Difference between revisions of "705 - Foundation Piling"

m |

|||

| Line 7: | Line 7: | ||

| − | ==GENERAL== | + | ==[[#GENERAL|GENERAL]]== |

Foundation piles are usually steel H sections or cast-in-place (CIP) concrete in steel shells. | Foundation piles are usually steel H sections or cast-in-place (CIP) concrete in steel shells. | ||

| Line 15: | Line 15: | ||

{{top}} | {{top}} | ||

| − | ==MATERIALS== | + | ==[[#MATERIALS|MATERIALS]]== |

| − | ===Bearing Capacity=== | + | ===[[#Bearing Capacity|Bearing Capacity]]=== |

| − | ====Dynamic Formula==== | + | ====[[#Dynamic Formula|Dynamic Formula]]==== |

Bearing capacity of foundation piling will be determined either by the static or dynamic formula. The dynamic formula is generally used. | Bearing capacity of foundation piling will be determined either by the static or dynamic formula. The dynamic formula is generally used. | ||

| Line 71: | Line 71: | ||

{{top}} | {{top}} | ||

| − | ====Ordering Pile Driving Charts==== | + | ====[[#Ordering Pile Driving Charts|Ordering Pile Driving Charts]]==== |

When the chart is needed immediately, complete Form 1157A (see '''''Figure 705-4''''') on-site and phone the information in to the C&T Bridge Construction Section. | When the chart is needed immediately, complete Form 1157A (see '''''Figure 705-4''''') on-site and phone the information in to the C&T Bridge Construction Section. | ||

| Line 77: | Line 77: | ||

{{top}} | {{top}} | ||

| − | ====Static Formula==== | + | ====[[#Static Formula|Static Formula]]==== |

When the static formula is used, Design Division will compute the length necessary and the piling will be driven to the penetration shown on the plans unless practical refusal is obtained at a higher elevation. | When the static formula is used, Design Division will compute the length necessary and the piling will be driven to the penetration shown on the plans unless practical refusal is obtained at a higher elevation. | ||

| Line 104: | Line 104: | ||

{{top}} | {{top}} | ||

| − | ====Determination of Bearing Value Using Dynamic Formula==== | + | ====[[#Determination of Bearing Value Using Dynamic Formula|Determination of Bearing Value Using Dynamic Formula]]==== |

'''Example:''' | '''Example:''' | ||

| Line 223: | Line 223: | ||

{{top}} | {{top}} | ||

| − | ==CONSTRUCTION== | + | ==[[#CONSTRUCTION|CONSTRUCTION]]== |

| − | ===Equipment=== | + | ===[[#Equipment|Equipment]]=== |

| − | ====Pile Hammers==== | + | ====[[#Pile Hammers|Pile Hammers]]==== |

Vibratory equipment may be used for sticking piles, but not for advancing piles. | Vibratory equipment may be used for sticking piles, but not for advancing piles. | ||

| Line 246: | Line 246: | ||

{{top}} | {{top}} | ||

| − | ====Leads==== | + | ====[[#Leads|Leads]]==== |

Leads used for pile driving are either swing or fixed-type. | Leads used for pile driving are either swing or fixed-type. | ||

| Line 254: | Line 254: | ||

{{top}} | {{top}} | ||

| − | ====Single Acting (Air) Hammers==== | + | ====[[#Single Acting (Air) Hammers|Single Acting (Air) Hammers]]==== |

The hammer is generally assumed to be developing its rated energy when it is striking the number of blows per minute as shown in the manufacturer's catalog. If a hammer will not develop its rated number of blows at bearing, the inspector should suspend driving operations. In most cases, the problem is caused by insufficient pressure at the hammer because of line losses caused by leaky connections, excessive line length, etc. | The hammer is generally assumed to be developing its rated energy when it is striking the number of blows per minute as shown in the manufacturer's catalog. If a hammer will not develop its rated number of blows at bearing, the inspector should suspend driving operations. In most cases, the problem is caused by insufficient pressure at the hammer because of line losses caused by leaky connections, excessive line length, etc. | ||

| Line 260: | Line 260: | ||

{{top}} | {{top}} | ||

| − | ====Closed-Top Type Hammer==== | + | ====[[#Closed-Top Type Hammer|Closed-Top Type Hammer]]==== |

The maximum rated energy should be used in calculating bearing only when the hammer is on the verge of ''floating'' on top of the pile. If this floating action is unattainable, the Contractor should furnish an instrument to measure the bounce chamber pressure and resulting hammer output. | The maximum rated energy should be used in calculating bearing only when the hammer is on the verge of ''floating'' on top of the pile. If this floating action is unattainable, the Contractor should furnish an instrument to measure the bounce chamber pressure and resulting hammer output. | ||

| Line 266: | Line 266: | ||

{{top}} | {{top}} | ||

| − | ====Open-Type Diesel Hammer==== | + | ====[[#Open-Type Diesel Hammer|Open-Type Diesel Hammer]]==== |

