Difference between revisions of "602 - Concrete Pavement Construction"

| Line 488: | Line 488: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

{{top}} | {{top}} | ||

Revision as of 14:26, 19 March 2014

GENERAL

-Reserved-

MATERIALS

Acceptance of Materials

Before paving operations start, the paving inspector should verify that all materials that need to be incorporated in the pavement have been tested and accepted. Most materials will be stockpiled in the Contractor’s yard on the project site. Often this is also the location of the batching plant.

|

| |

|---|---|

|

|

When the load transfer assemblies arrive on the project site, call Region materials personnel so they can verify that the assemblies were built according to the standard plans. Notice of acceptance by Region materials personnel is the required documentation. |

|

|

Check to see if the dowel bars and the fiber joint filler material are certified. Sampling and testing may be required. |

|

|

After the Contractor starts to set the load transfer assemblies on the grade, they must be visually inspected for:

|

|

|

The entire bar is to be coated with an approved epoxy coating to prevent corrosion, and the entire bar’s length is to be coated with an approved material to prevent concrete from adhering to the bar. |

|

|

Any material of uncertain origin should be piled separately and not used until it is determined that it meets specification requirements. |

|

|

Visually inspect the handling and storage of all materials used in the concrete paving operation. |

Tie Bars and Bent Bars

These items should be checked for certification, or sampled and tested when they arrive on a project.

Curing Compound

- Check certification, or sample and test each batch or lot.

- Material may be in drums or in a large tank. Inspection consists of seeing that the material is not contaminated or diluted and that it is mixed according to the manufacturer’s recommendations.

- A curing compound should not be used when stored from one construction season to the next without resampling and testing.

- Check yield of material to ensure correct coverage.

CONSTRUCTION

Concrete Testing Procedures

Quality control and Quality Assurance testing for concrete will be in accordance with Special provision 12SP604(B).

Placing and Finishing Concrete

The specifications set forth the equipment requirements necessary in the paving train. The specific equipment requirements have been greatly reduced during recent years. We are less concerned about the specific type or piece of equipment the Contractor uses and more concerned with the result. The inspector should note the trimming, placing, spreading, consolidation, finishing, texturing and curing equipment the Contractor plans to use to see if it fits the project on which it will be used. Equipment capacity and capability will not be the same on a small urban widening project as on a high production rural project. The Lansing Office concrete staff inspector will visit the project when paving starts to assist in determining equipment suitability and other related problems to get the project properly started. If there are questions about the condition and/or equipment capability, contact the Engineer.

Minimum Project Requirements

- Some method of trimming the base.

- A method of delivering and placing the concrete on the grade in a timely manner, without segregation.

- Installing lane ties, if needed.

- Consolidating and finishing the concrete, straight dging and floating.

- Edging and texturing the surface.

- Curing the pavement.

- Sawing and sealing the joints.

Screeds and pan floats must be checked for proper slope adjustment.

The inspector should verify that the membrane sprayer is in working condition before paving starts. If in doubt, the Contractor should demonstrate this capability.

Check to see that the Contractor has all the necessary hand tools, such as 5 foot (1.5 m) and 10 foot (3 m) straightedges, floats, edgers and stencils.

If forms are used, they should be checked for straightness, general condition, condition of locks, etc. before form setting operations begin. These forms serve the dual purpose of containing the plastic concrete and providing a track on which most of the concrete placing and finishing equipment rides. For radii of 150 feet (45 m) or less, flexible forms will be required (see subsection 602.03 of the Standard Specifications for Construction). Review the specifications and checklist, included in this manual, for specific form and backup rail requirements.

Grade Condition

After the aggregate base or open-graded drainage course (OGDC) is placed, shaped and compacted, it is brought to final grade, usually by an automatic trimmer. This machine operates off a string line for line and grade. The string line should be checked for sags before the final cut on the aggregate base, as most slipform paving equipment runs on the aggregate base for final grade.

Aggregate Base

- Behind the grading operation, the aggregate base should be checked for thickness, elevation and proper cross section.

- Thickness is checked by digging through the aggregate and recording the depth of the hole.

- Depth should be within 3/4 inch (15 mm) of plan thickness (example: a minimum of 31/4 inch (85 mm) when 4 inches (100 mm) depth is specified).

- Elevation and cross section are determined by stretching a string line across the grade from stakes set by the instrument crew.

- Measurements are made from the string line to the grade and recorded.

- Any significant variations from the plan should be brought to the Engineer’s and Contractor’s attention.

- Any areas where the grade appears to have been disturbed should be rechecked.

- The grade should be moist when paving operations start, but there should be no puddles of standing water.

Load Transfer Assemblies

After the base is properly compacted and fine trimmed to receive the concrete load, transfer assemblies are placed at joint locations. The inspector should work closely with the Contractor’s crew while they are setting these assemblies.

The assembly itself holds the dowel bars in position so they will not move during concrete placement and consolidation.

- The distance between joints should be checked.

- The assemblies must be positioned at right angles to the centerline as shown in Figure 602-5.

