Difference between revisions of "709 - Timber Sturctures"

m |

m (Removed 2012 Spec Book tagline link) |

||

| (6 intermediate revisions by 3 users not shown) | |||

| Line 4: | Line 4: | ||

<center><span STYLE="font: 40pt arial;">'''Timber Structures'''</span></center> | <center><span STYLE="font: 40pt arial;">'''Timber Structures'''</span></center> | ||

| − | |||

| − | ==GENERAL== | + | ==[[#GENERAL|GENERAL]]== |

| − | + | Structural timber and lumber consist of relatively strong and lightweight materials capable of supporting short-term overloads without sustaining permanent structural damage. Structural timber and lumber elements are used in formwork, temporary structures, sign supports, highway safety appurtenances, and bridges. | |

| + | |||

| + | Wood is orthotropic, meaning its material properties vary in different directions. Strength is greatest in the direction parallel to the grain and is weakest perpendicular to the grain. The material properties of wood also vary between different species of wood. Design provisions and tabulated design values for different species and grades of lumber are given in the American Association of State Highway and Transportation Officials (AASHTO) Standard Specifications for Highway Bridges, and the National Design Specification for Wood Construction (NDS). Wood species can be divided into two broad classes, hardwood and softwood. Hardwoods are from broadleaf trees (oak, maple), and softwoods from conifers (needle trees such as pine). Species with similar mechanical properties are classified into groups. Timber and lumber are further separated into categories – dimension lumber, boards and timbers. Generally the preferred species for timber bridge construction are Douglas Fir/Larch and Southern or Mixed Pine. | ||

| + | |||

| + | Timber and lumber grading at most saw mills is done by visual inspection, and assigned by appearance and strength factors. See Figure 1 for some visual examples. Some factors are : | ||

| + | |||

| + | *Number, size, and position of knots and holes | ||

| + | *Bark on edges | ||

| + | *Decay | ||

| + | *Checks and splits | ||

| + | *Machining defects | ||

| + | *Twisting, bowing, and warp | ||

| + | |||

| + | |||

| + | [[File:Fig709-01.png|600px|thumbnail|center|Figure 1. Timber and Lumber Terminology (http://timber.ce.wsu.edu/Supplements/Production/grading.htm)]] | ||

| + | |||

| + | Refer to: ASTM D9, Standard Terminology Relating to Wood, for definitions of additional terms relating to wood and wood preservation. Species and grading requirements for structural timber and lumber are given in [http://mdotcf.state.mi.us/public/specbook/files/2012/912%20Timber%20and%20Lumber.pdf section 912] of the Standard Specifications for Construction. Rules for grading are established by the U.S. Department of Commerce and maintained by the American Lumber Standards Committee. The highest grade is dense select structural, followed by dense No. 1, No. 1, and No. 2. See Figure 2 for typical grading marks. | ||

| + | |||

| + | [[File:Fig709-02.png|600px|thumbnail|center|Typical lumber grade marks. (http://www.fhwa.dot.gov/publications/publicroads/97winter/p97wi32.cfm)]] | ||

| + | |||

| + | Modern construction of timber bridges utilizes glulam (glued-laminated) for structural members. Glulam is an engineered, stress-rated product, consisting of selected and prepared layers of lumber that are bonded on their wide faces with waterproof structural adhesive. By assembling layers, or laminates, of different graded lumber, glulam composite members can be consistently manufactured . Construction of timber structures are not affected by inclement weather conditions such as rain and cold, and usually can be accomplished without the use of heavy equipment and highly skilled labor. | ||

| + | |||

| + | Beam type systems are the simplest type of timber bridge. Most consist of a series of longitudinal beams supported by piers and abutments. Typically spans can range from 10 to 20 feet depending on the beam type. Timber beam systems include sawn lumber and glulam lumber beams. Most beam type superstructures consist of sawn lumber 4 to 8 inches wide and 12 to 18 inches deep, spaced 3 feet or less apart. The deck is made from transverse timber planks. An overlay is typically not placed due to cracking from differential deflection. | ||