When using an open-type diesel hammer, the manufacturer's rated energy should be used, providing the hammer appears to be functioning properly. | When using an open-type diesel hammer, the manufacturer's rated energy should be used, providing the hammer appears to be functioning properly. | ||

| Line 272: | Line 272: | ||

{{top}} | {{top}} | ||

| − | ===Construction Inspection=== | + | ===[[#Construction Inspection|Construction Inspection]]=== |

Prior to the start of driving and during the operation, check all of the following: | Prior to the start of driving and during the operation, check all of the following: | ||

| Line 294: | Line 294: | ||

{{top}} | {{top}} | ||

| − | ===Test Piles=== | + | ===[[#Test Piles|Test Piles]]=== |

Will be driven prior to the regular piling so the results can be used as a guide in ordering piles and driving all the regular piling. | Will be driven prior to the regular piling so the results can be used as a guide in ordering piles and driving all the regular piling. | ||

| Line 302: | Line 302: | ||

{{top}} | {{top}} | ||

| − | ====Pile Penetration Observations==== | + | ====[[#Pile Penetration Observations|Pile Penetration Observations]]==== |

It is important at the start of the blow count to reference the pile to some fixed object, preferably the leads, providing they are not reset during the observation period. | It is important at the start of the blow count to reference the pile to some fixed object, preferably the leads, providing they are not reset during the observation period. | ||

| Line 308: | Line 308: | ||

{{top}} | {{top}} | ||

| − | ====Reference Stake==== | + | ====[[#Reference Stake|Reference Stake]]==== |

Driving a reference stake adjacent to the pile should be avoided because clay soil has the tendency to heave and sandy soil has the tendency to consolidate. | Driving a reference stake adjacent to the pile should be avoided because clay soil has the tendency to heave and sandy soil has the tendency to consolidate. | ||

| Line 318: | Line 318: | ||

{{top}} | {{top}} | ||

| − | ===Splicing=== | + | ===[[#Splicing|Splicing]]=== |

Steel piles and steel pile shells may be furnished in full length sections or the pile shells may be spliced according to the splicing method as shown on the plans or as approved by the Engineer. | Steel piles and steel pile shells may be furnished in full length sections or the pile shells may be spliced according to the splicing method as shown on the plans or as approved by the Engineer. | ||

| Line 326: | Line 326: | ||

{{top}} | {{top}} | ||

| − | ====Welded==== | + | ====[[#Welded|Welded]]==== |

Welded splices for piles will be made only by qualified welders using E6010, E7015, E7016 or E7018 electrodes. | Welded splices for piles will be made only by qualified welders using E6010, E7015, E7016 or E7018 electrodes. | ||

| Line 332: | Line 332: | ||

{{top}} | {{top}} | ||

| − | ====CIP Concrete Piles==== | + | ====[[#CIP Concrete Piles|CIP Concrete Piles]]==== |

Shells for CIP concrete piles will be spliced using a chill ring or other type backing detail as shown on the plans. | Shells for CIP concrete piles will be spliced using a chill ring or other type backing detail as shown on the plans. | ||

| Line 338: | Line 338: | ||

{{top}} | {{top}} | ||

| − | ====Steel Piles==== | + | ====[[#Steel Piles|Steel Piles]]==== |

Steel piles will be spliced as shown on the plans using preformed-preassembled bent plates or flat splice plates. | Steel piles will be spliced as shown on the plans using preformed-preassembled bent plates or flat splice plates. | ||

| Line 344: | Line 344: | ||

{{top}} | {{top}} | ||

| − | ====Full Penetration, Butt Welded==== | + | ====[[#Full Penetration, Butt Welded|Full Penetration, Butt Welded]]==== |

Full penetration butt welding of piles will be performed as outlined herein, with emphasis placed on burning, alignment and welding. | Full penetration butt welding of piles will be performed as outlined herein, with emphasis placed on burning, alignment and welding. | ||

