Chapter 6 - Surfacing

6.01 PAVEMENT SELECTION PROCESS

6.01.01 References

- Truck Operators’ Map, MDOT, issued annually (available from the Utility Coordination and Permits Section of the Development Services Division)

- Pavement Design and Selection Manual, MDOT, Current Edition

- Standard Specifications for Construction, MDOT, Current Edition

6.01.02 Equivalent Single Axle Load (ESAL)

Recognizing that automobile traffic has little deleterious effect on the load-carrying capacity of a pavement, the Department has adopted the concept of 18-kip (18,000 lbs.) axle load repetitions or ESAL as a meaningful unit of traffic measurement. (While there is no hard data available, some consider that it requires something on the order of 5,000 passenger cars to equal one 18-kip axle load. A General Accounting Office study has estimated that one 80,000 lb. truck causes wear equal to 9,600 cars.) The Bureau of Transportation Planning, in determining future traffic volumes for design purposes, is able to convert average daily commercial vehicles counts into ESAL repetitions. ESAL’s are available from the Project Planning Division.

6.01.03 Legal Truck Weights

Legal truck weights in Michigan, for vehicles exceeding 80,000 lbs. gross weight, are 18,000 lbs. per single axle and 13,000 lbs. per axle in tandem groups, with one 32,000 lbs. tandem pair permitted, provided certain minimum axle spacings are met. For vehicles less than 80,000 lbs. gross weight, maximum weights of 20,000 lbs. per single axle and 34,000 lbs. per tandem axle are permitted. Routes where these loads are permitted, regardless of the season, are shown in green on the Truck Operators’ Map, published by the Department.

The maximum gross load is 164,000 lbs. on 11 axles legally spaced. Overweight vehicles may be issued a permit for a specified trip or move.

6.01.04 AASHTO Interim Guide

In the middle 1950's, AASHO conducted the most extensive road test ever on a specially constructed track near Ottawa, Illinois. Utilizing a part of what is now I-80 and military personnel driving loaded trucks 24 hours per day for two years, this provided the data that led to the publication of the “AASHTO Interim Guide for Design of Pavement Structures 1972". The AASHTO design method is an empirically developed method which is used across the country by many public agencies.

6.01.05 Choice between Aggregate, Hot Mix Asphalt and Concrete

It is the general practice of the Department to not leave aggregate as a driving surface on a roadway. Therefore, at minimum, a new or existing aggregate road will generally be paved with a single course of hot mix asphalt material, regardless of how little traffic it serves.

Michigan differs from many of the states in having a wide range of soil types, varying from well drained sands to heavy clays, to rock outcroppings. Concrete has the advantage of rigidity and high strength relative to thickness and requires less elaborate mixing facilities at the plant. Hot mix asphalt is flexible, easier to repair, and it requires less time to open to traffic, needing only to cool. The Department tries to utilize the advantages of each material when selecting a pavement type.

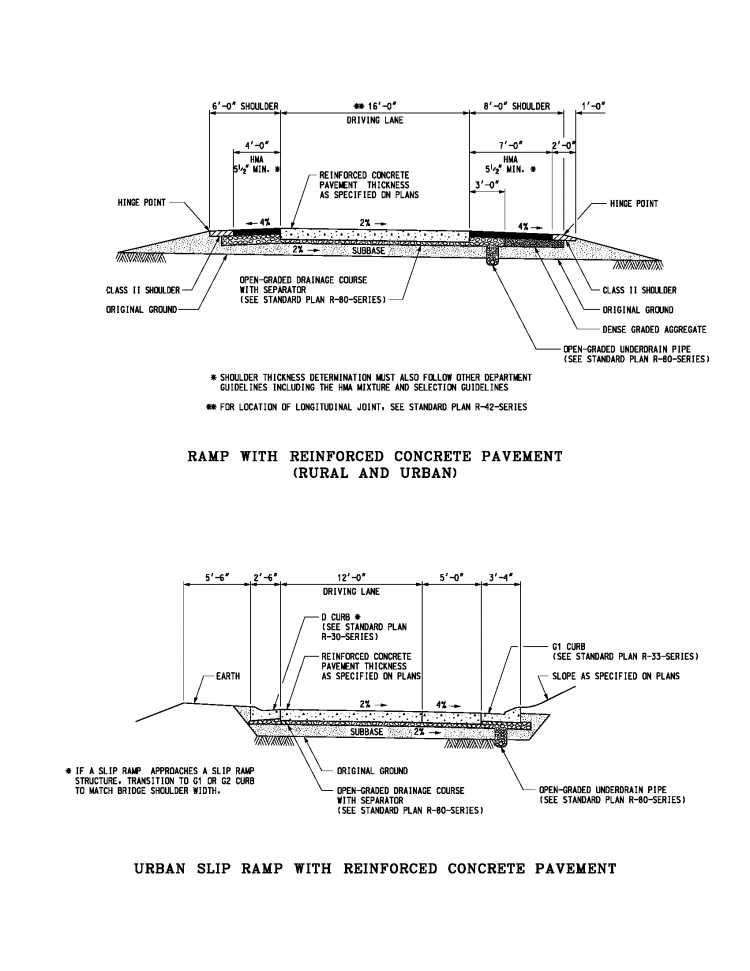

Ramps will usually have the same type of surfacing as is used on the freeway. One exception would be when the mainline is overlaid utilizing a different wearing surface material than the existing ramp. In this case, the new mainline surface material may extend up the ramps part-way depending on the condition of the ramps.

6.01.06 Pavement Design and Selection Policy

(Approved by EOC 2-9-2012)

6.01.06A Design

Pavement design will be performed using design methods outlined in the "Guide for Design of Pavement Structures", AASHTO, 1993. The design software accompanying AASHTO 1993 is the DARWin pavement design program.

6.01.06B Selection

Pavement selection will be determined using the life cycle cost analysis method when the project pavement costs exceed one million dollars as described in the “Pavement Design and Selection Manual.†Pavement costs are determined by separately calculating the cost of paving with both HMA and concrete. When the cost of either the HMA or concrete exceeds one million dollars, a life cycle cost analysis is required. For such projects, Pavement Operations of the Construction Field Services Division will conduct the pavement design and life cycle cost analysis in accordance with the “Pavement Design and Selection Manual.†MDOT staff and industry organizations will be provided an opportunity for review and comment, with final approvals by the Engineering Operations Committee. In accordance with state law, the low cost alternative will be selected.

Pavement designs and the life cycle cost analysis will be done by Pavement Operations for the following project categories.

- All new/reconstruction projects with pavement costs greater than one million dollars.

- Major rehabilitation projects (unbonded concrete overlays & rubblized with HMA surfacing) with pavement costs greater than one million dollars.

Certain fixes known under a different name (e.g. ‘inlay’) may still require a life cycle cost analysis, regardless of whether it is a 3R or 4R project. Questions should be directed to Pavement Operations. Assistance will be given to the Regions for other projects on an as-needed basis

Life cycle cost analysis will include the cost of initial pavement construction costs as well as maintenance costs over the service life. It will also include calculation of user costs for both initial construction and all future maintenance shown in the maintenance schedules. User costs will be calculated using the software titled “Construction Congestion Cost.â€

Informational life cycle cost analyses may be conducted for a variety of reasons prior to processing of an official analysis. In addition, some circumstances will require re-analysis, such as scope changes or scheduling delays. Projects must be monitored during project development to ensure that a valid life cycle cost analysis is in place prior to advertisement, and that the correct pavement type has been specified in the plans. The “Pavement Design and Selection Manual†contains details of these and many other aspects of the process.

6.01.07 Alternate Pavement Bidding

At times during pavement selection, the life-cycle cost between the two alternatives may be relatively close and all other design considerations relatively equal. Under these circumstances, bidding the project with alternate pavement options can allow market competition to determine best value.

On September 1, 2011 the Engineering Operations Committee approved a process for the identification and development of alternate pavement bid (APB) candidate projects.

Candidate selection criteria includes;

- Only freeway projects will be eligible.

- The project fix type must be either a complete reconstruction or a major rehabilitation (separated concrete overlay or HMA over rubblized concrete).

- Estimated construction costs must exceed $10,000,000 dollars.

- Each pavement alternate must be expected to have similar environmental, right of way, drainage, and utility impacts.

- Maintaining traffic concepts must be similar for both pavement alternates.

- Paving must be the controlling operation for the construction schedule.

- If the project meets all the above criteria, the TSC will request an informational LCCA. The proposed pavement designs will be developed using the MDOT Pavement Design and Selection Manual. The life cycle costs of the two pavement design alternates must be within 10%.

MDOT leadership may recommend other projects not meeting the above criteria.

The detailed selection and plan development process for Alternate Pavement Bidding is available on the Plan Development Services website (MDOT only).

6.02 AGGREGATE CONSTRUCTION

6.02.01 General

There are principally two types of natural aggregate produced commercially: 1) gravel and sand that is excavated and possibly washed and screened, and 2) crushed aggregates that may be made from gravel or quarried rock, but which are run through a crusher, then perhaps washed and screened for a given gradation.

In recent decades, other types in the form of artificial aggregates have appeared on the road building scene. Two examples are slag and recycled concrete. Both can be crushed and screened to meet most of the specification aggregate gradation requirements.

6.02.02 Glossary of Terms

Bank run - An aggregate excavated from a bank or pit without any subsequent processing.

Chert - An extremely fine-grained, hard rock composed mainly of silica and occurring commonly in limestone beds. It is considered an undesirable particle because of its susceptibility to fracture under freeze-thaw conditions.

Choking - Adding fines to an open-graded aggregate or rock to make it more densely graded.

CIP - Compacted in place.

Daylighted - Usually used when speaking of the drainage plane between the top of subgrade and the bottom of subbase. To daylight this drainage plane is to extend it to the roadway front slope where it can drain.

Dense graded - An aggregate having a range of particle gradation such that most of the voids between larger particles are filled by other smaller particles.

Fines - A silt and/or clay size material which will pass through the 0.075 mm sieve (ASTM No. 200.)