| + | |||

| + | Modern timber bridge construction utilizes longitudinal deck superstructures, consisting of glulam lumber panels nail or stress laminated together to form a rigid deck system. The wearing surface typically is hot mixed asphalt. The panels are typically between 8 and 16 inches. deep. This structure type can be used for clear spans up to 30 feet. See figure 3 for typical details of a stress laminated deck system. | ||

| + | |||

| + | [[File:Fig709-03.png|600px|thumbnail|center|stress laminated deck system showing typical components (United States Department of Agriculture, Forest Products Laboratory, General Technical Report FPL-GTR-125)]] | ||

| + | |||

| + | Treated lumber is highly resistant to decay, rot, and attack by insects. Properly treated and constructed timber structures can be expected to provide a design life of 50 years or more, and should be erected with this in mind. | ||

| + | |||

| + | |||

| + | |||

| + | {{top}} | ||

| + | |||

| + | ==[[#MATERIALS|MATERIALS]]== | ||

| + | |||

| + | Treated lumber to be incorporated in the structure will be inspected at the fabrication plant by independent commercial inspection agencies. Ensure Certificates of Compliance, inspection reports and preservative treatment reports accompany each shipment of treated lumber. Until these documents are received, treated lumber should not be incorporated into the work and any use of such material is considered unauthorized work. | ||

| + | |||

| + | Untreated timber, hardware and nails or spikes are often delivered without prior inspection and should be field inspected. All materials should be checked against plan dimensions and be visually inspected as to fastener grade, presence of defects, and signs of damage to galvanizing. All field inspected materials should be noted on FieldManager and a permanent record should be kept of delivery and placement. | ||

| + | Care should be taken during the process of unloading and placing timber materials so as not to deform or damage the timber. Ensure the Contractor is handling structural timber elements in accordance with [http://mdotcf.state.mi.us/public/specbook/files/2012/709%20Timber%20Structures.pdf subsection 709.03.C.1] of the Standard Specifications for Construction. When timbers are moved they should be lifted by methods which will prevent damage. | ||

| + | |||

| + | Moisture content of wood is the weight of water it contains divided by its dry weight. Moisture content is typically expressed as a percentage, and varies by species and structural application. Wood is a hygroscopic material, which means that it absorbs moisture in humid environments and loses moisture in dry environments. As the moisture content of wood changes, so does its strength. Wood with lower moisture content has higher strength. Moisture content of wood used in timber bridges is a function of use above or below the water line, temperature, and humidity. The effect of uneven drying in two different directions perpendicular to the grain can cause wood to warp. This commonly occurs in thin planks. If timbers are to be stored prior to use, they should be piled in such a manner as to minimize moisture gain or loss, or warpage. They should be piled on suitable blocking at least 12 in. above dry ground, and the area should be clear of weeds and debris. Timber and lumber must be protected by tarpaulins, canvas, waterproof paper, or plastic wrap. If timber and lumber is to be stored out of doors for a period of several months, untreated wood should be open stacked to allow air flow, and treated wood should be close stacked (no space between adjacent pieces). | ||

| + | |||

| + | All hardware, nails and spikes should be stored above ground in suitable containers and, unless galvanized, should be kept in a dry, weather proof room or shack. | ||

| + | |||

| + | {{top}} | ||

| + | ===[[#GLUE LAMINATED TIMBER|GLUE LAMINATED TIMBER]]=== | ||

| + | Glulam is an engineered, stress-rated product of a timber-laminating plant. It consists of selected and prepared lumber laminations that are bonded together on their wide faces with structural adhesive. An important point about glulam is that it is an engineered timber product rather than simply wood glued together. Laminated beams made with pieces of lumber that are nailed and glued together should not be confused with glulam. | ||

| + | |||

| + | The national product standard for glulam is the American National Standards Institute (ANSI) Standard for Wood Products-Structural Glued Laminated Timber, ANSI A190.1. This standard contains nationally recognized requirements for production, inspection, testing, and certification of structural glulam. It also provides material producers, suppliers, and users with a basis for a common understanding of the characteristics of glulam. The requirements in ANSI A190.1 are intended to allow the use of any suitable method of manufacture that will produce a product equal or superior in quality to that specified, provided the methods of manufacture are approved in accordance with requirements of the standard. | ||