| Line 350: | Line 350: | ||

{{top}} | {{top}} | ||

| − | ====Scarfing==== | + | ====[[#Scarfing|Scarfing]]==== |

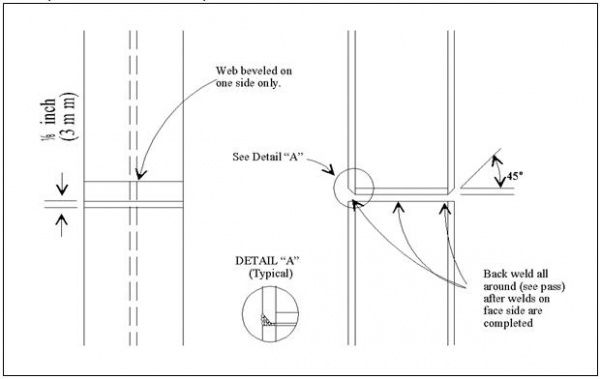

Scarfing the upper splice length of the piles preparatory to butt welding will be done by a cutting torch using a guide to assure a smoother chamber. A maximum of 1/8 inch (3 mm) land (shoulder) will be retained. If the end of the driven length of pile is damaged during the driving operation, it must be trimmed. | Scarfing the upper splice length of the piles preparatory to butt welding will be done by a cutting torch using a guide to assure a smoother chamber. A maximum of 1/8 inch (3 mm) land (shoulder) will be retained. If the end of the driven length of pile is damaged during the driving operation, it must be trimmed. | ||

| Line 358: | Line 358: | ||

{{top}} | {{top}} | ||

| − | ====Offhand Burning==== | + | ====[[#Offhand Burning|Offhand Burning]]==== |

Offhand burning will be permitted if trimming is minor. When it is necessary to cut a small section off the end of the driven pile length to square the end, burning must be done using a guide either clamped or tack welded in place. All adhering slag will be removed and the joint surfaces will be thoroughly cleaned by wire brushing before welding. A root opening of the butt joint will provide a 1/8 inch (3 mm) clear opening at the nearest point. When the 1/8 inch (3 mm) opening at the nearest point allows more than a ¼ inch (6 mm) opening at other points, correction will be made to provide the correct opening before welding. Beveling by cutting will be required for correcting openings wider than ¼ inch (6 mm). | Offhand burning will be permitted if trimming is minor. When it is necessary to cut a small section off the end of the driven pile length to square the end, burning must be done using a guide either clamped or tack welded in place. All adhering slag will be removed and the joint surfaces will be thoroughly cleaned by wire brushing before welding. A root opening of the butt joint will provide a 1/8 inch (3 mm) clear opening at the nearest point. When the 1/8 inch (3 mm) opening at the nearest point allows more than a ¼ inch (6 mm) opening at other points, correction will be made to provide the correct opening before welding. Beveling by cutting will be required for correcting openings wider than ¼ inch (6 mm). | ||

| Line 364: | Line 364: | ||

{{top}} | {{top}} | ||

| − | ====Root Opening==== | + | ====[[#Root Opening|Root Opening]]==== |

The root opening may be held by two wedges before tacking. The members to be welded will be brought into correct alignment along the pile length and held rigidly by clamps or by dogging. Clamps or dogs may be removed after tack welding sufficiently to hold the member in place. Where the parts are restrained against bending due to eccentricity in alignment, an offset not exceeding 10 percent thickness of the thinner part joint, but no more than 1/8 inch (3 mm), may be permitted as a departure from the theoretical alignment. In correcting misalignment, the parts will not be drawn into a greater slope than ½ inch per foot (12 mm in 300 mm). Offset measurement will be based upon the centerline of parts unless otherwise shown on the drawing. The root pass will be a stringer bead, placed with sufficient amperage to fully penetrate through the joint. Passes will be made symmetrically and will alternate on both flanges to minimize distortion. After the face side of both flanges and web have been welded completely, a backing bead will be made on the opposite side. | The root opening may be held by two wedges before tacking. The members to be welded will be brought into correct alignment along the pile length and held rigidly by clamps or by dogging. Clamps or dogs may be removed after tack welding sufficiently to hold the member in place. Where the parts are restrained against bending due to eccentricity in alignment, an offset not exceeding 10 percent thickness of the thinner part joint, but no more than 1/8 inch (3 mm), may be permitted as a departure from the theoretical alignment. In correcting misalignment, the parts will not be drawn into a greater slope than ½ inch per foot (12 mm in 300 mm). Offset measurement will be based upon the centerline of parts unless otherwise shown on the drawing. The root pass will be a stringer bead, placed with sufficient amperage to fully penetrate through the joint. Passes will be made symmetrically and will alternate on both flanges to minimize distortion. After the face side of both flanges and web have been welded completely, a backing bead will be made on the opposite side. | ||

| Line 370: | Line 370: | ||

{{top}} | {{top}} | ||

| − | ==MEASUREMENT AND PAYMENT== | + | ==[[#MEASUREMENT AND PAYMENT|MEASUREMENT AND PAYMENT]]== |

| − | ===Production Piles=== | + | ===[[#Production Piles|Production Piles]]=== |

| − | ====Recording Production Piles==== | + | ====[[#Recording Production Piles|Recording Production Piles]]==== |

Only the original length, splice lengths, final penetration bearing and cutoff lengths are recorded. | Only the original length, splice lengths, final penetration bearing and cutoff lengths are recorded. | ||

| Line 382: | Line 382: | ||

{{top}} | {{top}} | ||

| − | ====Required Bearing==== | + | ====[[#Required Bearing|Required Bearing]]==== |