- After they are properly positioned, they must be staked to the base using six pins per basket assembly.

- The basket pin must be in contact with the lower horizontal wire as shown in Figure 602-6.

After the Contractor completes staking the assembly, the inspector should check vertical alignment with the basket level to ensure that dowels are parallel with the pavement surface (Figure 602-6).

At this time, the bars should be visually checked for horizontal alignment by sighting over the tops of the bars to the previously set assemblies to see if the bars are parallel to the string line.

Even though the assemblies have been set at right angles to the string line, the bars may not be parallel to the string line due to improper fabrication of the assemblies.

Any apparent misalignment can usually be corrected by tapping the frame to realign the bars.

The bars should also be inspected for complete coating on at least two-thirds of the length of the bar.

Dowel Bar Inserter (DBI)

An approved mechanical device that automatically installs load transfer bars, at the required depth, and properly consolidates the surrounding concrete. The device may be used in lieu of load transfer assemblies.

When a dowel bar inserter (DBI) is used to install load transfer bars, the bars shall be placed at the same spacing as detailed for dowel bar assemblies in Standard Plan R-40 Series. The pavement shall be placed and consolidated full-depth prior to insertion of the dowel bars.

The DBI shall be capable of accurately inserting dowel bars at the joint spacing and location shown on the plans. The DBI shall be capable of inserting dowel bars into the full-depth plastic concrete at the specified location, and shall be capable of consolidating the concrete around the dowel bars such that no voids exist, without the supplemental use of hand-held vibrators.

The Contractor will take measurements of the inserted dowels relating to the specification tolerances. These measurements will be made every 500 feet and included in there Quality Control Plan provided to the Engineer when requested. .

The alignment of the dowel bars is crucial to the life of the pavement. If a dowel or group of dowels is not perfectly aligned longitudinally with the pavement, the life of the pavement and the joints can be significantly reduced. Therefore, wet depth and position alignment checks need to be performed every 500 feet to insure the proper depth, vertical and horizontal alignment of the dowels are being provided by the paving equipment and DBI.

Any out of tolerance joints shall be marked and replaced at the Contractor’s expense. If the dowels are consistently out of tolerance with respect to alignment and/or depth, the Contractor must stop production paving and take steps to correct the alignment problems. Dowel alignment problems can be created when too much concrete, commonly referred to as head, develops in front of the paver that has the DBI mounted to it. The amount of head carried by the DBI paver must be in accordance with the DBI and paver manufacturer’s recommended depth to provide consistent proper dowel alignment.

Many other factors can contribute to dowel alignment and depth problems when using a DBI. The important thing to remember is to be sure the DBI is consistent when placing dowels throughout each day’s production. Periodic wet and dry alignment/depth checks are necessary to ensure consistency. The inspector should also make sure the Contractor is following all of the DBI manufacturer’s recommendations for the use of this equipment.

Test Headers Are Required throughtout the project to insure Proper Alignment of Dowels bars in hardend concrete . Three are Required , But the engineer may Request more Depending on Contractor qualtity control measurements..

In the future Mitt Scan Measurements Will Be Required By the contractors as part of their Qualitity Measurements.

Expansion Caps

Expansion assemblies should be checked to make sure there are no voids under the expansion felt, between the ends and the forms or around the dowel bars. Expansion caps must be securely placed on opposite unwelded ends of the bars, with 1 inch (25 mm) space left between the end of the bar and the inside of the cap. When using the slipform paving method, the outside 4 inches (100 mm) of the expansion felt will be removed and replaced behind the paver.

It will be necessary for the Contractor to mark the center of the load transfer assemblies so that a saw cut can be made over these joints after the concrete has hardened. Usually, this is accomplished by setting a basket pin opposite the center of the joint outside the pavement limits. Normally, a ribbon is attached to the stake to identify its location.

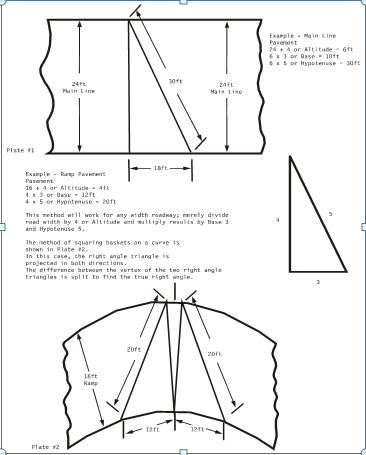

When setting load transfer assemblies for a widening, do not use the previous saw cut as a method of aligning the basket unless checked for angles. Align this joint with a right angler, or the 3-4-5 triangle method described in Figure 602-5.

Production Paving Projects

Concrete will be produced in a central mix plant.

Concrete will be transported to the job site in dump trucks or agitator trucks. The allowable haul time will depend on the type of hauling unit and the concrete temperature, as stated in the Standard Specifications.

The Contractor will provide a ticket system to record the batch numbers and have someone at the dump site to pick up the tickets.

