Difference between revisions of "706 - Structural Concrete"

| Line 390: | Line 390: | ||

This treatment is commonly used on piers and abutments beneath deck expansion joints to shield bearing areas from corrosive elements. Structural concrete to be sealed for any structure will be as shown on the plans or as designated by the Engineer. Manufacturing specifications, preparation of area to be covered, methods of mixing, proper applications and precautions in using are spelled out in the Standard Specifications for Construction. | This treatment is commonly used on piers and abutments beneath deck expansion joints to shield bearing areas from corrosive elements. Structural concrete to be sealed for any structure will be as shown on the plans or as designated by the Engineer. Manufacturing specifications, preparation of area to be covered, methods of mixing, proper applications and precautions in using are spelled out in the Standard Specifications for Construction. | ||

| − | == | + | ==MEASUREMENT AND PAYMENT== |

<span style="color: red"> -Reserved- </span> | <span style="color: red"> -Reserved- </span> | ||

Revision as of 15:28, 14 June 2013

GENERAL

The standard specifications contain details for form construction, covering material and size, stud and waler spacings, required moldings, bracing, oiling and removal.

Form Ties

Form rod’s tie size and spacing are generally the Contractor’s responsibility, but consideration must be given to pressures exerted against the forms that will have characteristics of a fluid head which, in turn, depends on temperature and speed of pouring.

Steel Bands

Steel bands may sometimes be used to hold forms in place. These will eliminate the use of tie rods by encompassing the forms with metal bands drawn tight, crimped and locked with a tool designed for this purpose. All bands should be checked for any rips and/or damaging folds.

Walers

All walers need to be inspected, especially in corner areas, for loose or "floating" wale ends. Joints in a waler row may be strengthened by having the ends of the top and bottom members staggered with the butt ends in different tie rod spacings. All butt splices in walers must be scabbed. Forms erected and left in an erected position for even short periods, must be reinspected, keeping in mind that wind and weather can cause distortions of both forms and bracing.

Stiffening longer braces is sometimes necessary. This may be done by spiking two pieces of lumber together into a tee-section or fastening a cross-member to a series of braces.

Inspecting Forms

Forms should be inspected when they show up on the site. The Contractor should be informed if reworking, relining or replacement is necessary to provide concrete shapes and surfaces as specified. This should be done before they are erected.

The plans are the usual source of information for steel reinforcement details about bar sizes, spacing, lap, etc. In forming the substructure units, it may be advantageous to weld an inner form rod to the end of a straight bar to continue with a form tie. An authorization is required for such welding.

Forming Walls, Columns and Girders

In forming walls and columns, it must be remembered that great pressures develop with increasing height and the pattern of waler spacing will be closer together near the bottom and further apart approaching the top. During pouring operations when a tie rod ruptures, it will often "pop" with an audible crack (heard and not seen). The walers and tie rods should be checked immediately. Wind may also exert great force on large area wall forms and should be taken into consideration when bracing.

When round steel column forms are used, they should be inspected for out-of-roundness that results from rough handling such as rolling assembled sections off trucks, etc. The resulting egg-shaped column will make it difficult to properly fasten the friction rings used to hold the girder or cap. If there is any doubt about the friction rings supporting girder bottoms, Contractors should use timber stifflegs, placed between rings and footing.

Stay-in-place, vertical metal joints and the small neoprene skirts used on the outside edge, which are fastened to the metal bulkhead within the wall, should be carefully and securely clamped between the vertical moldings when moldings are called for.

MATERIALS

-Reserved-

CONSTRUCTION

Superstructure

Form Bracing

The material to be used and the construction of ordinary forms is outlined clearly in the standard specifications except form bracing. It is impossible to set rules for bracing which will apply to all cases because the method used will depend on conditions at the work site. The Contractor must assume responsibility for adequate form bracing. Forms must be securely braced to prevent movement while placing concrete.

Floor Joist and Hanger

The size and spacing of joists and hangers used to support floor forms and their spacing are not given in the standard specifications since this depends on the form lumber thickness and the span distance between beams. These items should be proportioned to suit these conditions and design criteria.

The floor joists should be properly proportioned and spaced to support the flooring without excessive deflection under the load imposed. Joists may be supported by metal hangers hung over the beams or on wood bracing resting on the bottom flanges. Metal hangers should be the proper length so the underside of the concrete deck haunches will be flush with the bottom of the top flange of steel beams and the top of prestressed concrete beams.