Production piles are driven to the required bearing and the driving is stopped provided the pile has been driven to the minimum penetration as shown on the plans. | Production piles are driven to the required bearing and the driving is stopped provided the pile has been driven to the minimum penetration as shown on the plans. | ||

| Line 388: | Line 388: | ||

{{top}} | {{top}} | ||

| − | ====Overdriving==== | + | ====[[#Overdriving|Overdriving]]==== |

Any unnecessary production piling overdriving is to be avoided as it adds unnecessary project cost. | Any unnecessary production piling overdriving is to be avoided as it adds unnecessary project cost. | ||

| Line 394: | Line 394: | ||

{{top}} | {{top}} | ||

| − | ====Equipment Changes==== | + | ====[[#Equipment Changes|Equipment Changes]]==== |

All piles for a given foundation unit will be driven with the same hammer operated under the same conditions with the same cushion material as used to drive test piles. Changing hammers requires additional test pile driving at the Contractor’s expense. | All piles for a given foundation unit will be driven with the same hammer operated under the same conditions with the same cushion material as used to drive test piles. Changing hammers requires additional test pile driving at the Contractor’s expense. | ||

| Line 400: | Line 400: | ||

{{top}} | {{top}} | ||

| − | ====Variation==== | + | ====[[#Variation|Variation]]==== |

Piling will be driven with a variation of not more than ¼ inch per foot (20 mm/m) from vertical or the batter line shown on the plans. | Piling will be driven with a variation of not more than ¼ inch per foot (20 mm/m) from vertical or the batter line shown on the plans. | ||

| Line 406: | Line 406: | ||

{{top}} | {{top}} | ||

| − | ====Batter==== | + | ====[[#Batter|Batter]]==== |

The batter is checked by making a template to the shape shown on the plans. With a carpenter's level attached to the vertical side of the template, it should show when the template is held against the pile in its battered position. | The batter is checked by making a template to the shape shown on the plans. With a carpenter's level attached to the vertical side of the template, it should show when the template is held against the pile in its battered position. | ||

| Line 412: | Line 412: | ||

{{top}} | {{top}} | ||

| − | ====Pile Position==== | + | ====[[#Pile Position|Pile Position]]==== |

After driving, each pile position at the cutoff elevation will be within 6 inches (150 mm) of plan position, with a minimum 9 inches (225 mm) concrete cover in all directions. Piles used as pier columns will meet the plan accuracy requirements. | After driving, each pile position at the cutoff elevation will be within 6 inches (150 mm) of plan position, with a minimum 9 inches (225 mm) concrete cover in all directions. Piles used as pier columns will meet the plan accuracy requirements. | ||

| Line 418: | Line 418: | ||

{{top}} | {{top}} | ||

| − | ====Inspection==== | + | ====[[#Inspection|Inspection]]==== |

After driving CIP shell piling inspection will be done by using a mirror or light provided by the Contractor, suitable for illuminating the shell interiors. The shells will be free of bends, kinks or other deformations that would impair the completed pile strength. | After driving CIP shell piling inspection will be done by using a mirror or light provided by the Contractor, suitable for illuminating the shell interiors. The shells will be free of bends, kinks or other deformations that would impair the completed pile strength. | ||

| Line 424: | Line 424: | ||

{{top}} | {{top}} | ||

| − | ====Pile Tops==== | + | ====[[#Pile Tops|Pile Tops]]==== |

After driving the piling, piling tops will be immediately covered to keep out rain, sand, etc. The piling should be cut off within 1 inch (25 mm) of the specified elevation and filled with grade S1 concrete as soon as possible. | After driving the piling, piling tops will be immediately covered to keep out rain, sand, etc. The piling should be cut off within 1 inch (25 mm) of the specified elevation and filled with grade S1 concrete as soon as possible. | ||

| Line 430: | Line 430: | ||

{{top}} | {{top}} | ||

| − | ====Driving==== | + | ====[[#Driving|Driving]]==== |

Driving within a radius of 25 feet (7.5 m) will not be permitted until the concrete has attained 75 percent of its design strength. | Driving within a radius of 25 feet (7.5 m) will not be permitted until the concrete has attained 75 percent of its design strength. | ||

| Line 436: | Line 436: | ||

{{top}} | {{top}} | ||

| − | ====Concrete==== | + | ====[[#Concrete|Concrete]]==== |

Concrete should be cast in slowly so that an air pocket is not formed in the pile. An inspector should be present at all times during placement. No concrete will be placed in any pile until all piles within a 20 foot (6 m) radius have been driven and accepted. | Concrete should be cast in slowly so that an air pocket is not formed in the pile. An inspector should be present at all times during placement. No concrete will be placed in any pile until all piles within a 20 foot (6 m) radius have been driven and accepted. | ||

| Line 442: | Line 442: | ||

{{top}} | {{top}} | ||

| − | ====Piles 60 feet (20 m) or more in Length==== | + | ====[[#Piles 60 feet (20 m) or more in Length|Piles 60 feet (20 m) or more in Length]]==== |

