed, it will have to be cut into the surface at a later date when the concrete has attained the minimum required design strength. When texturing is delayed, the Contractor shall submit a plan for the Engineer’s approval for texturing the pavement after the concrete has reached the strength required and describing groove cutting equipment and slurry collection procedures. This work shall be at the Contractor’s expense. Therefore, it is imperative that the texture operations stay close to the fresh concrete placement operations and not fall critically behind because the cost of mobilizing a diamond cutting blade type groove cutting operation after the fact is high. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | {{top}} | |

| − | |||

| − | + | ====[[#Grooving Device|Grooving Device]]==== | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | | | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||