Fly ash - A by-product of the coal combustion process in electrical generating plants. It is a very fine light dust recovered from stack gases, composed primarily of silica, alumina, and various other oxides and alkalies. In the presence of lime and moisture, it has pozzuolanic (cementing) properties.

Foundry sand - The waste core sand from the steel casting process. Usually black or dark brown in color and likely to contain metal fragments and oil. The Department tests for permeability, in addition to the other usual tests. Environmental interests object to foundry sand because of the excessive leaching of the hydrocarbons or other additives, and it has been declared toxic. If used, it requires extensive testing for inertness or encapsulation. A permit is usually required for use.

Freeze-thaw durability - A measure of dilation percentage per 100 freeze-thaw cycles (Michigan Test Method 113 and 115). It is an aggregate's resistance to failure when incorporated in portland cement concrete and subjected to alternating cycles of freezing and thawing.

HMA – Hot Mix Asphalt (formerly referred to as “bituminousâ€). Also see Section 6.03.02.

Heavy media - A process used in coarse aggregate gravel production to separate low-gravity particles from the product. The aggregates are passed through a tank containing an agitated liquid composed of water, magnetite, and ferrosilicon. The specific gravity of the liquid is adjusted to that of the low-gravity fraction of the coarse aggregate, which contains the majority of the deleterious particles.

LM - Loose measure.

Loss by washing - After an aggregate or soil sample is dried and weighed, it is washed. The fine components (smaller silt sizes and clay) carried off by the water through a 0.075 mm sieve (ASTM No. 200) is the loss by washing.

Metal - A somewhat archaic term, dating back to the days of gravel roads, referring to the road surface structure whether it is aggregate, aggregate and HMA, or concrete. "Edge of Metal" would today be synonymous with "Edge of Pavement".

OGDC - Open-graded drainage course.

Open-graded - An aggregate gradation lacking sufficient fines to fill the voids between the larger aggregate particles. Material, other than fine aggregate, consisting of mostly one-size particles would be open-graded.

Passing 200 - The loss by washing plus the dried portion of the sample that passes the 0.075 mm sieve (ASTM No. 200). Usually about 0.5 to 1.0% more than the loss-by-washing figure.

Pea gravel - A natural gravel, essentially rounded. Usually a by-product of aggregate production for which there may be limited demand.

Processed aggregate - Material that has been mechanically processed in some way either by screening, washing, or crushing, to enhance its usability.

Select Subbase - An obsolete term, no longer proper terminology, but still used conversationally, that refers to a layer of dense graded processed aggregate placed on subbase to stabilize it, thus facilitating the operation of construction equipment. Comparable to what is now called "Aggregate Base".

Separation Course - An HMA or granular course between an old pavement and new pavement that is intended to eliminate or minimize reflective cracking in the new pavement.

Shrinkage - The reduction in volume of a soil or aggregate when compacted, as compared to its natural, in-place state. Sometimes used when referring to the additional material required to maintain the same volume in the compacted state as existed in the natural, in-place state.

Slag - An artificial aggregate produced as a by-product of the steel (blast furnace slag) and copper (reverberatory furnace slag) refining process, composed of the solidified remnant of the coke, limestone, and mineral impurities that float to the top of the molten metal. Of several different types, it is crushed and screened to specification aggregate gradation.

Stabilization - The process of adding a material to an aggregate to increase its stability and load-supporting capability. Typical stabilizing agents are water, soils high in fines, lime, HMA materials, and portland cement.

Top size - In a given aggregate gradation, the largest size aggregate particle.

Windrow - Aggregate or earth that has been graded into a longitudinal pile, usually parallel with the center of the road.

The following terms are defined in the Standard Specifications for Construction:

Earth grade

Subbase

Subgrade

6.02.03 Method of Measurement

Aggregates are measured in any of the following ways:

Ton (t) - requires scales and an inspector for weighing; applicable where thickness or area is not uniform.

Square Yard (Syd) - (of a given thickness) - requires field measurement for area, plus depth checks.

Cubic Yard, LM (Cyd) - requires "truck count" and measurement of each hauling unit in the field or computation of volume in the stockpile.

Cubic Yard, CIP (Cyd) (of a given thickness) - requires field measurement of area, plus depth checks.

In order for the method of measurement for aggregate bases and surface courses to be related to the nature of the work involved, aggregate measurement should be set up as follows:

6.02.03A Ton

Use where traffic will use the proposed aggregate surface such as:

- Reconstruction - through traffic maintained on an aggregate base.

- Reconstruction where some grade raises are gravel raises only.

- Shoulders on resurfacing projects.

6.02.03B Square Yard

Use where there will be no traffic on the proposed aggregate surface such as:

- New (relocation) construction

- Total reconstruction - through traffic detoured.

- Total reconstruction - part-width, traffic maintained on existing surface and reconstructed surface (not base).

- Widenings - one lane or more requiring new aggregate base.

6.02.03C Cubic Yard, LM

Use where small amounts of aggregate are involved such as:

- Gravel bases and surfaces for temporary roads.

- Gravel-surfaced crossovers.

- Driveway approaches (base or surface)

- Crossroad approaches less than 200 ft. long (base or surface).

- Total aggregate in the contract is less than 5,000 cubic yards.

Any combination of these three methods of measurement may be utilized on any one project.

6.02.03D Cubic Yard, CIP

This method is similar in application to the square yard unit of measurement, and is more commonly used with small quantities. Use only when recommended at the Plan Review Meeting.

The ton as a method of measurement for aggregates should not be used in the Detroit Metropolitan area. Use square yard whenever possible and cubic yard, LM or CIP when recommended at the Plan Review Meeting.

When aggregates are measured and paid for by the square yard, the total width of the aggregate should be used for the basis of measurement even though there is overlap, as shown in the example below:

6.02.04 Weight of Aggregates

While different materials in a compacted state weigh more or less than others, for general purposes compacted aggregates are considered as weighing 4,000 lbs/cyd. An exception is slag aggregate. See Section 6.02.08.

6.02.05 Subbase Stabilization

6.02.05A Purpose

A non-cohesive granular material may be practically impassable to wheeled equipment, and it may be difficult to compact, especially if the sand particles are rounded and one-sized. In order to build a project, it is often necessary to stabilize the sand just to enable construction equipment to get on it. By contrast, a clay subgrade, unless it is moisture-saturated, can be compacted, and it is quite traversable.

6.02.05B History

The practice of constructing a base with specification gravel on the top of subbase was instituted by the Department in 1955 on all concrete pavement projects. Its purpose was two-fold:

- To prevent rutting of the subbase (and subsequent contamination with subgrade material) by the contractor's equipment, and,

- To provide a stable foundation for placing the paving forms.

The practice was later extended to subbases under flexible surfaces, the material then being changed to the same as the aggregate base course. As the use of paving forms faded from general practice, one of the reasons for placing stabilizing material vanished. Also, about this time, evidence began to show that the compacted aggregate impeded the free drainage below the pavement, defeating to some extent the purpose of the subbase. Currently the Department generally uses this material under HMA. For new concrete pavements, an open graded material with improved drainage characteristics (Open Graded Drainage Course = OGDC) is typically used. See Section 6.02.06.

6.02.05C Thickness (typical)

Aggregate Base, 4 inch

6.02.05D Width

Under rigid pavements-

- 3 ft. (underdrain pipe) or 2 ft. (PDS) outside each edge

- See Standard Plan R-80-Series

Under flexible pavements

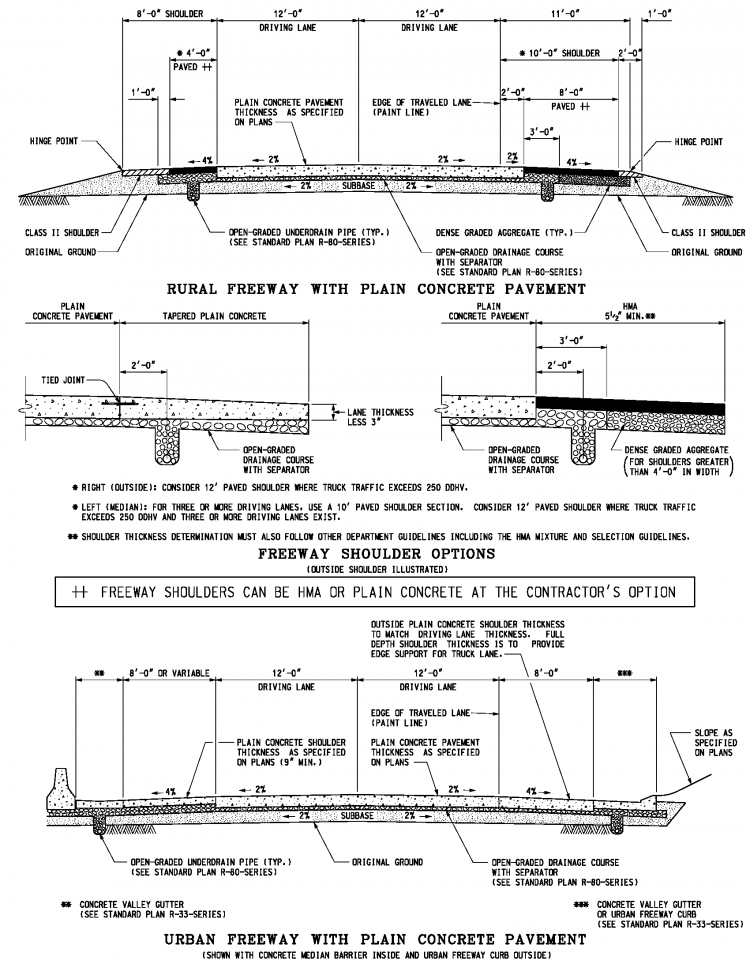

- Full width of paved surface including paved shoulders.

The additional width beyond the outside edge of concrete pavement is to facilitate the use of slip form equipment. If curb and gutter is proposed, the width of stabilization should not be increased because of the curb and gutter, unless the plans specify that integral curb and gutter is to be placed (in which case the stabilization should extend 3 ft. beyond the back of curb). If the contractor chooses to use integral curb and gutter, then the additional width must be paid for by the contractor. See Pavement Design Engineer for latest details.