T-Beam Type-Falsework

When the deck is to be of the cast-in-place concrete T-beam type, falsework is necessary. Falsework involves the placing and removal of temporary supports necessary for the construction of a permanent structure. Unless otherwise provided on the plans or approved by the Engineer, falsework will be supported on piling. Sketches must be submitted to C&T and Design Divisions whenever falsework is to be supported by any other means.

Falsework members should be adequate to carry the superimposed loads without excessive stress, crushing or deflection. A proposed falsework sketch that can be reproduced will be submitted by the Contractor for all concrete slab or concrete T-beam spans. Approval of the falsework and forms is required before any superstructure concrete is placed. Such approval, however, will not relieve the Contractor’s responsibility for the design adequacy and safety. Falsework will not be loosened or removed until the concrete has attained at least 70 percent of its design strength as determined by the Standard Specifications for Construction.

False Decking

See Section 706 of the Standard Specifications for Construction and the proposal for the false decking.

Bracing Fascia Forms

Particular care should be used in supporting and bracing fascia forms to ensure a pleasing appearance of the finished line and grade. Most Contractors now use a manufactured fascia bracket.

This bracket consists of two legs braced with a diagonal member is fastened to the top flange by a threaded bolt and is braced against the bottom flange and the vertical leg can be adjusted vertically to obtain the proper grade.

The horizontal leg carries the flooring and fascia forms and can be leveled if necessary by using hardwood wedges between the vertical leg and the bottom flange.

The Contractor may elect to use other means in forming the fascias. The fascia forms must be secured to the fascia girder and that only hardwood wedges should be used. Remember to obtain good lines and grades in finished concrete. The forms must remain securely in place during concrete forming.

Because of their location in the finished bridge, barrier, curb and railing lines are most important for appearance. Forms for this work should be constructed, aligned and braced with extreme care so they will remain rigid and true during the concrete placing. They should be graded for elevation, not just measured up a uniform distance from the deck surface. Forms scarred or worn from previous usage should be rejected before they are erected and braced.

Permanent Metal Deck Forms

See Section 706 of the Standard Specifications for Construction and the proposal for permanent metal deck forms.

Reinforcing Steel

Reinforcing steel should be stored on blocking.

The blocking should be arranged so the bars are off the ground for their entire length.

Reinforcing steel that has a light coating of rust may be used in the work.

Steel that has a rust scale or mud coating must be cleaned before it is used in the work.

Steel that is badly rust pitted should be rejected.

Epoxy-coated Resteel

Epoxy coated resteel must be stored on padded wood or padded steel cribbing and covered to prevent exposure to the sun's ultraviolet rays.

Epoxy coated resteel must be tied with coated tie wire. If the epoxy coating is damaged, it must be repaired as specified in subsection 706.03 of the Standard Specifications for Construction.

Bar Chairs

Each layer of reinforcing steel in the superstructure will be supported over the forms by approved chairs. Bar chairs are placed parallel to the beam and spaced (as measured between beam centers) at approximately the 1/4 and 3/4 points for beam spacings less than 9 feet (3 m) and at approximately the 1/6, 1/2 and 5/6 points for beam spacings 9 feet (3 m) and over.

Additional bar chairs are required outside the fascia beam to support the reinforcing steel along and near the fascia. On concrete box beams without slab ties, a bar chair will be required along the longitudinal centerline of each beam.

The upper layer of reinforcing steel will be supported over the supports for the lower layer of steel with rows of approved continuous steel bar supports consisting of a minimum of three longitudinal wires. Supports for holding reinforcement will be approved plastic or coated metal chairs.

When placing the top and bottom mat reinforcing, a check should be made on the bar size, number, spacing, length, tying and test tags. The bottom mat of resteel will be tied at alternate intersections where spacing is such that the product of the length and width is less than 120 square inches (77,500 mm2). Where the spacing is greater, all intersections will be tied. The top mat will be tied at all intersections regardless of spacing. Bars will be placed in the mat so the variation in spacing between adjacent bars will be less than 1/6 of the spacing shown on the plans. The top mat of reinforcing steel will be securely tied to the structural member at 5 foot (1.5 m) intervals along each beam or girder.

Placing Superstructure Concrete

Before placing any deck concrete, the inspector should check the forms and reinforcing steel to ensure cleanliness. All forms, joints and screeds should also be checked to ensure that their alignment and grade are correct. Check the details for the expansion device and verify the deck measurements to ensure the expansion device will fit properly after the deck is cast.

