602 - Concrete Pavement Construction

GENERAL

-Reserved-

MATERIALS

Acceptance of Materials

Before paving operations start, the paving inspector should verify that all materials that need to be incorporated in the pavement have been tested and accepted. Most materials will be stockpiled in the Contractor’s yard on the project site. Often this is also the location of the batching plant.

|

| |

|---|---|

|

|

When the load transfer assemblies arrive on the project site, call Region materials personnel so they can verify that the assemblies were built according to the standard plans. Notice of acceptance by Region materials personnel is the required documentation. |

|

|

Check to see if the dowel bars and the fiber joint filler material are certified. Sampling and testing may be required. |

|

|

After the Contractor starts to set the load transfer assemblies on the grade, they must be visually inspected for:

|

|

|

The entire bar is to be coated with an approved epoxy coating to prevent corrosion, and the entire bar’s length is to be coated with an approved material to prevent concrete from adhering to the bar. |

|

|

Any material of uncertain origin should be piled separately and not used until it is determined that it meets specification requirements. |

|

|

Visually inspect the handling and storage of all materials used in the concrete paving operation. |

Tie Bars and Bent Bars

These items should be checked for certification, or sampled and tested when they arrive on a project.

Curing Compound

- Check certification, or sample and test each batch or lot.

- Material may be in drums or in a large tank. Inspection consists of seeing that the material is not contaminated or diluted and that it is mixed according to the manufacturer’s recommendations.

- A curing compound should not be used when stored from one construction season to the next without resampling and testing.

- Check yield of material to ensure correct coverage.

CONSTRUCTION

Concrete Testing Procedures

Quality control and Quality Assurance testing for concrete will be in accordance with Special provision 12SP604(B).

MEASUREMENT AND PAYMENT

Pavement Coring

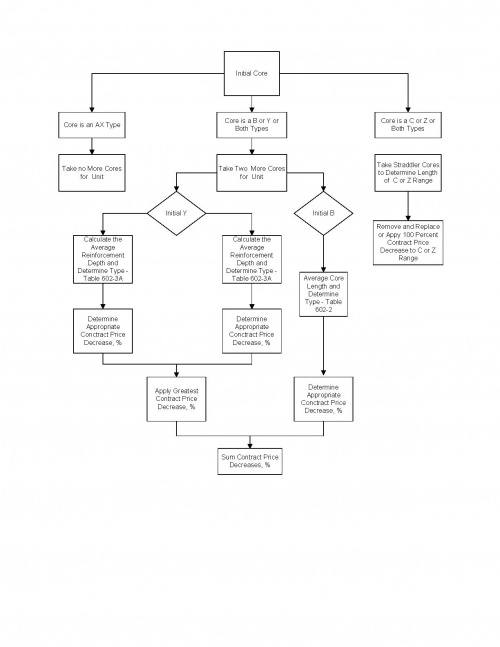

To determine pavement, shoulder and base course thickness and depth of reinforcement, cores shall be taken from the pavement before its final acceptance to determine the thickness of the pavement and depth of pavement reinforcement below the pavement surface according to MTM 201. Refer to subsection 602.04 of the Standard Specifications for Construction and the following flow chart (see Figure 602-9) for this determination.

Ride Quality

A specification to encourage the Contractor’s to construct the smoothest pavements possible and the method to measure the surface for smoothness.

The Contractors may use a California-type Profilograph or a GM-type Rapid Travel Profilometer to measure the pavement smoothness.

The Engineer will establish and mark the limits for Ride Quality Measurement including the POB, POE and any excluded areas.

The California-type Profilograph will produce a trace, or Profilogram, on graph paper, to a true 1:300 horizontal scale and true 1:1 vertical scale, which will be analyzed according to Michigan Test Method 204-88.

If a computerized Profilograph is used, a trace will not need to be analyzed, but should be spot checked with a blanking band.

The equipment must be calibrated before use.

Tire pressure should be 25.375 psi ± 1.015 psi (175 kPa ± 7 kPa) in the recording wheel.

The horizontal calibration will be checked by running the Profilograph over a measured 1000 foot (300 m) length which should produce a trace of 3.28 ft ± 0.118 in (1 m ± 3 mm). Calibration of the computerized version will be run over a distance of 1000 foot (300 m) and should produce a printout within ± 3.28 feet (1 m).

The vertical calibration is to be done according to the manufacturer’s specification and must be documented by the Contractor.

The GM-type Profilometer will be calibrated according to the user’s manual.

Software is provided which allows the operator to test the operation of the three buttons and computer system, along with a “bounce” test.

The vertical calibration of the laser sensor is to be done according to the manufacturer’s specification and must be documented by the Contractor.

The horizontal distance is calibrated by traveling a known distance and typing in the value on the keyboard while in the calibration mode. The continued reliability of the odometer will depend on a constant tire pressure.

The measurement/profile will be taken in the wheel tracks of each lane.

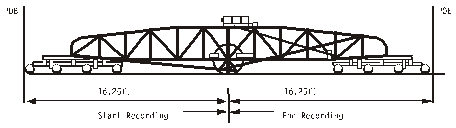

The starting position of Ride Quality using the California-type Profilograph is when the rear wheel assembly is entirely on the road surface, placing the recording wheel 16.25 feet (5 m) beyond the POB. The ending position will be when the front wheel assembly is at the POE, placing the recording wheel 16.25 feet (5 m) short of the POE. Whenever the run is stopped before the POE, the recording wheel should be placed at the same location for a restart. See Figure 602-10 for a Profilograph.

Measurement outside the POB or POE may be done to check for bumps, and will be paid as Ride Quality Measurement - Concrete.

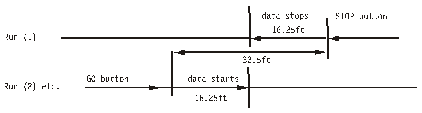

The software for the GM-type Profilometer has been designed to simulate the same starting and ending points as the California Profilograph. Starting the measurement (GO button) at the POB will start data recording at 16.25 foot (5 m) after the POB. Ending the run (STOP button) at the POE will stop the data recording 16.25 foot (5 m) prior to the POE. Caution should be taken when stopping the GM Profilometer between the POB and POE as in daily or short runs. As the recording data will stop 16.25 foot (5 m) prior pushing the Stop button, the next run will have to be started 32.5 foot (10 m) before that same point to start the data recording at the right point. See Figure 602-11 for an example of starting and stopping points.

The California Profilograph trace will have to be reduced, using a blanking band, to segments. Bumps which exceed the limits established by Special Provision can be located by using a bump template. The computer version will analyze the ride quality and locate the bumps which must be ground.

The rapid travel Profilometer can give data in inches per mile or by a ride quality index, along with the locations of must-grind areas.

Check the proposal for pay items and adjustment table for the item of Ride Quality.

Roadways, collector distributors, ramps and turn lanes that are not covered under a ride quality specification should be evaluated for smoothness and removable bumps in one of three ways:

By using a 10 foot (3 m) straightedge as per MTM 722-97.

By using a rolling straightedge available from the Construction and Technology equipment shop.

By using the rapid travel profilometer, which is programmed to check for bumps according to the Standard Specification for these areas. Contact the Construction Services section for use of this equipment.