603 - Concrete Pavement Restoration

GENERAL

This work consists of repairing portions of a concrete pavement with Portland cement concrete and the type of joints specified. Pavement includes mainline pavement, base course or concrete shoulders.

|

|

|

|---|---|

|

|

Tied repair grouted |

|

|

Contraction repair grouted |

|

|

Expansion repair grouted |

|

|

Expansion curb joint |

|

Joint, Tied, Special |

Patching

Before patching begins, the Engineer and the inspector should review the following items:

- Special Provisions

- Supplemental Specifications

- Project plans and drawings

- Standard Plans

- Standard Specifications

- Concrete pavement condition survey or project log

Inspection During Patching

- Layout patches

- Removals

- Various joints

- Placing and finishing concrete

- Sealing joints

- Shoulder or curb replacement

MATERIALS

Before patching begins, the inspector should verify that proper concrete mix design charts are being used and that all materials to be incorporated in the patches have been tested and accepted.

Concrete for patching must be produced by a NRMCA-certified plant, or have been accepted for use by the Region materials personnel as a noncertified, automated or manual plant.

The grade of concrete required is based on the time allowed between the casting of the repair and the intended opening of the repair to traffic.

Type or Grade of Concrete

Unless modified by special provision the grade of concrete required will be as follows.

|

|

|

|---|---|

|

|

|

|

|

|

Type P-NC (non-chloride)

Type P-NC concrete utilizing a Type C or Type E (non-chloride) set accelerator is the preferred patching mixture for use on MDOT projects. Use the manufacturer’s requirements for these set accelerators with the specified cement content to achieve a minimum flexural strength of 300 psi within the contract open-to-traffic time as determined for the project.

Load Transfer Assemblies

Load transfer assemblies for contraction (Cp) and expansion (E2) joints will be according to the Standard Plan R-39 and R-40 Series.

After the assemblies arrive on the project site, they must be visually inspected for the following items.

- Broken or missing welds or bent assemblies

- Proper height of dowels and joint filler for the pavement being repaired

- Holes in joint filler must match the dowel size with no space for leakage

- Use of approved expansion caps and their proper installation

- Verify tie wire of maximum nominal diameter of 0.177 in.

Dowel Bars and Lane Tie Bars

Deformed dowel bars for Trg joints will be epoxy coated, #9 x 18 inches long. Dowel bars for Crg and Erg joints will be epoxy coated, #10 x 18 inches long. Lane tie bars will be straight #5 deformed bars x 18 inches long.

The material used to secure in the dowel bars must be from the Qualified Products List.

Bond Breakers

The bond breaker used on the dowel bar assembly must be from the Qualified Products List. The bond breaker used for individually placed dowel bars may also be RC 250.

CONSTRUCTION

Patch Layout

The location of repairs will be listed on a log in the proposal, on the plans, or in the pavement condition survey log.

Locate, number and record, for future documentation, the size and type of joint or the repairs to be removed. The minimum concrete pavement patch length is 4 feet. However, additional patch length is recommended in faulted pavement scenarios. If additional length is needed for proper repair, the inspector should inform the Contractor of the new size after checking with the Engineer.

The Contractor will lay out the patch at right angles to the centerline before sawing starts. Check the Standard Plan R-44 Series for the sawing diagram.

Removing Old Concrete

Before removal, the concrete will be sawed full depth according to the details shown on the plans or in the proposal. This must be done with multiple passes within the same 12 hour period or in one pass. Transverse saw cuts will be made in a straight line at right angles to the pavement’s centerline, within a tolerance of 1 inch per lane width. The longitudinal joint adjacent to other lanes, ramps, shoulders, curb and gutter will be sawed full depth.

The pavement surface will be flushed immediately after the sawing operation to remove all slurry. Remove concrete pavement between narrowly spaced sawcuts at the end of the slab with air hammers and hand tools to minimize spalling.

Patches less than 100 feet in length will be removed without disturbing the subbase/subgrade according to subsection 603.03 of the Standard Specifications for Construction.

Repair isolated spalls of 10 in2 and greater per Standard Specification 602.03.P.1.

Intermediate Saw Cuts

Intermediate saw cuts, used to reduce slab size more than 6 feet for hauling, should be recorded for payment purposes. Curb sections removed with a patch will be recast with the pour and paid as concrete pavement repair.

