FieldManager

FieldManager

FieldManager is a construction management system employed by over 1000 users to manage and track road and bridge construction projects in Michigan. It will be used by MDOT’s Region, TSC and construction field offices, local government agencies and construction consultants. Business functions automated by FieldManager include the following.

- Contractor payments

- Inspector’s Daily Reports (IDR)

- Daily Diaries

- Work item progress

- Contract Modifications

- Material usage

- Stockpile management

- Estimates

- Project finalizations

Construction projects are initialized in FieldManager from files that have been created in Lansing using AASHTO’s Trns*port software. Once construction begins, FieldManager stringently monitors and reviews the work activities that occur throughout the life of each project. IDR information is captured on notebook computers directly at the construction sites and later transferred to a network, or desktop computer, located in the field office responsible for managing the project. More than 50 inquires are available to provide information when and where it is needed. FieldManager also sends pertinent data to Trns*port software on a daily basis.

The FieldManager suite of products consists of four components:

- FieldManager - The main component, which usually runs at the field office and manages product data by processing IDR’s, Contract Modifications and Estimates.

- FieldBook - Used to gather IDR information directly at the construction site and sends the IDR’s electronically to FieldManager.

- FieldPad - A subcomponent of FieldBook that runs on a hand held device.

- FieldBuilder - Allows local government and consulting agencies to establish their own respective FieldManager projects on contracts that will not be processed through the Trns*port system.

For information on acquiring the software, self-paced FieldManager and FieldBook Tutorials, FieldManager User’s Guide, Trns*port interface or technical questions, please call the FieldManager Help Line at 517-322-1556.

Current information on FieldManager system requirements, articles, press releases, events, presentations, license feed, etc., can be found at www.fieldmanager.com

Inspector's Daily Report (IDR)

Perhaps the single most important type of project documentation is the Inspector’s Daily Report (IDR) and its variations. Because of the IDR’s importance, it is imperative that it be prepared correctly, legibly and thoroughly. At the very minimum, a completed IDR must include all report header information, a statement in the body of the report and a signature.

The exact nomenclature and pay item code number shown in the proposal must be used when turning in a pay item. Any inaccuracy in nomenclature or code can be misleading, as many contracts contain pay items with similar nomenclature. When using the manual Inspector’s Daily Report Worksheet (IDRW), Form 1122-C, which will be input into FieldManager to generate IDR’s, it is good practice to emphasize both pay items and quantities by underlining, underlining in red, recording in a different color or some other method.

The recommended work flow method for submitting automated IDR’s or manual IDRW’s to the office for processing is to have each individual inspector complete the IDR and submit it to the office for processing. The senior technician then summarizes all pay items for all the inspectors on one report, adding any additional pay items or data needed. This completed, summarized IDR then becomes the primary documentation.

Regardless of the method used, it is always the senior technician’s responsibility to collect all reports daily, review them and turn them into the office technician. Either the senior technician or the office technician checks and initials all computations.

Inspectors should complete and submit reports no later than the first work day after the work was performed. The sooner information is put in writing, the more accurate it will be.

In addition to the pay items, other details to be documented in the body of the report include Subcontractor information, final pay item quantities, final pay item field measurement (these items should be clearly labeled as final measured), associated pay item test material usage and comments, comments on maintaining traffic and maintenance of traffic devices (traffic device checks must be recorded daily). Comments on attitude and quality of Contractor’s work may also be recorded.

Other details that should be recorded include complaints from the public, along with inspector responses to these complaints, unusual events, daily weather conditions and accidents. Exceptionally good or bad work may also be cited.

Questions regarding this process can be answered by calling the FieldManager Help Line at 517-322-1556.