| + | |||

| + | ANSI A190.1 requires that each glulam manufacturer maintain a strict quality control program for the production of glulam. This program must include continuing inspection and evaluation in areas related to manufacturing procedures, material testing, and quality control records. The inspections must be supervised by an independent third party to the manufacturer that meets specific qualification requirements outlined in the standard. The American Institute of Timber Construction (AITC) operates a continuing quality program for its members; however, any independent inspection agency may be used, provided it meets the requirements of the ANSI standard. Sometimes the markings will reference ANSI/AITC A190.1 as the grading standard. | ||

| + | |||

| + | In addition to quality marks, straight or slightly curved glulam beams must be stamped TOP at both ends to indicate the proper orientation of the beam. Because the bending strength of glulam beams is often different for the tension and compression zones, this marking is important to ensure that the member is correctly placed. See Figure 4 for an example of a product quality mark. | ||

| + | |||

| + | [[File:Fig709-04.png|600px|thumbnail|center|Inspection Stamp for Glulam lumber]] | ||

| + | |||

| + | {{top}} | ||

| + | ===[[#WEARING COURSE|WEARING COURSE]]=== | ||

| + | |||

| + | Timber bridge deck installations consisting of floor planks that are to be used as a permanent deck system must be protected from the abrasive wearing action of the traffic it carries. Traffic must also be provided with a skid resistant roadway surface, and a transverse cross sloped surface for drainage. The use of a wearing surface serves these important functions. Ensure the Contractor places the appropriate wearing surface as shown in the plans, and note any protective membrane required between the floor planks and wearing surface. | ||

| + | Before permanently bolting the curb timbers to the scupper blocks and flooring, ensure the Contractor lays out for the full length of the bridge so that any adjustment which may be required can be made with a minimum of cutting and/or re-drilling. The spacing of the holes for both the scupper bolts and the rail post bolts should be checked for accuracy of alignment. Major changes should be referred back to the fabricating plant. Minor corrections may be made at the site, but make certain that field cut or drilled sections are treated with preservative coating. Indiscriminate cutting and notching of treated timber should not be permitted. | ||

| + | {{top}} | ||

| + | |||

| + | ===[[#HARDWARE|HARDWARE]]=== | ||

| + | In general, hardware items must be supplied with certification, conforming to the type and size indicated in the plans. All structural steel hardware or hardware components consisting of iron based materials must have a Buy America Certification. The inspector should check the dimensions of the various hardware items and compare these dimensions with those shown in the plans. The method of securing the timber deck to the steel or timber stringers will be shown in the plans. | ||

| + | |||

| + | In the event that any item does not equal the type or dimensions shown in the plans, or if the certification is not provided, the Engineer should be notified. The hardware item in question should not be used in the work until approved. The hardware should be compared with the dimensions and type shown in the plans. Also take careful notice of any special requirements for the preservative treatment used. | ||

| + | |||

| + | For wood treated with Ammoniacal Copper Quat ACQ preservative, fasteners should be stainless steel or hot dipped galvanized in accordance with ASTM A653, batch or post-dipped process, with a minimum coating thickness of 1.85 ounces of zinc per square foot of surface area (Table 1 Coating Designation G185). Do not mix fastener types. Aluminum must not be in direct contact with ACQ treated wood. Non-metallic spacers are to be used where contact with aluminum could occur. Do not use aluminum fasteners. | ||

| + | |||

| + | The cost of hardware is generally included in the pay items for the timber structure. Refer to the project special provision. | ||

| + | {{top}} | ||

| + | |||

| + | ===[[#PLACING RIPRAP FOR TIMBER STRUCTURES|PLACING RIPRAP FOR TIMBER STRUCTURES]]=== | ||

| + | Ensure the Contractor exercises particular care when placing riprap stone around timber substructure units, to prevent damage to the members. Any members which are damaged should be replaced, when possible, or otherwise repaired and re-treated to the satisfaction of the Engineer. The contractor is responsible for the proper execution of work but advice or warning from the inspector can sometimes avert damage and costly repairs. | ||