Occasionally, the inspector should pick up these tickets from the Contractor and check to see that the concrete is within the specified time limits.

Count the tickets to determine the total concrete received. Compare this to the theoretical amount required to compute the overrun or underrun. The cause of any underrun should be determined and corrections should be made immediately. Possible causes include thin pavement, narrow width of slab or improper scale readings at the concrete plant.

Dual Lane Operation

The spreading operation should be kept reasonably close to the following description so no more than 30 minutes elapse between layers of concrete, or between placing and finishing the concrete.

Tie bars are placed at the center longitudinal joint.

A lane tie bar installer is often mounted on the rear and in the center of the Paver a laborer will place reinforcement bars of proper length and diameter according(Standard Plan R-41 Series).

Bar spacing, as required to the nearest free edge, An Inspector should check the spacing of Bars as soon as possible after paving starts.

Check the bar depth after finishing operations are complete, as they have a tendency to settle due to the vibration of paving equipment.

Slipform Pavers/Riding Finishing Machine

The slipform paver uses a lower slump concrete to minimize edge slump. Therefore, full width vibrators are necessary to eliminate all internal honeycombs. The inspector should check to see that the vibrators are working. Bubbles should be apparent around each operating vibrator.Conctactors should have a Vibrator monitor as per Special Provision 604B

It is important that the slipform paver, or finishing machine, has the correct concrete amount in the screed, or strike-off plates, to prevent overloading that will cause slipping of the track or drive wheels. This will result in chatter bumps on the surface. Inadequate concrete in the screed fronts will leave low spots on the surface.

Form riding finishing machines, and some slipform pavers, have two oscillating screeds that shape the surface of the concrete. For the best results, the front screeds should have about an 8 inch (200 mm) roll of concrete in front of it. The second should have a smaller roll, about 4 inches (100 mm). A slow, steady forward movement with a uniform supply of concrete in front of the finisher will produce the best surface finish. Slipform pavers are equipped with extrusion plates to form and finish the concrete. Slipform pavers are equipped with spray bars to add water as an aid to finishing. The inspector should insist that water added be kept to a minimum. It should not be added continually, but only occasionally when a minor delay has occurred, or for other similar reasons. It is better to use a slightly higher slump initially than to continually add water to the pavement surface.

If a pan float, or other mechanical float, is used behind the slipform paver or the finishing machine, it should leave the concrete surface in a substantially finished condition.

Some slipform paving machines are equipped with transverse screeds for additional floating. Tears or open areas indicate improper screed adjustments, inadequate vibration or perhaps a harsh mix. Attempts to correct the equipment should be made before changing the mix.

The edge condition should be noted immediately behind the slipform paver. Check for edge slump with the 5 foot (1.5 m) straightedge. The edgers on the paver should be adjusted to minimize edge slump. When the concrete leaves the trailing edge of the edgers, it should slump down and out to the proper width and elevation. For this reason, it is essential to maintain a uniform slump from load to load.

Check the pavement behind the paver or finisher to verify the proper width, crown and/or slope.

After machine finishing, the slab surface should be checked by the Contractor=s finisher using a 10 foot (3 m) straightedge and the 5 foot (1.5 m) lap method of straightedging. Any high or low areas indicated by the straightedges are to be corrected. The areas needing correction may be hand floated, if necessary, to seal the surface. On slipform paving, the finisher should stop the straightedge about 4 to 6 inches (100 to 150 mm) from the edge to keep from slumping the edge with the added weight of the straightedge.

Concrete Pavement, Unbonded Overlay

This item is used for a situation when existing concrete pavement and shoulders are to be overlaid with a new concrete surface. The existing concrete typically undergoes Hot Mix Asphalt (HMA) or concrete joint repairs and is then overlaid with a HMA bond breaker layer before the new concrete surface is paved. .

Concrete Pavement, Unbonded Overlay is typically paid for by volume in cubic yards. The inspector will determine the volume of concrete used each day, based on the number of batches used for pavement and shoulders, and the nominal volume of concrete per batch. This amount will be documented by the batch ticket printouts. This item shall include all materials, labor, and equipment necessary to furnish and place the concrete mixture. Periodic wet depth checks shall be taken throughout the day to verify the pavement thickness and confirm the volume of concrete placed. Using the wet depth checks, the pavement width, and length of the day’s production, a volume of concrete placed can be computed. This volume can then be compared to the volume from the total day’s production on the Contractor’s batch tickets.

Random unscheduled daily yield checks on the volume produced by the batch plant should be performed to verify the amount of concrete produced per batch. This volumetric yield check can then be applied to all batches leaving the plant and compared to the computed total volume placed during the day’s production. The yield check should provide a simple verification of the batch ticket volume printed by the batch plant. This procedure should be part of the Contractor’s quality control plan and periodically verified through MDOT quality assurance testing where appropriate. This method of checking the volume of concrete can be used wherever concrete is being paid for by volume.