When valley gutter or urban freeway curb is used, the Aggregate Base should be extended to include the width of valley gutter or urban freeway curb in order to avoid a marked change in type of base material under the valley gutter or urban freeway curb.

6.02.05E Criteria for Use

Aggregate base is typically used under all HMA and some concrete pavements placed on subbase material. Aggregate base may also be used as a construction platform directly on subgrade when recommended at the Plan Review Meeting.

6.02.06 Open Graded Drainage Course

6.02.06A Purpose

Research has concluded that open graded bases provided the most suitable method for removing water from the roadway section. Materials for OGDC are specifically designed to allow water to drain freely and still provide a suitable paving platform. The OGDC is drained by an open graded underdrain that is located under the shoulder in a geotextile wrapped trench. The trench is backfilled with an open graded material.

OGDC gradations initially required 0-15% passing the 4.75 mm sieve (ASTM No. 4) and 100% passing the 37.5 mm sieve (1½â€). In some instances contractors reported difficulty paving over this material because of lesser stability than traditional dense graded bases. For this reason this gradation is no longer used. Current OGDC gradations provide improved drainability and stability.

The department has revised the specified gradation several times since the early 1980's. The perceived instability of OGDC continues to be an issue. National studies continue to show the benefits of open graded bases. However, gradations continue to be studied that will maintain drainability and increase stability. Drainability of OGDC is on the order of 300 to 500 ft. horizontally per day. The lateral drainage path, to the nearest underdrain, should be no more than 30 ft.

6.02.06B Typical Cross Section

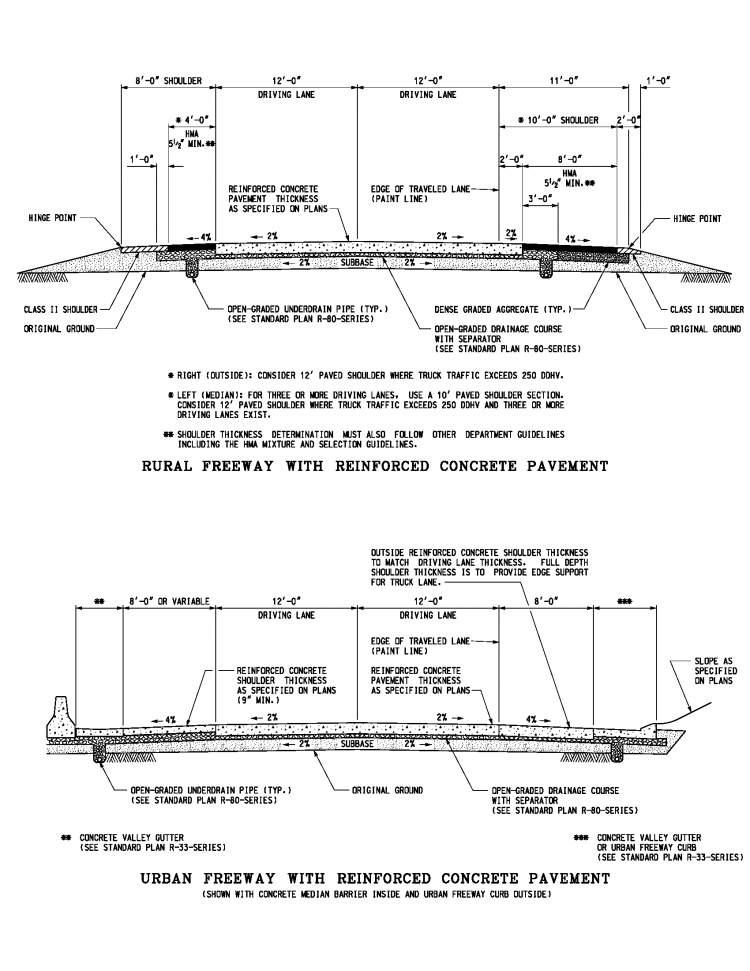

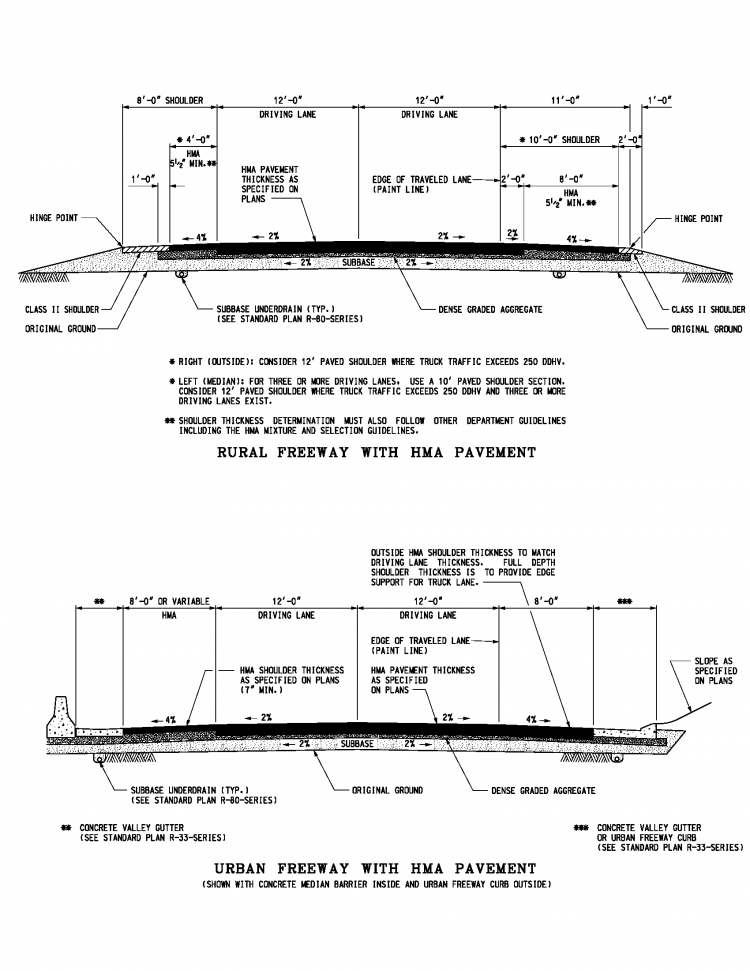

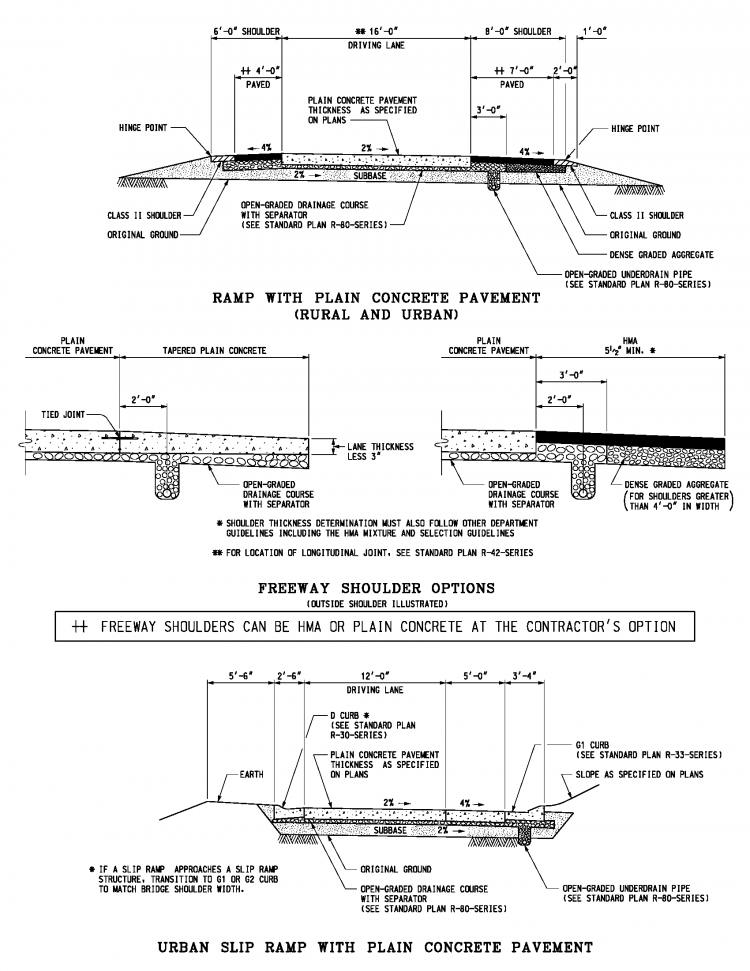

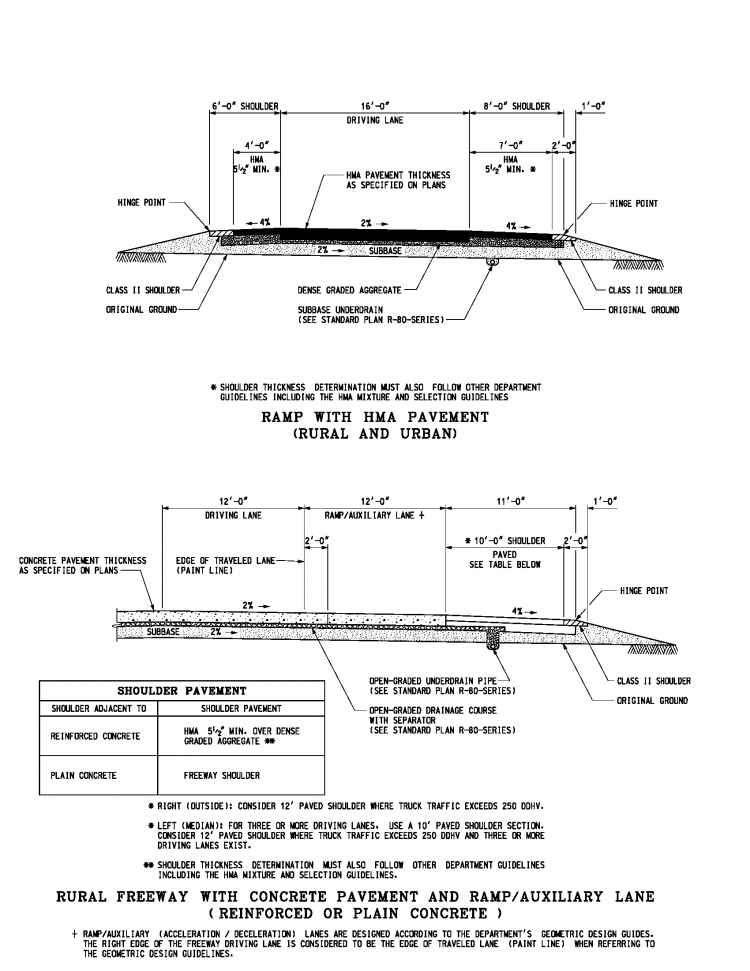

The OGDC is usually shown on the typical cross-section extending 3 ft. beyond the edge of pavement. It is typically 4 inches thick with either a geotextile separator or a dense aggregate separator course placed between the OGDC and the subbase.

