Difference between revisions of "Chapter 7 - Appurtenances"

| Line 446: | Line 446: | ||

'''Current Use:''' | '''Current Use:''' | ||

| − | # Use when connecting Guardrail, Type | + | # Use when connecting Guardrail, Type B to Bridge Barrier Railing, Type 5 without expansion at backwall. |

{{top}} | {{top}} | ||

| + | |||

====[[#7.01.16E Guardrail Anchorage, Bridge, Detail T-5 Standard Plan R-67-Series)|7.01.16E Guardrail Anchorage, Bridge, Detail T-5 Standard Plan R-67-Series)]]==== | ====[[#7.01.16E Guardrail Anchorage, Bridge, Detail T-5 Standard Plan R-67-Series)|7.01.16E Guardrail Anchorage, Bridge, Detail T-5 Standard Plan R-67-Series)]]==== | ||

Revision as of 16:08, 23 February 2016

7.01 ROADSIDE SAFETY BARRIERS

7.01.01 References

- Guide for Selecting, Locating, and Designing Traffic Barriers, AASHTO 1977

- A Guide to Standardized Highway Barrier Rail Hardware, AASHTO AGC ARTBA Joint Committee, 1995

- A Supplement to A Guide for Selecting, Designing and Locating Traffic Barriers, Texas Transportation Institute and FHWA, March 1980

- Roadside Design Guide , AASHTO, 2011, 4th edition

In addition, there are a number of National Cooperative Highway Research Program (NCHRP) research publications and reports of the major research and testing agencies that are available either within the Design Division or in the Transportation Library.

7.01.02 Application of Section 7.01

In writing this portion of Chapter 7 it should be noted that the concepts presented will not necessarily be considered as absolutes to be rigidly adhered to, but will be considered as an aid to enhance the engineering judgement of the designer. Even when the word "should" is used, it is recognized that there may be circumstances unique to a situation that will suggest, or even dictate, alteration of a recommended treatment.

It is also intended that the barrier treatments recommended will be applicable to state trunkline projects and not necessarily to local government projects, except as local agencies wish to incorporate them.

7.01.03 History of Guardrail and Barrier in Michigan

The practice of placing an artificial obstruction to prevent an errant vehicle from going down a steep embankment or into an area of water probably originated in the 1920's in the form of a line of posts placed at the edge of the shoulder. At some point in time the system was improved by the addition of connecting planks, which in turn were replaced by a more maintenance-free system of two steel cables. This design is illustrated on the old E-4-A-75 Series of standard plans. Following World War II some metal beam designs were introduced. One that found limited use in Michigan was the Tuthill Highway Guard, a convex smooth steel beam, 12" wide, fastened to spring steel supports, which were mounted on either wood or steel posts. In the early 1950's the concept of a metal beam was further refined with the introduction of the W-beam with the two corrugations that are essentially what we are familiar with today.

Initially, the W beam was not galvanized and had to be painted. The next step was to galvanize it for more economical maintenance.

The first installations of W-beam rail involved attaching the beam element directly to posts placed 12'-6" on centers, at a top of rail height of 24". This design later became known as our Beam Guardrail - Type A. Research and crash testing in the late 1950's and early 1960's, principally by the state of California and by General Motors at its Milford Proving Grounds, produced the recommendations of closer post spacing, (6'-3"), blocking out the beam from the post, and a higher top of rail mounting height. This resulted in Michigan's development of our Beam Guardrail - Type C in 1965, and Beam Guardrail - Type B in 1966. The most recent significant change in guardrail type in Michigan occurred in 1984 with the adoption of thrie beam, now called Guardrail, Type T.

Until 1995, four basic end treatments had been used in conjunction with steel beam guardrail. Initially, a curved end shoe was placed on both ends of the run. The concept of turning down or burying the ending to form an anchorage was developed about 1966. The first standard plan to be approved by what was then the Federal Bureau of Public Roads was issued in 1968. A variation of the turned down ending, featuring the elimination of the first two posts (so the ending would collapse under impact) appeared in 1971 with the issuance of Standard Plan III-65A.