Aggregate Base

After removing the old slab, cleaning up loose material should be done by hand so as not to disturb the existing base. If the existing base was more than 2 inches low before removal, corrections can be made by adding aggregate base material and compacting.

If the existing base is less than 2 inches low, additional aggregate base material is not necessary, and the void will be filled with concrete included in the concrete patching pay item.

Any low base caused by the Contractor’s operation will be filled with concrete at the Contractor’s expense.

Joints

According to Standard Plan R-44 Series, place Contraction Joint (Crg) or Expansion Joint (Erg) at transverse joints where the repair meets existing pavement. Tied Joint (Trg) may be permitted as needed.

The same type of joint should be used in the second and third pours, if needed.

Expansion Joints (Erg)

Care should be taken to place enough expansion joints (Erg) for the pavement being repaired. Expansion requirements will vary based on condition of existing pavement and temperature at time of repair.

Erg joints should be used only if the repair extends across the entire width of the roadway. If only one lane is being repaired, every effort should be made to match the joint in the original slab.

Transverse Joints

Transverse joints in pavement, shoulders and curb repairs will be the type shown on the plans. Where existing curbs are to be left in place and expansion space is provided in the adjacent lane repair, an expansion joint (Esc) will be constructed in the curb by sawing and chipping out the existing concrete. It is important that the width of the joint be equal to the width of the joint in the adjacent lane repair. The Esc joint will align with the expansion joint in the repair. The expansion joint filler will be shaped to fit the existing curb cross section.

Expansion joint filler, for the Erg joints, will be 1 inch wide and extend the full depth of the patch minus 1-1/2 inch. Holes drilled into the joint filler must fit snugly around the dowel bars. The joint filler will extend the full depth of the patch until the joint is to be sealed. At that time, the top 1-1/2 inch of the filler will be removed to form the joint reservoir for sealing.

Care must be taken to ensure that the holes drilled into the existing slab for dowel bars are true to the horizontal and vertical planes of the roadway. Dowels not in alignment will restrict the Crg or Erg joints from working properly. Some adjustment may be needed in the drilling machine for proper alignment of the dowel bars, or to ensure that the holes miss the reinforcement steel in the existing pavement.

For long one lane repairs spanning an existing joint, Cp or E2 joints should be constructed according to the Standard Plan R-44 Series.

Longitudinal Joints

Where more than one lane is cast in a single pour, longitudinal joints will be constructed in line with existing longitudinal joints and to a depth of one-third the thickness of the pavement, either by sawing or by forming. Lane ties will be according to the Standard Plan R-44 Series.

Dowels

It is important that all holes are cleaned of the drilling residue by using an air wand fully inserted into the hole. Enough grout is placed into the hole to completely fill the space between the bar and the hole. The bars will be inserted slowly with a twisting motion until they are seated properly. Wipe the excess grout off the face of the existing pavement.

The portion of the dowel bars for Crg and Erg joints that extend beyond the face of the existing pavement will be uniformly coated with an approved bond breaker. An approved expansion cap will then be properly installed on each dowel for Erg joints, making sure the cap is not pushed past the 1 inch stops. Deformed bars used in Trg joints and lane ties need not be coated with a bond breaker.

Prior to concrete placement, the inspector should confirm that the epoxy on grout has properly set. This is usually accomplished by obtaining a properly mixed sample, observing the set and the time required to reach set.

Forms

Lumber used for forms on the shoulder side of the repair will be nominal 2 inch width and full depth and in one piece for repairs 10 feet or less in length. For repairs greater than 10 feet, wood or metal forms can be used since they can be locked or spliced to provide a continuous form. Form material between lanes can be nominal 1 inch lumber. Care should be taken to reestablish the grade between patch edges for a good ride.

Occasionally, the existing shoulder is in good shape, sound and flush with the edge of the pavement; and with care in removing the old pavement, it could be used as the side form. If the Engineer feels that the existing shoulder can be left, the Contractor must saw between the shoulder and the old slab to eliminate any breakup of the shoulder during removal. If there is any breakup, or after the removal of the slab the shoulder does not form a vertical, continuous edge to finish to, a side form will be required.

Placing and Finishing Concrete

Concrete will be placed usually the same day the existing concrete is removed and cast full depth in a single pour.

Immediately before placement of concrete, the existing pavement faces and the base will be dampened. Standing water must be removed before concrete placement.