| + | {{top}} | ||

| + | |||

| + | ===[[#PRESERVATIVE TREATMENT|PRESERVATIVE TREATMENT]]=== | ||

| + | Preservative treatment of structural timber and lumber is absolutely essential to provide protection against decay, rot, and attack by insects. Generally the preservative is applied through pressure treatment, to drive the preservative (penetrate) into the lumber. The preservative will penetrate the outer sapwood. The heartwood consists of dense old dead wood in the center of the timber, which gives the wood its strength, but is difficult to treat. The type and amount of preservative treatment depends on the application and wood species, whether it is designed for above ground exposure, or ground contact, or if used for human conveyances. | ||

| + | |||

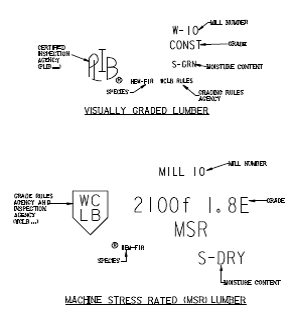

| + | The project special provision will state the preservative requirements. The special provision will also spell out the certification requirements for the preservative retention level. In addition, refer to section 912 of the Standard Specifications for Construction. Table 1 below gives preservative retention requirements. MDOT always has the right to sample the wood for preservative retention as certification verification. | ||

| + | |||

| + | Field cuts in treated timber should be coated with a 2.0 percent solution of copper naphthenate, based on copper as metal, meeting American Wood Protection Association (AWPA) Standard M4, in accordance with [http://mdotcf.state.mi.us/public/specbook/files/2012/912%20Timber%20and%20Lumber.pdf section 912.03]. Surfaces which are to be painted, such as railings and rail posts, should not be coated with preservative. Preservatives should be applied to holes using an approved type of bolt hole treater. | ||

| + | |||

| + | [[File:Fig709-05.png|600px|thumbnail|center|Table 1. Preservative retention requirements. Standard Specifications for Construction, Table 912-10.]] | ||

| + | |||

| + | {{top}} | ||

| + | |||

| + | ==[[#CONSTRUCTION|CONSTRUCTION]]== | ||

| + | |||

| + | Thorough inspection and erection in conformance with plans, special provisions, and specifications is required. The following items should be reviewed: | ||

| + | {{top}} | ||

| + | ===[[#Contract Plans and Specifications|Contract Plans and Specifications]]=== | ||

| + | Review the Contract, and pay particular attention to material requirements and designations for lumber species and grade, working stress, and preservative treatments. Ensure all structural timber and lumber used is in accordance with [http://mdotcf.state.mi.us/public/specbook/files/2012/912%20Timber%20and%20Lumber.pdf subsection 912] of the Standard Specifications for Construction. Know where and how specific members are to be arranged, fastened, primed, and painted. | ||

{{top}} | {{top}} | ||

| − | == | + | |

| + | ===[[#Timber and Lumber Members|Timber and Lumber Members]]=== | ||

| + | Upon delivery, inspect the members to ensure that they are grade-marked by a grading agency certified by the American Lumber Standards Committee. Check the Certificate of Inspection to ensure that it designates the correct destination and project. Ensure the Contractor does not store timber and lumber materials directly on the ground, as they can be contaminated with dirt or water. | ||

| + | {{top}} | ||

| − | |||

| + | ===[[#Fasteners/Incidental Materials|Fasteners/Incidental Materials]]=== | ||

| + | Fasteners that are typically used in timber structure construction include bolts, washers, nuts, drift pins, dowels, nails, and screws. Check for compliance with the contract by noting the type and size of materials required. Ensure all structural steel materials used are in accordance with [http://mdotcf.state.mi.us/public/specbook/files/2012/906%20Structure%20Steel.pdf subsection 906] of the Standard Specifications for Construction, and all miscellaneous metals and hardware used are in accordance with [http://mdotcf.state.mi.us/public/specbook/files/2012/908%20Misc%20Metal%20Products.pdf subsection 908] of the Standard Specifications for Construction. Pay particular attention to thread length and galvanization requirements. | ||

