703 - Mortar and Concrete Patching Repair and Resurfacing Mixes

GENERAL

Mortar and concrete patching, repair and resurfacing mixtures will be combined in proportions specified for the various types. Unless otherwise specified, air entrained concrete or mortar will be required.

Section 712 of the Construction Manual details the construction specifics in relation to deck patching and substructure patching utilizing these mixes.

Slag aggregates are not to be used.

MATERIALS

Provide materials in accordance with subsection 703.02 of the Standard Specifications for Construction.

| Materials | Requirements |

|---|---|

| Portland Cement Type I, Type IA | 901 |

| Silica Fume | 901 |

| Polypropylene Fibers | 902 |

| Coarse Aggregate 6AA, 6A, 26A | 902 |

| Fine Aggregate, 2NS | 902 |

| Latex Emulsion Admixture | 903 |

| Water Reducing and Water Reducing-Retarding Admixtures | 903 |

|

Air-Entraining Admixtures || 903 | |

| Water | 911 |

Equipment

Equipment for producing concrete by volumetric batching and continuous mixing will conform to ASTM C 685. The Contractor will be required to demonstrate that the equipment is properly calibrated for yield and proportions by certification and by field tests. Equipment use will be permitted provided that a satisfactory product is obtained, as determined by the Engineer.

A. Mixing Concrete and Mortar

Concrete and mortar patching mixtures may be mixed and transported by any method described in section 701 of the Standard Specifications for Construction. Latex modified concrete (LMC) mixtures will be furnished in continuous mixing equipment. See section 712 of the Construction Manual for information related to the calibration of LMC mixing units.

Mixture Requirements

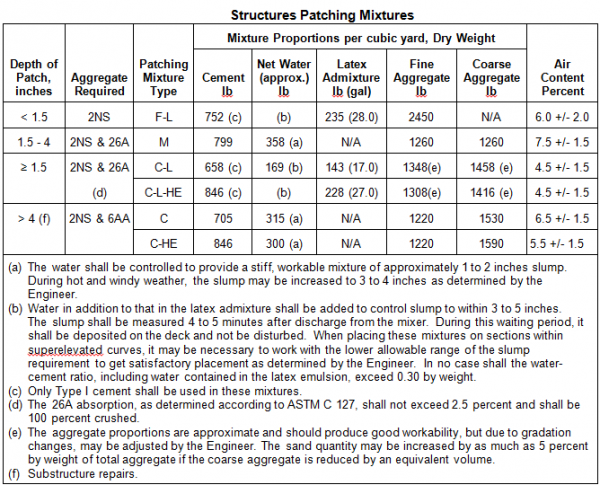

Mixture proportions for structures patching mixtures can be found in table 703-1 in the Standard Specifications for Construction.

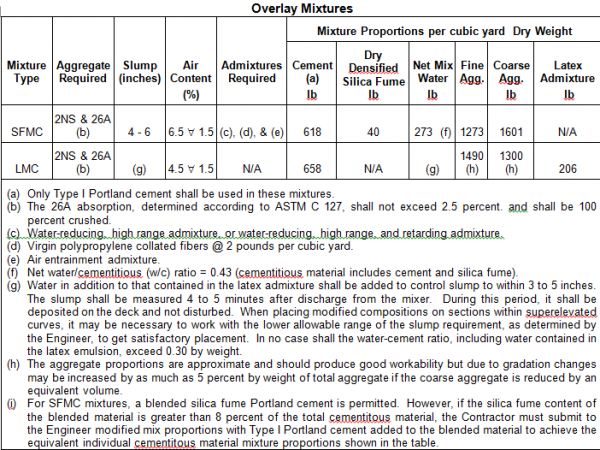

Mixture proportions for overlay mixtures can be found in table 703-2 in the Standard Specifications for Construction.

A. Structures Patching Mixtures

There are 6 types of structures patching mixtures listed in table 703-1 of the Standard Specifications for Construction. Mixtures are selected based on depth of the repair and length of curing time available. The structures patching mixtures include:

B. Overlay Mixtures

Overlay mixtures are used for shallow and deep rigid overlays on existing bridge decks. See section 712 of the Construction Manual for details regarding the construction of rigid overlays.

Overlay mixtures include Latex Modified Concrete (LMC), Silica Fume Modified Concrete (SFMC) and Grade D Slag Cement.

1. LMC

LMC is used for shallow overlays (typically 1.5” – 2”). The latex and small aggregate gradation enable it to adhere to existing decks with minimal depth of material. Table 703.02 in the Standard Specifications for Construction provides the mixture proportions.

2. SFMC

SFMC is used for deep overlays (2”-4”). SFMC provides a dense less permeable concrete to protect the existing deck and reinforcing steel. SFMC is susceptible to cracking if not wet cured properly or if placed too thick. Table 703.02 in the Standard Specifications for Construction provides the mixture proportions.

3. Grade D Slag Cement

Grade D Slag Cement is a mixture intended for rigid overlays indicating an average designed depth of greater than 4”. Grade D Slag Cement is not as susceptible to cracking as SFMC, however; utilizes a larger aggregate gradation. The mixture proportion is available via special provision.