The Breakaway Cable Terminal (BCT) ending was adopted in 1973 with the issuance of Standard Plan III-58A. After 22 years as the standard guardrail terminal in most states, the FHWA disallowed further installation of the BCT on the National Highway System (NHS) after December 31, 1995. This, along with the adoption of new crash testing criteria (NCHRP 350) ended the use of the BCT as well as other traditional un-patented endings.

This initiated the development and use of a number of proprietary terminals. The Department has divided these terminals into two basic categories of flared gating terminals and tangent terminals. Current standard designs are described in Section 7.01.25 along with other designs previously used.

Development of concrete barrier in this country, principally concrete median barrier having the concave safety shape, is generally attributed jointly to General Motors and to the state of New Jersey, both of whom conceived shapes that bear their names. Michigan's first concrete barrier was on the DeQuindre Yard bridge, on I-94 in Detroit, in 1965. Although the New Jersey shape was used in this initial installation, the GM shape was adopted as standard. In 1976 the New Jersey shape was adopted as standard.

7.01.04 Deleted

7.01.05 Basic Concepts for Roadside Control

The following are basic concepts and design options for the use or non use of roadside barriers. The primary sources of information for roadside control are found in the AASHTO documents listed in Section 7.01.01, "References".

- A collision with a roadside barrier is considered a crash, because the barrier itself is a roadside obstacle.

- A roadside barrier may increase the frequency of crashes, therefore a barrier should only be installed if it will reduce the severity of potential crashes.

- When considering the design options for roadside treatment and the progression of design options basic concepts for roadside control should be as follows.

- Remove the obstacle or redesign it so it can be safely traversed.

- Relocate the obstacle to a point where it is less likely to be struck.

- Reduce impact severity by using an appropriate breakaway or traversable device.

- Redirect a vehicle by shielding the obstacle with a longitudinal traffic barrier and/or crash cushion.

- Delineate the obstacle if the above alternatives are not appropriate.

- Generally, a roadside barrier should be placed as far from the traveled way as conditions will permit. See Section 7.01.30G.

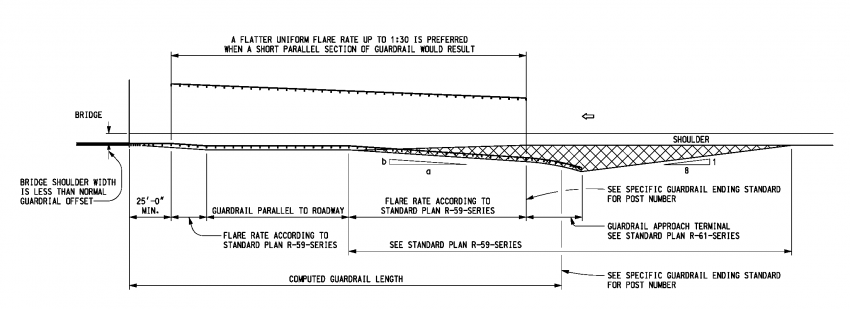

- Standard Plan R-59-Series depicts guardrail at approaches to bridges, both over and under. It is intended for new construction, where it is possible to grade approach fill sections to accommodate the flared ending. Generally, the more flare that can be achieved, the shorter the rail needs to be to afford the desired protection.

- Longer runs of parallel barrier may be required on upgrading projects, where less than ideal existing conditions preclude the use of flares as called for by Standard Plan R-59-Series.

- To uniformly compute the length of need for roadside barriers, a guardrail worksheet has been developed and should be used on both new and upgrading projects. Computation methods used on this worksheet complies with the guidelines described in the Roadside Design Guide. It still remains important that all designers become familiar with the "Guide" to understand the design process. For determining the length of need when non traversable embankments are the only obstacles of concern, see Section 7.01.30. The worksheet shall be used by all designers, including consulting firms performing work for the Department, to compute guardrail length of needs. The designer should fill in all data and compute each individual barrier run. This will assure proper compliance to standards and allow each barrier run calculation to be documented and checked for accuracy. Construction field offices should be sent the completed worksheets for reference during project construction. The worksheet does not cover all situations which may occur in the field, although it is expected to cover most installations. Any situation not covered by the worksheet shall be similarly documented, along with a sketch providing the details of the guardrail installation.

7.01.06 Guardrail Worksheet

The guardrail worksheet is shown on the following pages.

