Difference between revisions of "717 - Downspouts and Drains"

m |

|||

| (4 intermediate revisions by 2 users not shown) | |||

| Line 7: | Line 7: | ||

| − | ==GENERAL== | + | ==[[#GENERAL|GENERAL]]== |

| − | + | The bridge deck drainage system includes the bridge deck, sidewalks, railings, gutters, downspouts, and inlets (or scuppers), referred to as the bridge drain casting assembly. The primary objective of the drainage system is to remove runoff from the bridge deck before it collects in the gutter to a point that exceeds the allowable design spread. | |

| + | |||

| + | Proper bridge deck drainage provides many benefits: | ||

| + | *Efficiently removing water from the bridge deck enhances public safety by decreasing the risk of hydroplaning. | ||

| + | |||

| + | *The structural integrity of the bridge is preserved, by removing corrosive or otherwise harmful runoff. | ||

| + | |||

| + | *Aesthetics are enhanced (e.g., the avoidance of staining substructure and superstructure members). | ||

| + | |||

| + | *Erosion on the bridge abutment slopes is reduced. | ||

| + | |||

| + | *Settlement of approach slabs is reduced | ||

| + | |||

| + | For proper function, the drainage system must be installed at locations shown on the plans, as the scupper spacing is important for intercepting the calculated flow that meets the allowable water spread criteria. The AASHTO LRFD Bridge Design Specifications 2.6.6.3 specifies the allowable spread of water on the deck. For bridges where the highway design speed is less than or equal to 45 mph, the spread should not encroach on more than one-half the width of any designated traffic lane. For bridges where the highway design speed is greater than 45 mph, the spread should not encroach on any portion of the designated traffic lanes. These items are taken into account during the design phase; however, it is important to understand these requirements, and ensure the Contractor installs all scuppers at the appropriate stationing as shown on the plans. Gutter flow should be intercepted at cross slope transitions to prevent flow across the bridge deck. | ||

| + | |||

| + | The bridge drain casting assembly is detailed in the [http://mdotcf.state.mi.us/public/design/englishstandardplans/ Bridge Standard Plan Series B101]. Note that the location and placement of the drain casting must be as indicated in the plans. Downspouts must be supported at the intermediate spacing shown on the plans, or closer if field conditions warrant moving a support. Care must be taken to verify the support spacing such that that the downspout deflection remains within allowable tolerances. | ||

| + | |||

| + | Alternate drain casting or down spout assemblies and materials may also be used, and will be detailed in the plans and specifications. Call Bridge Field Services with any questions regarding drain casting assemblies or materials. | ||

| + | |||

| + | {{top}} | ||

| + | |||

| + | ==[[#MATERIALS|MATERIALS]]== | ||

| + | |||

| + | Bridge deck downspouts can be polyethylene (PE) pipe Schedule 40 (specifically ASTM D2447, PE 3406), or fiberglass reinforced thermosetting resin pipe (RTRP), in accordance with subsection 909.08 of the Standard Specifications for Construction. | ||

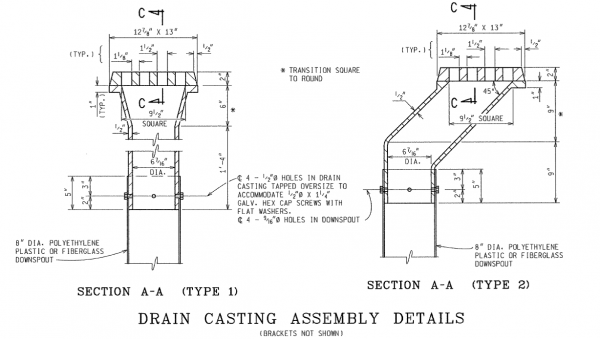

| + | The drain casting assembly as detailed in [[Bridge deck downspouts can be polyethylene (PE) pipe Schedule 40 (specifically ASTM D2447, PE 3406), or fiberglass reinforced thermosetting resin pipe (RTRP), in accordance with [http://mdotcf.state.mi.us/public/specbook/files/2012/909%20Drainage%20Products.pdf subsection 909.08] of the Standard Specifications for Construction.|bridge standard plans B101]] consists of a slotted grey cast iron grate, with a transition coupler to facilitate attachment of circular pipe. Ensure all drain castings and miscellaneous metal materials are in accordance with [http://mdotcf.state.mi.us/public/specbook/files/2012/908%20Misc%20Metal%20Products.pdf subsection 908] of the Standard Specifications for Construction. See Figure 1. | ||

| + | [[File:Fig717-01.png|600px|thumbnail|center|Figure 1. Drain Casting Assembly Details from Standard Plan Series B101]] | ||

