Difference between revisions of "708 - Prestressed Concrete"

| Line 46: | Line 46: | ||

{{top}} | {{top}} | ||

| − | ===[[# | + | ===[[#PRESTRESSED CONCRETE ELEMENTS|PRESTRESSED CONCRETE ELEMENTS]]=== |

Prestressing, refers to the process of pulling steel tendons in the beam into tension before the concrete is placed in the forms. After the concrete has hardened, the stressed tendons are released and transmit a compressive stress to the concrete. This offsets tension forces on the concrete and increases the load-carrying capacity of the beam. The result is similar to pressing on the ends of a set of books in order to pick up the whole set of books at once. | Prestressing, refers to the process of pulling steel tendons in the beam into tension before the concrete is placed in the forms. After the concrete has hardened, the stressed tendons are released and transmit a compressive stress to the concrete. This offsets tension forces on the concrete and increases the load-carrying capacity of the beam. The result is similar to pressing on the ends of a set of books in order to pick up the whole set of books at once. | ||

| + | |||

| + | {{top}} | ||

| + | |||

| + | ====[[#Beams|Beams]]==== | ||

| + | |||

| + | The Department uses four general kinds of prestressed concrete beams: | ||

| + | |||

| + | * Side by side box beams | ||

| + | * Spread box beams | ||

| + | * AASHTO I-girders (Types I-IV) | ||

| + | * Bulb-tee girders (e.g. Michigan 1800 girders) | ||

| + | |||

| + | Prestressed concrete beams vary in width, length, and depth. In general, deeper beams will span longer distances for the same loading conditions. Likewise, deeper beams used for the same span length may have wider beam spacing, and thus carry larger loads. | ||

| + | |||

| + | Another beam type that has occasionally been used is the bulb-T beam. This beam shape can be a more effective section due to its larger bottom flange that allows more prestressing strands to be used. It also features a wider top flange that makes the shape more stable during handling, transport and erection. | ||

| + | |||

| + | {{top}} | ||

| + | |||

| + | =====[[#Prestressing|Prestressing]]===== | ||

| + | |||

| + | Prestressing is generally defined as the preloading of a structure, before application of service loads, to improve its performance in specific ways. Precast concrete elements can be prestressed by pre-tensioning or post-tensioning. Pre-tensioning and post-tensioning are subcategories of prestressing and refer to whether the strands are tensioned before concrete placement or after concrete placement, respectively. | ||

| + | |||

| + | :# Pre-tensioning: Is typically performed at the fabrication facility by using hydraulic jacks to tension seven-wire steel strands in the beam casting bed before the concrete is placed. After the concrete has reached its minimum required release strength, the tensioned strands are released by cutting at each end, which transmits a compressive force to the concrete via bond between the strands and concrete. This offsets tensile stresses in the concrete from dead load and live load and increases the load-carrying capacity of the beam. | ||

| + | |||

| + | Pre-tensioning is typically used with beams and girders, although it can be used with other elements such as soundwall posts and panels, and other types of PBES such as precast pier caps, precast deck panels, etc. Concrete spun poles are also prestressed. | ||

| + | |||

| + | :# Post-Tensioning: Is performed similarly to pre-tensioning but the tensioning of the strands takes place after the concrete has been placed and cured, and the post-tensioning force is distributed to the concrete via mechanical anchorages. The most common application for post-tensioning in the Department is with side by side box beams. After side by side box beams are erected the grouted keyways between the beams are filled with non-shrink grout and cured. Typically the same seven wire strand used in pre-tensioning is grouped to make a tendon and then placed transverse to the beams centerline through ducts in the intermediate diaphragms. In some cases, more rigid steel rods are used for post-tensioning instead of seven wire strands. The quantity of ducts and the number of strands per duct are proportional to the beam length and depth. After hydraulic jacks are used to tension the tendons to the proper load, the force is locked in and the ducts are filled with non-shrink grout. Post-tensioning side by side box beams reduces differential deflection between adjacent beams and allows more effective live load distribution. Post-tensioning can also be used to transmit a compressive load in pier caps, decks, and PBES in order to offset tensile forces in the element. | ||

| + | |||

| + | {{top}} | ||

| + | |||

| + | ====[[#Concrete Spun Poles|Concrete Spun Poles]]==== | ||

| + | Prestressed concrete spun poles are used to mount cameras and other Intelligent Transportation System (ITS) equipment at high elevations in order to provide the proper vantage point. Similar to beams, strands are pre-tensioned and then the forms are rotated at a high speed to create a pole that is hollow in the middle. | ||

