707 - Structural Steel

GENERAL

Structural steel construction involves the fabrication, handling, erection, bolting and welding of steel members used in structural applications. Most structural steel for Department projects is comprised of bridge elements – plate girders and rolled beams, intermediate and end diaphragms, connection plates and stiffeners, cover plates, beam bearings, pin and hanger assemblies and foundation piling. All these elements can be further defined as primary or secondary members, per 707.01 of the MDOT Standard Specifications for Construction. Structural steel may be in the form of plate, rolled or bent shapes, hollow structural shapes, tube railing, steel deck grating, modular expansion joints, bars and pins, etc. Structural Steel also includes other highway appurtenances such as sign and lighting support structures, tower lighting units, mast arm traffic signal supports, and bridge mounted signs.

Structural steel elements are typically fabricated at steel fabricators around the country, who must be certified by the American Institute of Steel Construction (AISC) to the appropriate level for the work being conducted. Bolting, welding, and coating of structural steel takes place both at fabrication shops and in the field, depending on the application. The departments Structural Fabrication Unit of Bridge Field Services oversees the departments QA program for fabrication of structural steel, and should be consulted for any issues that arise out of structural steel fabrication, erection, or construction.

Shop Plans

Shop plans with complete detailed dimensions are submitted to MDOT for review and approval. This review and approval are required prior to fabrication, but MDOT does not check every dimension for accuracy. The submission is revised to ensure it is complete and in general conformance with the contract plans.

The Contractor is solely responsible for the correctness of working drawings. Errors found during the review of the shop drawings will be pointed out by MDOT but undiscovered errors are the Contractor's responsibility.

Upon receipt of the shop fabrication and erection plans at the field office, the inspector will check each sheet against MDOT’s general plans. Particular attention should be directed to span lengths and anchor bolt spacing. The sole plate thickness diagram on the shop plans will be checked. If this has not been done, it will be necessary to perform this work on the bridge site.

Shop Drawing Submittal - The Contractor/fabricator shall submit to the Engineer (Resident, Project, Delivery) the number of copies of the shop drawings according to Chapter 10 of the Bridge Design Manual and subsection 104.02 of the Standard Specifications for Construction. The Engineer (Resident, Project, Delivery) shall forward these to the Bridge Design Unit or Bridge Consultant Coordination Unit of the Design Support Area.

Approved Shop Drawing Distribution - Upon receipt of the five sets of approved shop drawings from the Design Support Area, the Engineer (Resident, Project, Delivery) shall forward two sets of these copies to the Contractor.

Structural Steel Weights (Shop Bills) - The Contractor/fabricator shall submit to the Engineer (Resident, Project, Delivery) four copies of the shop bills according to Chapter 10 of the Bridge Design Manual and Section 707 of the Standard Specifications for Construction. The Engineer (Resident, Project, Delivery) shall forward these to the Bridge Design Unit or Bridge Consultant Coordination Unit of the Design Support Area.

Approved Structural Steel Weights (Shop Bills) Distribution - Upon receipt of the two sets of approved structural steel weights from the Design Support Area, the Engineer (Resident, Project, Delivery) shall forward one set to the Contractor.

Erection Plan

The erection plan will be studied and the location and orientation of match-marked pieces noted. These markings are usually placed on the end of a member and will be erected with this marking in the same location as shown on the erection diagram.

Field Bolt List

The field bolt list, as furnished with the shop plans, should be understood by the inspector. Bolt lengths are predetermined for a particular joint and it is important that each lap thickness have the proper bolt length. Bolts which are too long may not have sufficient thread length, so that bolt length minus thread length leaves a grip length greater than the thickness of the materials being jointed, and the nut jams before drawing the materials together. The bolt must engage all threads of the nut to ensure proper bolt/nut capacity.

Falsework

Falsework is a form of temporary support and may be required in the erection of steel for some projects. Often it is required at beam splices, usually on long spans or when special erection procedures are called for. A drawing of the proposed falsework must be submitted by the Contractor and approved by the Engineer. Such approval does not relieve the Contractor’s responsibility for design adequacy. The inspector should ensure that the falsework is assembled as shown on the approved drawings and that all bolted and welded connections are properly completed.

MATERIALS

Delivery Checklist

- Upon delivery of structural steel, the inspector should check for the shop inspector's "approved for use" stamp on all principal members.

- Where steel is shipped to the job without the recommended approval mark, the region Bridge Engineer is to be advised before erection.

- C&T Structural Fabrication Engineer should be contacted to verify that the steel has been inspected and approved.

- Fabrication reports must be placed in the project files but usually they are not received until after the material has been shipped.