| − | + | {{top}} | |

| − | + | ==[[#CONSTRUCTION|CONSTRUCTION]]== | |

| + | Deck drains, downspouts, and supports should be checked to ensure that their location and size is in accordance with details shown on the plans, including the correct orientation of the drain casting slots. Ensure the Contractor does not cut bridge deck reinforcement that is in conflict with setting the drain casting assembly. Adjustments may be required to address conflicts with deck reinforcement, diaphragms or beam flanges. Ensure the Contractor properly secures the drain casting to adjacent bridge deck reinforcement to ensure the casting does not move or rotate during deck casting. | ||

| − | + | Ensure the Contractor properly secures the downspout pipe to the outlet of the drain casting to prevent leakage on to structural elements of the bridge. | |

| − | + | Once the deck is cast, ensure the Contractor covers the drain castings to prevent debris or curing compound from entering them during subsequent sidewalk or barrier pours, or other construction operations. | |

| + | All iron and steel products must meet Buy America requirements. | ||

| + | {{top}} | ||

| − | ==MEASUREMENT AND PAYMENT== | + | ==[[#MEASUREMENT AND PAYMENT|MEASUREMENT AND PAYMENT]]== |

<span style="color: red"> -Reserved- </span> | <span style="color: red"> -Reserved- </span> | ||

| + | |||

| + | {{top}} | ||

| + | |||

| + | [[Category:Construction Manual]] | ||

Revision as of 09:39, 9 April 2014

GENERAL

The bridge deck drainage system includes the bridge deck, sidewalks, railings, gutters, downspouts, and inlets (or scuppers), referred to as the bridge drain casting assembly. The primary objective of the drainage system is to remove runoff from the bridge deck before it collects in the gutter to a point that exceeds the allowable design spread.

Proper bridge deck drainage provides many benefits:

- Efficiently removing water from the bridge deck enhances public safety by decreasing the risk of hydroplaning.

- The structural integrity of the bridge is preserved, by removing corrosive or otherwise harmful runoff.

- Aesthetics are enhanced (e.g., the avoidance of staining substructure and superstructure members).

- Erosion on the bridge abutment slopes is reduced.

- Settlement of approach slabs is reduced

For proper function, the drainage system must be installed at locations shown on the plans, as the scupper spacing is important for intercepting the calculated flow that meets the allowable water spread criteria. The AASHTO LRFD Bridge Design Specifications 2.6.6.3 specifies the allowable spread of water on the deck. For bridges where the highway design speed is less than or equal to 45 mph, the spread should not encroach on more than one-half the width of any designated traffic lane. For bridges where the highway design speed is greater than 45 mph, the spread should not encroach on any portion of the designated traffic lanes. These items are taken into account during the design phase; however, it is important to understand these requirements, and ensure the Contractor installs all scuppers at the appropriate stationing as shown on the plans. Gutter flow should be intercepted at cross slope transitions to prevent flow across the bridge deck.

The bridge drain casting assembly is detailed in the Bridge Standard Plan Series B101. Note that the location and placement of the drain casting must be as indicated in the plans. Downspouts must be supported at the intermediate spacing shown on the plans, or closer if field conditions warrant moving a support. Care must be taken to verify the support spacing such that that the downspout deflection remains within allowable tolerances.

Alternate drain casting or down spout assemblies and materials may also be used, and will be detailed in the plans and specifications. Call Bridge Field Services with any questions regarding drain casting assemblies or materials.

MATERIALS

Bridge deck downspouts can be polyethylene (PE) pipe Schedule 40 (specifically ASTM D2447, PE 3406), or fiberglass reinforced thermosetting resin pipe (RTRP), in accordance with subsection 909.08 of the Standard Specifications for Construction. The drain casting assembly as detailed in [[Bridge deck downspouts can be polyethylene (PE) pipe Schedule 40 (specifically ASTM D2447, PE 3406), or fiberglass reinforced thermosetting resin pipe (RTRP), in accordance with subsection 909.08 of the Standard Specifications for Construction.|bridge standard plans B101]] consists of a slotted grey cast iron grate, with a transition coupler to facilitate attachment of circular pipe. Ensure all drain castings and miscellaneous metal materials are in accordance with subsection 908 of the Standard Specifications for Construction. See Figure 1.

CONSTRUCTION

Deck drains, downspouts, and supports should be checked to ensure that their location and size is in accordance with details shown on the plans, including the correct orientation of the drain casting slots. Ensure the Contractor does not cut bridge deck reinforcement that is in conflict with setting the drain casting assembly. Adjustments may be required to address conflicts with deck reinforcement, diaphragms or beam flanges. Ensure the Contractor properly secures the drain casting to adjacent bridge deck reinforcement to ensure the casting does not move or rotate during deck casting.

Ensure the Contractor properly secures the downspout pipe to the outlet of the drain casting to prevent leakage on to structural elements of the bridge.

Once the deck is cast, ensure the Contractor covers the drain castings to prevent debris or curing compound from entering them during subsequent sidewalk or barrier pours, or other construction operations. All iron and steel products must meet Buy America requirements.

MEASUREMENT AND PAYMENT

-Reserved-