Concrete Pavement, Miscellaneous, Non-Reinforced Unbonded Overlay

This pay item shall be used for ramp reconstruction, ramp overlay, gore areas and approach areas. The quantity for miscellaneous pavement associated with overlay projects will be measured and paid for as described in the section for Concrete Pavement, Unbonded Overlay.

Grade Control

Grade control is critical when paving a concrete overlay. Overruns can be controlled by monitoring the grade of the surface the overlay is to be placed on prior to paving the bond breaker layer and the overlay. Recorded string line depth checks on the grade control prior to paving the overlay are important to monitor the volume of concrete to be placed and keep it close to the actual plan quantity.

Grade control is again the critical item for controlling Contractor material quantities, and final profiles when paving miscellaneous concrete. Smaller miscellaneous areas are typically formed prior to paving miscellaneous concrete. The forms can benefit the grade control process. However, matching the grades in approaches, and ramp gore areas can lead to pavements that do not drain properly or have a safe profile for the public. If not included in the plans, a set of detail grades should be computed and plotted prior to the beginning of the project to attempt to alleviate grade problems. The detail grades should be computed from the plan profiles for the adjacent pavement. After the detail grades are computed, they should be plotted to determine the proposed gore/approach cross sections prior to beginning the project. If the detail grades are determined prior to any paving, with the approval of the Engineer, the inspector can typically adjust the mainline and/or ramp grades to allow for a safe gore and approach pavement.

Conventional edgers should be used to round the top corner. It should be left with a radius not exceeding 1/4 inch (6 mm). Edge slump should be rechecked with the 5 foot (1.5 m) straightedge behind all finishing operations. Any edge slump exceeding 3/8 inch (9 mm) should be corrected before the concrete sets. If continuing slumps of up to 1/4 inch (6 mm) occur, the Contractor should adjust the edgers on the trailing end of the side forms to eliminate the slump.

Expansion Joint Filler

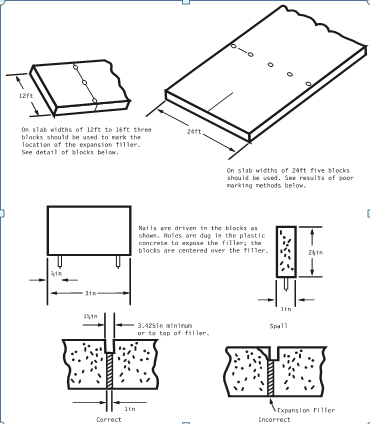

During final finishing operations. The previously removed 4 inch (100 mm) end section of the expansion filler material should be replaced and the concrete consolidated around the joint filler. The expansion joint filler location should also be marked for sawing at a later date. The best method of doing this is by working from a bridge spanning the pavement. The expansion filler top is exposed in about five locations across a 24 foot (7.2 m) pavement by using a small trowel to remove the concrete. A small block is then placed on top of the expansion filler. The block should extend to the surface and be held in place by nails extending into the filler. Later the joint is sawed out from block to block (Figure 602 7).

Concrete Texturing

Following floating, the surface is to be textured longitudinally with a burlap drag. Even though the final texturing will be by metal tines, it is important that the slab be properly textured initially with burlap to give the surface a slightly roughened, gritty texture.

Usually 36 to 60 inches (900 to 1500 mm) of burlap should be in contact with the pavement surface. Two layers of burlap may be required to impart a gritty surface. The burlap should be cleaned of built-up mortar daily and replaced when it is no longer effective. It should be kept moist to avoid removing water from the concrete surface.

When slipform paving, it is better not to have the burlap drag extend over the edges, as it may cause the concrete to slump, or tear the edges.

When completing the metal tining, texturing operations shall not delay curing. Timely application of curing compound is critical to the final strength and durability of the concrete pavement. Application of the curing compound must take precedence over texturing the surface with the metal tines. If texturing has to be delayed, it will follow at a later date when the concrete has attained 28 days design compressive strength. In this case, the Contractor shall submit a plan for the Engineer’s approval for texturing the pavement after the concrete has reached the strength required to support the equipment. This work shall be at the Contractor’s expense.

The last 4 inches (100 mm), can be hand dragged by the finishers doing the edging.

A strip of artificial grass mat may be used in place of burlap. After burlapping, the surface is to be grooved transversely or longitudinally with a wire tine comb. Either machine or hand methods may be used. The tine grooves should be 1/8 to 1/4 inch (3 to 6 mm) deep, 1/8 inch (3 mm) wide, on about 1/2 inch (13 mm) centers for Transverse tinning and 1/8inch to 1/4inch deep, 1/8 inch wide and 3/4 inch on centers for longitudinal tinning. Tine marks should not be overlapped. Overlapping decreases the spacing, which results in breakage. The grooves should be one continuous pass across the entire pavement surface.

Tining Device

The tining device must be a tracked machine accurately adjusted to the crown and the pavement slope to ensure uniform contact between the tines and the pavement. It must also be adjusted to lift off the pavement just as the tine head reaches the edge to avoid breaking down the edges when slipform paving. Check the tining periodically to see that the operator is obtaining a uniform surface, with groove depths from 1/8 to 1/4 inch (3 mm to 6 mm). Following tining, the Contractor is to stencil the pavement 12 inches (300 mm) from the edge of the pavement so the numbers can be read in the direction of traffic.