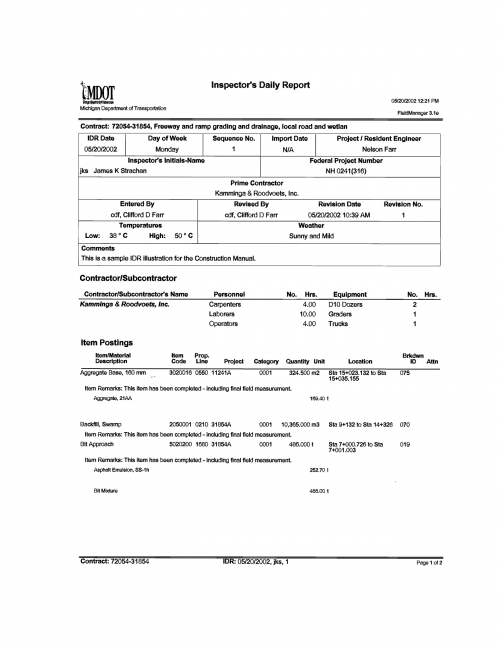

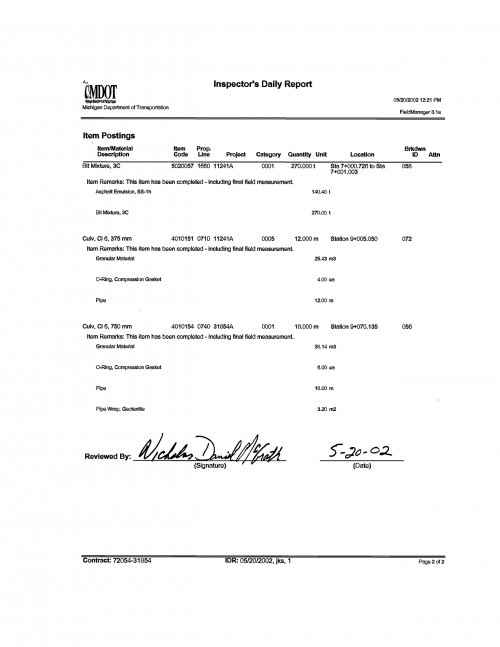

A sample IDR is shown in Figure 101-1.

Using FieldManager to Track Design-Build Contracts

The purpose of this section is to provide instructions on how to utilize FieldManager to track design-build contracts. When design-build contracts are awarded, the managing office will receive the FieldManager initialization file (live contract) through FieldNet, which contains three-to-five pay items used to pay the contractor. However, design-build contracts do not use typical construction work items; therefore, FieldManager will utilize two contracts. In addition to the “live contract,” the managing office will also use a “shadow contract”, which will be used to:

- Document construction activities

- Document work items

- Track material usage and approvals

In short, continue using MDOT procedures when documenting the above items in the shadow contracts.

It is critical to track and document material usage on design-build contracts. Book 2 section 2 of

design-build contracts require the design-build team to provide MDOT with the estimated quantities for all items that require inspection or testing in accordance with MDOT’s Material Source Guide. The team must submit this information with or before the “released for construction” documents. The managing office will manually enter this information into the shadow contract.

FieldNet will be used for the live contract pay estimates, contract modifications, and contractor performance evaluations; however, FieldNet will not be used to process these electronic files for shadow contracts.

Documenting Procedures for Live and Shadow Contracts

- When the initialization file is received through FieldNet, contact the FieldManager Help Desk to acquire a shadow contract initialization file.

- Use the following contract ID naming convention:

- Live contract: 38103-105785

- Shadow contract: _38103-105785X

- Use the following project number naming convention:

- Live contract: 105785A

- Shadow contract: _105785AX

- Adding shadow contract items and materials:

a. Add items through:

- Contract modifications, or

- Tracked as unattached items

b. Add materials associated with items as needed.

- Subcontracts – Enter subcontracts into the live contract and the shadow contract; this includes the design subcontract.

- Construction Started Date – Populate the FieldManager Docu > General tab > “Construction started date” is to be populated when the design starts (just after award) on the live and shadow contracts, as the designer is a subcontractor.

- Contract Files – Include shadow contract documents in the original live contract files.

- Contractor Performance Evaluations (CPE) – Shadow contract CPEs will not be used for official contract documentation, but they must be generated before FieldManager will allow a final estimate to be completed. Use N/A to fill out the ratings tab for shadow contract CPEs.

- Archiving Shadow Contracts – Archive the contract in FieldManager after completing the final estimate, as is required with the live contract.

- FieldNet – You can use FieldNet to transfer shadow contract files between FieldManager and FieldBook, as can be done with any live contract. Contact the FieldManager Help Desk should you wish to use this feature.

- Contractor Read-Only (CRO) Files – In most cases, managing offices will not be creating biweekly shadow contract estimates. Therefore, contractors will not automatically receive CRO files as estimate creation is the auto-send CRO trigger. Users can still send CRO files to contractors via FieldNet by using FieldManager’s File > Export > Transfer contracts functionality.

- Stockpiles – This feature can be used on shadow contracts depending on how the managing office chooses to track contractor progress within the shadow contract.

To request a shadow contract or FieldManager support for design-build contracts, please contact the FieldManager Help Desk at 517-322-1556.

Office Technician Certification Requirements

The requirement to follow all applicable documentation and project administration oversight procedures for federal and state funded projects is of paramount importance. Failure to follow the procedures can result in loss of State and/or Federal-Aid funding for the projects.

All staff performing the role of Office Technician and handling the oversight of project documentation for state or Federal-Aid projects must have a current, non-expired, MDOT Office Technician Certification on file. These requirements apply to all State and Federal-Aid funded projects, MDOT, and/or local agency, including all projects overseen by the local agency, MDOT, and/or their consultant representative including maintenance projects that are let through the MDOT letting system. Certification expiration notices will not be sent out as it is the responsibility of each certified person to schedule their renewal and maintain current certification. All existing office technician certification or similarly titled certifications expire after four (4) years unless stated otherwise.

