Difference between revisions of "803 - Concrete Sidewalk, Ramps, and Steps"

| Line 5: | Line 5: | ||

<center><span STYLE="font: 40pt arial;">'''Concrete Sidewalk, Ramps, and Steps'''</span></center> | <center><span STYLE="font: 40pt arial;">'''Concrete Sidewalk, Ramps, and Steps'''</span></center> | ||

| − | <center>[http://mdotcf.state.mi.us/public/specbook/files/2012/803%20Conc%20Swalk%20Ramps%20Steps.pdf 2012 STANDARD SPECIFICATIONS FOR CONSTRUCTION - SECTION | + | <center>[http://mdotcf.state.mi.us/public/specbook/files/2012/803%20Conc%20Swalk%20Ramps%20Steps.pdf 2012 STANDARD SPECIFICATIONS FOR CONSTRUCTION - SECTION 803]</center> |

| Line 17: | Line 17: | ||

==MATERIALS== | ==MATERIALS== | ||

| + | <span style="color: red"> -Reserved- <span> | ||

| − | |||

==CONSTRUCTION== | ==CONSTRUCTION== | ||

| Line 29: | Line 29: | ||

After concrete has gained sufficient strength, the forms shall be removed and the edges backfilled and compacted to within 1 inch (25 mm) of the sidewalk surface and left in a neat condition. | After concrete has gained sufficient strength, the forms shall be removed and the edges backfilled and compacted to within 1 inch (25 mm) of the sidewalk surface and left in a neat condition. | ||

| + | |||

===Joints=== | ===Joints=== | ||

Revision as of 13:01, 6 June 2013

GENERAL

The base for sidewalk and ramps should be trimmed to grade and be firm and uniform. Check the elevation to ensure surface water will drain over the curb unless otherwise specified on the plans. The sidewalk should slope 2 percent toward the street. Either fixed form or slipform methods may be used to place concrete. Details of sidewalk ramps are shown on the Standard Plan R-28 series.

Sidewalks are usually 4 inches (100 mm) thick, except all driveways where the thickness will be increased as shown on the plans. Refer to the Standard Plan R-29 Series and Section 801 of this manual for more details.

MATERIALS

-Reserved-

CONSTRUCTION

The concrete should be struck off, spaded along any fixed forms and floated to a smooth surface.

The surface of sidewalks and steps shall be broomed to roughen the surface slightly. The surface of sidewalk ramps should be textured with a coarse broom perpendicular to the slope of the ramp.

All concrete should be coated with a white membrane curing compound at the rate of 1 gallon per 25 square yards (1 liter per 5 m2).

After concrete has gained sufficient strength, the forms shall be removed and the edges backfilled and compacted to within 1 inch (25 mm) of the sidewalk surface and left in a neat condition.

Joints

The sidewalk should be jointed into 16 to 36 foot2 (1.4 to 3.5 m2) areas as detailed on the Standard Plans R-29 Series. Expansion joint locations are also shown here.

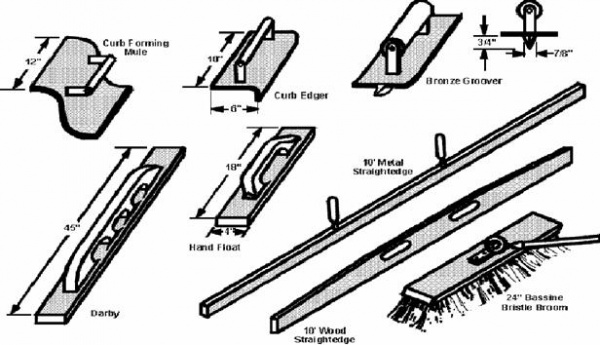

Joints may be sawed or formed. Usually a groover and edger will be used to form joints in the plastic concrete. See Figure 802-1 for examples of hand tools commonly used. These joints must be cut to at least 3 of the thickness of the concrete to control cracking. A straightedge should be placed across the walk to guide the edger so that a straight joint is constructed.

All edges and joints should be rounded with an approved finishing tool.

MEASUREMENT AND PAYMENT

Measurement and payment for sidewalks and ramps is on a square foot (square meter) basis of the thickness specified. Measurement and payment for steps is on a cubic yard (cubic meter) basis.