Difference between revisions of "Process for Documenting Certified Materials in FieldManager"

Jump to navigation

Jump to search

JohnsonN23 (talk | contribs) m (replaced with article) |

(→Process for Documenting Certified Materials in FieldManager: Updated text and added visual sample forms for Concrete, HMA, and Aggregate) |

||

| (5 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| − | |||

| − | |||

| − | |||

| − | This revised process is not affecting the method of verifying and documenting material when the basis of acceptance is | + | <div style="text-align: center;">[mailto:Change?body=http://mdotwiki.state.mi.us/construction/index.php/Material_Source_List_Forms_(501)-Processing_and_Approval_Procedure Email this Page]</div> |

| + | ==[[#Process for Documenting Certified Materials in FieldManager|Process for Documenting Certified Materials in FieldManager]]== | ||

| + | |||

| + | This revised process is not affecting the method of verifying and documenting material when the basis of acceptance is “test.” Also, the requirements for documenting aggregate, bituminous, and concrete delivery tickets are not affected. | ||

The processes outlined in this article can apply to active projects, as well as, projects yet to be audited; if reasonable assurance can be made that the certified material used with the pay items is as specified on the certification document. | The processes outlined in this article can apply to active projects, as well as, projects yet to be audited; if reasonable assurance can be made that the certified material used with the pay items is as specified on the certification document. | ||

| − | |||

| − | |||

| − | |||

The following process remains in effect for documenting certified materials in FieldManager: | The following process remains in effect for documenting certified materials in FieldManager: | ||

| − | # When all components making up a pay item are certified from the same source, each component of the pay item is not required to be listed and associated in FieldManager and FieldBook. | + | # When all components making up a pay item are certified from the same source, each component of the pay item is not required to be listed and associated in FieldManager and FieldBook. The relationship of the material to the pay item will be one to one, whenever this is the case. Example: If Guardrail Type B is the pay item, Guardrail Type B would also be the material associated with it, and would include the steel beams, posts, hardware, etc. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | # When additional material components are certified from other sources, these components will be associated to the pay item, and only the sources will be verified and documented. The quantity approved of each of these certified material components will no longer need to be documented in FieldManager and FieldBook. | |

| + | # Using the above guardrail example, if the wood products are certified from a different source than the steel products, the wood products would be associated with the pay item Guardrail Type B, and the source certifying the wood products would be identified. The assumption is then made that if the guardrail was completed according to the plans, then the proper quantities of all associated components were supplied. | ||

| + | # This does not relieve the construction/project engineer from verifying in the field that material quantities used are as specified by MDOT plans and procedures. This verification should be documented accordingly by means of IDR, or other project documentation. | ||

| + | # The construction/project engineer will check the material delivered to the project against the materials source list and/or FieldBook associations. | ||

| + | # When the basis of acceptance is “general certification” or “test data certification,” the construction/project engineer will verify that a signed certification has been sent to the project office, and document the source in FieldManager. | ||

| + | # When the basis of acceptance is “certification from an approved manufacturer/supplier,” the construction/project engineer will verify the source is listed in the Materials Source Guide and document in FieldManager. If the sources on the certification document provided to the project office does not agree with the materials source list submitted by the contractor, the construction/project engineer will require a revised materials source list. | ||