For repairs more than 15 feet in length, the repair area in adjacent lanes, ramps, or shoulders will be cast separately.

The concrete should be struck off using two passes with a vibrating screed or roller screed. Check the surface with a straightedge. Care in edging, especially along the joint edges, will reduce spalling when forming materials are removed. Any spalling of the joint must be repaired.

For repairs 15 feet or less in length, the screed will be placed parallel to the centerline of the roadway. More than 15 feet in length, the screed will be placed perpendicular to the centerline of the roadway.

An immersion-type vibrator is required for consolidation of the concrete, with special attention given to the area around the dowel bars. The vibrator should be placed in the concrete in a vertical position for best consolidation.

The concrete surface will be struck off twice with a vibratory screed. For repairs 15 feet or less in length, the screed will be placed parallel to the centerline of the roadway. For repairs more than 15 feet in length, the screed will be placed perpendicular to the centerline of the roadway.

Straightedging

While the concrete is still plastic, the surface will be straightedged as follows.

For repairs 10 feet or less in length, the straightedging will be done by placing the straightedge parallel to the pavement centerline with the ends resting on the existing pavement and drawing the straightedge across the repair. The straightedging of 6 feet, 8 feet, and 10 feet repairs will be accomplished by use of a straightedge not exceeding the length of the repair by more than 6 inches. The straightedge will be in contact with the existing pavement while drawing it across the repair. Any high or low spots exceeding 1/8 inch will be corrected. Recheck after corrections are made.

For repairs more than 10 feet in length, the first and last measurement will be made with approximately half the straightedge resting on the existing pavement; and the second and next to last measurement will each be made with 2 inches to 3 inches of the straightedge resting on the existing pavement. Any irregularities will be treated as above.

Texturing

The surface of the repair should have a texture similar to the adjacent pavement.

Stenciling

The month and the year will be stenciled in each repair. If the existing stationing is removed within the patch area, the station will be restenciled in the repair at the appropriate location. If a Swiss hammer is being used for strength testing, a small area in each corner should be troweled smooth.

Curing Patches

Curing compound will be applied immediately after all free water has evaporated from the surface. White membrane curing compound will be used, unless the repair is to be overlaid with HMA, and then transparent curing compound will be used. Either type of curing compound will be applied in 2 coats at a rate of not less than 1 gallon per 25 yd² for each coat.

Insulated blankets having a minimum thickness of 2 inches will be placed over the repaired area when the curing compound has been applied and when the air temperature during the curing period falls below 50°F for all concrete repairs. Edges and seams in the blanket will be secured to prevent loss of heat. Test beams, for open to traffic strengths, will be cured the same as the repair. Insulated blankets may be removed when the concrete has attained a flexural strength of 300 psi for P-NC concrete and 550 psi for P1 and P1M concrete.

Strength Requirements

The concrete repairs may be opened to traffic when the concrete has attained a flexural strength of 300 psi for repairs constructed with Type P-NC concrete, and 550 psi for repairs constructed with Grade P1 or P1M concrete. Traffic may be allowed over the repair before cleaning and sealing the joints.

Strength test beams, for acceptance and open to traffic, should be made on the job and cured the same as the repairs. This includes being placed under the blankets if blankets are used as an aid to curing. Beams should be cast at the start of the pour and broken at different times to establish the length of curing time necessary to reach the required strength. Increasing or decreasing the time between making and testing the beams will give the inspector a good indication of the time needed to achieve the required strength.

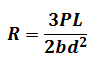

The flexural strength is calculated using the following equation per ASTM C293 – Standard Test Method for Flexural Strength of Concrete (Using Simple Beam With Center Point Loading):

Where:

- R = modulus of rupture or flexural strength in psi

- P = maximum applied load in lbs

- L = span length in inches

- b = average specimen width in inches

- d = average specimen depth in inches

Calculate the average specimen width (b) and depth (d) by measuring the width and depth at each end of the beam and taking the average of those measurements.

