|

|

| Line 12: |

Line 12: |

| | ===[[#Cofferdams|Cofferdams]]=== | | ===[[#Cofferdams|Cofferdams]]=== |

| | | | |

| − | A cofferdam is a substantially watertight enclosure which will permit substructure construction above a tremie seal or subfooting, in the dry and without damage to the work. Cofferdams must conform to all conditions included in the [http://www.michigan.gov/deq/ Department of Environmental Quality (DEQ)] or other project permits. The Contractor must obtain permission to deviate from the plans or approved permits.

| + | Steel sheet piling may permanent, temporary, or temporary left in place, meaning the sheeting was designed to support earth pressures during staged construction, and removal of the sheeting may be detrimental to permanent structures. Sheeting may also be part of a cofferdam, along with other structural components such as bracing, struts, walers, tie backs, and other related structural components act to create a water tight seal, as to construct substructure elements in the dry. Steel sheeting consists of new or used continuous interlock-type steel sections including connections and corner pieces. Steel sheet piling can resist loads via cantilever capacity, or in combination with bracing such as walers and struts. |

| | | | |

| − | Cofferdams are usually constructed around a template made of large timbers, H piling, or welded tube piling which serves as bracing when the enclosed area is dewatered. Care should be taken in driving the first sheet pile making sure it is as plumb as possible. Out-of-plumb sheeting leads to many problems, particularly at the corners. Water leakage through sheeting joints is common, but can usually be stopped by dropping fine cinders into the water outside the cofferdam where the leakage is occurring. The cinders will plug the joints and stop, or at least materially reduce, the water flow into the cofferdam.

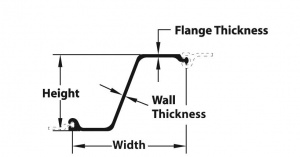

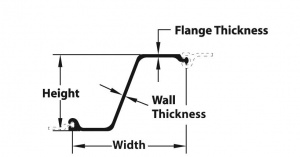

| + | Used steel sheet piling must be in good condition, and its use must be approved by the Engineer prior to driving. The most common steel sheet piling shapes are the PZ types. For example, for a PZ-27 section, the P stands for “pile” the Z is for the “type or shape”, and 27 represents the unit weight per ft2 of material. '''''Figure 704-1''''' shows a typical PZ shape configuration: |

| | + | |

| | + | [[File:704-1.JPG|thumbnail|right|Figure 704-1: Typical PZ shape]] |

| | | | |

| | {{top}} | | {{top}} |

| Line 23: |

Line 25: |

| | ===[[#Sheet Piling|Sheet Piling]]=== | | ===[[#Sheet Piling|Sheet Piling]]=== |

| | | | |

| − | Steel sheet piling may be:

| |

| − |

| |

| − | * permanent.

| |

| − |

| |

| − | * temporary.

| |

| − |

| |

| − | * part of a cofferdam.

| |

| − |

| |

| − | Sheet piling must be of the continuous interlocked type, either new or used and in good condition.

| |

| − |

| |

| − | Adequate toe and/or bracing must always be provided to support the piling and provide safe working conditions.

| |

| − |

| |

| − | Check plans and specifications for the required minimum section modulus. Measure the individual pile length to determine driven lengths for payment considerations where sheet piling will or might be left in a permanent location.

| |

| − |

| |

| − | Cold-rolled sheeting will be permitted for all applications.

| |

| | | | |

| | {{top}} | | {{top}} |

| Line 46: |

Line 33: |

| | ===[[#Permanent Sheeting|Permanent Sheeting]]=== | | ===[[#Permanent Sheeting|Permanent Sheeting]]=== |

| | | | |

| − | Permanent sheeting will be driven to the penetration called for on the plans and the area measured for payment will include the full length from a plan cutoff to plan penetration. Permanent steel sheet piling section modulus shall be as specified on the plans and furnished with suitable connecting and corner pieces. Cold rolled sheeting will be permitted.