See spec book for mean texture depth requirements per ASTM E965

Membrane Curing

Membrane curing compound is to be applied as soon as the free water has left the surface. Often the same machine is used for tining, curing and applying the compound. Usually this is as soon as tining is complete. However, texturing shall not delay the curing compound application. If it becomes necessary to apply the curing compound prior to texturing, the texturing must be completed after the concrete has obtained its 28 day design compressive strength.

Make sure the curing compound has been mixed according to the manufacturer’s recommendation before the compound is transferred from the drums to the tank on the curing machine.

It should be constantly re-circulated or stirred during application.

Insist on a uniform application of each of the two coats for textured surfaces. One coat is required for non-textured surfaces. Coverage is 1 gallon per 25 square yards (1 liter per 5 m2) for each coat.

The important point is to get enough material on the exposed surface to completely seal the tops, bottoms and sides of the grooves with an unbroken membrane. Timely coverage is critical to the final strength and durability of the concrete.

The slab edges should be spray cured promptly if the forms are removed before the desired strength is met.

Depending on the wind, sometimes the curing compound may have to be applied in two different directions to get proper coverage.

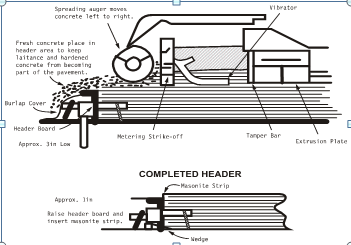

Header Joints

Night header joints should receive the inspector’s attention, as they are often the location of bumps in the finished pavement.

When it is anticipated that paving will resume within seven (7) days, paving is suspended on a transverse contraction or expansion joint.

An adjustable header board is staked in place in the center of the load transfer device assembly.

The header top should be left at least 1/2 inch (12 mm) below the pavement surface and the finishing equipment passed over the header.

The area adjacent to the header must be filled with fresh concrete.

Do not permit partially hardened concrete, or laitance, carried in the vibratory box to be used in this area.

Just before the finishing equipment passes over the header, the concrete adjacent to the header should be vibrated with a hand held vibrator.

It is a good idea to spread burlap or plastic over the projecting ends of the dowels to facilitate cleanup of excess concrete. Since the header board may not match the crown of the pavement, it is a good idea to insert pieces of 1/4 inch (6 mm) Masonite behind the header board to be adjusted to the exact elevation of the finished pavement after the finishing equipment has passed over the header joint (Figure 602-8).

The finishers will now be able to straightedge the pavement up to and across the header. When slipform paving, the last 10 feet (3 m) or so of the longitudinal bulkhead joint adjacent to the header should be formed to prevent the slab from becoming over width. This over width will cause spalling of the edge when the paver is backed to the header.

Leaving the header is also an operation that needs close attention. The header board should be removed carefully to avoid damage to the green concrete.

After the concrete is placed, the header should be thoroughly vibrated to eliminate voids. As the slipform paver or finishing machine starts forward, there is a tendency for the concrete to cling to the screeds and the float pans, leaving the surface low in these areas. It is important that the Contractor straightedge this area carefully. Stretch a string line parallel to the centerline from 10 feet (3 m) behind the header to 30 feet (9 m) in front to check the header for the need of corrective work while the concrete is plastic.

Date and stationing should be stenciled in the concrete by the Contractor, on the night and morning sides of the header.

INSPECTION DURING AND FOLLOWING CONCRETE PLACEMENT

Inspect the previous day’s pavement for uniformity of texturing and curing. Have areas been missed, or textured too shallow or too deep? Are there thin spots or streaks in the curing membrane? Has the edge of the slab been completely coated with curing compound? Check for any honeycomb in the edge and have it patched.

At this time, the relief sawing of the transverse joints should be complete or in progress. Look for any random cracks that would indicate sawing was not completed in a timely manner. Also, look at the relief saw cuts for excessive raveling, indicating they were sawed too soon. Check for correct depth of the saw cuts.

When sawing of the joints to final width begins, the inspector should check on the width and the depth (Standard Plan R-39 Series). Location of saw cuts for contraction joints should be over the center of the assembly. It is important that the expansion joint saw cuts be made exactly over the expansion felt. This is accomplished by sawing from block to block as explained under Finishing the Concrete.

The centerline longitudinal joint will be sawed within 24 hours, but not until the concrete has hardened sufficiently that no raveling or spalling occurs. All traffic must be kept off the pavement until the longitudinal joint has been sawed. Since the upper 1 inch (25 mm) of the longitudinal joint must be sawed a minimum of 1/4 inch (5 mm) wide, and the lower one-third need only be 1/8 inch (3 mm) wide, the Contractor will often use two saws operating in tandem. (Standard Plan R-41 Series).

Transverse joints will be sealed with hot poured rubber.