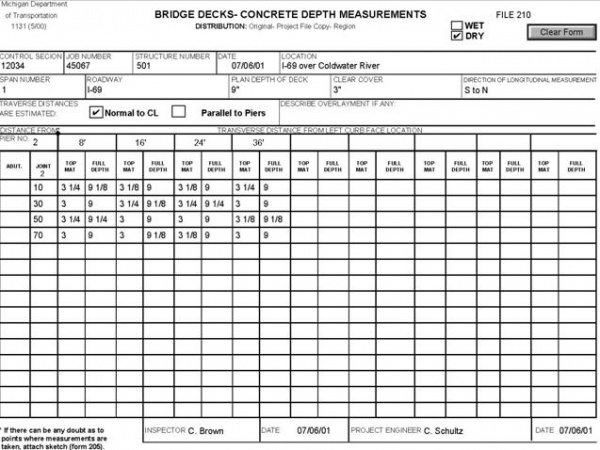

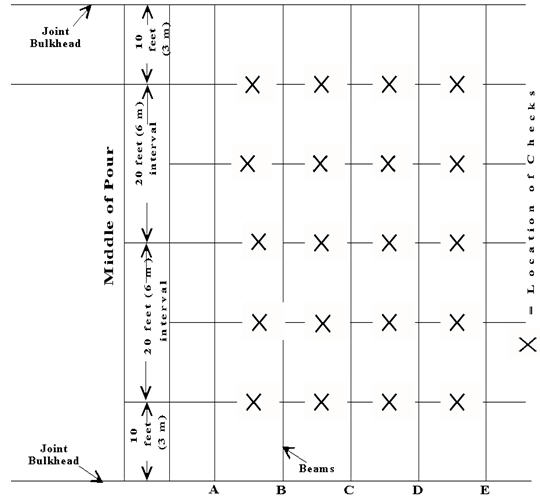

Setting the screeds on finishing machines is to be done by Contractor personnel from information shown on the plans or provided by the Engineer. Checking the screed is to be done by the inspector. After the screed rails have been set, the finishing machine is passed over the deck to check for plan slab thickness and resteel cover. The results are recorded on Form 1131 - Bridge Decks - Concrete Depth Measurements (Figure 706-1) as dry measurements. Measurements should be taken near each bulkhead [within 10 feet (3 m)], then at some interval [such as 20 feet (6 m)] for the remaining distance, including center span. Transverse spacing should aim for the center of the bay (see Figure 706-2).

During concrete casting, wet measurements will be taken at or near the same locations as the dry checks. These are recorded on Form 1131 as wet measurements. Enough wet checks should be taken at each location to ensure that proper cover and thickness is being obtained. If depth checks show a lack of cover or thickness, additional checks should be taken. A copy of Form 1131 should be sent to the Region Engineer/C&T Engineer.

Substructure

All steel reinforcement should be accurately placed in the position shown on the plans and firmly held during the placing of concrete. As placement progresses the following should be checked:

- Bar spacing - Will be within a tolerance of 1/6 of the spacing shown on the plans and the clear cover shown on the plans is a minimum requirement.

- Bar ends - When checking the cover, the bar ends should also be checked to ensure sufficient distance from the forms or joints.

- Bars - May be tied at alternate intersections if the product of the length and width of the spacing is less than 120 square inches (77,500 mm2).

- Epoxy-coated Resteel - Must be tied with coated wire.

- Bottom Mat of a Footing - Is generally supported by left-in-place or commercial grade concrete brick while the top mat is suspended by tie wire that is cut off and tucked into the concrete before it has attained its initial set.

- Laps - Should be checked to ensure that they equal the minimum shown on the plans and both ends of the lap will be tied.

- Substitutions - No bar substitutions should be allowed without an Engineer’s approval.

- Welding - On steel reinforcement will not be done at any time.

Subfooting

The purpose of a subfooting is to provide a working surface on which footing forms may be erected, reinforcing steel placed and substructure concrete cast without the presence of mud or water. Subfootings have no structural significance and pegs may be inserted for bracing the bottom of footing forms.

Subfootings are not normally required in construction of structures. Exceptions will be indicated on the plans or recommended by the Region Soils Engineer. Subfooting will be paid as Concrete, Grade S2.

When subfootings are required, foundation excavation will be measured to the bottom of the subfooting rather than to bottom of the footing. If the Contractor elects to place subfootings at company expense, payment for unclassified excavation will be measured to plan bottom of footing only. If subfootings are used, all inspection procedures will be followed as dictated under footings.