7.01.10 Clear Zone – History

For a number of years road designers and safety authorities considered 30' a desirable requirement for a safe roadside free of obstacles. This was based upon a study by General Motors in the early 1960's which revealed that of 211 cases at the proving grounds involving vehicles leaving the road, 80% did not travel more than 29' from the edge of pavement. The 1967 “Yellow Book†(Highway Design and Operational Practices Related to Highway Safety, AASHTO), page 20, rounded this distance off to 30'. The 2nd edition of the “Yellow Bookâ€, published in 1974, reiterated the 30' distance, but called for an application of engineering judgement by emphasizing that the "30' distance is not a “magic number" (page 38). The 1977 Barrier Guide defined clear zone, in the glossary on page iv, as "That roadside border area, starting at the edge of the traveled way, available for safe use by errant vehicles. Establishment of a minimum width clear zone implies that rigid objects and certain other features with clearances less than the minimum width should be removed, relocated to an inaccessible position outside the minimum clear zone, or remodeled to make safely traversable, breakaway, or shielded."

The 1977 Barrier Guide introduced the concept that rate of sideslope, speed of traffic, horizontal curvature, and ADT would affect the width of clear zone. The 30' width was retained for 60 mph speed in combination with flat side slopes, tangent roadway alignment, and ADT exceeding 6,000. However, a graph on page 16 adjusts this basic 30' for traffic speed and rate of sideslope. These adjustments are both up or down (wider or narrower) for either descending or ascending slope. A formula on page 17 further adjusts the clear zone for horizontal curvature. Finally, a procedure shown on pages 60-65 adjusts the clear zone downward (narrower) for ADT's below 6,000. The Supplement to the 1977 Barrier Guide expanded on the clear zone criteria that begins on page 15 of the Barrier Guide by including a series of tables prepared by the state of Illinois that show clear zone requirements for various degrees of curve. These criteria have been criticized by a number of states because of the extreme clear zone widths, particularly for the combination of sharp curve, higher speed, high traffic volume and steep slope.

In anticipation of a proposed revision of the 1977 Barrier Guide, FHWA in April 1986 afforded the states a measure of relief with respect to clear zone requirements. It provided a formula for a curve correction factor that is based upon increasing the value for clear zone for a tangent section, obtained from the Barrier Guide. This new formula is more reasonable than the formula on page 17 of the Barrier Guide. It was adopted by the Department in July 1986. In 1989 the Roadside Design Guide was issued by AASHTO and adopted by MDOT as a guide. Updates to the Roadside Design Guide were published in 1996, 2002, 2006 and 2011.

7.01.11 Current Clear Zone Criteria

Virtually everyone agrees that a flat, smooth, unobstructed area adjacent to the driving lanes is highly desirable and significantly improves roadside safety. The only point of contention is how wide to make this area. The designer needs to understand that the clear zone distance is not an absolute number. Some designers have erroneously believed, that in all cases, the need for protecting motorists ends at the selected clear zone distance.

The Department measures the clear zone from the outer edge of the through lane. When determining clear zones in auxiliary lane areas, use the volume of the through lanes and the freeway design speed to obtain the clear zone distance. The resulting clear zone distance should be measured from the outer edge of the through lane and is not to be less than 23 ft out from the outer edge of the auxiliary lane.

The Roadside Design Guide defines the clear zone as a variable distance from the traveled way, depending on design speed, ADT, and embankment slope rate and direction.

The Clear Zone Distances Table presents a range of values that can be used for specific conditions. These numbers are based on limited data that was gathered under non- typical conditions and extrapolated to account for sloped roadsides. Also the values obtained from the Clear Zone Distances Table are based on an assumption of constant side slope throughout the clear zone. They must not be perceived as absolute. In situations where the side slope changes within the calculated clear zone, the clear zone must be recalculated based upon a weighted average calculation. An example of this procedure is shown in Section 13.02.08 of this manual.

Application of the values in the Clear Zone Distances Table is dependent on the extent of work and the roadway classification. The higher values should be used on new construction, reconstruction and on all freeways.

When evaluating existing conditions and when designing rehabilitation projects, we should attempt to use the higher values; however, economics, existing field conditions, and other restraints may justify using the lower values.