{{top}} | {{top}} | ||

| − | |||

| − | + | ===[[#Shop Drawings|Shop Drawings]]=== | |

| + | Bridges made from timber require shop drawings to be submitted. The Contractor must submit the documents to the Engineer for review and approval according to the special provision. The designer will typically review and approve the shop drawings. Review the shop drawings for understanding of the orientation of each member, and how connections are to be made. Please contact Bridge Field Services with any questions. | ||

{{top}} | {{top}} | ||

| − | ==MEASUREMENT AND PAYMENT== | + | ==[[#MEASUREMENT AND PAYMENT|MEASUREMENT AND PAYMENT]]== |

<span style="color: red"> -Reserved- </span> | <span style="color: red"> -Reserved- </span> | ||

{{top}} | {{top}} | ||

| + | |||

| + | [[Category:Construction Manual]] | ||

| + | [[Category: Division 7]] | ||

| + | [[Category: Section 709]] | ||

Revision as of 11:45, 19 January 2022

GENERAL

Structural timber and lumber consist of relatively strong and lightweight materials capable of supporting short-term overloads without sustaining permanent structural damage. Structural timber and lumber elements are used in formwork, temporary structures, sign supports, highway safety appurtenances, and bridges.

Wood is orthotropic, meaning its material properties vary in different directions. Strength is greatest in the direction parallel to the grain and is weakest perpendicular to the grain. The material properties of wood also vary between different species of wood. Design provisions and tabulated design values for different species and grades of lumber are given in the American Association of State Highway and Transportation Officials (AASHTO) Standard Specifications for Highway Bridges, and the National Design Specification for Wood Construction (NDS). Wood species can be divided into two broad classes, hardwood and softwood. Hardwoods are from broadleaf trees (oak, maple), and softwoods from conifers (needle trees such as pine). Species with similar mechanical properties are classified into groups. Timber and lumber are further separated into categories – dimension lumber, boards and timbers. Generally the preferred species for timber bridge construction are Douglas Fir/Larch and Southern or Mixed Pine.

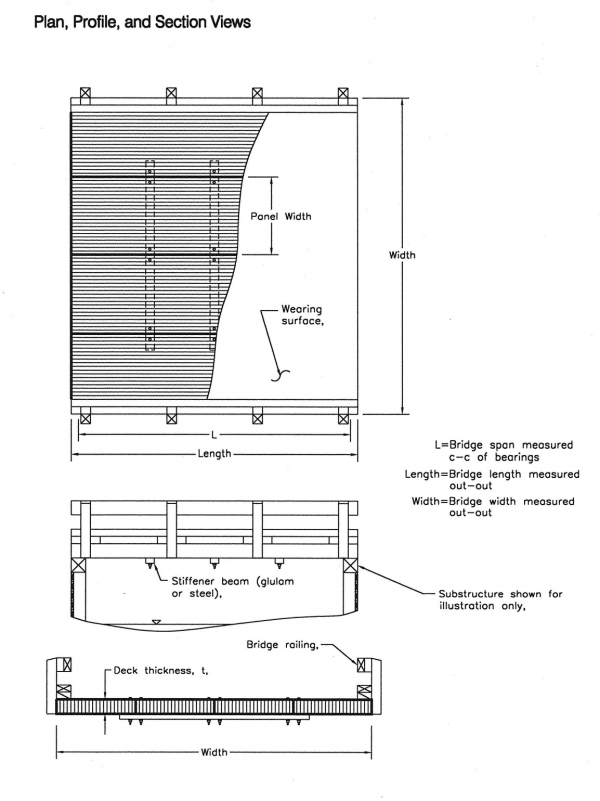

Timber and lumber grading at most saw mills is done by visual inspection, and assigned by appearance and strength factors. See Figure 1 for some visual examples. Some factors are :