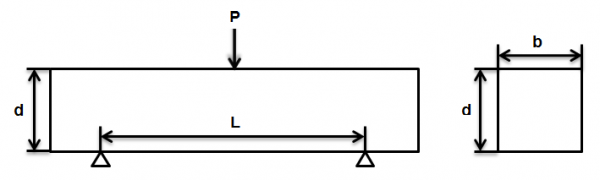

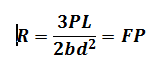

When using a concrete beam tester with center point loading and a 16 inch span length (L), the flexural strength equation above may be simplified using the modulus of rupture factors in table 1. The simplified equation is as follows:

Where:

- F = modulus of rupture factor in in²

Sawing and Sealing Joints

Sawing Joints

The joint reservoir of the Erg joints will be saw cut 1 inch wide and 1-1/2 inch deep. The joint reservoir for the Crg joints will be saw cut 1/2 inch wide and 3/4 inch deep. Both types of joint reservoirs shall extend the full width of the patch. The Contractor may saw an initial relief cut or saw to the plan dimensions as soon as the concrete has hardened sufficiently so that no excess raveling or spalling occurs. All edging will be done with a 1/8 inch to 1/4 inch radius along the entire perimeter before texturing.

Cleaning Joints

All concrete remaining on top of the expansion joint filler will be removed before abrasive blast cleaning. All joints to be sealed will be abrasive blast cleaned and then cleaned with a jet of compressed air, free of oil and water, having a minimum pressure of 90 psi, immediately before sealing.

Sealing Joints

All joints and all saw cuts that were made in pavements, shoulders or gutters over cutting will be cleaned and then sealed. Longitudinal bulkhead joints, joints in base course repairs, joints in repairs constructed in preparation for HMA overlays and Trg joints will not be constructed with joint reservoirs and need not be sealed. A backer rod will be placed in the bottom of Cp and Crg joint reservoirs after the final cleaning and before sealing with hot-poured sealant. Seal the joint reservoir to no greater than 1/8 inch (after cooling) below the concrete pavement surface.

HMA Shoulder Replacement

Before opening to traffic, HMA shoulders will be restored to the existing line and grade using a plant-mixed HMA mixture, as directed by the Engineer. Cold patch mixtures used for temporary patching will be replaced with plant-mixed HMA mixtures, unless shoulder reconstruction is a part of the project and has not been completed. The HMA mixture will be compacted by mechanical or hand methods suitable for the size hole being filled. HMA plant mixtures will be placed at a temperature suitable for compaction. Concrete shoulders will be constructed as shown on the plans. Materials removed from the shoulder will be disposed of by the Contractor.

Diamond Grinding and Longitudinal Grooving

Diamond grinding is used to restore the surface longitudinal profile and improved ride quality of a PCC pavement. And many times is done in conjunction with other PCC pavement restoration treatments. Grinding is performed on the roadbed in the longitudinal direction for the entire lane width as specified on the plans.

Usually 54 to 59 blades per foot are required to produce a level surface with a corduroy-type texture. The peaks and ridges of the corduroy should average 1/8 inch. If the area ground results in a surface with fins more than 1/4 inch high, the spacing of the blades should be adjusted. Grinding equipment that causes ravels, aggregate fractures, spalls or distress of the transverse or longitudinal joint should not be permitted.

The transition between ground and unground pavements should be gradual and result in an acceptable ride quality. Care should be taken to assure that positive drainage is maintained at all times in the transitions between the mainline edge and auxiliary lanes, ramp lanes and shoulders.

Groove pavement 0.12 ± 0.03 inches wide by 0.16 ± 0.03 inches in depth, with a land area between the grooves of 0.75 ± 0.05 inches.

When the Special Provision for Pavement Ride Quality is included in the contract, the Engineer will submit the Ride Quality Plan to the pavement evaluation group at Construction Field Services for concurrent review and to coordinate ride quality acceptance testing.

Control and Disposal of Grinding Residue

The requirements for disposing of grinding residue are detailed in the Special Provision for Managing Diamond Grinding Slurry from Ride Quality Concrete. The grinding operation produces slurry of ground concrete and water to cool the blades. Prior to beginning the grinding operation, the Engineer will approve the disposal method. At no time should slurry be discharged within 100 feet of any natural stream or lake or within 5 feet of a water-filled ditch. Nor should it be allowed to enter a closed drain system. Check the project proposal for allowed discharge areas.

Random samples of the slurry should be taken for chemical testing of the grinding residue and cooling water.

The inspector should make the following checks during the diamond grinding operation:

- Texture

- Overlap of successive passes of grinding head

- Blade Spalling

- Pattern

- Aggregate hardness

- Sand Patch test to verify macro texture depth

MEASUREMENT AND PAYMENT

-Reserved-