Hot and Cold Weather

During hot weather, additional precautions must be taken to obtain high quality pavement. Concrete placement is prohibited when the concrete temperature exceeds 90°F (32°C). Even with concrete temperature at 80°F (27°C), it may be difficult for the final finishing and texturing to be completed before the concrete hardens. Under these conditions, there is a strong desire by the Contractor’s finishers to add water to the pavement surface to lubricate their floats and straightedges. Any water added is to be in the form of mist from a fog sprayer. This limits the amount of water added and minimizes dilution of the cement paste on the concrete surface.

For hot weather conditions, the inspector can refer to Table 706-1 of the Standard Specifications for Construction. This table gives evaporation rates for conditions for paving concrete based on air temperature, concrete temperature, relative humidity, and wind velocity. If the evaporation rate exceeds 0.15 lbs/ft2/hr from the table, then the Contractor should not pave. In any combination of weather conditions, the Contractor must be able to ensure to the Department that they can prevent premature drying of the pavement surface during the paving process.

In extreme weather conditions, timely application of the curing compound is not always the complete solution to preventing premature drying of the pavement surface. Extreme weather conditions can require additional steps to aid in the prevention of premature surface drying and other adverse effects caused by hot weather. Continuous, constant temperature moist curing, covering the entire surface of the pavement with continuously wet burlap, and reducing the concrete mix temperature (cement, aggregate and/or water temperature) are examples of other options for helping reduce the impact of hot weather on concrete pavement. With the exception of continuous moist curing, the curing compound should still be applied when using these options for paving in hot weather. The Contractor’s Quality Control Plan must be reviewed before paving begins. The Quality Control Plan must contain adequate detail regarding the plan for properly curing the concrete in accordance with MDOT and American.

Protection from cold weather is the Contractor’s responsibility. Although concrete will withstand below freezing temperature due to heat of hydration, it is considered good practice to provide a protective covering of insulated blankets or straw when freezing temperatures are anticipated. When cold weather is anticipated, the pavement should be covered as soon as possible. However, the pavement must be able to support the weight of the insulating blankets or straw without damaging the surface.

If the Contractor neglects to cover the pavement in a timely manner, and the temperatures drop below freezing during the curing period, the inspector should note the areas involved and notify the Engineer. Arrangements can be made to take special cores from the area in question to determine whether or not the concrete has been damaged.

Rain Damage

Protection from damage by rain is the Contractor’s responsibility and the inspector should avoid giving the Contractor any instructions as to covering the concrete, or other protective measures. If the Contractor is unable to texture the pavement, or the texture is washed away, they will be required to groove the hardened concrete.

If serious rain damage occurs, such as breaking down of slipformed edges or erosion of the surface by water running off the pavement, repairs should be made as soon as the rain stops. Water on the surface should be carefully removed with straightedges to avoid working the water into the concrete. Fresh concrete should then be added and the surface refinished.

If the rain has damaged the curing membrane, this should be corrected by respraying the area after the rain has stopped.

Miscellaneous Paving

In addition to the main paving operation, most projects will involve some miscellaneous paving. This might be semi-production work on service roads or ramps. Other times it will involve strictly hand work at street intersections.

The quantity of paving involved will dictate the type of equipment to be used. As with production pavement, the inspector should ensure that methods and equipment proposed will ensure quality work.

Trimming the base will usually be a combination of a road grader and hand methods.

Forms are used for hand work. Radii of less than 150 feet (45 m) will require flexible forms.

Concrete may be placed without a spreader providing it can be placed without segregation.

All areas along forms and joints will be consolidated with a vibrator. The vibrator will be inserted vertically into the concrete to ensure complete consolidation and will not be used to move the concrete.

Screeding of the surface will usually be by a form-riding finishing machine or a hand-pulled vibrating strike off. Sometimes roller screeds or lightweight slipform pavers are used.

Straightedging gaps and other areas subject to high-speed traffic is important. A string line check of these areas is also helpful.

Burlapping, tine texturing and curing will normally be done with hand held equipment. Make sure tining is done in one continuous pass from edge to edge. Do not permit tining each way from centerline, as a poor appearance will result.

Applying the curing compound will be done from a bridge or by using a boom so uniform coverage can be obtained.

Concrete Shoulders

When concrete shoulders are called for on the plans, they will be constructed according to the current specifications and Standard Plan R-112 Series.

Preparation of the grade is similar to that required for pavement; shaped to the required line, grade and cross section and compacted to the required specific density. The edge of the pavement should be cleaned of any dirt or other foreign material. Shoulders adjacent to pavement will require lane ties to keep the shoulder from separating from the pavement.

Expansion joint filler is placed in line with opposite expansion joints in the pavement as per Standard Plan R-42 Series. Load transfer devices are omitted from concrete shoulders.

Just before concrete is placed, the edge of pavement and the entire base should be dampened.

See the Standard Plan R-45 Series

Concrete is usually placed on the grade directly from hauling units. Normally a modified slipform paver will be used to strike off, consolidate and finish the shoulder concrete.