- Number, size, and position of knots and holes

- Bark on edges

- Decay

- Checks and splits

- Machining defects

- Twisting, bowing, and warp

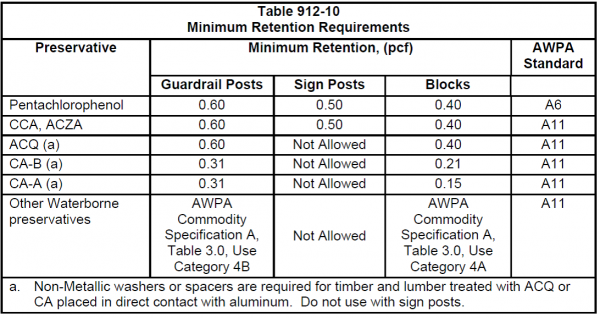

Refer to: ASTM D9, Standard Terminology Relating to Wood, for definitions of additional terms relating to wood and wood preservation. Species and grading requirements for structural timber and lumber are given in section 912 of the Standard Specifications for Construction. Rules for grading are established by the U.S. Department of Commerce and maintained by the American Lumber Standards Committee. The highest grade is dense select structural, followed by dense No. 1, No. 1, and No. 2. See Figure 2 for typical grading marks.

Modern construction of timber bridges utilizes glulam (glued-laminated) for structural members. Glulam is an engineered, stress-rated product, consisting of selected and prepared layers of lumber that are bonded on their wide faces with waterproof structural adhesive. By assembling layers, or laminates, of different graded lumber, glulam composite members can be consistently manufactured . Construction of timber structures are not affected by inclement weather conditions such as rain and cold, and usually can be accomplished without the use of heavy equipment and highly skilled labor.

Beam type systems are the simplest type of timber bridge. Most consist of a series of longitudinal beams supported by piers and abutments. Typically spans can range from 10 to 20 feet depending on the beam type. Timber beam systems include sawn lumber and glulam lumber beams. Most beam type superstructures consist of sawn lumber 4 to 8 inches wide and 12 to 18 inches deep, spaced 3 feet or less apart. The deck is made from transverse timber planks. An overlay is typically not placed due to cracking from differential deflection.

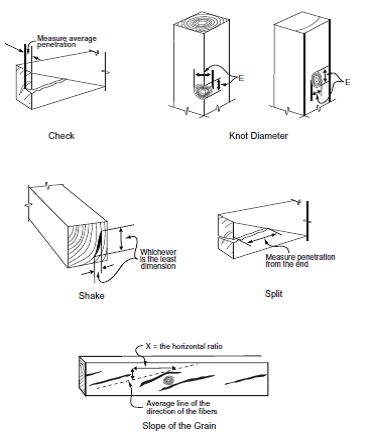

Modern timber bridge construction utilizes longitudinal deck superstructures, consisting of glulam lumber panels nail or stress laminated together to form a rigid deck system. The wearing surface typically is hot mixed asphalt. The panels are typically between 8 and 16 inches. deep. This structure type can be used for clear spans up to 30 feet. See figure 3 for typical details of a stress laminated deck system.

Treated lumber is highly resistant to decay, rot, and attack by insects. Properly treated and constructed timber structures can be expected to provide a design life of 50 years or more, and should be erected with this in mind.

MATERIALS

Treated lumber to be incorporated in the structure will be inspected at the fabrication plant by independent commercial inspection agencies. Ensure Certificates of Compliance, inspection reports and preservative treatment reports accompany each shipment of treated lumber. Until these documents are received, treated lumber should not be incorporated into the work and any use of such material is considered unauthorized work.

Untreated timber, hardware and nails or spikes are often delivered without prior inspection and should be field inspected. All materials should be checked against plan dimensions and be visually inspected as to fastener grade, presence of defects, and signs of damage to galvanizing. All field inspected materials should be noted on FieldManager and a permanent record should be kept of delivery and placement. Care should be taken during the process of unloading and placing timber materials so as not to deform or damage the timber. Ensure the Contractor is handling structural timber elements in accordance with subsection 709.03.C.1 of the Standard Specifications for Construction. When timbers are moved they should be lifted by methods which will prevent damage.