- It is the Engineer's responsibility to check steel as received and report shipping damage to the paint or the steel members to C&T Structural Fabrication Engineer and the Contractor for repair or replacement.

- Errors in fabrication will also be reported to C&T Structural Fabrication Engineer by the Engineer.

- The Engineer should use care in authorizing any corrective work until the responsibility for the error has been determined.

- The proposed corrective work should be reviewed by the C&T Structural Fabrication Engineer prior to its approval.

- Masonry and bearing plates should be checked for damage in handling and shipping.

- Structural steel should be stored on adequate supports to preserve its shape and quality.

- Members are to be stored in an upright position and should be thoroughly braced to avoid overturning, which may damage the member itself, adjacent members or material, or injure personnel in the immediate vicinity.

- Members should be so arranged that depressions, troughs, and similar "moisture traps" may be eliminated as much as possible.

- The blocking should be high enough so that the steel members don't come in contact with the ground or sit in ponded water or mud.

- Padding must be used to prevent paint damage when chains or cables are used to brace or erect structural steel.

- Related items such as bolts, washers, plates, and rockers should also be protected from damage, dirt, and corrosion.

CONSTRUCTION

Erection

The first field erection operation is the placing of masonry plates.

Masonry Plates

These plates are placed on the concrete bridge seats of abutments and piers as shown on the plans. The inspector will see that concrete surfaces are perfectly flat at bearing locations and, if necessary, see that all high spots are ground to provide full bearing under each plate. Check plates to see they are not warped. The inspector should check the bearing of each individual plate by applying pressure to corners of the plate. Lead sheets should be placed under the masonry plates when so designated on the plans. Low spots under edges of plates should not be filled with grout as this thin layer often will not bond and will deteriorate under load and weathering action.

Masonry plates and expansion rockers will be match-marked to the centerline of bearing line previously marked on the concrete bearing surface by the instrument crew. If masonry plates are not center marked, it will be necessary for the inspector to establish these marks on each unit. In doing this, locate the match line by using anchor bolt holes as the center. When erecting each unit, these marks will match the centerline of bearing lines previously placed on the bridge seat.

At the time of erection, machine finished bearing surfaces will be coated with a suitable commercial grade lubricant suitable for bearings.

On projects where sole plates are welded to the bottom flange of WF-beams or girders, it will be necessary to shift the entire beam to align marks.

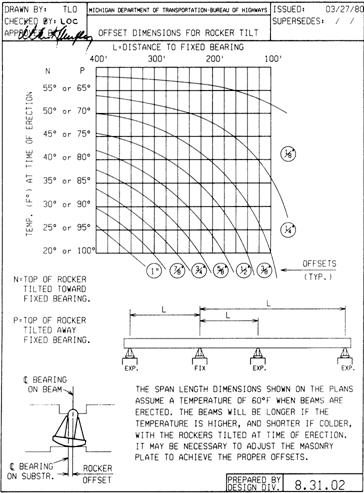

Use the Offset Dimension for Rocker Tilt chart (see Figure 707-1) to adjust for temperature.

In considering suspended span ends, the required opening should be maintained at the moving end. It makes little difference what the opening is under a field welded stay plate because it will never move. A check should also be made at independent backwalls to verify enough beam end clearance to accommodate the maximum expansion.

Horizontal Stabilization

As WF-beams and plate girders are erected, sufficient horizontal stabilization must be provided for each beam to prevent the beam from tipping over.

This is an important phase of erection and may prevent serious accidents and damage to steel beams caused by high winds or crane booms striking erected sections.

|

|

|

|---|---|

|

|

Bolting beams to piers or abutments |

|

|

Placing diaphragms as erection progresses |

|

|

Placing falsework |

Placement Sequence

Particular attention will be given to cantilevered center spans. End diaphragms and lateral bracing on skewed bridges will be placed as erection progresses to assure proper fit or to determine assembly problems at the earliest phase possible. These members are, in effect, control members and must be placed in proper sequence. Project inspectors should insist that skewed diaphragms be placed at the time each stringer is set and before any final bolting of intermediate diaphragms. If the fabrication and design are correct, all the steel should fit.

Flame cutting is not allowed to bring members and connections into proper alignment.

If reaming is required to bring members and connections into proper alignment, it should be approved by the Engineer. Excessive pressure should not be used to force members into place, particularly on diaphragm assembling. Sweep can be forced into the main member by diaphragms rammed into place when the length of the diaphragm has as little as a 13 mm error. This develops across the structure to a serious sweep. When the bridge components don't appear to assemble correctly, a careful check must be made to determine if the pieces are properly match-marked.