Immediately behind the machine in the finishing operation, check the surface for proper slope or crown.

Edges will be inspected for slump, thickness and to ensure that they are all free from contamination by base material.

Floating will be done only as necessary to close the surface.

Relief cuts must be sawed to the proper depth to control cracking. After curing, the joints are to be sawed to the final width and depth and sealed with the same seal as used in the pavement.

Rumble strips will be placed according to the standard plan.

Texturing is done with a burlap drag or a stiff broom.

The surface and outside edge should be coated with white membrane curing compound at a rate of 1 gallon per 25 square yards (1 liter per 5 m2).

Base Course Paving

Another type of miscellaneous paving is concrete base course. This is usually a widening placed adjacent to an existing pavement which is in need of resurfacing.

General construction methods are similar to those described above for concrete pavement. A few important differences are mentioned here.

The edge of the existing pavement may be in poor condition. Check the plans to determine if any corrective work is required on this edge before casting concrete against it.

Base course mat are non-reinforced. Plane-of-weakness joints may be either formed or sawed. No joint seals are required. No load transfer assemblies are used in base course. Review the Standard Plan R-42 Series for joint layout and header joints in non-reinforced base course.

Straightedge tolerance is more liberal, 3/8 inch in 10 feet (9 mm in 3 m). Texturing is done by burlap drag. The surface should not be tined, as it will be difficult to clean before placing the overlay.

Cure with a transparent compound instead of white. Only one application is required at the rate of 1 gallon per 25 square yards (1 liter per 5 m2) of surface.

OPENING TO TRAFFIC

Often the Contractor will want to use the new pavement as a haul road for his batch trucks at the earliest possible time, or he may want to place a wheel or track on new pavement edge to pave the adjacent lane. Other times it will be important to open an intersection or drive to traffic as soon as possible.

The inspector and Contractor should try to anticipate the need for early openings and arrange to make an extra set of beams when the concrete in question is being cast. These beams should be cured under environmental conditions similar to the pavement being cast.

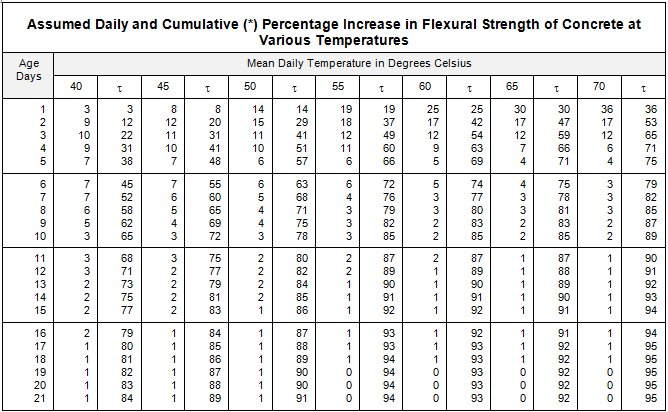

The follow the Table 104.1 in from Section 104 of the Standard Specifications for Construction, to determine when equipment may be allowed on the pavement.

No load is to be permitted on the pavement until the centerline joint is sawed, the contraction joints relief cut, the expansion joints sawed out to full width and temporary or permanent seals installed. Curing is to be continued until a flexural strength of 550 psi (3.8 MPa) has been obtained.

When job control beams are not available, the curing surface treatment film will not be broken by Contractor’s equipment or other traffic until the concrete has attained 70 percent of the anticipated minimum strength as determined from the following table.

STREET INSPECTOR’s REPORT

Inspector’s Report of Concrete Placed, Form 1174R, is the primary report required of the paving inspector. It should be prepared for each day that pavement is cast. In addition to the original copy to the Engineer and a copy to the Construction Services Section, the inspector should retain a copy.

Any unusual happenings should be noted in the remarks section of the report. Often this is most important when a problem develops and the circumstances surrounding the problem are being reconstructed later. Any material accepted on the basis of visual inspection should be noted in the remarks. The back of the form should be used for sketches, when necessary, to describe any irregular areas.

In addition to the daily report, the field book prepared before the project started can be used to note additional information concerning the paving operation. Depending on the type of project, it may be necessary for the street inspector to complete an Inspector’s Daily Report, Form 1122B documenting traffic control, equipment used or other work activities in progress.

Reports and documentation requirements should be reviewed with the Engineer before paving starts.

Keep in mind that some quantities must be documented at the time of placement while others can be checked later. An example of the former is areas where high-strength concrete is used and is to be paid for.