Tremie Seal Cofferdam

The purpose of tremie seal is to provide lateral support to cofferdam sheeting and provide sufficient mass to resist hydrostatic pressure when a cofferdam is pumped out. Grade T tremie concrete mix is required. Before placing any tremie concrete, the inspector should check the excavation for proper depth.

The arches of sheeting should be checked carefully to be sure they are clean to the full depth of the tremie. This will provide a watertight seal.

Tremie concrete must be carefully placed in a compact mass by means of a tremie pipe. Tremie concrete shall not be disturbed by mechanical vibrators or by other means after being deposited. The consistency of tremie concrete should be such that it will flow freely to prevent voids or honeycomb pockets. A slump of 3 to 5 inches (75 mm to 175 mm) is needed. The concrete will be placed full depth in one continuous operation, completing the work to grade progressively from one end of the cofferdam to the other.

Measuring Tremie Thickness

Care must be exercised to obtain the required seal thickness, as well as a reasonably level surface. A measuring device can be made using a 1/2 inch (13 mm) pipe of the required length with a 6 inch (150 mm) diameter metal plate fastened at the bottom end.

A wood pole and plate should be avoided because in overcoming buoyant force of the wood, you may be inadvertently forcing the plate into the tremie’s top surface causing a high top grade. Before placing operations are started, the water elevation surface should be referenced to a benchmark on the cofferdam sheeting above the water level. A measuring pole is marked for a distance from plan elevation at the top of seal to the elevation at the water surface. The water height must be checked often as the concrete will raise the water level in the cofferdam.

Tremie Checklist

A tremie pipe or bottom dump bucket will be used.

The tremie will have a hopper of at least 2 cubic foot (0.2 m3) capacity with a watertight discharge tube not less than 10 inches (250 mm) in diameter and of sufficient strength to perform the work.

The tremie’s lower end will be equipped with a suitable valve or device which will be tightly closed while the tremie is being charged and lowered into position, and which can be fully opened in the lower position.

The tremie will be supported to permit free movement of the discharge end over the entire work surface and to permit raising or lowering to adjust the concrete flow.

Care should be taken that the tremie tub is kept full to the bottom of the hopper.

When a batch is dumped into the hopper, the concrete flow will be induced by slightly raising the discharge end of the tube.

The tremie will be kept in the freshly deposited concrete at all times, being withdrawn only at the completion of each pour, or as required by piling or cofferdam bracing.

After withdrawing the tremie, it will be recharged with concrete above water and lowered to the new position where the discharge end can be set into the freshly deposited concrete.

Dewatering Cofferdams

Cofferdams will not be dewatered until the tremie concrete has attained a modulus of rupture of at least 325 psi (2.25 MPa) as determined by breaking test beams cured in water on top of the tremie concrete. Concrete cylinders will not be used to determine the tremie concrete strength. This strength check provided by breaking the cured beams will in no way be construed as relieving the Contractor of responsibility for failure in any cofferdam part.

All laitance or other unsatisfactory material will be removed from the exposed surface by scraping, chipping or other means, which will not injure the concrete surface, to ensure a clean surface of firm concrete to the grade specified.

Tremie surface tolerances are -0.0 inch to +6 inches (-0.0 mm to +150 mm). All concrete in excess of this tolerance will be removed.

Footings

The Contractor will be furnished with a stakeout diagram and elevation references to use in determining footing locations and excavation or fill elevations.

Upon completion of the excavation, the Engineer will verify line and grade. A foundation soils check should be made by the Region Soils Engineer. The inspector should make sure that all necessary corrections indicated in the foundation inspection report are made before the forming is started.

Placing Footing Concrete

After the footing forms are in place, they will be checked for dimensions and bracing. If discrepancies are found, the Contractor and Engineer will be notified. All foreign material such as water, mud, sand, etc., will be removed from inside the forms because it might coat the reinforcing steel and reduce the bond between steel and concrete.

For footings supported on piling, the piles should be checked to see that they are clean and properly cut off. The top surface of treated timber piling will be given a minimum of three coats of preservative. The tops of CIP piling should be cleaned of any foreign matter between the shell top and the concrete core top. Generally, the core is filled to within 1 inch (25 mm) of the shell top so this area always requires attention.

Care should be taken when placing concrete so the steel reinforcement or forms are not dislodged.