6.02.06C Usage

The Engineering Operations Committee, on September 9, 1987, decided that OGDC should be used under all full lane width concrete pavements that are one-half mile or more in length. Exceptions may be made. Contractor equipment, other than spreading and trimming equipment, should not drive directly on the Open Graded Drainage Course. These traffic loadings, directly on the OGDC, cause infiltration of the subbase material into the OGDC layer. This inhibits the drainability of the OGDC.

The designer should review the project with the Construction Field Services Division to determine if construction equipment may run on the open graded base. The designer should check with the Pavement Design Engineer (Construction Field Service Division) for recommendations, if a different base is required.

6.02.07 Crushed Concrete Aggregate

With the development of equipment that can crush concrete on a large scale, it is now feasible to recycle crushed concrete aggregates. Its usage is defined in the current Standard Specifications for Construction.

Experience has shown that crushed concrete fines, i.e., crushed concrete sand, causes a very harsh mix, difficult to place and finish, as well as being difficult to consolidate in the field, leading to low compressive strength. For this reason, crushed concrete sand is now prohibited in new concrete. In addition, concrete fines contain chlorides from previous use which causes accelerated rusting of steel in the concrete. MDOT experience has also shown that concrete fines have erratic absorption rates which prevent a consistent water/cement ratio during construction. This can result in less durable concrete.

Crushed concrete aggregates have a tendency to leach out a precipitate that clogs the pores of geotextiles. They are not permitted as OGDC underdrain backfill.

6.02.08 Slag

6.02.08A General

Slag is an artificial aggregate produced as a waste by-product of the iron, steel, and copper industries. Until the downturn in American steel production it was abundant in Michigan, but rather localized. Slag associated with iron and steel making is basically located in the Detroit metropolitan area; in Sault Ste. Marie, Ontario; and in the Burns Harbor-East Chicago area of Indiana. Slag aggregates are available on Great Lakes docks by boat shipment from the Indiana and Ontario sources. The only working copper smelting facility is at White Pine in Ontonagon County. Slag is produced to Department aggregate specifications. When the word "slag" is used alone in the specifications it is understood to mean either blast furnace slag or reverberatory furnace slag.

Blast furnace slag is lighter in weight than natural aggregates, whereas steel furnace slag is heavier. Approximate weights are:

Blast furnace slag - 144 lbs/cubic foot Natural aggregate - 148 lbs/cubic foot Steel furnace slag - 184 lbs/cubic foot

6.02.08B Blast Furnace Slag

Blast furnace slag is acceptable for any aggregate use provided it meets the material requirements for that particular use. It is normally blended with other softer aggregates in order to meet AWI requirements.

6.02.08C Reverberatory Furnace Slag

Reverberatory furnace slag is acceptable for all aggregate uses except as fine aggregate for concrete (because it is a manufactured sand.) While it is somewhat heavier than natural aggregate, no weight factor has been applied. It is available in the copper mining area of the Upper Peninsula but is seldom used on trunkline projects.

6.02.08D Steel Furnace Slag

Steel furnace slag often contains ingredients that are still chemically active, causing it to expand, or gases to be released, on contact with water. Its use is therefore restricted; at the present time it can only be used in Hot Mix Asphalt (HMA).

Because of a calcium carbonate leachate, steel furnace slag should not be used as an OGDC in combination with a pavement drainage system. The leachate tends to clog the geotextile wrap, effectively negating the pavement drainage system.

6.02.09 Aggregate Base and Surface Courses

6.02.09A General

By policy, the Department does not construct permanent aggregate-surfaced roadways; i.e., an HMA surface is our minimum. Discussion of Aggregate Surface Course, even though it is included in the Standard Specifications for Construction, is therefore almost a moot subject. It is only used occasionally for surfacing a park and ride lot, county road relocation, or on a lengthy local road approach.

6.02.09B Difference between Base and Surface Courses

When an aggregate is intended for surface use, soil binder (clay) will be added to make it more dense and the surface more stable, i.e., less loose, under traffic. Binder does not materially add to its load-supporting capability. On the other hand, binder in a base course is undesirable because it impedes the free drainage of water and is susceptible to frost heave.

6.02.09C Substitution

Occasionally, a project will have a rather large quantity of one type of aggregate and a small quantity of another; e.g., a substantial amount of base course and a little surface course, perhaps for driveways. To avoid a high contract price for the small-quantity material, the designer is encouraged to use the large-quantity type of aggregate for everything. Generally, base course can be substituted for surface course since, if it is too loose, it can be made acceptable by adding soil binder.

Conversely, it is less desirable to substitute surface course for base course.

6.02.09D Conditioning Aggregate Base

Conditioning Aggregate Base is shaping the aggregate surface to the required grade or cross-section as specified in the Standard Specifications for Construction preparatory to HMA resurfacing. It does not apply to the shaping of aggregate base stabilization preparatory to concrete paving.

6.02.10 Aggregate Approaches

It is the practice of the Department to construct an HMA surface on all existing gravel approaches to the trunkline (see Section 12.02.03). The purpose is primarily to keep loose gravel off the through pavement.

6.02.11 Aggregate Additives

6.02.11A General

Calcium chloride and water used to facilitate shaping and compaction are not paid for separately, but are included in other contract items.

6.02.11B Dust Palliative Pay Item

Calcium chloride used as a dust palliative, as when maintaining traffic, should be estimated at the rate of 7.5 tons per mile of two-lane width (or two-shoulder width). The pay item is "Dust Palliative, Applied."

6.02.12 Sand Lift (Grade Lift)

Sometimes, rather than surfacing a road surface or removing it for replacement, a sand lift is used above the old pavement. Use of this method of construction has declined as recycling techniques have been improved thereby increasing the value of old pavement surfaces. A sand and gravel cushion of less than 18 inches should not be used, because there is evidence that reflective cracking is not significantly prevented in a flexible pavement. Experience has also shown that when a gravel lift is compacted, the percentage of fines increases, resulting in a dense-graded mixture which tends to trap water. An HMA base course should be used instead. An added advantage to using an HMA base course is the ease of maintaining traffic during construction.

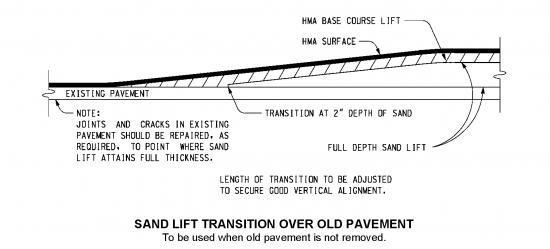

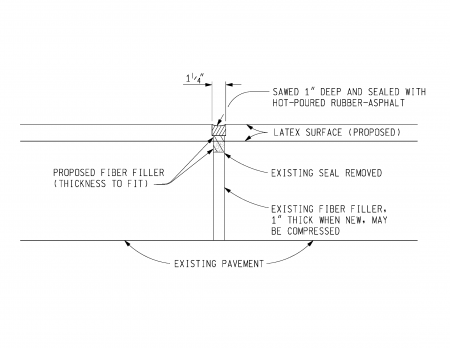

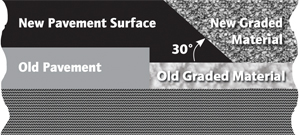

When a sand lift is used and a transition is necessary to meet the existing pavement surface, the transition should be as illustrated below.

6.03 HOT MIX ASPHALT (HMA) CONSTRUCTION)

6.03.01 General)

Asphalt, a refined product of crude petroleum, is a cementing agent in much the same way that portland cement is a cementing agent in concrete. Portland cement forms a cohesive mortar layer around aggregate particles of various sizes, as asphalt cement also does. A fundamental difference between the two is that portland cement concrete is rigid. An HMA mixture, on the other hand, is "flexible" in the sense that, depending on the unique properties of the mixture, it can flow. It is thermoplastic, becoming more pliable as heat is applied. It can be specified so that its temperature, viscosity, and durability characteristics can be matched to specific traffic and climatic conditions.

6.03.02 Glossary of Terms

Aggregate - Mineral substances (natural or "manufactured"), such as gravel, crushed stone, slag, cinders, sand, crushed concrete or combinations thereof.

Aggregate Wear Index (AWI) - A numerical value, derived by the Department, for measuring the resistance to polishing of the coarse aggregate in a given HMA pavement mixture. The higher the number, the greater the friction property. The number is determined by measuring the wet friction of a coarse aggregate concrete sample after it has been subjected to 4 million passes of a weighted, rubber-tired wheel on a circular test track. More recently, AWI numbers are being computed based on the weighted percentages from a petrographic rock analysis of a particular aggregate sample.

Alligator cracking - failure of an HMA surface, usually caused by inadequate base in combination with excess soil moisture, evidenced by closely spaced irregular and interconnected cracks. As deterioration progresses, traffic dislodges the loosened pieces of asphalt and complete failure will occur.