Heat Straightening

Kinks or sharp bends are cause for rejection. If it is necessary to straighten bent material, methods will be used to prevent fracture or other injury. If heating is permitted by the Engineer, it must be supervised by one of C&T’s fabrication inspectors. Temperature greater than 1200°F (649°C) is not allowed. The straightened member will be allowed to cool slowly and water will not be used to reduce the temperature. After straightening, the inspector will check the surface for fine cracks. Hammering which will damage and distort surfaces will not be done.

Minor Misalignment of Holes

If minor hole misalignment occurs on projects not specifically set up for reaming, the Engineer will be consulted regarding corrective measures to be used. Often the main splice plates on girder splices appear to be slightly out of alignment. When this occurs, the plates need to be inverted or rotated according to the match-marking. Never ream on main girder splice plates.

The inspector will observe reaming operations to ensure the correct size reamer is being used. Also, holes will be reamed perpendicular to the member faces and all burrs will be removed. Members should be tightly clamped together to prevent metal chips from getting between surfaces.

Deck Drains

After the steel is erected, the inspector will check the deck drain locations to ensure that water will not be drained directly over some members, such as diaphragms, and that they extend well below the bottom flanges of the beams or girders.

Bolted Field Splices

All field splice plates should be shipped in the assembled and drilled position, except that they are moved back one-half joint. The plates are brought forward on the beams to their final position. Occasionally, ironworkers inadvertently take the plates off, thus creating considerable difficulties. All plates, including the flanges, are required to be match-marked and it should be possible to determine the location and orientation of each plate. The match-marking scheme used should be shown on the approved shop drawings.

If the plate hole alignment is difficult to achieve and they appear to require reaming, a mismatch should be suspected. The only reaming should be an occasional hole that missed being reamed during fabrication.

The joint should be straightedged or stringlined during the final bolting operation and adjustments made as required in grade or alignment to ensure straightness at the splice.

Camber

On WF-beam and plate girder spans, the normal sag which occurs when the beam is loaded is necessary to offset this by either fabricating a camber in a beam or thickening the concrete haunch over the beams. Sometimes a combination of both is used. Also, beams may not be true to line and variances in elevation have to be provided for. Therefore, a convenient method of establishing the finished grade before casting concrete is desirable.

The superstructure plans for steel deck girder bridges may show a construction camber diagram sketch and another indicating top of screed elevations with slab thickness ordinates.

Plan camber of structural steel and precast prestressed beams is built into the member with a small plus or minus tolerance permitted as shown on the plans. The fabrication is checked by an inspection agency or the C&T shop inspector to see that the members are fabricated to the tolerance permitted. In steel members, the camber in the shop is usually measured with the beam on its side. Estimated reduction in camber is then tabulated on the plans to cover camber loss due to the weight of the member, forms and reinforcing steel; welding of stud shear connectors; and the deflection from the weight of the concrete deck.

It is the Contractor's responsibility to erect the beams within the permitted camber tolerance. Any corrective work to obtain this camber is the Contractor's responsibility. Any proposed corrective work should be reviewed by the C&T Bridge Engineer before approving.

When camber varies from the plan, it should be possible to adjust haunches and/or top of slab grades to allow for discrepancies.

High Strength Steel Bolts

When heavy hexagon bolts and heavy semifinished hexagon nuts are used, a hardened washer must be assembled under the nut or bolt head, whichever is the element being turned. Bolts and nuts may be washer faced but these faces do not take the place of a hardened washer. Bolts, nuts, and washers supplied for shop painted or galvanized members must be galvanized.

|

|

|

|---|---|

|

Heavy Hexagon Bolts |

Are identified by three radial lines 120° apart, the legend A 325 , and the manufacturer's mark on the top of the head. |

|

Heavy Semifinished Hexagon Nuts |

Are identified by three circumferential marks, or by the designation C, DH, or 2H, and the manufacturer's mark on at least one face. |

|

A 325 Bolts |

See Table 707-1. Minimum Bolt Tension for ASTM A 325 Bolts |

|

ASTM A 325, Type 1 Bolts |

Are required in all structured applications. |

|

| |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Bolted Joint Assembly

The slope of surfaces of bolted parts in contact with the bolt head and nut will not exceed 1:20 with respect to a plane normal to the bolt axis. Where an outer face of the bolted parts has a slope of more than 1:20, a smooth beveled washer will be used to compensate for the lack of parallelism.