| + | |||

| + | |||

| + | {{top}} | ||

| + | |||

| + | ===[[#PREFABRICATED BRIDGE ELEMENTS AND SYSTEMS (PBES)|PREFABRICATED BRIDGE ELEMENTS AND SYSTEMS (PBES)]]=== | ||

| + | |||

| + | PBES can refer to either singular precast elements such as deck panels, footings, columns, pier caps, abutments, etc., or a system that contains multiple elements such as beams with a portion of the deck already attached. The connections between PBES elements or between PBES elements and cast in place elements are of utmost importance. One of the primary advantages of prefabricated elements is the speed at which they can be constructed which minimizes disruption to traffic. If the connections are not properly laid out or constructed, significant delays can result. Therefore, it is important for connection details to be checked by both the Contractor and the Inspector on-site prior to concrete placement or connection of elements, to ensure proper fit-up. All the necessary connection details should be in the design plans. | ||

| + | |||

| + | The use of templates by the Contractor and fabricator is encouraged. At the fabricator’s plant the dimensions should be checked by both the fabricator’s quality control (QC) personnel and the department’s (QA) quality assurance personnel. The Contractor and Inspector are also encouraged to work closely with the fabricator’s QC and the department’s QA to ensure construction goes as smooth as possible. | ||

| + | |||

| + | Connection methods for PBES include, but are not limited to: | ||

| + | |||

| + | * Grouted keyways or pockets | ||

| + | * Grouted mechanical splice sleeves | ||

| + | * Post-tensioning | ||

| + | |||

| + | {{top}} | ||

| + | |||

| + | ===[[#SOUNDWALLS|SOUNDWALLS]]=== | ||

| + | |||

| + | Sound walls, or noise abatement walls, can be detailed differently but typically are constructed of two types of elements, panels and posts. Both the panels and posts may be precast and prestressed or precast with conventional steel reinforcement. | ||

| + | |||

{{top}} | {{top}} | ||

Revision as of 13:11, 12 May 2014

-This section currently undergoing substantial revision-

GENERAL

Structural precast concrete members are cast in forms at a facility certified by the Prestressed Concrete Institute (PCI) that is typically a location other than their final position in the structure. Precast concrete beams are also longitudinally prestressed (bonded pre-tensioned strands) and in the case of side-by-side box beams, are transversely prestressed (post-tensioned strands) as well. Prestressing and post-tensioning of precast concrete elements allows for longer, more efficient spans than traditionally reinforced concrete members by introducing pre-compression into the concrete members. The pre-compression force is typically designed to be larger than the effect of applied loads on the element, and therefore, stresses are well controlled.

Other structural elements that are prestressed include concrete spun poles and in some cases, Prefabricated Bridge Elements and Systems (PBES) other than beams, and sound wall posts and/or panels.

Structural precast concrete elements that are not prestressed include, but may not be limited to, sound wall posts and panels, culverts, and some PBES. Although structural precast concrete elements are typically fabricated off-site, they require on-site inspection to ensure successful forming, casting, transport, handling, and placement into their final position in the structure.

Shop Drawing Submittal

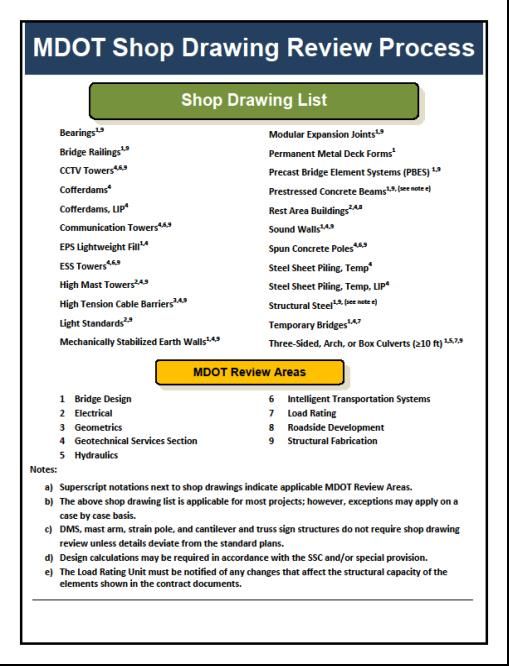

Shop drawings with complete detailed dimensions are submitted to MDOT for review and approval. Approved shop drawings are required prior to the start of fabrication, but MDOT does not check every dimension for accuracy. The submission is reviewed to ensure it is complete and in general conformance with the contract plans. The Contractor is solely responsible for the correctness of shop drawings. Errors found during the review of the shop drawings will be pointed out by MDOT but undiscovered errors are the Contractor's responsibility.