PAVEMENT CORING

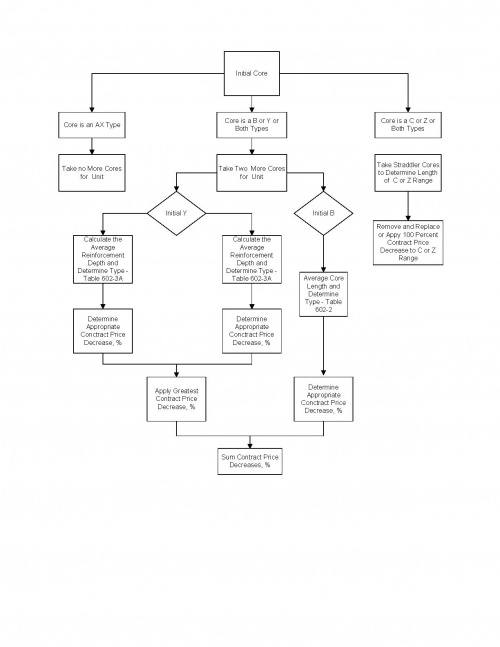

To determine pavement, shoulder and base course thickness , cores shall be taken from the pavement before its final acceptance to determine the thickness of the pavement according to MTM 201. Refer to subsection 602.04 of the Standard Specifications for Construction and the following flow chart (see Figure 602-9) for this determination.

MEASUREMENT AND PAYMENT

Ride Quality

A specification to encourage the Contractor’s to construct the smoothest pavements possible and the method to measure the surface for smoothness.

The Contractors may use a California-type Profilograph or a GM-type Rapid Travel Profilometer to measure the pavement smoothness.

The Engineer will establish and mark the limits for Ride Quality Measurement including the POB, POE and any excluded areas.

The California-type Profilograph will produce a trace, or Profilogram, on graph paper, to a true 1:300 horizontal scale and true 1:1 vertical scale, which will be analyzed according to Michigan Test Method 204-88.

If a computerized Profilograph is used, a trace will not need to be analyzed, but should be spot checked with a blanking band.

The equipment must be calibrated before use.

Tire pressure should be 25.375 psi ± 1.015 psi (175 kPa ± 7 kPa) in the recording wheel.

The horizontal calibration will be checked by running the Profilograph over a measured 1000 foot (300 m) length which should produce a trace of 3.28 ft ± 0.118 in (1 m ± 3 mm). Calibration of the computerized version will be run over a distance of 1000 foot (300 m) and should produce a printout within ± 3.28 feet (1 m).

The vertical calibration is to be done according to the manufacturer’s specification and must be documented by the Contractor.

The GM-type Profilometer will be calibrated according to the user’s manual.

Software is provided which allows the operator to test the operation of the three buttons and computer system, along with a “bounce” test.

The vertical calibration of the laser sensor is to be done according to the manufacturer’s specification and must be documented by the Contractor.

The horizontal distance is calibrated by traveling a known distance and typing in the value on the keyboard while in the calibration mode. The continued reliability of the odometer will depend on a constant tire pressure.

The measurement/profile will be taken in the wheel tracks of each lane.

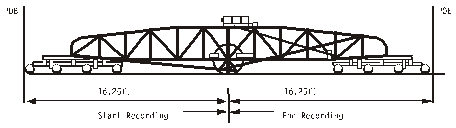

The starting position of Ride Quality using the California-type Profilograph is when the rear wheel assembly is entirely on the road surface, placing the recording wheel 16.25 feet (5 m) beyond the POB. The ending position will be when the front wheel assembly is at the POE, placing the recording wheel 16.25 feet (5 m) short of the POE. Whenever the run is stopped before the POE, the recording wheel should be placed at the same location for a restart. See Figure 602-10 for a Profilograph.

Measurement outside the POB or POE may be done to check for bumps, and will be paid as Ride Quality Measurement - Concrete.

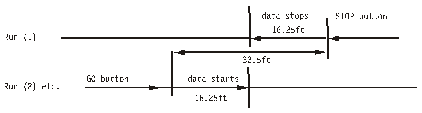

The software for the GM-type Profilometer has been designed to simulate the same starting and ending points as the California Profilograph. Starting the measurement (GO button) at the POB will start data recording at 16.25 foot (5 m) after the POB. Ending the run (STOP button) at the POE will stop the data recording 16.25 foot (5 m) prior to the POE. Caution should be taken when stopping the GM Profilometer between the POB and POE as in daily or short runs. As the recording data will stop 16.25 foot (5 m) prior pushing the Stop button, the next run will have to be started 32.5 foot (10 m) before that same point to start the data recording at the right point. See Figure 602-11 for an example of starting and stopping points.

The California Profilograph trace will have to be reduced, using a blanking band, to segments. Bumps which exceed the limits established by Special Provision can be located by using a bump template. The computer version will analyze the ride quality and locate the bumps which must be ground.

The rapid travel Profilometer can give data in inches per mile or by a ride quality index, along with the locations of must-grind areas.

Check the proposal for pay items and adjustment table for the item of Ride Quality.

Roadways, collector distributors, ramps and turn lanes that are not covered under a ride quality specification should be evaluated for smoothness and removable bumps in one of three ways:

By using a 10 foot (3 m) straightedge as per MTM 722-97.

By using a rolling straightedge available from the Construction and Technology equipment shop.

By using the rapid travel profilometer, which is programmed to check for bumps according to the Standard Specification for these areas. Contact the Construction Services section for use of this equipment.