Asphalt cement - An asphalt that is refined to meet specifications for paving, industrial, or a special purpose, in a semi-solid state at ambient temperature. It is a product of the crude oil distillation process.

Asphalt emulsion - Minute globules of asphalt cement that have been mixed with water and an emulsifying agent to form a heterogeneous system. Emulsions are classified as slow-, medium-, or rapid-setting depending on the time it takes for them to break or separate into asphalt and water on application. Each type is available in several grades for particular application requirements.

Asphalt rejuvenator - An additive, somewhat in the nature of a light oil that, when added to an existing HMA surface or to reclaimed asphalt, softens it and increases its penetration. Usually used in conjunction with heater-planing but sometimes in hot-mix recycling. The Department rarely calls for it.

Asphalt Stabilized Crack Relief Layer (ASCRL) - An HMA mixture primarily used as a base course in a multi-course overlay of a concrete pavement to delay reflective cracking. It typically contains less asphalt cement and aggregate fines than standard HMA base course.

Bitumen - A term used synonymously with "asphalt," but more encompassing since it includes materials such as tars. Bitumens are soluble in carbon disulfide.

Black base - A conversational term used synonymously with HMA base course.

Blotter - An application of clean sand, to absorb and soak up an excess of asphalt on a pavement surface.

Blotter course - The first course of a two-course HMA surfacing in which the mix is modified to absorb the excess bitumen from asphalt-rich patches. Used to avoid removal of the patches prior to resurfacing.

Bond coat - See "tack coat."

Break(ing) - The stage during the curing of an asphalt emulsion coating when the asphalt droplets separate from the water and coalesce to form a continuous film of asphalt.

Breakdown rolling - The initial rolling operation after an HMA course has been laid down.

Butt joint - A construction joint, frequently used at the end of a days paving where a vertical saw cut face is provided for ease of resuming paving the next day. It can also be used for tying in to existing pavement. An alternative to a butt joint is a feathered joint.

Cationic emulsion - An asphalt emulsion, generally acidic in nature, prepared with an emulsifier that produces asphalt globules which are electro-positively charged.

Cold milling - The process of removing an existing surface by grinding particles away, usually by means of a machine-driven rotating drum containing a large number of carbide steel-tipped teeth.

Coulter wheel - A sharpened disc that, when brought to bear under pressure on an HMA surface, is capable of cutting through the surface. Sometimes used for trimming, it does the work of a saw faster and more economically, but with less precision.

Cracking stone - A non-technical term, relating to what happens when the thickness of the HMA course being laid is so thin that the paver screed or roller actually breaks some of the larger stone in the mix. This often occurs during feathering, but it is not considered a good construction practice for top course.

Crushing - The process by which an existing HMA surface, on a gravel base, is crushed and broken up in place by equipment such as a milling machine or a hammermill. Resulting particles, which become part of an aggregate base for resurfacing, are no larger than about 2 inches in diameter. Artificial heat is not used.

Cutback Asphalt - Synonymous with "liquid asphalt," the more preferred term used in Michigan specifications.

Drainable HMA base - A mixture composed of mostly one-size coarse aggregate that has an interconnected air void structure that will allow surface water to drain through it.

Drum mixer - A type of HMA plant that combines the drying of aggregates and the mixing of aggregates, asphalt, and mineral filler in a single rotating drum.

Emulsion - See Asphalt Emulsion.

Extraction - A laboratory test that separates the asphalt from the mineral aggregates in an asphalt paving mixture. Once separated, the components of the mix can be measured and tested.

Feathered joint - A construction method whereby the thickness of an HMA course is gradually thinned to "zero" as at the springline of a crossroad approach. While it cannot be thinned to nothing, raking out the large aggregate after paving allows a thin course.

Flow - A test in the Marshall Method of Design that measures the amount of movement or strain (in 0.01 inches) occurring in a prepared specimen during the application of the load in the stability test. It gives an indication of the resistance to deformation (shoving/rutting) that a compacted pavement will have under traffic. See Marshall Test.

Flushing - A phenomenon that occurs when there is more asphalt cement in a mix than is required to coat the aggregate particles and fill the voids. Under traffic and hot sun, the excess asphalt rises to the surface, filling the voids in the surface and being visibly shiny and perhaps slippery. It can also occur, even without an asphalt excess, if traffic is allowed on the mat before it has cooled sufficiently after paving. Moisture in the mix will also cause flushing immediately after paving.

Fog coat - A thin coating of asphalt bond coat, approximately 0.05 gal/syd sometimes used to seal areas that have been milled.

Hot Mix Asphalt (HMA) – (formally referred to as “bituminous†or “hot-mixâ€) A mixture of asphalt cement and aggregates, usually plant produced, used as a flexible pavement in road construction.

HMA aggregate - The HMA surfacing mixture composed of coarse and fine aggregates, mineral filler (when required), and asphalt. Differentiated from HMA concrete, the aggregate used is a gravel; the percentage of crushed (retained on the 4.75 mm sieve) is less, the aggregates are unwashed, and it is dense graded. This is now an obsolete term within the Department but designers may occasionally encounter it.

HMA base course – An HMA mixture of generally lesser strength and quality than HMA leveling or top courses and incorporating a reduced percentage of asphalt, used as a base for surfacing mixtures. Sometimes called "black base.â€

HMA binder course – An HMA concrete mixture incorporating relatively large crushed aggregate particles (100% passing 37 mm). Used as a stable base for surfacing mixtures. Usually more stable than HMA base course because of the aggregate interlock of the crushed particles and the higher asphalt content. While HMA Binder Course was a major pay item a few years ago, the term is now obsolete and is included here principally to aid in understanding old plans.

HMA leveling course - The HMA course under the top course. Besides adding strength and bulk to the total surfacing, it can be used to fill in slight irregularities in the underlying surface.

Lift - A term referring to the layer of HMA mixture laid down in one pass of the paver. A surface paved in two courses is constructed of two lifts.

Liquid Asphalt - An asphalt cement that has been made liquid by blending with petroleum solvents (diluents) of various degrees of volatility. Upon exposure to the atmosphere, the diluents evaporate, leaving the asphalt cement. These materials are devised according to their use. Liquid asphalts fall into three classes:

- Rapid-curing liquid asphalt (RC) - Composed of asphalt cement and various amounts of naphtha or gasoline type diluents to make up the different grades of fluidity.

- Medium-curing liquid asphalt (MC) - Made similar to the rapid-curing except that the diluent is a kerosene.

- Slow-curing liquid asphalt (SC) - Made with a heavy distillate or low-volatile oils.

Used sometimes for blending, it is so liquid that its penetration cannot be measured. Sometimes spoken of in contrast to “penetration asphalt†(the penetration of which can be measured)

Log (log job) - A written narrative that explains to the contractor, and to our own construction forces, the nature and scope of the work to be done. A log job is used for simple projects when the work can, for the most part, be described verbally.

Marshall Test - A laboratory procedure used to design or determine the properties of HMA paving mixtures. It can be used to determine the optimum proportions of aggregates, mineral filler, and asphalt cement needed to provide desired properties in a mix. Generally, thought of as a test for stability.

Mat - A term for the asphalt pavement; likely to be heard during construction.

Mineral filler - A fine mineral aggregate (usually fly ash or crusher dust), at least 70% of which passes the 0.075 mm sieve (ASTM No. 200) used to fill the voids in the mix, increasing the stability. Added in the plant, it tends to stiffen the mix.

Mix design - The laboratory process whereby the proportions of ingredients are determined for an HMA mix having certain predetermined qualities of stability and durability.

Open-Graded Friction Course (OGFC) – An HMA mixture used as a surface course, using predominantly a single size aggregate to form a porous layer. This allows rapid surface drainage and inhibits hydroplaning.

Penetration - The property of asphalt cement that is determined by a laboratory test measuring viscosity semi-solid asphalts, enabling the material to be classified into standard grades. A 1.00 mm diameter needle, with a truncated tip, is weighted to 100 g and allowed to bear on the surface of asphalt, at 25ï‚°C for 5 seconds. The penetration, in units of 0.1 mm, is then measured. The results are classified into standard penetration ranges of 85-100, 120-150, 200-250, and 250-300 for HMA mixtures used in Michigan. The lower the number, the harder the asphalt. No longer specified, Performance Grade asphalts are.

Performance Grade (PG) - Asphalt binder specification based on climate and attendant pavement temperatures at which the binder is expected to serve.

Plant-mix – An HMA mix produced in a stationary plant, as opposed to road-mix or a stabilized-in-place mixture.

Precoated sand - Sand that has been coated with asphalt. Has been used to impart a more skid-resistant texture, to a new HMA surface having low skid resistance, by uniformly spreading it at up to 2 lbs/syd on the pavement surface, then rolling. No longer used in Michigan.

Prime coat - A sprayed-on application of liquid asphalt, tar, or an asphalt emulsion on an untreated surface, such as gravel, prior to the placement of an HMA mat or seal coat. Its purpose is to close off the aggregate openings, preventing further penetration of succeeding asphalt treatments, and to aid in maintaining the shape of the final grading during paving operations. Not used by the Department.

Raveling - The progressive separation of aggregate particles in a pavement surface under the action of traffic and natural forces. Raveling occurs either from the top down or from the edges inward. A typical failure will occur at the pavement edge where there may be inadequate base support.

Reclaimed asphalt pavement (R.A.P.) - An existing HMA surface, or portion of same, that has been removed, crushed, and may be used for recycling. Proprietary R.A.P. is material owned by a contractor that may have been obtained from an unknown source, e.g., a commercial parking lot, local street, or state trunkline.

Residual - An old term that describes a road oil which has had somewhat limited refining so that it exhibits the properties of a heavier liquid asphalt, such as an SC (slow-cure).