It is the responsibility of the MDOT Design Project Manager (PM) to ensure their project’s shop drawings are being reviewed by all applicable technical reviewers. This process is outlined in Chapter 10 of the MDOT Bridge Design Manual. Figure 708.1-1 and Figure 708.1-2 below summarize MDOT’s electronic shop drawing review process and provides a listing of shop drawings to be reviewed with annotations indicating which MDOT Review Areas need to be involved in their review. Note that this shop drawing listing is general in nature and is applicable for most projects; however, exceptions may apply on a case by case basis and it is the responsibility of the PM to ensure the shop drawings are being reviewed by all applicable parties.

Allow the fabricator or supplier to work directly with MDOT Technical Review Areas to expedite the review of the shop drawings. Contact the Bridge Field Services Structural Fabrication Unit with questions.

The contractor/fabricator shall submit to the Engineer the shop drawings in electronic format according to subsection 104.02 of the Standard Specifications for Construction. The Bridge Design Engineer will coordinate review of the drawings and stamp “Approved.” The approved drawings will be distributed according to the Bridge Design Manual.

Approved Shop Drawing Distribution

Upon receipt of the approved shop drawings from the Bridge Design Engineer, the Engineer shall forward them to the Contractor.

Upon receipt of the shop fabrication and erection drawings at the project office, the inspector will check each sheet against MDOT’s general plans. Particular attention should be directed to span lengths.

Upon completion of the work, the contractor shall furnish the Department one set of complete set of shop drawings on a medium approved by the Department.

PRESTRESSED CONCRETE ELEMENTS

Prestressing, refers to the process of pulling steel tendons in the beam into tension before the concrete is placed in the forms. After the concrete has hardened, the stressed tendons are released and transmit a compressive stress to the concrete. This offsets tension forces on the concrete and increases the load-carrying capacity of the beam. The result is similar to pressing on the ends of a set of books in order to pick up the whole set of books at once.

Beams

The Department uses four general kinds of prestressed concrete beams:

- Side by side box beams

- Spread box beams

- AASHTO I-girders (Types I-IV)

- Bulb-tee girders (e.g. Michigan 1800 girders)

Prestressed concrete beams vary in width, length, and depth. In general, deeper beams will span longer distances for the same loading conditions. Likewise, deeper beams used for the same span length may have wider beam spacing, and thus carry larger loads.

Another beam type that has occasionally been used is the bulb-T beam. This beam shape can be a more effective section due to its larger bottom flange that allows more prestressing strands to be used. It also features a wider top flange that makes the shape more stable during handling, transport and erection.

Prestressing

Prestressing is generally defined as the preloading of a structure, before application of service loads, to improve its performance in specific ways. Precast concrete elements can be prestressed by pre-tensioning or post-tensioning. Pre-tensioning and post-tensioning are subcategories of prestressing and refer to whether the strands are tensioned before concrete placement or after concrete placement, respectively.

- Pre-tensioning: Is typically performed at the fabrication facility by using hydraulic jacks to tension seven-wire steel strands in the beam casting bed before the concrete is placed. After the concrete has reached its minimum required release strength, the tensioned strands are released by cutting at each end, which transmits a compressive force to the concrete via bond between the strands and concrete. This offsets tensile stresses in the concrete from dead load and live load and increases the load-carrying capacity of the beam.

Pre-tensioning is typically used with beams and girders, although it can be used with other elements such as soundwall posts and panels, and other types of PBES such as precast pier caps, precast deck panels, etc. Concrete spun poles are also prestressed.

- Post-Tensioning: Is performed similarly to pre-tensioning but the tensioning of the strands takes place after the concrete has been placed and cured, and the post-tensioning force is distributed to the concrete via mechanical anchorages. The most common application for post-tensioning in the Department is with side by side box beams. After side by side box beams are erected the grouted keyways between the beams are filled with non-shrink grout and cured. Typically the same seven wire strand used in pre-tensioning is grouped to make a tendon and then placed transverse to the beams centerline through ducts in the intermediate diaphragms. In some cases, more rigid steel rods are used for post-tensioning instead of seven wire strands. The quantity of ducts and the number of strands per duct are proportional to the beam length and depth. After hydraulic jacks are used to tension the tendons to the proper load, the force is locked in and the ducts are filled with non-shrink grout. Post-tensioning side by side box beams reduces differential deflection between adjacent beams and allows more effective live load distribution. Post-tensioning can also be used to transmit a compressive load in pier caps, decks, and PBES in order to offset tensile forces in the element.

Concrete Spun Poles

Prestressed concrete spun poles are used to mount cameras and other Intelligent Transportation System (ITS) equipment at high elevations in order to provide the proper vantage point. Similar to beams, strands are pre-tensioned and then the forms are rotated at a high speed to create a pole that is hollow in the middle.