Templates, which are used to hold vertical steel in place during concrete placing, are to be laid out by the Contractor and checked by the inspector prior to pouring. All vertical reinforcement should be installed and tied in place prior to placing concrete. Sticking vertical reinforcement is not allowed.

Concrete should be placed in a continuous operation with no interruption in excess of 45 minutes between the placing of contiguous portions of concrete. Compaction should be by means of mechanical, high frequency internal vibrators. Vibrators will be manipulated to thoroughly work the concrete around the reinforcement and embedded fixtures, and into the corners and angles of the forms. The vibrators will be inserted vertically and withdrawn slowly.

The vibration will be of sufficient duration and intensity to thoroughly compact the concrete but without causing segregation or localized formation of grout.

Slump tests, air checks and temperature checks are required.

The top surface of the concrete will be finished with a wooden float to a smooth and level surface. During the finishing operation, the inspector should see that a keyway conforming to approximate plan dimensions is placed where called for on the plans. Curing should be started as soon as possible after finishing.

Joints

Joints are a source of considerable trouble. It is impossible to be too careful when placing these joints. It is extremely important to keep these joints straight and true at all times, particularly when premolded neoprene joint sealer is to be used. Forming for the joints should be secured very well before casting the deck as any movement of the forms will create a major problem with joint alignment. Be sure that expansion is provided in the forms when casting across an expansion joint.

Fiber Joint Fillers

Where joint filler is used, it is to be placed and adequately supported prior to starting the concrete pour. The material must be tested prior to use. It is best used in as large pieces as possible to avoid matching and piecing which can leave numerous concrete fins in the joint. During the concrete placing, precautions are necessary to avoid damaging or displacing the material.

On vertical surfaces where there is no support under the joint, the material should be firmly attached to one of the contacting surfaces to prevent its falling out when the concrete contracts and the joint opens. Special care must be taken when machine-finishing decks to keep the filler in position due to the lack of support in the absence of conventional joint forming.

Joint filler for all joints should be measured in place and the measurements entered in the field book prior to pouring; but computations may be used to substantiate final pay quantities.

Expansion Joint Devices

The Contractor will use expansion joint devices from the list of approved devices contained in the proposal.

The Contractor will inform the Engineer which expansion joint devices are selected for each location.

The Engineer will furnish the standard shop drawings of the joint device. These drawings will be general and will not include dimensions peculiar to the specific installation. These dimensions will be the Contractor’s responsibility and will not be reviewed by MDOT.

The devices will be installed as shown on the plans and the standard shop drawings.

All welding will be done according to subsection 707.03.D.10.d

All epoxy will be certified and dated.

Tack welding used to support the device will be done at the shear developers or form hanger supports.

No welding to the beam will be allowed.

All galvanized surfaces damaged by welding or cutting of the devices will be repaired.

The gland area and the glands will be protected at all times.

Poured Joint Sealer

Poured joint sealers will be of the type shown on the plans or specified in the proposal. Where hot-poured or cold-applied joint sealer is specified, the material handling requirements will be as specified under subsection 602.03.

Hot-Poured Joint Sealer

Where plans call for joint sealing with hot-poured rubber-asphalt type filler, special care and equipment are required to obtain a satisfactory job.

The material must be heated in a double boiler to a specified temperature and the material temperature should be maintained at or very near the temperature specified by the manufacturer. Direct heating will not be permitted.

An armored, high temperature thermometer should be used to check the heated material temperature.

The receiving joint should be sandblasted and all loosened particles blown out with compressed air, leaving the metal or concrete sides clean, dry and exposed.

Concrete joints may require only a power-driven wire brush and compressed air to clean them satisfactorily.

When hot-poured rubber-asphalt type filler is used, it should be poured somewhat high to allow for settlement and contraction when the material cools. Alternatively it could be placed in two separate passes.

Use of bituminous pipe caulking compound in the vertical curb joint will help retain the hot-poured filler in the top of the sidewalk joint.

Cold Applied Joint Sealer

When specified, expansion and construction joints in bridge decks may be sealed with a self-leveling, two component, polyurethane elastomeric, cold applied joint sealer. It may be either a machine mixed and applied type, or a slower setting hand mixed and applied type. This sealer is intended for use in concrete or steel faced joints in which the predicted movement does not exceed 40 percent of the average joint width. The location and configuration of the joints will be as shown on the plans.

Neoprene Joint Seals

Where neoprene is used in joints, the joints are normally sawn in the deck and formed in curbs and sidewalks.