Prior to assembling, all joint surfaces, including those under the bolt head, nut, or washer must be free of oil, grease, burrs, dirt, or other foreign material that would prevent the solid seating of the parts. On shop painted steel, a carefully controlled coating of zinc rich primer has been applied to all faying (i.e., contact or friction) surfaces. No other coating should be applied to these surfaces prior to bolting.

When making bolted attachments to existing structural steel, the contact surfaces on the old steel should be blast cleaned and prime coated with zinc rich paint as called for on the plans or in the specifications.

Bolt Tension

Each bolt must be tightened to provide the minimum bolt tension shown in Table 707-1.

All bolts and nuts that have been snug tightened only may be removed and reused. Bolts and nuts that have been tightened beyond the snug stage will not be reused if loosened or removed.

Turn-of-Nut Tightening

All bolts will be tightened by the turn-of-nut method. If required because of bolt placement and wrench operation clearances, tightening may be done by turning the bolt while the nut is restrained from rotation. Impact wrenches, if used, will be of adequate capacity and sufficiently supplied with air to perform the required tightening of each bolt in approximately ten seconds.

There will first be enough bolts brought to a snug tight condition to ensure that the joint parts are brought into full contact with each other. Snug tight is defined as the tightness attained by a few impacts of an air impact wrench or the full effort of a person using an ordinary spud wrench. Note that when the plates or parts being bolted cannot be drawn into full contact by "snug tightening" bolts, a few temporary bolts should be fully tightened to force the surfaces into contact. These temporary bolts should then be marked for removal and replacement. The remainder of the bolts should then be snugged and tightened. Then remove and replace the bolts tightened to force surface contact.

All bolts in the joint will be tightened by first the snugging and then by applying the applicable amount of nut rotation as specified in Table 707-2. Nut Rotation From Snug Tight Condition.

The element being turned, either the nut or the bolt, will be marked after snugging to visually verify the proper rotation has been achieved. The marking should be done with a felt tip ink pen (do not use keel, chalk or soap stone) according to the scheme shown in Figure 707-2.

Tightening will progress systematically from the most rigid part of the joint to its free edges. During this operation there will be no rotation of the part not being turned by the wrench. This usually requires the stationary element being restrained by a spud wrench. After tightening, the bolt must, as a minimum, engage all threads of the nut to ensure proper bolt/nut capacity.

Table 707-2. Nut Rotation From Snug Tight Condition*

|

| ||||

|---|---|---|---|---|

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

Over 12 diameters |

No research work has been performed by the Research Council on Structural Connections to establish the turn-of-nut procedure when bolt lengths exceed 12 diameters. Therefore, the required rotation must be determined by actual tests in a suitable tension device simulating the actual conditions. | |||

*Nut rotation is relative to bolt, regardless of the element (nut or bolt) being turned.

Welding

Field Welding

Field welding and nondestructive testing will be performed according to subsection 707.03.D.10 of the Standard Specifications for Construction and the current American Welding Society (AWS) Bridge Welding Code D1.5. Field welding is not allowed unless shown on the plans or authorized by the Engineer.

All structural field welding will be done by the Shielded Metal Arc Welding (SMAW) process using E7018 electrodes. Gas Metal Arc Welding (GMAW) and other gas shielded processes are prohibited. Submerged Arc Welding (SAW) and Flux Cored Arc Welding (FCAW) may be allowed for field welding when approved by the Engineer.

Welder Qualifications

Structural welding or welding repair work will require MDOT qualification testing. The field welder must present a certification stating qualifications according to AWS Specifications within the previous two-year period. The Project Engineer will contact the C&T Structural Fabrication Engineer to arrange for welder qualification testing. The Engineer may require a confirming qualification test during work progression.

Field welders must be qualified in the position, shape of joint, classification of electrode, base metal type, and preferably the maximum electrode diameter actually being used to perform the work.

All welding falls into one of two categories: either fillet (F) series or groove (G) series. Fillet welding is encountered when any two structural shapes or plates are joined by lapping or butting together without any joint preparation and, conversely, groove welding requires a specified root opening. Because groove welding requires a greater skill and the welder qualification test is somewhat more severe than the fillet weld test, MDOT grants automatic qualification for certain (F) positions, provided the welder has passed a corresponding or higher (G) qualification test. The following Table 707-3. Welder QualificationBType and Position Limitations is furnished to assist in ascertaining which positions automatically qualify other positions.

