707 - Structural Steel

-THIS SECTION UNDER REVISION-

GENERAL

Structural steel construction involves the fabrication, handling, erection, bolting and welding of steel members used in structural applications. Most structural steel for Department projects is comprised of bridge elements – plate girders and rolled beams, intermediate and end diaphragms, connection plates and stiffeners, cover plates, beam bearings, pin and hanger assemblies and foundation piling. All these elements can be further defined as primary or secondary members, per 707.01 of the MDOT Standard Specifications for Construction. Structural steel may be in the form of plate, rolled or bent shapes, hollow structural shapes, tube railing, steel deck grating, modular expansion joints, bars and pins, etc. Structural Steel also includes other highway appurtenances such as sign and lighting support structures, tower lighting units, mast arm traffic signal supports, and bridge mounted signs.

Structural steel elements are typically fabricated at steel fabricators around the country, who must be certified by the American Institute of Steel Construction (AISC) to the appropriate level for the work being conducted. Bolting, welding, and coating of structural steel takes place both at fabrication shops and in the field, depending on the application. The departments Structural Fabrication Unit of Bridge Field Services oversees the departments QA program for fabrication of structural steel, and should be consulted for any issues that arise out of structural steel fabrication, erection, or construction.

Project Scheduling

Once a bridge project is awarded, the contractor will place an order with a structural steel fabricator. The structural steel fabricator will then need to place an order with a steel mill for the required plates and shapes. The steel mills produce heats of different types and sizes of steel. For example, a mill may produce 36-inch rolled beams one week and piling the following week. Other mills may exclusively produce plates but only roll certain thicknesses once or twice a month. Structural steel rolled in a given heat is typically already devoted to an already placed order, and the mill rolling typically occurs between four to twelve weeks after the order has been placed. Many factors influence when a fabricator can take delivery from a mill, including demand from other states’ bridge programs, demand from other domestic and international industries, cost, availability, and stockpiles of raw material; and production status of mills around the country. Fabricators do not stockpile most types of beams or plate steel. This is consistent with the just-in-time concept of manufacturing common in industry today.

For some small orders or certain types of steel, such as pin and hangers (link plates and pins), fabricators can purchase the needed steel through warehouses or they may have their own supply. For emergencies, such as from a high load impact, fabricators can purchase the needed steel items from national warehouses. However, the cost of this steel may be much higher, and is not economically feasible (to the fabricator or the state) for large orders.

Table 707.1 below details the recommended timelines in which steel delivery to the project site can be expected. Table 707.1

| Work Item – Order and Delivery of Steel Beams | Time |

|---|---|

| Plate Girders and Rolled Beams – with flange thicknesses less than three inches | 26 weeks after award |

| Bascule, Arch, Tub Girder, High Performance Steel (HPS Grade 70 or 100), Plate Girders and Rolled Beams – with flange thicknesses three inches or greater | Consult Structural Fabrication Unit )(*) |

- (*)Contact Matthew Filcek (517-322-5709) or Jeff Weiler (517-322-1235) of the Operations Field Services Division’s Structural Fabrication Unit for assistance in developing the timeframes for order and delivery of steel in preparing the progress clause.

For plate girders and rolled beams with flange thicknesses less than three inches, the recommended time from award to delivery at the project site is based on the following.

- Up to three months for steel delivery from mill to fabricator

- Up to two months for fabrication

- Up to one month for submittal and approval of requests for information (RFI’s) and shop drawings, and shipping of the fabricated product to the project site

While in many cases delivery can occur before the 26 week time frame, there are many variables which can influence steel delivery and frequently they cannot be determined at the time the progress clause is written. In addition to the factors influencing delivery of steel from the mill to the fabricator, the contractor that is awarded the contract and the fabricator they choose can affect the timeline. The fabricator chosen by the contractor may have less work or greater production capabilities than another fabricator. Some fabricators may try to book their production schedules such that by late winter or early spring they are fully booked through the summer or into fall. For this reason jobs let in the spring may have fewer fabricators available to complete the work and the jobs can be difficult to complete in one season especially if designed for part-width construction. In addition, the timeline to deliver steel beams for stage one of a part-width project may take the majority of the recommended timeline for delivery of both stages as the fabricator may elect to apply some aspects of fabrication to both stages instead of completing stage one in total before starting on stage two. The mill order and other milestones may take equal time whether they include one or both stages.

For the reasons outlined above, it is recommended that the Table 707.1 be used when developing progress clauses for projects with steel superstructures. Careful consideration is to be made on projects with staged construction, or interim completion or interim open to traffic dates.