Sawing Construction Joints - The joint groove at each transverse construction joint will be sawed to the dimensions shown on the plans. The joint groove will be symmetrical about the construction joint.

Sawing Expansion Joints - The expansion joint groove will be sawed to the dimensions shown on the plans and will be symmetrical about the filler centerline.

If the saw cut does not make contact with the filler used to form the joint’s lower part, the saw cut depth will be increased until it extends below the filler top.

Cleaning After Sawing - All deleterious material that may damage adjacent concrete by blocking the sawed joint or preclude later satisfactory operation or cleaning will be removed immediately after the sawing operation is completed.

Patching Transverse Joints - Patching transverse joints will be done as specified under Subsection 602.03.P.

Installing Seals - The installed seal’s top will be 1/4 inch (7mm) below the deck’s surface.

The joint seal will be installed in one continuous piece through the joint length as shown on the plans and according to the manufacturer’s recommendations.

Equipment - There are several different mechanical devices for inserting the neoprene which should result in the material being firmly held in the joint, slightly compressed and in tight contact with both surfaces.

Concrete Curing

Curing is one of the most important phases of any concrete operation.

Concrete curing aids in the development of strength and resistance to weathering. Proper curing also adds to the wear-resistant qualities which are essential in deck concrete. Curing is based on the idea of retaining the mixing water in the concrete as the chemical reaction takes place. Two methods used to accomplish this are:

- Keeping the surface wet to prevent evaporation; or

- Sealing the surface to retain mix water.

Curing should be started as soon as possible after the concrete is placed and textured.

The Standard Specifications for Construction require that all concrete floors, wearing surfaces, bridge seats and other exposed top surfaces be cured for a period of seven days. All other surfaces must be cured for five days.

The curing methods allowed on different parts of the structure vary and the standard specifications should be consulted to determine the proper method to be used.

When wetted burlap or other similar curing types requiring water are used, they should be checked frequently to ensure that the concrete surface is kept continuously wet. This is especially true on hot, dry days.

Bridge Deck Curing

Requirements for Two-Step Process:

Bridge deck curing will be instituted as soon as texturing is complete.

Bridge decks will be sprayed with curing compound as specified in subsection 903 for immediate protection until concrete is sufficiently hard to allow wet curing to be applied (no later than the following morning).

It must be applied with spray equipment capable of producing a continuous uniform film of the required thickness [not less than 1 gallon per 150 square feet (0.2L/m2) per coat].

Application of curing compound shall progress so as not to leave more than 10 linear feet of textured concrete surface exposed without using curing compound at any time.

First phase to be applied immediately upon completion of concrete finishing operations. Second phase will be applied as soon as the first coat becomes dry enough to avoid runoff, and consists of covering the concrete surface with clean, contaminate free burlap as soon as the curing compound has dried sufficiently to prevent adhesion and the concrete surface will support it without deformation; in any case, within two hours after the concrete was cast.

A minimum of 12 hours prior to the commencement of concreting operations, the burlap shall be soaked continuously in water. A network of soaker hoses shall be installed over the wet burlap as soon as the concrete surface will support it without deformations. A continuous layer of 4 mil polyethylene film shall be placed over the entire deck.

Care should be taken to prevent overspray in sidewalk, parapet, brush block, etc., areas as this spray has been found to destroy the bond of subsequent concrete pours.

If these areas are sprayed, it will be necessary to sandblast them before the subsequent pour is made.

Transparent Membrane Curing Compound

When transparent membrane curing compound is to be used:

It must be applied with spray equipment capable of producing a continuous, uniform, nonsagging film of the required thickness [not less than 1 gallon per 300 square feet (0.14 L/m2) per coat].

It is to be applied in two coats.

The first coat is to be applied as soon as the forms are removed, and the second applied not less than 30 minutes or more than 2 hours after the first coat.

It will not be used on surfaces where other concrete is to be bonded or where joint waterproofing or epoxy sealants are to be applied.

Surfaces of steel dowels, anchors, waterstops or similar devices must be compound free at the time of encasement.

Water Repellant Treatment

This treatment is commonly used on piers and abutments beneath deck expansion joints to shield bearing areas from corrosive elements. Structural concrete to be sealed for any structure will be as shown on the plans or as designated by the Engineer. Manufacturing specifications, preparation of area to be covered, methods of mixing, proper applications and precautions in using are spelled out in the Standard Specifications for Construction.

MEASUREMENT AND PAYMENT

-Reserved-