Approximately 2 cubic feet (0.05 m3) of Type R-2 mortar will be placed in the bottom of the steel shell before placing the grade S1 concrete. | Approximately 2 cubic feet (0.05 m3) of Type R-2 mortar will be placed in the bottom of the steel shell before placing the grade S1 concrete. | ||

| Line 448: | Line 448: | ||

{{top}} | {{top}} | ||

| − | ====Upper 1/3 Pile Shell==== | + | ====[[#Upper 1/3 Pile Shell|Upper 1/3 Pile Shell]]==== |

Concrete in the pile shell’s upper third [not to exceed 25 feet (7.5 m)], will be vibrated by an approved method. | Concrete in the pile shell’s upper third [not to exceed 25 feet (7.5 m)], will be vibrated by an approved method. | ||

| Line 454: | Line 454: | ||

{{top}} | {{top}} | ||

| − | ===Record-Keeping=== | + | ===[[#Record-Keeping|Record-Keeping]]=== |

| − | ====Test Pile Records==== | + | ====[[#Test Pile Records|Test Pile Records]]==== |

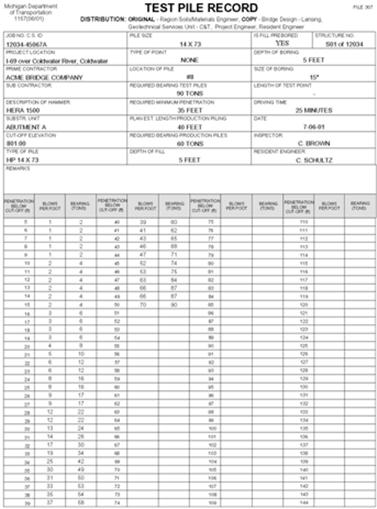

Test pile records will be kept on Form 1157. | Test pile records will be kept on Form 1157. | ||

| Line 465: | Line 465: | ||

{{top}} | {{top}} | ||

| − | ====Timber or Treated Timber Piling==== | + | ====[[#Timber or Treated Timber Piling|Timber or Treated Timber Piling]]==== |

Where timber or treated timber piling is called for on the plans, the Engineer will furnish the Contractor with the lengths to be ordered. | Where timber or treated timber piling is called for on the plans, the Engineer will furnish the Contractor with the lengths to be ordered. | ||

| Line 473: | Line 473: | ||

{{top}} | {{top}} | ||

| − | ====CIP Concrete and Steel Pile==== | + | ====[[#CIP Concrete and Steel Pile|CIP Concrete and Steel Pile]]==== |

The Contractor will be responsible for ordering pile lengths for CIP concrete and steel piling based on test pile results. | The Contractor will be responsible for ordering pile lengths for CIP concrete and steel piling based on test pile results. | ||

| Line 479: | Line 479: | ||

{{top}} | {{top}} | ||

| − | ====Pile Sketch==== | + | ====[[#Pile Sketch|Pile Sketch]]==== |

A pile sketch will be made if the pilings are not numbered on the plans or if the final driven position changes. | A pile sketch will be made if the pilings are not numbered on the plans or if the final driven position changes. | ||

| Line 485: | Line 485: | ||

{{top}} | {{top}} | ||

| − | ====Form 1161 - Foundation Piling Record==== | + | ====[[#Form 1161 - Foundation Piling Record|Form 1161 - Foundation Piling Record]]==== |

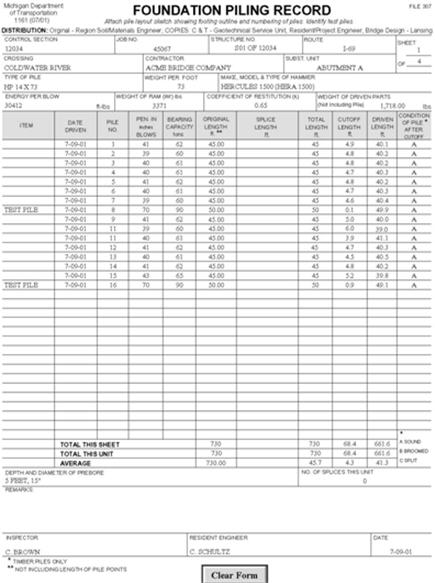

Regular piling information is kept on this form. Measurements for driven lengths and cutoffs will be made in feet (m) and inches (mm). | Regular piling information is kept on this form. Measurements for driven lengths and cutoffs will be made in feet (m) and inches (mm). | ||

| Line 500: | Line 500: | ||

{{top}} | {{top}} | ||

| + | |||

| + | [[Category:Construction Manual]] | ||

Revision as of 09:07, 24 July 2013

GENERAL

Foundation piles are usually steel H sections or cast-in-place (CIP) concrete in steel shells.