Moisture content of wood is the weight of water it contains divided by its dry weight. Moisture content is typically expressed as a percentage, and varies by species and structural application. Wood is a hygroscopic material, which means that it absorbs moisture in humid environments and loses moisture in dry environments. As the moisture content of wood changes, so does its strength. Wood with lower moisture content has higher strength. Moisture content of wood used in timber bridges is a function of use above or below the water line, temperature, and humidity. The effect of uneven drying in two different directions perpendicular to the grain can cause wood to warp. This commonly occurs in thin planks. If timbers are to be stored prior to use, they should be piled in such a manner as to minimize moisture gain or loss, or warpage. They should be piled on suitable blocking at least 12 in. above dry ground, and the area should be clear of weeds and debris. Timber and lumber must be protected by tarpaulins, canvas, waterproof paper, or plastic wrap. If timber and lumber is to be stored out of doors for a period of several months, untreated wood should be open stacked to allow air flow, and treated wood should be close stacked (no space between adjacent pieces).

All hardware, nails and spikes should be stored above ground in suitable containers and, unless galvanized, should be kept in a dry, weather proof room or shack.

GLUE LAMINATED TIMBER

Glulam is an engineered, stress-rated product of a timber-laminating plant. It consists of selected and prepared lumber laminations that are bonded together on their wide faces with structural adhesive. An important point about glulam is that it is an engineered timber product rather than simply wood glued together. Laminated beams made with pieces of lumber that are nailed and glued together should not be confused with glulam.

The national product standard for glulam is the American National Standards Institute (ANSI) Standard for Wood Products-Structural Glued Laminated Timber, ANSI A190.1. This standard contains nationally recognized requirements for production, inspection, testing, and certification of structural glulam. It also provides material producers, suppliers, and users with a basis for a common understanding of the characteristics of glulam. The requirements in ANSI A190.1 are intended to allow the use of any suitable method of manufacture that will produce a product equal or superior in quality to that specified, provided the methods of manufacture are approved in accordance with requirements of the standard.

ANSI A190.1 requires that each glulam manufacturer maintain a strict quality control program for the production of glulam. This program must include continuing inspection and evaluation in areas related to manufacturing procedures, material testing, and quality control records. The inspections must be supervised by an independent third party to the manufacturer that meets specific qualification requirements outlined in the standard. The American Institute of Timber Construction (AITC) operates a continuing quality program for its members; however, any independent inspection agency may be used, provided it meets the requirements of the ANSI standard. Sometimes the markings will reference ANSI/AITC A190.1 as the grading standard.

In addition to quality marks, straight or slightly curved glulam beams must be stamped TOP at both ends to indicate the proper orientation of the beam. Because the bending strength of glulam beams is often different for the tension and compression zones, this marking is important to ensure that the member is correctly placed. See Figure 4 for an example of a product quality mark.

WEARING COURSE

Timber bridge deck installations consisting of floor planks that are to be used as a permanent deck system must be protected from the abrasive wearing action of the traffic it carries. Traffic must also be provided with a skid resistant roadway surface, and a transverse cross sloped surface for drainage. The use of a wearing surface serves these important functions. Ensure the Contractor places the appropriate wearing surface as shown in the plans, and note any protective membrane required between the floor planks and wearing surface. Before permanently bolting the curb timbers to the scupper blocks and flooring, ensure the Contractor lays out for the full length of the bridge so that any adjustment which may be required can be made with a minimum of cutting and/or re-drilling. The spacing of the holes for both the scupper bolts and the rail post bolts should be checked for accuracy of alignment. Major changes should be referred back to the fabricating plant. Minor corrections may be made at the site, but make certain that field cut or drilled sections are treated with preservative coating. Indiscriminate cutting and notching of treated timber should not be permitted.

HARDWARE

In general, hardware items must be supplied with certification, conforming to the type and size indicated in the plans. All structural steel hardware or hardware components consisting of iron based materials must have a Buy America Certification. The inspector should check the dimensions of the various hardware items and compare these dimensions with those shown in the plans. The method of securing the timber deck to the steel or timber stringers will be shown in the plans.