Engineer Certification Program

The department received approval from the Federal Highway Administration (FHWA) to adopt a four-year record certification program for MDOT and local government engineers. The FHWA also granted our request to extend the certification of currently certified engineers by one year.

The attached Engineer Certification Program information supersedes the procedure set forth in Section 110 of the 2003 Construction Manual.

The Engineer Certification Program procedure is revised as follows:

- Reflects the four-year certification period.

- Requires the person performing office technician duties to attend office technician training during each four-year certification period.

- The review team is changed to reflect current practice.

- Wage rate interviews and certified payrolls will be checked during the review of the active project for compliance.

- The certification review team may further monitor the project documentation at anytime during the four-year certification period, if necessary.

We request that you encourage all qualified local agency engineers in your area to take advantage of the four-year certification program.

A revised record certification list is also attached to reflect the additional year.

Review Procedure

Engineer Certification Program

The certification period is four years. In order to be eligible for the four year certification, the engineer must meet the following criteria:

- Recommendation for certification by the region or TSC.

- A minimum of two projects must be completed and accepted, and an active project must be available for review.

- Newly appointed or non-certified engineers must participate in project administration training (i.e., office technician training).

- The person performing the office technician duties must attend office technician training during each four year certification period. The Certification Review Team may waive this requirement for members of the Office Technology Training Team. The office technician training may also be waived if the engineer passes at least 95 percent of the criteria to become certified.

A local agency engineer must be an employee of a local government agency, and meet the above criteria.

The region or TSC notifies the Engineer of Construction and Technology in writing when an engineer meets the eligibility criteria. For local governments, you must indicate the engineer and agency.

A certification review team is established consisting of Construction and Technology Division staff with knowledge and experience in construction and materials documentation, as well as a representative from the region, if available. The team is responsible for certification review of the delivery/project engineers’ project records, and a subsequent recommendation to the Engineer of Construction and Technology and the region engineer. Following is the procedure and items the team will review:

- Notify the engineer to be certified and setup the time and date for the review.

- Review a minimum of two projects.

- Review a minimum of 15 contract items. The selection ratio is 10 final and 5 interim items. From the projects available for review, projects and items selected will represent significant monetary value.

- Select items based on methods of measurement such as volume, weight, length, area, unit, etc. It is mandatory that major items such as earthwork, bituminous, concrete and aggregate surfaces be reviewed and, when applicable, that one force account item be reviewed.

- Review the supporting documentation for any extensions of time approved without liquidated damages.

- Review the project and material documentation for each selected item to verify that specifications are met and required approvals for materials or specification changes are in place.

- Review a contract modification for extras approved by the region engineer, TSC manager or delivery engineer to determine if the format and explanation are consistent with the Construction Manual and applicable bureau of highway instructional memoranda.

- Check wage rate interviews and certified payrolls for compliance to the prevailing wages set forth in the contract.

- Upon completion of the review, the review team will meet with the engineer to discuss their findings. If deficiencies are found by the review team, the engineer will be given 30 days to address them.

- Once the review team is notified that the deficient items have been addressed, they will conduct a follow-up review.

- Upon completion of the follow-up review, the team will make its recommendation to certify or not certify to the Engineer of Construction and Technology and the region engineer.

- The engineer and region is notified in writing whether the Engineer of Construction and Technology and region engineer approve the recommendation from the team or not.

- If approved, the MDOT or local agency engineer is certified for four years to submit final estimates without further review.

- The certification review team may further monitor the project documentation at any time during the four year certification period, if deemed necessary.

- If a new engineer is assigned before a project is closed out, the final estimate will be submitted under the certification of the engineer who completed the majority of the work on the project. The region engineer or TSC manager must provide the Construction and Technology Division’s Region Services Unit with a list of projects that will be closed out under the departing certified engineer.

The Project Record Certification, Form 1117, requires an abbreviated response from the team indicating that:

- Proper documentation was used,

- Measurements were according to specifications,

- Documents were signed and dated,

- Documentation was identified for the project, and

- All materials used were tested or certified, and shown to be within specifications.

The team will indicate this on the form as pass, fail, or not applicable (P, F, NA). An engineer must pass (P) 80 percent of each criteria (measurement per specification, proper testing and test documents and prescribed forms completed, signed and dated) to become certified.

If the engineer does not meet the 80 percent criteria, or if the criteria are met and the failing items (F) are of major concern to the Engineer of Construction and Technology and the region engineer, the engineer will not be certified. The region will review all projects for one year. If after this period of time, the region believes the engineer has met the certification criteria, a request for a records review is made in writing to the Engineer of Construction and Technology.