Fluted shells are usually an allowable alternate but rarely used. Occasionally the plans specify treated timber piles.

MATERIALS

Bearing Capacity

Dynamic Formula

Bearing capacity of foundation piling will be determined either by the static or dynamic formula. The dynamic formula is generally used.

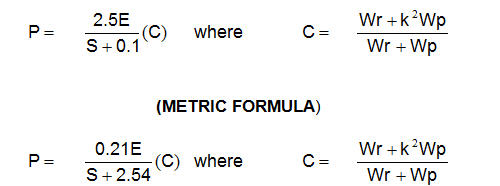

Using the dynamic formula, test piles are driven with pile lengths determined from these results. When using the dynamic formula first solve for the coefficient (C) and then solve for (S) using the following equations. A worked example is included.

The following information is necessary so bearing charts can be made up prior to the start of work. The bearing charts are obtained by providing the Lansing Construction & Technology, Bridge Construction Section with the hammer information along with the minimum and maximum estimated pile lengths to be used. Charts can also be developed in the field using the formula.

|

|

|

|---|---|

|

|

manufacturer's maximum rated energy in foot (joules). |

|

|

weight of striking parts of the hammer (ram) in pounds (kilograms). |

|

|

weight of the parts being driven and including the anvil (if any), driving helmet, driving cap, mandrel, pile weight, etc., in pounds (kilograms). |

|

|

coefficient of restitution of the impact areas. |

|

|

bearing resistance value in pounds (kiloNewtons). |

|

|

pile set, the average penetration in inches (mm) per blow for the last 10 blows of the hammer. |

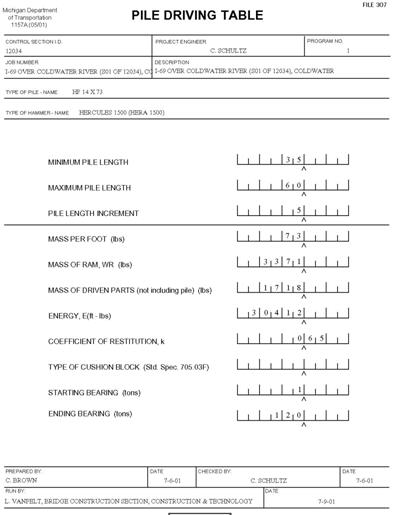

Ordering Pile Driving Charts

When the chart is needed immediately, complete Form 1157A (see Figure 705-4) on-site and phone the information in to the C&T Bridge Construction Section.

Static Formula

When the static formula is used, Design Division will compute the length necessary and the piling will be driven to the penetration shown on the plans unless practical refusal is obtained at a higher elevation.

|

|

|

|---|---|

|

|

a bearing of 1-1/2 times the required pile bearing as determined by using the dynamic formula. |

|

|

a bearing of 2 times the required pile bearing as determined by using the dynamic formula. |

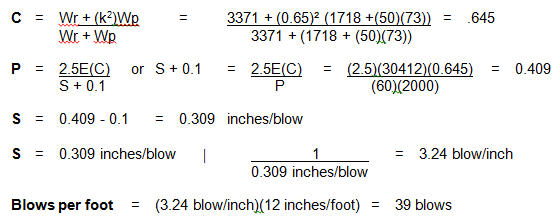

Determination of Bearing Value Using Dynamic Formula

Example:

|

|

|

|

|---|---|---|

|

|

|

weight of striking parts of hammer |

|

|

|

weight of parts being driven including pile weight [(1718) + (50 ft)(73 lbs/ft)] |

|

|

|

energy of hammer |

|

|

|

coefficient of restitution for laminated Micarta blocks |

|

|

|

bearing resistance |

|

|

|

pile set, average penetration in inches/blow for the last ten hammer blows |

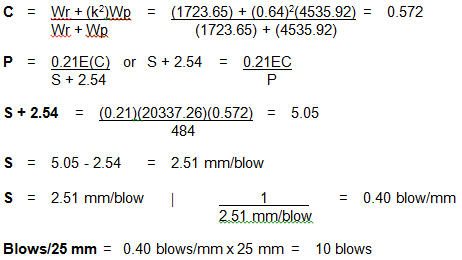

Metric Example:

|

|

|

|

|---|---|---|

|

|

|

weight of striking parts of hammer |

|

|

|

weight of parts being driven including pile weight |

|

|

|

energy of hammer |

|

|

|

coefficient of restitution for laminated Micarta blocks |

|

|

|

bearing resistance |

|

|

|

pile set, average penetration in mm/blow for the last ten hammer blows |

CONSTRUCTION

Equipment

Pile Hammers

Vibratory equipment may be used for sticking piles, but not for advancing piles.