| + | # All materials certifications require a signature. | ||

| + | |||

| + | |||

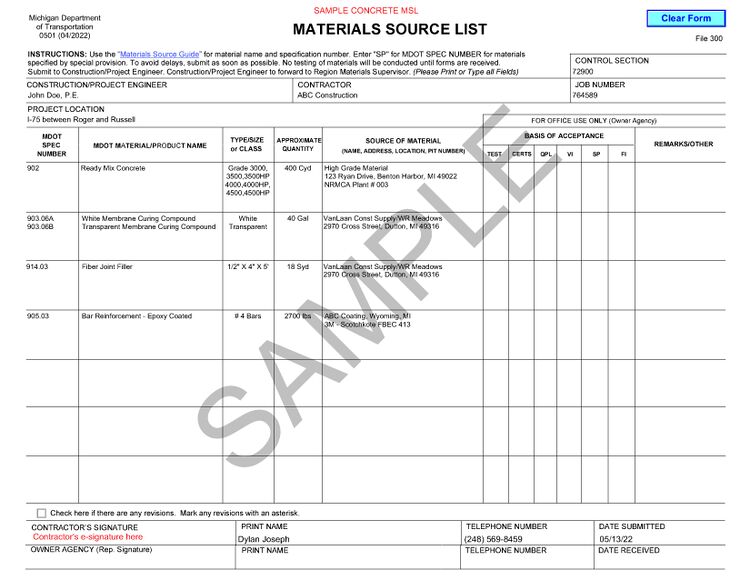

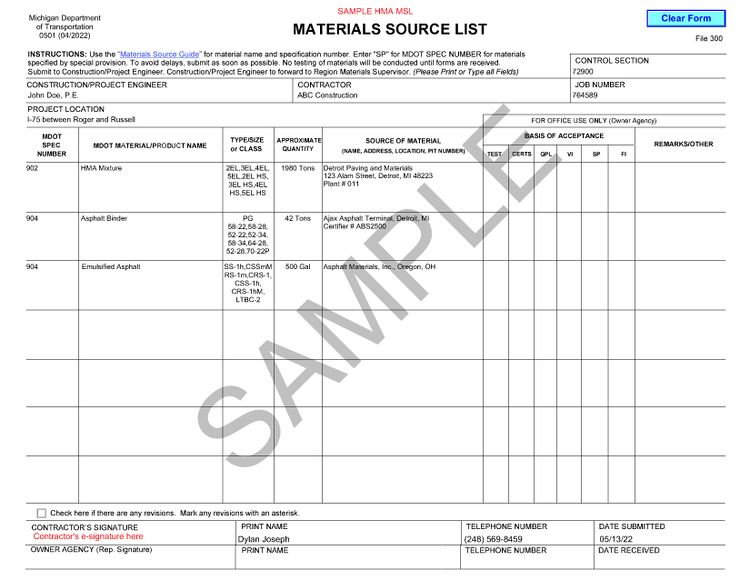

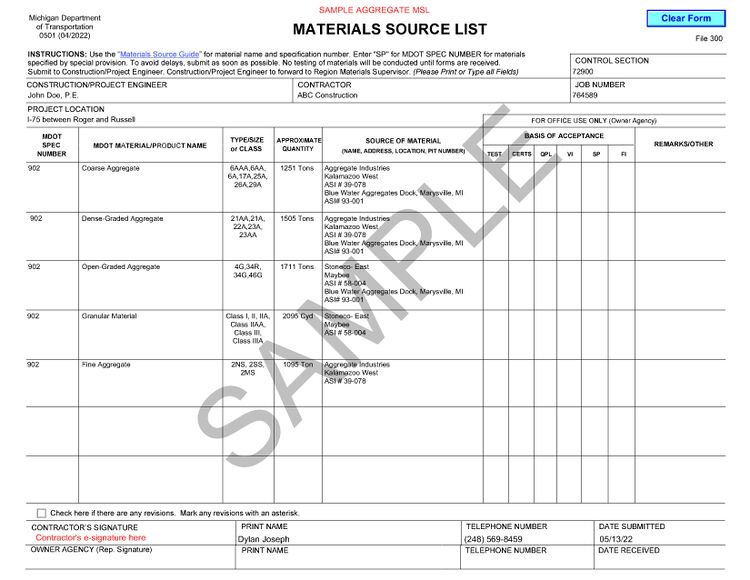

| + | The following are three examples of MSL’s for Concrete, HMA, and Aggregate. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | : | + | [[File:Sample Concrete MSL - Form 0501.jpg|thumb|center|750px|link=//{{SERVERNAME}}/images_construction/1/1e/Sample_Concrete_MSL_-_Form_0501.pdf|Sample: Concrete MSL]] |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | : | + | [[File:Sample HMA MSL - Form 0501.jpg|thumb|center|750px|link=//{{SERVERNAME}}/images_construction/7/7e/Sample_HMA_MSL_-_Form_0501.pdf|Sample: HMA MSL]] |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:Sample Aggregate MSL - Form 0501.jpg|thumb|center|750px|link=//{{SERVERNAME}}/images_construction/a/a6/Sample_Aggregate_MSL_-_Form_0501.pdf|Sample: Aggregate MSL]] | |

| − | |||

| − | <div style="text-align: right;">[mailto:Change?body= | + | <div style="text-align: right;">[mailto:Change?body=http://mdotwiki.state.mi.us/construction/index.php/Material_Source_List_Forms_(501)-Processing_and_Approval_Procedure Email this Page]</div> |

{{top}} | {{top}} | ||

| + | |||

| + | |||

[[Category:Construction Manual]] | [[Category:Construction Manual]] | ||

[[Category:Division 1]] | [[Category:Division 1]] | ||

[[Category:Section 105]] | [[Category:Section 105]] | ||

Latest revision as of 16:09, 25 May 2022

Process for Documenting Certified Materials in FieldManager

This revised process is not affecting the method of verifying and documenting material when the basis of acceptance is “test.” Also, the requirements for documenting aggregate, bituminous, and concrete delivery tickets are not affected.

The processes outlined in this article can apply to active projects, as well as, projects yet to be audited; if reasonable assurance can be made that the certified material used with the pay items is as specified on the certification document.

The following process remains in effect for documenting certified materials in FieldManager:

- When all components making up a pay item are certified from the same source, each component of the pay item is not required to be listed and associated in FieldManager and FieldBook. The relationship of the material to the pay item will be one to one, whenever this is the case. Example: If Guardrail Type B is the pay item, Guardrail Type B would also be the material associated with it, and would include the steel beams, posts, hardware, etc.

- When additional material components are certified from other sources, these components will be associated to the pay item, and only the sources will be verified and documented. The quantity approved of each of these certified material components will no longer need to be documented in FieldManager and FieldBook.

- Using the above guardrail example, if the wood products are certified from a different source than the steel products, the wood products would be associated with the pay item Guardrail Type B, and the source certifying the wood products would be identified. The assumption is then made that if the guardrail was completed according to the plans, then the proper quantities of all associated components were supplied.

- This does not relieve the construction/project engineer from verifying in the field that material quantities used are as specified by MDOT plans and procedures. This verification should be documented accordingly by means of IDR, or other project documentation.

- The construction/project engineer will check the material delivered to the project against the materials source list and/or FieldBook associations.

- When the basis of acceptance is “general certification” or “test data certification,” the construction/project engineer will verify that a signed certification has been sent to the project office, and document the source in FieldManager.

- When the basis of acceptance is “certification from an approved manufacturer/supplier,” the construction/project engineer will verify the source is listed in the Materials Source Guide and document in FieldManager. If the sources on the certification document provided to the project office does not agree with the materials source list submitted by the contractor, the construction/project engineer will require a revised materials source list.

- All materials certifications require a signature.

The following are three examples of MSL’s for Concrete, HMA, and Aggregate.