Rubblizing - The process by which a portland cement concrete pavement is broken up into small pieces, ranging from sand size to a maximum of 6 inches, with the majority of pieces in the 1 inch to 2 inch size range. A resonant pavement breaker or multi-headed breaker is specified. Projecting pieces of steel reinforcement are cut off below the surface, the pavement is rolled with a (minimum) 10 ton steel wheeled roller, and depressions of 1 inch or more are filled with coarse aggregate.

Rutting - The formation of longitudinal depressions in the wheel paths that result when an HMA pavement or underlying base has insufficient stability to support traffic. It is usually evidenced as two continuous wheel "tracks" in the traveled lane, sometimes only visible during a rain or when measured with a straightedge.

Scratch coat - A thin course, e.g., ¾ inch of HMA surfacing sometimes used when there is considerable joint and surface deterioration of an underlying concrete pavement after HMA surfacing has been milled off, or to fill ruts. Applied directly to the pavement to be resurfaced, it gets its name from the appearance of the HMA material after it is laid down. The paver screed is set so low that the thickness of the mat may actually be less than the largest dimension of some of the aggregate particles, causing the particles to be pushed ahead of the screed, creating a scratchy appearance.

Screed - The part of the paving machine that levels and compacts the HMA mixture prior to rolling and densification.

Seal coat - The sequence of laying up a thin HMA surface consisting of a prime coat and alternate layers of an asphalt emulsion and stone chips. The terms, single, double, and triple seal, refer to the number of applications of asphalt emulsion and chips. Also known as prime and seal.

Segregation - A separating of the larger from the smaller aggregate particles in an aggregate or HMA mixture. The larger particles, being heavier, have a tendency to roll to the outside of a pile when dropped. The larger particles also have a tendency to rise to the top of a mixture when vibrated because they are unable to sink to the bottom as do the finer, smaller particles. Segregation is objectionable in an HMA mix because the mix will be non-uniform, possess less than design strength, and will have an uneven texture, allowing moisture to enter especially in the areas of the larger particles. This likely will cause raveling of the HMA surface.

Separation course - A layer to prevent bonding of an upper pavement course to a lower pavement course. It may be sand, gravel, or a low asphalt-content HMA mix.

Sheet asphalt - A sandy HMA mixture where the maximum size aggregate is that passing a 4.75 mm sieve (ASTM No. 4) or smaller. (Also called a sand asphalt HMA mixture.)

Shoving - The action of an HMA mixture, lacking stability, moving forward as a result of braking traffic. Most commonly observed as a series of bumps at the approaches to signalized or stop-control intersections.

Slurry seal - A rather liquid mixture consisting of asphalt emulsion and sand used as a thin crack and joint sealer. It is usually applied by a special machine. A variation is a tar emulsion protective coating used in parking lots as protection against deterioration caused by fuel drippings.

Stability - One of the tests used in the Marshall Method of Design to determine the maximum load in pounds, applied at 140F, which can be applied to a prepared bituminous mixture specimen (4†x 2½†high cylinder) before it fails. This test, along with the flow test, provides an indication of the ability of the pavement to carry traffic loads. Also see Marshall Test and Flow.

Stabilization – The process of increasing the load-carrying capacity of underlying layers or layers underlying the pavement by adding a stabilizing agent. Asphalt cement is most commonly used as a stabilizing agent, but asphalt emulsions, portland cement or lime have also been used. Other terms of stabilization are stabilization-in-place and in situ recycling.

Stage construction – In HMA construction, delaying placement of the top course until some time after placing the lower courses. Usually requires adding more asphalt cement to the leveling course mix so that it can carry traffic. While sometimes done for economic reasons, it also can occur when the advent of winter brings an end to the paving season.

Stringline – A technique for obtaining accurate grade control by placing taut wire or string alongside the roadway to be paved, accurately set to grade. The electronic controls on the paver are thus guided, which in turn controls the screed elevation.

Stripping - The loss of adhesion between the asphalt coating and the aggregate particle leading to deterioration of the bituminous pavement. Caused by incompatibility of the asphalt and the aggregate, which may be aggravated by moisture in the mat.

Structural number (SN) - An index number derived from an analysis of traffic, roadbed soil conditions, and a regional factor that may be converted to thickness of flexible pavement layers through the use of suitable layer coefficients related to the type of material being used in each layer of the pavement structure. (See the 1993 AASHTO Guide for Design of Pavement Structures.)

Superpave (Superior Performing Asphalt Pavement) - An improved system for specifying the components of asphalt concrete, asphalt mix design and analysis and asphalt pavement performance prediction.

Tack coat - A thin HMA coating of an asphalt emulsion. Routinely sprayed on a paved surface just before HMA paving to increase the adhesion of the new surface. Sometimes called a bond coat.

Tenting - The phenomenon, most noticeable in mid- to late winter, where the HMA surface at a crack tends to heave up on each side of the crack, forming a "peak". This is caused by the action of water entering the crack, then freezing. With the spring thaw, traffic forces the peaks down.

Thermal cracking - Transverse cracks at a somewhat regular spacing found in an HMA pavement, caused by cold weather contraction that exceeds the tensile strength of the surface.

Top course - The last and final HMA course to be placed in a surfacing or resurfacing operation.

Viscosity - The resistance of a fluid to flow under gravity. Performance grading is now used instead of viscosity grading.

VMA - Voids in the mineral aggregate. The space between aggregate particles available for asphalt and the "passing 200" fines. It allows sufficient asphalt content to provide adequate particle coating, as well as a 3-4% air content to help prevent flushing.

Wearing course - Until recently, a term referring to the top course of an HMA concrete pavement. With adoption of the term "top course," the use of this term is being discouraged.

Wedging - The practice of placing HMA material in selected low spots to further level the base prior to resurfacing. If used continuously along the pavement edge, it would flatten an excessive crown. If used along the center portion of the pavement, it would build up a too-flat crown.

6.03.03 Philosophy of the Use of HMA Surfacing

Both the HMA and portland cement concrete industries are vital parts of Michigan's economy. The Department therefore endeavors to make impartial use of both materials. Because of its adaptability to the maintenance of traffic, needing only to cool before traffic can be allowed on it, asphalt is the common type of resurfacing in use. It is also used rather extensively as the pavement type on new construction in the areas of the state having granular soils.

The purpose of resurfacing is to extend the useful life of a pavement for a given length of time, usually for a period of 8 to 12 years, but sometimes for as little as 3 to 5 years. If no design life is specified when a resurfacing project is assigned, assume it to be 10 years. In some situations a shorter design life may be desired.

6.03.04 Surface Preparation

6.03.04A Conditioning Aggregate Base / Surface

When existing aggregate base/surface remains in place see Section 6.02.09D.

6.03.04B Concrete or Composite (HMA on Concrete) Pavement

6.03.04B1 Crown and Superelevation Modification

Current methods for modifying pavement crown and superelevation are expensive and need careful consideration. Many resurfacing projects call for modifying the crown from the former parabolic configuration to the current 2% cross-slope and/or upgrading pavement superelevation. Modification of pavement slope is typically accomplished by wedging with HMA and/or cold-milling. The need for modification will be based on a safety analysis and applicable design standards. Crown modification may include changing the shape, changing the rate of the cross slope, adjusting the crown point location or a combination of the three. Existing pavement slope(s) should be thoroughly reviewed during the project design (including cross-sectioning where applicable) to minimize construction problems and cost overruns.

6.03.04B2 Cleaning Pavement

The Standard Specifications for Construction state that the pavement surface must be clean prior to resurfacing. Some designers have purposely omitted the item when milling is done on the assumption that sweeping after the milling accomplishes the desired result. The fallacy with this is that several weeks can elapse between milling and resurfacing, giving the pavement time for dirt to be tracked upon it once more. The pay item "Pavt, Cleaning", measured as a lump sum, should therefore be included in all resurfacing projects. It can be deleted during construction if for some reason it is not needed.

6.03.04B3 Removing Pavement for Joints

All joints on the trunkline where HMA surface is started or terminated should be butt joints. Construction of a butt joint requires removal of the existing surface to a depth sufficient to receive the resurfacing, so that it will be flush with the adjacent surface at the joint. Whereas this work was once done by means of a jackhammer, much of it today is done by a milling machine. The pay item “Pavt for Butt Joints, Remâ€, measured in square yards, includes removing and disposing of concrete or HMA materials. The removal depth, width and taper shall be according to the Standard Specifications for Construction.

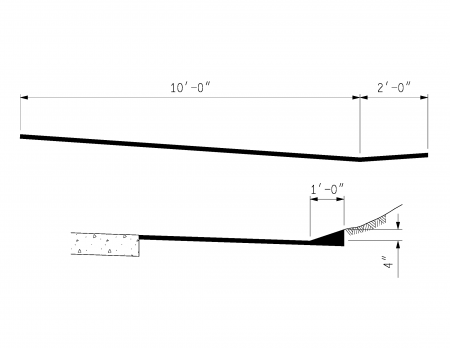

Paving of side street approaches may be ended by feathering unless recommendations to the contrary are received from the Plan Review Meeting. Feathering is much more economical than a butt joint, but it has a tendency to eventually loosen where it is extremely thin unless extra precaution is taken during construction to fine up the mix, especially for feathering. Refer to the Standard Specifications for Construction for the taper rate of feathered joints.

A butt joint, if used on a side street approach, could vary in length depending on the nature of the side street. For a low volume, low speed side street, a 10 ft. length generally would be adequate. However, at major intersections where the volume and speed are comparable to mainline, the required length of the transition should also be comparable. Thicker overlays may also require longer transitions.

6.03.04B4 Edge Trimming

An old HMA pavement, whether over gravel or concrete, develops a ragged edge over the years. Sometimes this is merely raveling, other times it may be extruded material overhanging the underlying pavement edge. This loose or uneven material may need to be removed prior to resurfacing by trimming and truing the edge, as determined in the Plan Review Meeting. This is usually done by means of either a saw or a coulter wheel, the base being left undisturbed.

The pay item of "Edge Trimming", measured in feet, covers the work of cutting the pavement edge, prior to removing HMA shoulder material adjacent to the traveled lane, and the removal of the severed debris. If it is necessary to remove HMA over concrete material near the edge, but within the traveled lane, the work will be paid for as HMA Surface, Rem.

