Difference between revisions of "709 - Timber Sturctures"

| Line 51: | Line 51: | ||

==[[#CONSTRUCTION|CONSTRUCTION]]== | ==[[#CONSTRUCTION|CONSTRUCTION]]== | ||

| − | + | Thorough inspection and erection in conformance with plans, special provisions, and specifications is required. The following items should be reviewed: | |

| + | {{top}} | ||

| + | |||

| + | ===[[#Contract Plans and Specifications|Contract Plans and Specifications]]=== | ||

| + | Review the Contract, and pay particular attention to material requirements and designations for lumber species and grade, working stress, and preservative treatments. Ensure all structural timber and lumber used is in accordance with [http://mdotcf.state.mi.us/public/specbook/files/2012/912%20Timber%20and%20Lumber.pdf subsection 912] of the Standard Specifications for Construction. Know where and how specific members are to be arranged, fastened, primed, and painted. | ||

| + | {{top}} | ||

| + | |||

| + | |||

| + | ===[[#Timber and Lumber Members|Timber and Lumber Members]]=== | ||

| + | Upon delivery, inspect the members to ensure that they are grade-marked by a grading agency certified by the American Lumber Standards Committee. Check the Certificate of Inspection to ensure that it designates the correct destination and project. Ensure the Contractor does not store timber and lumber materials directly on the ground, as they can be contaminated with dirt or water. | ||

| + | {{top}} | ||

| + | |||

| + | |||

| + | ===[[#Fasteners/Incidental Materials|Fasteners/Incidental Materials]]=== | ||

| + | Fasteners that are typically used in timber structure construction include bolts, washers, nuts, drift pins, dowels, nails, and screws. Check for compliance with the contract by noting the type and size of materials required. Ensure all structural steel materials used are in accordance with [http://mdotcf.state.mi.us/public/specbook/files/2012/906%20Structure%20Steel.pdf subsection 906] of the Standard Specifications for Construction, and all miscellaneous metals and hardware used are in accordance with [http://mdotcf.state.mi.us/public/specbook/files/2012/908%20Misc%20Metal%20Products.pdf subsection 908] of the Standard Specifications for Construction. Pay particular attention to thread length and galvanization requirements. | ||

| + | {{top}} | ||

| + | |||

| + | |||

| + | ===[[#Shop Drawings|Shop Drawings]]=== | ||

| + | Bridges made from timber require shop drawings to be submitted. The Contractor must submit the documents to the Engineer for review and approval according to the special provision. The designer will typically review and approve the shop drawings. Review the shop drawings for understanding of the orientation of each member, and how connections are to be made. Please contact Bridge Field Services with any questions. | ||

{{top}} | {{top}} | ||

Revision as of 08:54, 9 April 2014

GENERAL

Structural timber and lumber consist of relatively strong and lightweight materials capable of supporting short-term overloads without sustaining permanent structural damage. Structural timber and lumber elements are used in formwork, temporary structures, sign supports, highway safety appurtenances, and bridges.

Wood is orthotropic, meaning its material properties vary in different directions. Strength is greatest in the direction parallel to the grain and is weakest perpendicular to the grain. The material properties of wood also vary between different species of wood. Design provisions and tabulated design values for different species and grades of lumber are given in the American Association of State Highway and Transportation Officials (AASHTO) Standard Specifications for Highway Bridges, and the National Design Specification for Wood Construction (NDS). Wood species can be divided into two broad classes, hardwood and softwood. Hardwoods are from broadleaf trees (oak, maple), and softwoods from conifers (needle trees such as pine). Species with similar mechanical properties are classified into groups. Timber and lumber are further separated into categories – dimension lumber, boards and timbers. Generally the preferred species for timber bridge construction are Douglas Fir/Larch and Southern or Mixed Pine.

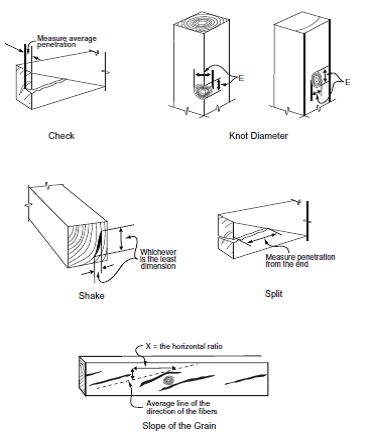

Timber and lumber grading at most saw mills is done by visual inspection, and assigned by appearance and strength factors. See Figure 1 for some visual examples. Some factors are :

- Number, size, and position of knots and holes

- Bark on edges

- Decay

- Checks and splits

- Machining defects

- Twisting, bowing, and warp

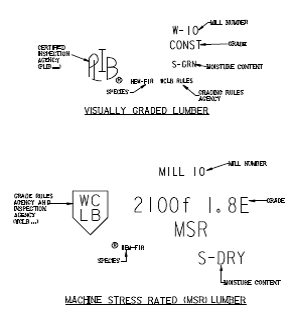

Refer to: ASTM D9, Standard Terminology Relating to Wood, for definitions of additional terms relating to wood and wood preservation. Species and grading requirements for structural timber and lumber are given in section 912 of the Standard Specifications for Construction. Rules for grading are established by the U.S. Department of Commerce and maintained by the American Lumber Standards Committee. The highest grade is dense select structural, followed by dense No. 1, No. 1, and No. 2. See Figure 2 for typical grading marks.