Clear zone for 3R-nonfreeway projects must be selective and generally "fit" conditions within the existing right-of-way and character of the road. Some roadside improvements that should be considered may include removal, relocation, or shielding of such obstacles as culvert headwalls, utility poles, and bridge supports that are within the selective clear zone.

The designer should also be aware that current clear zone distances and 3R guidelines serve as general guidance for Heritage Routes (See Section 3.09). Narrow pavement, narrow shoulders, winding and/or rolling alinement, steep side slopes, roadside obstacles and narrow right-of-way are common characteristics of Heritage Routes that sometimes prevent the use of even the lower range of the Clear Zone table. Where economic or environmental concerns are great, and there is no history of crash concentration, shorter clear zone distances may be considered to preserve the characteristics of the Heritage Route. Some areas of concern may be addressed with appropriate traffic signing. When distances below the ranges offered in the Clear Zone Distances Table are used, the rationale for the alternative treatment should be noted in the project file.

Tree removal should be considered as stated in Section 3.09.03C. Some alternatives are also offered in the next two sections 7.01.11A and 7.01.11B).

7.01.11A Treatment/Consideration of Obstacles Outside the Calculated Project Clear Zone

Occasionally, there may be opportunities to improve the roadside safety on a project for a small cost by addressing a few obstacles outside the determined clear zone. Examples of these opportunities are as follows:

- When installing landscape items: Since we have control over the location of new items, we can provide additional protection to the motorist by applying a more generous clear area to these items. For instance, our freeway guideline for a long time has been to plant trees at least 50 feet off the edge of traffic lanes.

- When isolated trees, volunteer growth, utility poles, etc. are present: Depending on aesthetic concerns, it may be possible to offer the motorist a very generous clear area (beyond that required by the Clear Zone Distances tables) by simply removing or relocating a few isolated obstacles.

- Obstacles near the bottom of a ditch are more likely to be hit by an errant vehicle since the ditch tends to funnel the vehicle. Relocating the obstacle further up the back slope, or even slightly up the front slope (closer to road but still outside the clear zone limit), would usually be preferable.

- A clear runout area beyond the toe of a traversable (smooth and free of fixed objects) but non-recoverable (between 1:4 and 1:3) foreslope is desirable since vehicles traversing this steep slope are likely to continue to the bottom. The extent of this clear runout area can be determined by subtracting the distance between the edge of traveled way and the breakpoint of recoverable foreslope from the clear zone distance. This distance should be at least 10' if feasible.

7.01.11B Treatment/Consideration of Obstacles Inside the Calculated Project Clear Zone

Where the following conditions exist, it may be necessary to retain trees that otherwise would be considered for removal.

- At landscaped areas, parks, recreation or residential areas or where the functional and/or aesthetic values will be lost.

- Exceptional or unique trees (because of their size, species, or historic value).

- On designated heritage roads and low speed roads (including low speed urban areas).

- At locations where cumulative loss of trees would result in a significant change in character of the roadside landscape.

- Behind nontraversable backslopes.

- Behind vertical curbs, particularly in low speed areas.

- Where shrubs and/or ornamental trees exist that would have a mature diameter of 4" or less at 4'-6" above ground line.

- Where removal would adversely affect endangered/threatened species, wetland, water quality, or result in significant erosion/sedimentation problems.