Shop Drawing Review Process

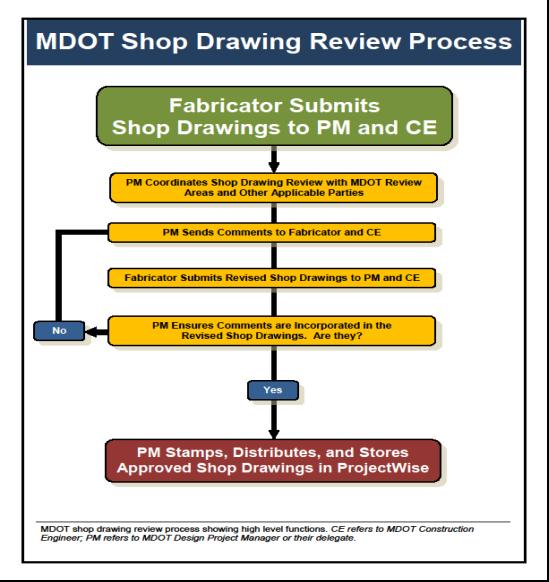

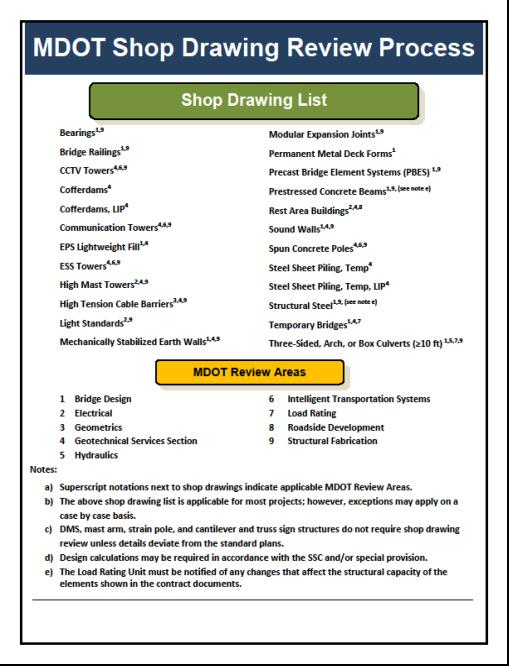

It is the responsibility of the MDOT Design Project Manager (PM) to ensure their project’s shop drawings are being reviewed by all applicable technical reviewers. This process is outlined in Chapter 10 of the MDOT Bridge Design Manual. Figure 707.1-1 and Figure 707.1-2 below summarize MDOT’s electronic shop drawing review process and provides a listing of shop drawings to be reviewed with annotations indicating which MDOT Review Areas need to be involved in their review. Note that this shop drawing listing is general in nature and is applicable for most projects; however, exceptions may apply on a case by case basis and it is the responsibility of the PM to ensure the shop drawings are being reviewed by all applicable parties.

MATERIALS

Delivery Checklist

- Upon delivery of structural steel, the inspector should check for the shop inspector's "approved for use" stamp on all principal members.

- Where steel is shipped to the job without the recommended approval mark, the region Bridge Engineer is to be advised before erection.

- C&T Structural Fabrication Engineer should be contacted to verify that the steel has been inspected and approved.

- Fabrication reports must be placed in the project files but usually they are not received until after the material has been shipped.

- It is the Engineer's responsibility to check steel as received and report shipping damage to the paint or the steel members to C&T Structural Fabrication Engineer and the Contractor for repair or replacement.

- Errors in fabrication will also be reported to C&T Structural Fabrication Engineer by the Engineer.

- The Engineer should use care in authorizing any corrective work until the responsibility for the error has been determined.

- The proposed corrective work should be reviewed by the C&T Structural Fabrication Engineer prior to its approval.

- Masonry and bearing plates should be checked for damage in handling and shipping.

- Structural steel should be stored on adequate supports to preserve its shape and quality.

- Members are to be stored in an upright position and should be thoroughly braced to avoid overturning, which may damage the member itself, adjacent members or material, or injure personnel in the immediate vicinity.

- Members should be so arranged that depressions, troughs, and similar "moisture traps" may be eliminated as much as possible.

- The blocking should be high enough so that the steel members don't come in contact with the ground or sit in ponded water or mud.

- Padding must be used to prevent paint damage when chains or cables are used to brace or erect structural steel.

- Related items such as bolts, washers, plates, and rockers should also be protected from damage, dirt, and corrosion.

CONSTRUCTION

Fabrication of Structural Steel

A. Prefabrication Meeting

The Structural Fabrication Unit will conduct a prefabrication meeting with the fabricator when deemed necessary. Prefabrication meetings are generally scheduled when the fabrication is more complex in nature or the fabricator is new to working with the Department but can be held for any project.