Modern construction of timber bridges utilizes glulam (glued-laminated) for structural members. Glulam is an engineered, stress-rated product, consisting of selected and prepared layers of lumber that are bonded on their wide faces with waterproof structural adhesive. By assembling layers, or laminates, of different graded lumber, glulam composite members can be consistently manufactured . Construction of timber structures are not affected by inclement weather conditions such as rain and cold, and usually can be accomplished without the use of heavy equipment and highly skilled labor.

Beam type systems are the simplest type of timber bridge. Most consist of a series of longitudinal beams supported by piers and abutments. Typically spans can range from 10 to 20 feet depending on the beam type. Timber beam systems include sawn lumber and glulam lumber beams. Most beam type superstructures consist of sawn lumber 4 to 8 inches wide and 12 to 18 inches deep, spaced 3 feet or less apart. The deck is made from transverse timber planks. An overlay is typically not placed due to cracking from differential deflection.

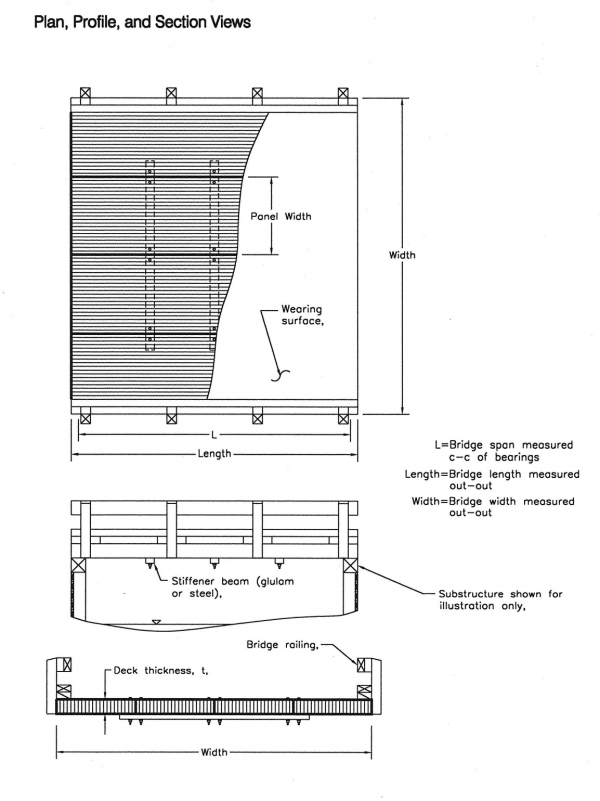

Modern timber bridge construction utilizes longitudinal deck superstructures, consisting of glulam lumber panels nail or stress laminated together to form a rigid deck system. The wearing surface typically is hot mixed asphalt. The panels are typically between 8 and 16 inches. deep. This structure type can be used for clear spans up to 30 feet. See figure 3 for typical details of a stress laminated deck system.

Treated lumber is highly resistant to decay, rot, and attack by insects. Properly treated and constructed timber structures can be expected to provide a design life of 50 years or more, and should be erected with this in mind.

MATERIALS

-Reserved-

CONSTRUCTION

Thorough inspection and erection in conformance with plans, special provisions, and specifications is required. The following items should be reviewed:

Contract Plans and Specifications

Review the Contract, and pay particular attention to material requirements and designations for lumber species and grade, working stress, and preservative treatments. Ensure all structural timber and lumber used is in accordance with subsection 912 of the Standard Specifications for Construction. Know where and how specific members are to be arranged, fastened, primed, and painted.

Timber and Lumber Members

Upon delivery, inspect the members to ensure that they are grade-marked by a grading agency certified by the American Lumber Standards Committee. Check the Certificate of Inspection to ensure that it designates the correct destination and project. Ensure the Contractor does not store timber and lumber materials directly on the ground, as they can be contaminated with dirt or water.

Fasteners/Incidental Materials

Fasteners that are typically used in timber structure construction include bolts, washers, nuts, drift pins, dowels, nails, and screws. Check for compliance with the contract by noting the type and size of materials required. Ensure all structural steel materials used are in accordance with subsection 906 of the Standard Specifications for Construction, and all miscellaneous metals and hardware used are in accordance with subsection 908 of the Standard Specifications for Construction. Pay particular attention to thread length and galvanization requirements.

Shop Drawings

Bridges made from timber require shop drawings to be submitted. The Contractor must submit the documents to the Engineer for review and approval according to the special provision. The designer will typically review and approve the shop drawings. Review the shop drawings for understanding of the orientation of each member, and how connections are to be made. Please contact Bridge Field Services with any questions.

MEASUREMENT AND PAYMENT

-Reserved-