6.03.04B5 Cold Milling HMA Surface

The development of the rotating drum milling machine around 1976 opened the way for economical, large scale removal of existing HMA surfaces, i.e., volume production without labor intensity. This capability has subsequently encouraged recycling on a large scale, and has made work such as removal for patching and butt joints comparatively easy. While the difficulty of removal, whether HMA or concrete, varies with the hardness of the aggregate and the depth of removal, it is possible to remove up to 4" or 4½†of existing HMA in a single pass of the milling machine. (However, it is usually more economical for a contractor to remove a 4" thickness of asphalt in two passes.) Machine widths, i.e., drum widths, vary from about 12" to about 12'-6". The smaller drums are available on a variety of equipment. Although a minimum 12" of width may be removed by milling, for practical purposes provide a minimum of half a lane width when reclaiming a curb face covered by previous resurfacing.

About 1½†depth is the minimum that can be cold milled economically. (Lesser depths can obviously be removed, for reasons other than economy.)

Any hand work required when removing HMA surface around catch basins, manholes, or SCANDI loops should not be paid for separately, but noted as included in payment for "Cold Milling HMA Surface". This should be clearly stated on the plans or in the proposal.

Occasionally, when requested by Construction, stringline control may be called for in conjunction with cold-milling. This is not feasible where only 1" or 1½†is being removed, however, as there simply is not enough latitude available for grade adjustment. "Cold Milling HMA Surface" may be measured by either square yard or by the ton. The unit to use will usually be determined at the Plan Review Meeting.

Where there will be varying cold milling depths use tons. When square yards are used, the thickness of HMA surfacing to be removed must be clearly indicated on the plans or in the log. Cores should be taken prior to construction (one every 1000 ft. per lane) to verify the thickness to be milled and the condition of the underlying material.

When a milling machine is used to construct a butt joint to receive the full depth of all resurfacing courses, the butt joint should be included in the payment for Cold Milling. When the depth of milling is reduced to less than the full resurfacing depth at the joint, it should be paid for as Pavt for Butt Joints, Rem. Butt joints for driveway approach removal should also be paid for as Pavt for Butt Joints, Rem. The butt joint should be detailed on the plans showing either full or reduced removal depth against the existing pavement and indicating the appropriate pay item.

6.03.04B6 Removing HMA Surface

The table below summarizes the applications for the pay items “Pavt, Rem†and “HMA Surface, Remâ€:

| Thickness of HMA cap to be removed | Underlying Pavement is: | Pay item for removing HMA surface |

|---|---|---|

| 12†or less | Either removed or left-in-place |

HMA Surface, Rem Square Yard |

| More than 12†| Either removed or left-in-place |

Pavt, Rem Square Yard |

There are a number of methods for removing HMA surface:

- Motor grader with ripper teeth

Suitable for HMA over aggregate. Largely obsolete for removing an HMA surface from underlying concrete. - Jackhammer

Being labor intensive, only suitable for small areas such as preparing a butt joint. - Front end loader

Suitable for removing an HMA surface from underlying concrete. On recycling projects the material is processed through an aggregate crushing plant. - Cold-milling Machine

Fastest, most modern method for removing an HMA surface over a pavement that is to be left in place. The machines are relatively expensive, however, which may put them beyond the means of small contractors. - Heater-planer

By softening the material with either direct or indirect flame, volume production is possible. This method tends to be energy-inefficient and environmentally objectionable, if smoke is not controlled. Not many large machines are located in this part of the country. A heat-planer may cause damage to the material, if it is to be recycled (direct flame can burn asphalt to ash).

6.03.04B7 Removing HMA Patches

Existing surface patches (not full-depth patches) may need to be removed prior to resurfacing. Generally, they are composed of cold patch material placed by maintenance forces. Cold patch is likely to be rich in bitumen, which tends to bleed through the hot resurfacing causing an asphalt-rich spot that can be weak and lacking in surface texture. Some of the cold patch materials do not need to be removed because they are not sensitive to heat. The pay item is “HMA Patch, Rem†measured by the square yard.

6.03.04B8 Joint and Crack Cleanout

Joint and crack cleanout covers the work of removing existing joint sealant and foreign materials, to a depth of up to 1" from transverse and longitudinal joints and cracks prior to resurfacing. The work is usually done with a hooked device, not unlike a stove poker. The pay item is "Joint and Crack, Cleanout", measured in feet of joints and cracks so treated. Cleaned cracks 1†wide and greater shall be filled with hand patching.

Neoprene joint seals should always be removed prior to resurfacing. Some hot poured rubber sealants need to be removed as they can cause the mat to slide when hot and while being rolled. See Section 6.03.04B(14) for treatment of existing pressure relief joints.

6.03.04B9 Hand Patching

There are two methods of placing HMA patching material: by machine and by hand. Obviously, larger areas that would make machine placement cost effective will be patched by a paver. The pay item of "Hand Patching," measured in tons of HMA material necessary to fill the void, is used to compensate the contractor for the additional effort required to do the work by hand (the pay item includes payment for material as well as for labor).

Depressions must usually be patched prior to paving the first course. Hand patching will generally be used for filling in depressions and where cold patches have been removed.

Hand Patching is a difficult item to estimate because of the many variables involved. When Detail 7 or 8 joint repairs are done using a milling machine, quantities of hand patching will increase about 50%. The problem is magnified because this item has a relatively high cost and is prone to large overruns during construction.

A quantity of Hand Patching should always be included with joint repair items. The following guidelines are offered to aid in estimating Hand Patching:

| Joint Repair | Estimate |

|---|---|

| Detail 7 | 5 tons / 100 ft of repair |

| Detail 8 | * 10 tons / 100 ft of repair |

| Holes, old patches, etc. | Approximate Area and Depth |

* Based on a depth of 11†and a width of 18â€. This estimate may need to be adjusted based on the size of the repair.

Details for joint and crack repairs are shown on Standard Plan R-44-Series.

6.03.04B10 Repairing Pavement Joints and Cracks

The Detail 7, surface repair for joints or cracks, and Detail 8, full depth repair for joints or cracks, do not include the corresponding "Hand Patching". Design quantities for either repair seldom match as constructed quantities. A cursory surface inspection is unlikely to reveal the extent of joint deterioration and construction forces complain that, for a given number of joints set up on a project for repair, there may be an equal number, equally deteriorated, for which no repair quantities are provided.

It is not unusual for Construction to pay for 12' of joint repair as, i.e., 7' of Detail 7 and 5' of Detail 8. Designers should attempt to break down quantities to the extent possible, but should realize, the extent of joint deterioration can only be determined after the joint is opened up.

There are two pay items involved with Detail 7 and 8 joint repairs, "Pavt Joint and Crack Repr, Det __†and "Hand Patching". See preceding Section 6.03.04B(9).

If the project includes milling off the old HMA surface, it may be recommend at The Plan Review that the milling machine drum be lowered perhaps 1" into the deteriorated joint to remove the deteriorated concrete and debris. If this is done, the contractor is merely compensated for the additional milled material that is removed, and the additional new surfacing material required to fill the deeper void at the joint. If, after the milling has been done, it appears that the joint is in such condition as to require a bona-fide Detail 7 or 8 joint repair, then the engineer will order that this be done. The subsequent repair would then be paid for as an ordinary Detail 7 or Detail 8 joint repair.

6.03.04B11 Pavement Patching

Pavement patching consists of a cast in place concrete patch, in most situations. A concrete patch is used when a Detail 7 or Detail 8 repair method is not sufficient. Standard Plan R-44-Series illustrates a concrete patch design. Full depth HMA patches are used in lieu of concrete patches only when maintaining traffic concerns warrant the change. Full depth HMA patches are typically recommended on low commercial volume routes. Full depth HMA patches should only be used on freeways when maintaining traffic is an overriding concern.

Backfill material for a full depth HMA patch is mainline top course mixture and is paid for as Hand Patching. See Section 6.03.09.

The patching mixture will be placed flush with the surface of the existing pavement. The patch is paid for as “Pavt Repr, Rem†in square yards of material removed, and as “Hand Patching†in tons to the cover the HMA mixture put back.

6.03.04B12 Guidelines for Preparing a Deteriorated Jointed Reinforced Concrete Pavement for an HMA Overlay

The Engineering Operations Committee has approved the following guidelines for repairs to jointed reinforced concrete pavement in preparation for an HMA overlay.

- 1. Traffic Volume Range 0-5,000 ADT (per roadway)

- Replace all joints and cracks having a distress severity level of 1 with a Detail 8 repair. Remove all cold patch material and loose concrete from all remaining joints and cracks and replace with a Detail 7 patch. All previously placed concrete repairs are to be left as is, except cold milling of concrete repairs faulted more than ¾†is optional (in lieu of replacement).

- 2. Traffic Volume Range 5,000-10,000 ADT (per roadway)

- Repair all joint, cracks, and undowelled repairs having a distress severity level of 1 with a dowelled concrete repair. Remove all cold patch material and loose concrete from all remaining joints and cracks and replace with a Detail 7 patch. Cold mill all undowelled repairs faulted more than ½â€.*

- 3. Traffic Volume Range 10,000 and up ADT (per roadway)

- Replace all joints, cracks, and undowelled repairs having distress severity levels of 1 and 2 with a dowelled concrete repair. Remove all cold patch material and loose concrete from all remaining joints and cracks and replace with a Detail 7 patch. Cold mill all undowelled repairs faulted more than ½â€.*

- * In lieu of cold milling replace all remaining undowelled repairs with dowelled repairs if the replacement cost (based on total pavement repair and overlay cost) is less than 15 percent above the cold milling cost.

6.03.04B13 Additional Uses of Detail 8 Joint Repairs

- When the expected functional life of the repaired pavement is no greater than 5 years.

- When the overall integrity of the pavement has deteriorated to the extent that the load transfer and slab flexure capacity no longer allows the pavement to function as a rigid pavement.

- When the pavement has deteriorated to the extent that it can no longer accept the stresses that would be imposed upon it by the installation or action of load transfer devices.