B. Shop Inspection

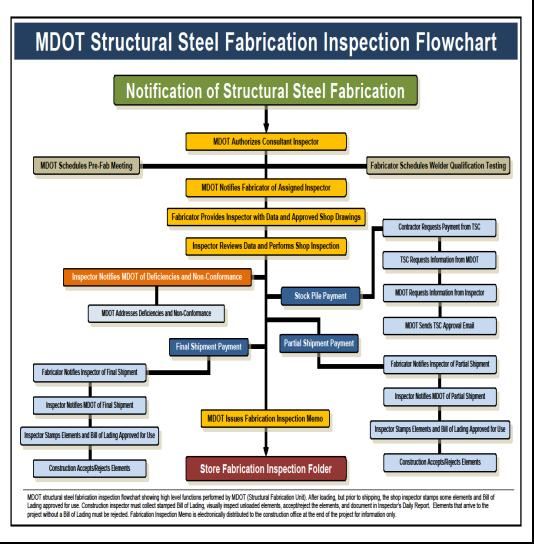

Quality assurance inspection is performed on all structural steel fabricated for the Department during all phases of the fabrication process. The Department’s quality assurance program is implemented by Bridge Field Service’s Structural Fabrication Unit and utilizes vendor Certified Welding Inspectors (CWI) to perform shop inspection at structural steel fabrication facilities nationwide. The contractor is required to provide MDOT an accurate 2 week notice prior to the beginning of fabrication so that shop inspection can be coordinated in accordance with subsection 707.03 of the MDOT Standard Specifications for Construction. Throughout the fabrication process the shop inspector will inspect the materials and fabricated elements for conformance to Department specifications, collect all documentation regarding the fabrication, and verify Buy America provisions were met. If problems arise during the fabrication, the shop inspector will contact the Structural Fabrication Unit for resolution. Once fabrication is complete and the elements are ready to be shipped to the project site, the shop inspector will stamp the elements as well as the shipping documents “Approved for Use”. See Figure 707.2. The CWI then submits all fabrication documentation to the Bridge Field Services Structural Fabrication engineer for placement into the corresponding ProjectWise folder.

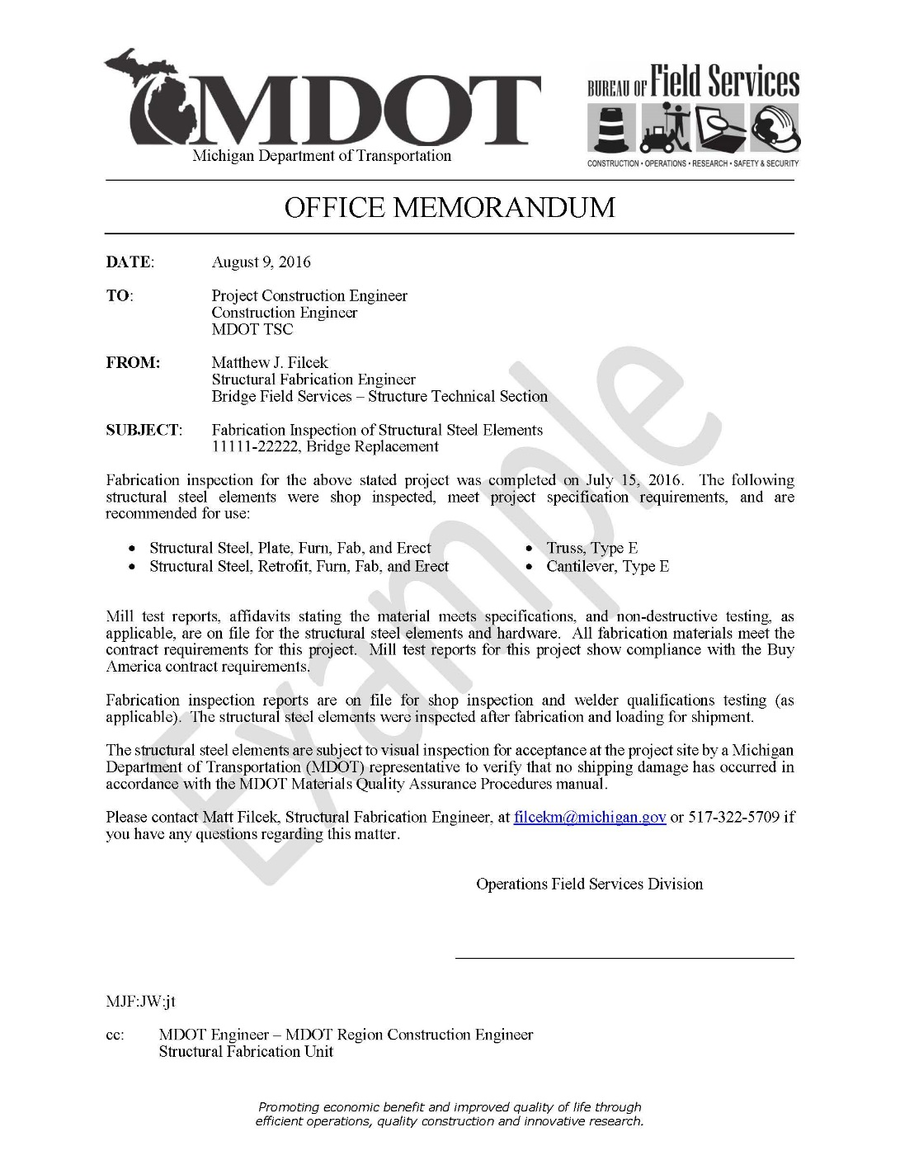

The Structural Fabrication Unit will send a fabrication inspection memorandum electronically to the project office at the end of each project. This memorandum is not the basis of acceptance, but rather a brief summary of the fabrication inspection for the project. The project office should place this memorandum in their project files and use it as a reference when requesting fabrication information from the Structural Fabrication Unit. See Figure 707.3 for more information on the fabrication inspection process and Figure 707.4 for a sample inspection memorandum.

MEASUREMENT AND PAYMENT

-Reserved-