PREFABRICATED BRIDGE ELEMENTS AND SYSTEMS (PBES)

PBES can refer to either singular precast elements such as deck panels, footings, columns, pier caps, abutments, etc., or a system that contains multiple elements such as beams with a portion of the deck already attached. The connections between PBES elements or between PBES elements and cast in place elements are of utmost importance. One of the primary advantages of prefabricated elements is the speed at which they can be constructed which minimizes disruption to traffic. If the connections are not properly laid out or constructed, significant delays can result. Therefore, it is important for connection details to be checked by both the Contractor and the Inspector on-site prior to concrete placement or connection of elements, to ensure proper fit-up. All the necessary connection details should be in the design plans.

The use of templates by the Contractor and fabricator is encouraged. At the fabricator’s plant the dimensions should be checked by both the fabricator’s quality control (QC) personnel and the department’s (QA) quality assurance personnel. The Contractor and Inspector are also encouraged to work closely with the fabricator’s QC and the department’s QA to ensure construction goes as smooth as possible.

Connection methods for PBES include, but are not limited to:

- Grouted keyways or pockets

- Grouted mechanical splice sleeves

- Post-tensioning

SOUNDWALLS

Sound walls, or noise abatement walls, can be detailed differently but typically are constructed of two types of elements, panels and posts. Both the panels and posts may be precast and prestressed or precast with conventional steel reinforcement.

Types

There are three general kinds of precast prestressed concrete beams in use:

- the box beam

- the prestressed I-beam

- the prestressed 1800 beam

The precast prestressed concrete beams vary in width, length, and depth. The deeper types will span longer distances for the same loading conditions. Also, for the same span length, the deeper types will carry a larger load.

Construction Inspection

When the beams arrive on the job site, inspect the beams before they are unloaded. Check one end of each beam for a stamp or tag stating “approved for use.” If the beams are approved for use, a memorandum will be sent to the TSC from Construction and Technology stating the approval of each beam and verification of all certification and test results. Look for damage to the concrete surfaces in either the form of cracks, particularly in the area near the bearing plate (diagonal or radiating), and fine tension cracks near mid-span, or spalled off pieces. Bring any damage to the attention of the Engineer and make a record of the damage in the daily report. Also note in the daily report when the beams arrive in good condition.

Considerable care should be exercised when handling prestressed members. Usually there is no way to repair a damaged member, short of refabrication. Beams should be kept in an upright position at all times. The method of stockpiling and transporting members is covered in detail in subsection 708.03 of the Standard Specifications for Construction. Beams shall be supported at two points no more than 3 feet (1 m) from the ends of the beams.

I-Beam and 1800 Beams

Check beam markings and compare to the beam layout sheet in the plans. Make sure the beams are placed in the right location and direction. They may fit in more than one place but there is only one correct location and direction for each beam.

Lifting devices, usually loops of cable, are cast into the member and these should be the only attachment used when moving a beam. The lifting device must have adequate capacity to lift the beams and set them in place. Never lift the beam near the center. If the beam has to be set down before being placed, never allow it to be supported at the center. Crib it under the ends. The prestressing forces pulling in on the ends of the beam hold up the dead weight of the beam and there is no top reinforcement. If the beam is supported or lifted at the center, the prestressing forces will cause the beam to crack.

The beams in a structure may also be different widths. When setting the beams, be sure to have the right size neoprene bearing pad is used and is centered under the bearing plate of the beam.

Box Beams

To ensure that box beams will fit properly on the substructure units, the beam widths should be checked. Beam bearing pads must be shimmed in an approved manner during erection to provide full bearing contact with the bottoms of the beams. This needs to be checked on every box beam. Note in the daily report when the beam erection has been completed.

The beams should be set with spaces between the beams as specified on the plans or shop drawings and with the seal washers placed in the duct holes. The space between the beams should be completely filled, full depth, with R-2 mortar and cured for at least 48 hours. The deck width should be measured by the Contractor as soon as the beams are set to assure that post tensioning rods or tendons will be fabricated to the proper length.

All hardware dimensions must be as shown on the plans or shop drawings. Tendons or rods should be tensioned with calibrated jacks according to a Contractor-supplied calibration chart showing the corresponding jack pressures and rod elongations necessary to gradually build up to the required stressing force. After the tensioning is complete, the tendon or rod holes will be grouted as described in the standard specifications.

Do not stand behind the jacking machine or rod holes during jacking procedures. If a tendon or rod snaps, it will cause serious injury.

MATERIALS

-Reserved-

CONSTRUCTION

-Reserved-

MEASUREMENT AND PAYMENT

-Reserved-