| |

| | | | |

| | {{top}} | | {{top}} |

| Line 52: |

Line 38: |

| | ===[[#Temporary Sheeting|Temporary Sheeting]]=== | | ===[[#Temporary Sheeting|Temporary Sheeting]]=== |

| | | | |

| − | Temporary sheeting may be driven to the penetration determined by the Contractor unless otherwise noted by the design plans. The area measured for payment extends from ground line to the bottom of the excavation unless other limits are designated. It does not normally include the toe.

| |

| − |

| |

| − | Temporary steel sheet piling shall have a minimum nominal section modulus of 18.1 in<sup>3</sup>/ft (973,000 mm<sup>3</sup> per meter) of wall.

| |

| | | | |

| | {{top}} | | {{top}} |

| Line 60: |

Line 43: |

| | ===[[#Inspection of Cofferdams|Inspection of Cofferdams]]=== | | ===[[#Inspection of Cofferdams|Inspection of Cofferdams]]=== |

| | | | |

| − | There are several general items to keep in mind about cofferdams:

| |

| − |

| |

| − | The Contractor is responsible for its design and construction.

| |

| − |

| |

| − | It should be constructed so that it does not hinder navigation or the river flow.

| |

| − |

| |

| − | Its design should be adequate to provide a safe working area.

| |

| − |

| |

| − | Where it is required to protect adjacent property or roadways, it will be "soil-engineered," and reviewed to ensure adequacy and stability with proper wales and bracing.

| |

| − |

| |

| − | When requested by the Engineer, the Contractor is required to submit sketches of the proposed cofferdam for review.

| |

| − |

| |

| − | The Contractor must secure an approval for his method of construction from DEQ in water crossing situations. A well point system may be used on land to control ground water. It cannot be used in waterways because it causes siltation.

| |

| − |

| |

| − | If the Contractor's operation is suspect of water pollution or siltation, the Engineer will ask for a DEQ inspection as provided by Section [http://mdotcf.state.mi.us/public/specbook/files/2012/107%20Legal%20Rel,%20Resp%20to%20Public.pdf 107] of the Standard Specifications for Construction.

| |

| − |

| |

| − | Water pumped from cofferdams during the dewatering operation must be pumped through a geotextile filter bag before entering the watercourse.

| |

| − |

| |

| − | Dewatering shall not begin until the tremie seal (if using) has obtained the minimum strength according to [http://mdotcf.state.mi.us/public/specbook/files/2012/706%20Str%20Conc%20Construction.pdf 706.03.H.3].

| |

| − |

| |

| − | Piling used in a cofferdam is included in the pay item for Cofferdams, lump sum.

| |

| − |

| |

| − | Cofferdams, left in place, include designing, furnishing, installing, maintaining and cut- off of the sheet piling at the elevation shown in the plans.

| |

| | | | |

| | {{top}} | | {{top}} |

704

Steel Sheet Piling and Cofferdams

2012 STANDARD SPECIFICATIONS FOR CONSTRUCTION - SECTION 704

Steel sheet piling may permanent, temporary, or temporary left in place, meaning the sheeting was designed to support earth pressures during staged construction, and removal of the sheeting may be detrimental to permanent structures. Sheeting may also be part of a cofferdam, along with other structural components such as bracing, struts, walers, tie backs, and other related structural components act to create a water tight seal, as to construct substructure elements in the dry. Steel sheeting consists of new or used continuous interlock-type steel sections including connections and corner pieces. Steel sheet piling can resist loads via cantilever capacity, or in combination with bracing such as walers and struts.

Used steel sheet piling must be in good condition, and its use must be approved by the Engineer prior to driving. The most common steel sheet piling shapes are the PZ types. For example, for a PZ-27 section, the P stands for “pile” the Z is for the “type or shape”, and 27 represents the unit weight per ft2 of material. Figure 704-1 shows a typical PZ shape configuration:

Figure 704-1: Typical PZ shape

[top of page]

[top of page]

[top of page]

[top of page]

[top of page]

-Reserved-

[top of page]