Drop hammers are not permitted for driving permanent piling.

Hammers used for pile driving will be:

- single acting steam (air),

- double acting steam (air), or

- diesel-powered.

In leads which do not bind or restrain free vertical movement, and equipped with a suitable bonnet or cap which will accurately hold the pile top in correct position with reference to the ram, in order to distribute the ram blow over the entire top of the pile.

Leads

Leads used for pile driving are either swing or fixed-type.

The Contractor should be encouraged to use the fixed-type wherever possible as they do a better job of holding the pile in position.

Single Acting (Air) Hammers

The hammer is generally assumed to be developing its rated energy when it is striking the number of blows per minute as shown in the manufacturer's catalog. If a hammer will not develop its rated number of blows at bearing, the inspector should suspend driving operations. In most cases, the problem is caused by insufficient pressure at the hammer because of line losses caused by leaky connections, excessive line length, etc.

Closed-Top Type Hammer

The maximum rated energy should be used in calculating bearing only when the hammer is on the verge of floating on top of the pile. If this floating action is unattainable, the Contractor should furnish an instrument to measure the bounce chamber pressure and resulting hammer output.

Open-Type Diesel Hammer

When using an open-type diesel hammer, the manufacturer's rated energy should be used, providing the hammer appears to be functioning properly.

Construction Inspection

Prior to the start of driving and during the operation, check all of the following:

- Excavation - The excavation will be complete.

- Embankment Areas - Embankment will be completed to the bottom of substructure concrete elevation.

- Battered Piles - Proper elevation of fill or cut. Check to ensure that battered piles will clear the toe of any cofferdam sheet piling.

- Wall-type Abutments - On certain types of abutments, an error in grade could easily result in the piling being too close to or possibly outside the wall forms.

- Pile Layout - The Contractor will do the actual pile layout. The layout should then be checked by the inspector.

- Soil Borings and Blow Count Data - Prior to driving, the inspector should become familiar with the soil borings in the footing area. The problem of leaving the piling hung up on a thin, hard layer underlain by unsuitable material can be avoided.

- Embankment Areas - When specified, holes will be pre-bored to the elevation shown on the plans. The diameter of the pre-bored hole shall be equal or slightly greater than the piling diameter.

- Refusal - The specifications allow stopping at absolute refusal if minimum pile penetration has been achieved. If an underlying soft material layer exists, the region soils Engineer or representative or the C&T Lansing office should be contacted to determine if penetration is necessary, requiring extra work.

Test Piles

Will be driven prior to the regular piling so the results can be used as a guide in ordering piles and driving all the regular piling.

Will be driven to practical refusal with bearing observations taken at 1 foot (300 mm) intervals.

Pile Penetration Observations

It is important at the start of the blow count to reference the pile to some fixed object, preferably the leads, providing they are not reset during the observation period.

Reference Stake

Driving a reference stake adjacent to the pile should be avoided because clay soil has the tendency to heave and sandy soil has the tendency to consolidate.

Soil heaving and consolidating soil would raise or lower the reference stake causing erroneous penetration readings affecting the recorded bearing.

Besides the penetration readings, the inspector will simultaneously record the distance the pile point is below cutoff. This is accomplished by having the piling marked off in 1 foot (300 mm) intervals starting from the point and referencing the piling marks to a grade stake set at cutoff elevation.

Splicing

Steel piles and steel pile shells may be furnished in full length sections or the pile shells may be spliced according to the splicing method as shown on the plans or as approved by the Engineer.

Splices will be made according to subsection 707.03.D.10 b,c,d of the Standard Specifications for Construction with the welding done by a certified welder qualified in the 2G position for welding the pile in the vertical position. If the piling is spliced while lying on the ground, the welder will also be qualified in the 3G position. There is no limit to the number of splices made on any one pile.

Welded

Welded splices for piles will be made only by qualified welders using E6010, E7015, E7016 or E7018 electrodes.

CIP Concrete Piles

Shells for CIP concrete piles will be spliced using a chill ring or other type backing detail as shown on the plans.

Steel Piles

Steel piles will be spliced as shown on the plans using preformed-preassembled bent plates or flat splice plates.

Full Penetration, Butt Welded

Full penetration butt welding of piles will be performed as outlined herein, with emphasis placed on burning, alignment and welding.

Scarfing

Scarfing the upper splice length of the piles preparatory to butt welding will be done by a cutting torch using a guide to assure a smoother chamber. A maximum of 1/8 inch (3 mm) land (shoulder) will be retained. If the end of the driven length of pile is damaged during the driving operation, it must be trimmed.

All splices require welding. Splicing devices which do not develop the full plan weld are not permitted.