6.03.04B14 Surfacing Over Pressure Relief Joints

Pressure relief joints have been used in concrete pavement since 1975. The foam filler placed in those joints should be removed prior to resurfacing, if possible to do so. Sometimes the pavement is so compressed that the foam filler is almost a solid. In this case it is not only very difficult to remove but it will do no harm if left in place.

Problems seem to occur when the width of the opening exceeds about 1â€. Lack of support leads to inadequate compaction of the new surface mix over the crack or joint. The poorly compacted, porous mix is subject to cracking, water penetration, and early failure. When setting up logs for resurfacing of roadways that have had previous joint repair and pressure relief, the designer should call for removing the joint filler if the joint is more than 1†wide. The void should then be filled with a sand-asphalt mixture before resurfacing. Payment for sand-asphalt should be included in other surface preparation payment items.

Note: Cracks over 1†wide should likewise be cleaned and filled with a sand-asphalt mixture.

6.03.04B15 Wedging

Wedging is used to build up insufficient areas in the existing surfacing, such as to increase insufficient crown, to increase superelevation, or to level out sags that distort the profile. While the regular HMA surfacing can be thickened to take out up to 1†of sag, wedging, as a separate operation, must be used for thicker modifications.

Wedging shall be 3" or less using the same HMA mix as the top course of the mainline pavement. Additional wedging can be accomplished with variable thickness in the leveling and/or base course.

6.03.04B16 Scratch Coat

An 80 lbs/syd (about ¾†thick) scratch coat is usually required whenever a pavement is cracked and seated, or the existing HMA cap is removed from a composite pavement and the exposed concrete surface has joint and surface deterioration. This is to prevent ravelling of the old concrete under traffic, and possibly a rolling ride when the finished pavement is in place. The material is similar to an HMA leveling course, perhaps modified to use a different size aggregate, computed in addition to the regular rate of resurfacing proposed for the project. If, for some reason, the scratch coat needs to be thicker (as recommended at the Plan Review Meeting) then consideration should be given to reducing the regular leveling course by the additional application rate in excess of the nominal 80 lbs. A scratch coat should be provided on all such applicable projects unless it is specifically deleted at the Plan Review Meeting.

A scratch coat can also be used to fill longitudinal irregularities such as rutting or faulting between lanes. Scratch coat quantities should be shown separately from the regular resurfacing quantities, and designated as "scratch coat", e.g. HMA, LVSP (Scratch Coat).

6.03.05 Adjusting Drainage Structures and Utilities

It is the practice of the Department to adjust the elevation of manhole and catch basin covers to fit the finished elevation of proposed resurfacing. Designers should therefore provide quantities for this adjustment, but with the knowledge that site by site decisions will be made on construction relative to tapering the surfacing down (or up) to meet the cover at its existing elevation. Depressed covers, e.g., possibly as much as 1" low, can sometimes be tolerated in the gutter, and a manhole cover in the center of a lane that is ½†low may not pose a problem. On the other hand, a cover in the lane wheeltrack that is ½†low will be a constant annoyance to the motorist. Some local agencies, for reasons of economy, will shape the new HMA to fit the existing elevation of the cover even if it is 1½†to 2" low. This practice may be acceptable on low volume, low speed residential streets, but it is not acceptable on a street designated as trunkline.

6.03.05A Adjusting Drainage Structures Covers

The item of "adjusting" applies where the elevation of the cover is changed 6" or less. It applies to manhole covers, whether drainage or utility, inlets, and to catch basin covers. While adjustment is usually upward, it can apply where the cover is lowered as well, as might occur in a widening situation.

If the existing structure is in poor condition, it should be reconstructed.

Normally, adjustment is by means of raising the casting with a masonry lift. From time to time, various manufacturers introduce adjusting rings that raise the lid or grate without necessitating adjustment of the frame.

Designers should take the maintaining traffic scheme into account when setting up drainage structure adjustment quantities. If it is determined that traffic will be carried on the leveling course for a period of time, it may be necessary to adjust the covers twice. In this case it might be prudent to contact the Region/TSC for confirmation of the need for double adjustment.

There have been occasional problems with settlement of the HMA surfacing in the area for 10" to 12" around manhole covers, the area usually disturbed during adjusting. There are several theories as to the cause of this settlement: allowing traffic over the cover before normal strength mortar has attained strength, inadequate compaction around the cover, and deterioration of the manhole itself. The problem has been particularly prevalent in the urban areas.

One method that has proven successful in overcoming this problem is cutting out approximately a 6' square around the cover, after the leveling course is laid, and recasting it with concrete base course about 2" below the finished grade of the top course. This method of adjustment was approved by the Engineering Operations Committee on January 19, 1983.

6.03.05B Drainage Structure Cover, Adjust, Additional Depth

The item of "adjust additional depth" applies where the elevation for the cover is changed more than 6†(unless reconstruction to top of footing is necessary, in which case the work is paid for as a new structure). Additional depth adjusting also applies where the corbel (cone) of an existing structure must be rebuilt to adjust the lateral location of the cover.

Frequently, drainage structures set up on plans to be adjusted are found on construction to be in such poor condition that they require additional depth adjusting, resulting in a cost overrun. To compensate for this, designers should set up a lump sum quantity of "entire project" additional depth adjusting of drainage structures equal to 25% of the total of structures set up on the plans to be adjusted. (This figure of 25% will be in addition to the number of structures known to require additional depth adjusting and so set up on the plans.) On projects where the drainage structures are unusually old, or where there is a large volume of heavy trucks, the 25% estimate should be increased to 40%.

6.03.05C Measurement and Payment

The pay item “Dr Structure Cover, Adj, Case 1â€, measured as each, applies to structures located in pavement (including curb and gutter). Removal and replacement of pavement is included in this pay item, while replacement of the curb and gutter is paid for separately.

The pay item “Dr Structure Cover, Adj, Case 2â€, measured as each, applies to structures located outside the pavement area.

The pay item “Dr Structure Cover, Adj, Add Depth†is measured per foot beginning 6†from the level of the existing structure (in the direction of adjustment) to the limit of the additional depth of adjustment. This also requires payment for, “Dr Structure Cover, Adj, Case __.

If a new cover is required in conjunction with an Adjustment it is paid for separately. Also, see Standard Specifications for Construction for details.

6.03.05D Adjusting Water Shutoffs and Gate Boxes

The pay items “Water Shutoff, Adj, Case __†and “Gate Box, Adj, Case __†measured as each, should be set up as applicable. Case 1 refers to structures located in hard surfaced travel areas and unit prices includes saw cutting, removing and replacing existing pavement, curb, or curb and gutter, and adjusting the water shutoff or gate box to final grade. Case 2 refers to structures located outside existing pavement, curb, or curb and gutter and unit prices includes restoring disturbed vegetated or sidewalk areas.

6.03.05E Facilities Owned by Private/Public or Municipal Utility

Manholes, shut-off valves, etc. owned by a private/public or municipal utility that require adjustment or reconstruction may be altered by the facility owner. The facility owner should be contacted to discuss whether they want to adjust the facility or have the MDOT contractor do this work. The designer should coordinated efforts with the Region/TSC utility coordination engineer for contacting the effected utility. If the work will be done by the utility, such structures should be referenced by a note on the plans to the effect that the work will be done by others. The Region/TCS utility coordination engineer should include language regarding this work in the projects utility coordination clause.

6.03.05F Adjusting and Placing Monument Boxes

Payment for installing or adjusting monument boxes in paved areas will be according to the current specifications for "Monument Box, Adj†or "Monument Box Preservation"

In addition, it is required that all monument boxes be adjusted whether shown or not. To ensure that all government corners are adjusted or preserved, the designer shall place the following note on the plans or in the log of any project that includes section or quarter corners.

It is the intent that all government corners on this project be preserved and that, where necessary, monument boxes be placed or adjusted whether shown or not.

Monument box castings are furnished by the contractor according to Standard Plan R-11-Series.

If a Design Unit has a resurfacing project to design without benefit of a survey, the Design Engineer should check with the Survey Section to determine if a pickup survey to locate monument boxes could be made within the time available to complete the plans.

Designers may encounter monument boxes in existing pavements at previous survey or construction control points. On a major reconstruction project these monuments probably need not be preserved, whereas on a resurfacing job, a quantity should be set up to adjust or place new boxes. The Lansing Survey Unit should be contacted by the Design Unit whenever these points are encountered on a project.

For additional information concerning monumentation, see Section 5.14.

6.03.06 Special Base Treatments

For detailed information and applications of each of the following specified treatments contact the Region/TSC Soils Engineer and the Pavement Design Engineer. Also contact the Region/TSC Soils Engineer and the Pavement Design Engineer regarding any emerging technologies and applications that may be available.

6.03.06A Concrete Pavement Cracking and Seating

Michigan has used this method on a limited number of projects with mixed results. Pavement Cracking and Seating was developed as a means to reduce or eliminate reflective cracking in an HMA over concrete pavement. The process involves cracking of the old concrete slab prior to placing an HMA overlay. The results of the process have varied from a severely cracked slab with portions literally pounded into the subgrade to cracking so slight that it is hardly visible. Cracking and Seating is only effective when the bond between the steel reinforcement and the concrete is broken. Research has shown that breaking this bond is difficult to accomplish. Cracking and Seating should only be used when the concrete slab is nonreinforced and where an approved base course exists. The Region Soils Engineer and the Pavement Design Engineer should be consulted. An effective Cracking and Seating operation yields concrete pieces ranging from 18†to 48â€.

A major advantage to this method is that traffic can be maintained on a Crack and Seated surface. This is particularly useful on two lane roads where lane closures are difficult. High traffic volumes can cause high dust levels.

The Region/TSC Soils Engineer and the Pavement Design Engineer should be consulted when designing an HMA overlay for a Cracked and Seated pavement. They should also be consulted to determine whether Cracking and Seating is an appropriate fix type for a project. A special provision is required.

6.03.06B Rubblizing Concrete Pavement