|

Qualification Test |

Type of Weld and Position of Welding Qualified* | ||

|---|---|---|---|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

*Position of welding: F = Flat, H = Horizontal, V = Vertical, OH = Overhead

Groove Welds

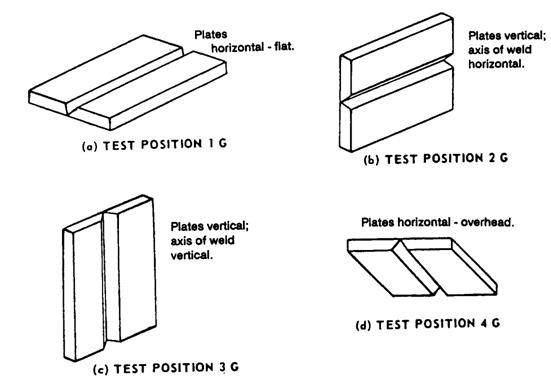

For the purpose of determining the welder’s ability to make a groove weld in various positions, the following tests are required as shown in Figure 707-3.

|

Test Position |

Description |

|---|---|

|

|

The test plates are placed in an approximately horizontal plane and the weld metal deposited from the upper face side. This test will qualify the welder for flat position welds only. |

|

|

The test plates are placed in an approximately vertical plane with the welding groove in an approximately horizontal plan. This test is satisfactorily performed and will qualify the welder for both flat and horizontal welds. |

|

|

The test plates are placed in an approximately vertical plane with the welding groove approximately vertical. All passes are made starting at the bottom of the joint and progressing to the top of the joint. This is called uphill welding or vertical up and is the only vertical welding allowed. Welding a vertical joint downward is never acceptable. |

|

|

The test plates are placed in an approximately horizontal plane and the weld metal deposited from the underside. Completion of the 3G, and 4G welder tests qualifies for all positions of fillet and groove welding. |

Fillet Welds

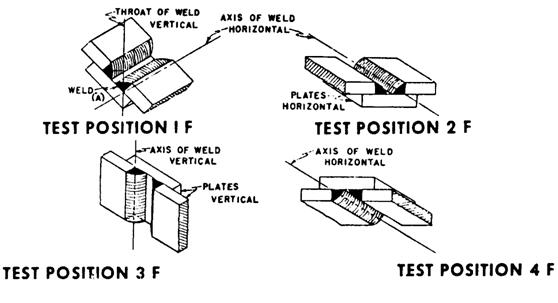

For the purpose of determining the welder’s ability to make fillet welds in the various positions, the following positions for tests are required as shown in the following table:

|

|

|

|

|

|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Contractor may use E6010, E7015, E7016, or E7018 electrodes only for pile splicing.

Shear Developers

Shear developers are used to provide a composite section between the concrete deck and the steel beams supporting it. This composite section generally allows the designer to reduce the beam size required. They are in the form of steel studs and are welded to beam flanges at the spacing shown on the plans.

Stud shear developers are being certified in the same manner as electrodes and must be selected from the Qualified Products List.

Other shear developers may be used providing the supplier certifies that they meet the requirements of the current AWS D1.5, Section 7, “Stud Welding.”

Defective stud welds can usually be attributed to four main causes:

- welding on contaminated coatings (oil, grease etc.), wet, or moist beams with damp ferrules.

- welding with insufficient amperage.

- welding with a stud gun that is out of adjustment (arc length and plunge).

- welding too close to the flange edge.

Before welding studs to the beams, the specifications require that all coatings be removed by grinding in the weld area and that all moisture, oil, grease, or other dirt be removed.

New operators have a tendency to tip the studs slightly, increasing the chances of producing defective welds. Also, they sometimes do not hesitate long enough to allow the weld metal to cool.

When the welding operation is delayed due to rain, the flange surface must be dry before commencing welding and any ferrules which were dampened due to the rain must be replaced with dry ones.

Prior to the welding operation, it is advisable for the Engineer to discuss with the Contractor the procedure which will be used to repair all studs which lack a full 360° fillet. The Contractor can repair defective studs by manually adding either a fillet weld to each stud that lacks weld metal, using E7015, E7016, or E7018 electrodes, or by adding new studs adjacent to the defective ones.

Testing Studs

Studs are tested by ringing with a hammer. To test the studs, the inspector should allow to cool before testing. The first two studs welded will be bent to a 30 degree angle without breaking the weld. If the weld breaks, repairs will be made and the next set of studs tested along with the studs that were repaired. The rest of the studs on that beam can then be checked for proper welding. Sufficient tests should be made to insure proper procedures are being followed (bend over additional studs). If a weld defect is found, the stud may be bent to an angle of 15 degrees away from the defect. If no weld break occurs, the stud is acceptable. No welding will be done when the temperature of the base material is below 32°F (0°C) or when the surface is wet or exposed to rain or snow.

MEASUREMENT AND PAYMENT

-Reserved-