In the event that any item does not equal the type or dimensions shown in the plans, or if the certification is not provided, the Engineer should be notified. The hardware item in question should not be used in the work until approved. The hardware should be compared with the dimensions and type shown in the plans. Also take careful notice of any special requirements for the preservative treatment used.

For wood treated with Ammoniacal Copper Quat ACQ preservative, fasteners should be stainless steel or hot dipped galvanized in accordance with ASTM A653, batch or post-dipped process, with a minimum coating thickness of 1.85 ounces of zinc per square foot of surface area (Table 1 Coating Designation G185). Do not mix fastener types. Aluminum must not be in direct contact with ACQ treated wood. Non-metallic spacers are to be used where contact with aluminum could occur. Do not use aluminum fasteners.

The cost of hardware is generally included in the pay items for the timber structure. Refer to the project special provision.

PLACING RIPRAP FOR TIMBER STRUCTURES

Ensure the Contractor exercises particular care when placing riprap stone around timber substructure units, to prevent damage to the members. Any members which are damaged should be replaced, when possible, or otherwise repaired and re-treated to the satisfaction of the Engineer. The contractor is responsible for the proper execution of work but advice or warning from the inspector can sometimes avert damage and costly repairs.

PRESERVATIVE TREATMENT

Preservative treatment of structural timber and lumber is absolutely essential to provide protection against decay, rot, and attack by insects. Generally the preservative is applied through pressure treatment, to drive the preservative (penetrate) into the lumber. The preservative will penetrate the outer sapwood. The heartwood consists of dense old dead wood in the center of the timber, which gives the wood its strength, but is difficult to treat. The type and amount of preservative treatment depends on the application and wood species, whether it is designed for above ground exposure, or ground contact, or if used for human conveyances.

The project special provision will state the preservative requirements. The special provision will also spell out the certification requirements for the preservative retention level. In addition, refer to section 912 of the Standard Specifications for Construction. Table 1 below gives preservative retention requirements. MDOT always has the right to sample the wood for preservative retention as certification verification.

Field cuts in treated timber should be coated with a 2.0 percent solution of copper naphthenate, based on copper as metal, meeting American Wood Protection Association (AWPA) Standard M4, in accordance with section 912.03. Surfaces which are to be painted, such as railings and rail posts, should not be coated with preservative. Preservatives should be applied to holes using an approved type of bolt hole treater.

CONSTRUCTION

Thorough inspection and erection in conformance with plans, special provisions, and specifications is required. The following items should be reviewed:

Contract Plans and Specifications

Review the Contract, and pay particular attention to material requirements and designations for lumber species and grade, working stress, and preservative treatments. Ensure all structural timber and lumber used is in accordance with subsection 912 of the Standard Specifications for Construction. Know where and how specific members are to be arranged, fastened, primed, and painted.

Timber and Lumber Members

Upon delivery, inspect the members to ensure that they are grade-marked by a grading agency certified by the American Lumber Standards Committee. Check the Certificate of Inspection to ensure that it designates the correct destination and project. Ensure the Contractor does not store timber and lumber materials directly on the ground, as they can be contaminated with dirt or water.

Fasteners/Incidental Materials

Fasteners that are typically used in timber structure construction include bolts, washers, nuts, drift pins, dowels, nails, and screws. Check for compliance with the contract by noting the type and size of materials required. Ensure all structural steel materials used are in accordance with subsection 906 of the Standard Specifications for Construction, and all miscellaneous metals and hardware used are in accordance with subsection 908 of the Standard Specifications for Construction. Pay particular attention to thread length and galvanization requirements.

Shop Drawings

Bridges made from timber require shop drawings to be submitted. The Contractor must submit the documents to the Engineer for review and approval according to the special provision. The designer will typically review and approve the shop drawings. Review the shop drawings for understanding of the orientation of each member, and how connections are to be made. Please contact Bridge Field Services with any questions.

MEASUREMENT AND PAYMENT

-Reserved-