Difference between revisions of "702 - Mortar and Grout"

m |

|||

| Line 159: | Line 159: | ||

==CONSTRUCTION== | ==CONSTRUCTION== | ||

| − | <span style="color: red"> -Reserved- <span> | + | <span style="color: red"> -Reserved- </span> |

==MEASURMENT AND PAYMENT== | ==MEASURMENT AND PAYMENT== | ||

| − | <span style="color: red"> -Reserved- <span> | + | <span style="color: red"> -Reserved- </span> |

Revision as of 08:59, 11 June 2013

GENERAL

Mortar and grout is a mixture of:

- cement.

- fine aggregate (except for expansive grout).

- concrete admixtures (when specified).

- water.

Stiff mixtures are classified as mortars. Fluid mixtures are classified as grouts.

MATERIALS

|

|

|

|---|---|

|

Portland Cement Type I, Type IA |

|

|

Masonry Cement Type N, Type S, Type M |

|

|

Hydrated Lime Type S, Type SA |

|

|

Air - Entraining Admixture |

|

|

Fine Aggregate 2NS, 2MS |

|

|

Water |

|

|

|

|

|

Non-shrinking Mortars and Grouts |

|

|

Expansive Grouts |

|

Mortars and grouts:

- may be remixed but will not be retempered or used after they have begun to set.

- will be used only when the materials being mortared or grouted are at a temperature of 40°F (5°C) or higher and will remain so for the duration of the required curing period.

Mixture Requirements

Standard Mortars and Grouts

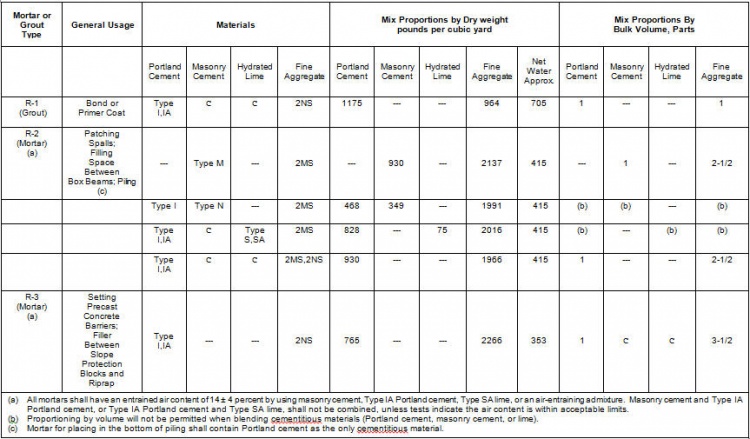

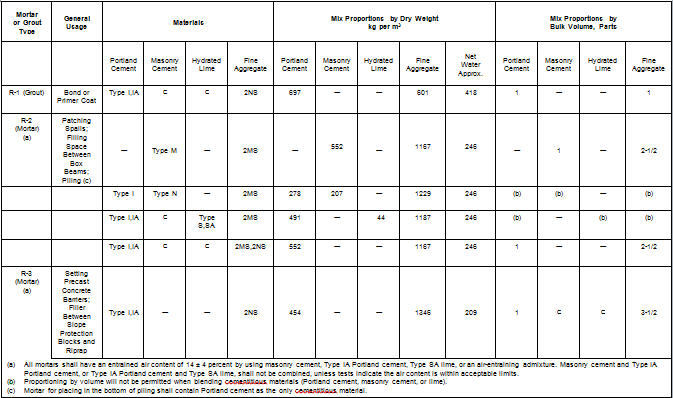

The cement and fine aggregates will be proportioned by weight for batches of 1 cubic yard (1 m3) or more, and by weight or volume for smaller batches. Table 702-1 gives the mix proportioning information for standard mortars (R-2 & R-3) and grout (R-1). Water is added in amounts necessary to obtain the consistency required for the work.

Non-shrinking Mortar and Grout

Nonshrinking mortar and grout will not be used in contact with prestressing tendons or other highly stressed steel.

Type H-1 (Non-metallic)

- Used for dowels and anchor bolts.

- Will be a premixed material.

- The material selected will be from the Qualified Products List.

- Water will be added in amounts necessary to obtain a mortar or grout consistency required for the work.

Expansive Grout, Type E-1

Expansive grout, Type E-1, is used for filling the void around post-tensioned tendons in precast concrete box beams. The grout will be proportioned as follows:

|

|

|

|---|---|

|

Portland Cement Type I |

|

|

Water, Maximum |

|

|

Expansive Admixture |

|

*As recommended by the manufacturer

Requirements:

No sand will be used in the grout mixture.

The grout will attain a 28-day minimum compressive strength of 3000 psi (25 MPa), according to ASTM C 942, but the grout will be proportioned by these specifications.

The expansive admixture, including any plasticizing or water reducing agent, will not contain chloride ions >0.50 percent by admixture weight nor any fluorides, sulfides, nitrates or thixotropic additives.

The admixture may be in liquid or solid form.

Aluminum powder of the proper fineness and quantity, or other approved gas evolving material that is well dispersed throughout the admixture, will be used.

The grout will have an unrestrained expansion of 5 percent to 10 percent, according to ASTM C 940, except that the grout will be proportioned by these specifications and the expansion will be determined at three hours.

CONSTRUCTION

-Reserved-

MEASURMENT AND PAYMENT

-Reserved-