Offhand Burning

Offhand burning will be permitted if trimming is minor. When it is necessary to cut a small section off the end of the driven pile length to square the end, burning must be done using a guide either clamped or tack welded in place. All adhering slag will be removed and the joint surfaces will be thoroughly cleaned by wire brushing before welding. A root opening of the butt joint will provide a 1/8 inch (3 mm) clear opening at the nearest point. When the 1/8 inch (3 mm) opening at the nearest point allows more than a ¼ inch (6 mm) opening at other points, correction will be made to provide the correct opening before welding. Beveling by cutting will be required for correcting openings wider than ¼ inch (6 mm).

Root Opening

The root opening may be held by two wedges before tacking. The members to be welded will be brought into correct alignment along the pile length and held rigidly by clamps or by dogging. Clamps or dogs may be removed after tack welding sufficiently to hold the member in place. Where the parts are restrained against bending due to eccentricity in alignment, an offset not exceeding 10 percent thickness of the thinner part joint, but no more than 1/8 inch (3 mm), may be permitted as a departure from the theoretical alignment. In correcting misalignment, the parts will not be drawn into a greater slope than ½ inch per foot (12 mm in 300 mm). Offset measurement will be based upon the centerline of parts unless otherwise shown on the drawing. The root pass will be a stringer bead, placed with sufficient amperage to fully penetrate through the joint. Passes will be made symmetrically and will alternate on both flanges to minimize distortion. After the face side of both flanges and web have been welded completely, a backing bead will be made on the opposite side.

MEASUREMENT AND PAYMENT

Production Piles

Recording Production Piles

Only the original length, splice lengths, final penetration bearing and cutoff lengths are recorded.

Required Bearing

Production piles are driven to the required bearing and the driving is stopped provided the pile has been driven to the minimum penetration as shown on the plans.

Overdriving

Any unnecessary production piling overdriving is to be avoided as it adds unnecessary project cost.

Equipment Changes

All piles for a given foundation unit will be driven with the same hammer operated under the same conditions with the same cushion material as used to drive test piles. Changing hammers requires additional test pile driving at the Contractor’s expense.

Variation

Piling will be driven with a variation of not more than ¼ inch per foot (20 mm/m) from vertical or the batter line shown on the plans.

Batter

The batter is checked by making a template to the shape shown on the plans. With a carpenter's level attached to the vertical side of the template, it should show when the template is held against the pile in its battered position.

Pile Position

After driving, each pile position at the cutoff elevation will be within 6 inches (150 mm) of plan position, with a minimum 9 inches (225 mm) concrete cover in all directions. Piles used as pier columns will meet the plan accuracy requirements.

Inspection

After driving CIP shell piling inspection will be done by using a mirror or light provided by the Contractor, suitable for illuminating the shell interiors. The shells will be free of bends, kinks or other deformations that would impair the completed pile strength.

Pile Tops

After driving the piling, piling tops will be immediately covered to keep out rain, sand, etc. The piling should be cut off within 1 inch (25 mm) of the specified elevation and filled with grade S1 concrete as soon as possible.

Driving

Driving within a radius of 25 feet (7.5 m) will not be permitted until the concrete has attained 75 percent of its design strength.

Concrete

Concrete should be cast in slowly so that an air pocket is not formed in the pile. An inspector should be present at all times during placement. No concrete will be placed in any pile until all piles within a 20 foot (6 m) radius have been driven and accepted.

Piles 60 feet (20 m) or more in Length

Approximately 2 cubic feet (0.05 m3) of Type R-2 mortar will be placed in the bottom of the steel shell before placing the grade S1 concrete.

Upper 1/3 Pile Shell

Concrete in the pile shell’s upper third [not to exceed 25 feet (7.5 m)], will be vibrated by an approved method.

Record-Keeping

Test Pile Records

Test pile records will be kept on Form 1157.

Timber or Treated Timber Piling

Where timber or treated timber piling is called for on the plans, the Engineer will furnish the Contractor with the lengths to be ordered.

Treated timber piles (furnished) will be paid for by the length determined by the Engineer.

CIP Concrete and Steel Pile

The Contractor will be responsible for ordering pile lengths for CIP concrete and steel piling based on test pile results.

Pile Sketch

A pile sketch will be made if the pilings are not numbered on the plans or if the final driven position changes.

Form 1161 - Foundation Piling Record

Regular piling information is kept on this form. Measurements for driven lengths and cutoffs will be made in feet (m) and inches (mm).

The information should be recorded onto the form directly and not on separate sheets of paper that are easily misplaced. To ensure against loss, a copy of each day's driving should be made, or a permanent record can be made in a bound field book.

Note: See examples of Form 1157 - Test Pile Record and Form 1161 - Foundation Piling Record - shown in Figures 705-2 and 705-3.