7.01.11C Clear Zone Distance Chart

| CLEAR ZONE DISTANCES (IN FEET FROM EDGE OF DRIVING LANE) | |||||||

|---|---|---|---|---|---|---|---|

| DESIGN SPEED |

DESIGN ADT |

FILL SLOPE | CUT SLOPE | ||||

| 1:6 OR FLATTER |

1:5 TO 1:4 |

1:3 | 1:3 | 1:4 TO 1:5 |

1:6 OR FLATTER | ||

| 40 mph or Less |

under 750 | 7 - 10 | 7 - 10 | ** | 7 - 10 | 7 - 10 | 7 - 10 |

| 750 - 1500 | 10 -12 | 12 - 14 | ** | 10 -12 | 12 - 14 | 12 - 14 | |

| 1500 - 6000 | 12 - 14 | 14 - 16 | ** | 12 - 14 | 14 - 16 | 14 - 16 | |

| over 6000 | 14 - 16 | 16 - 18 | ** | 14 - 16 | 16 - 18 | 16 - 18 | |

| 45-50 mph |

under 750 | 10 - 12 | 12 - 14 | ** | 8 - 10 | 8 - 10 | 10 - 12 |

| 750 - 1500 | 14 - 16 | 16 - 20 | ** | 10 - 12 | 12 - 14 | 14 - 16 | |

| 1500 - 6000 | 16 - 18 | 20 - 26 | ** | 12 - 14 | 14 - 16 | 16 - 18 | |

| over 6000 | 20 - 22 | 24 - 26 | ** | 14 - 16 | 18 - 20 | 20 - 22 | |

| 55 mph |

under 750 | 12 - 14 | 14 - 18 | ** | 8 - 10 | 10 - 12 | 10 - 12 |

| 750 - 1500 | 16 - 18 | 20 - 24 | ** | 10 - 12 | 14 - 16 | 16 - 18 | |

| 1500 - 6000 | 20 - 22 | 24 - 30 | ** | 14 - 16 | 16 - 18 | 20 - 22 | |

| over 6000 | 22 - 24 | 26 - 32* | ** | 16 - 18 | 20 - 22 | 22 - 24 | |

| 60 mph |

under 750 | 16 - 18 | 20 - 24 | ** | 10 - 12 | 12 - 14 | 14 - 16 |

| 750 - 1500 | 20 - 24 | 26 - 32* | ** | 12 - 14 | 16 - 18 | 20 - 22 | |

| 1500 - 6000 | 26 - 30 | 32 - 40* | ** | 14 - 18 | 18 - 22 | 24 - 26 | |

| over 6000 | 30 - 32* | 36 - 44* | ** | 20 - 22 | 24 - 26 | 26 - 28 | |

| ≥ 65 mph |

under 750 | 18 - 20 | 20 - 26 | ** | 10 - 12 | 14 - 16 | 14 - 16 |

| 750 - 1500 | 24 - 26 | 28 - 36* | ** | 12 - 16 | 18 - 20 | 20 - 22 | |

| 1500 - 6000 | 28 - 32* | 34 - 42* | ** | 16 - 20 | 22 - 24 | 26 - 28 | |

| over 6000 | 30 - 34* | 38 - 46* | ** | 22 - 24 | 26 - 30 | 28 - 30 | |

| * | Where a site specific investigation indicates a high probability of continuing crashes, or such occurrences are indicated by crash history, the designer may provide clear zone distances greater than 30 feet as indicated. Clear zones may be limited to 30 feet for practicality and to provide a consistent roadway template if previous experience with similar projects or designs indicates satisfactory performance. |

| ** | Since recovery is less likely on the unshielded, traversable 1:3 slopes, fixed objects should not be present in the vicinity of the toe of these slopes. |

7.01.11D Curve Correction Factors Table

The Curve Correction Factors Table shown below shall be applied to horizontal curves with radii less than or equal to 2950 ft.. The curve correction factor (Kcz) shall be applied to the outside of curve only. The inside portion of the curve will be treated as a tangent section.

| CURVE CORRECTION FACTORS (Kcz) | |||||||

|---|---|---|---|---|---|---|---|

| Radius (ft) |

DESIGN SPEED (mph) | ||||||

| 40 | 45 | 50 | 55 | 60 | 65 | 70 | |

| 2950 | 1.1 | 1.1 | 1.1 | 1.2 | 1.2 | 1.2 | 1.2 |

| 2300 | 1.1 | 1.1 | 1.2 | 1.2 | 1.2 | 1.2 | 1.3 |

| 1970 | 1.1 | 1.2 | 1.2 | 1.2 | 1.3 | 1.3 | 1.4 |

| 1640 | 1.1 | 1.2 | 1.2 | 1.3 | 1.3 | 1.3 | 1.4 |

| 1475 | 1.2 | 1.2 | 1.3 | 1.3 | 1.4 | 1.4 | 1.5 |

| 1315 | 1.2 | 1.2 | 1.3 | 1.3 | 1.4 | 1.4 | |

| 1150 | 1.2 | 1.2 | 1.3 | 1.4 | 1.5 | 1.5 | |

| 985 | 1.2 | 1.3 | 1.4 | 1.5 | 1.5 | 1.5 | |

| 820 | 1.3 | 1.3 | 1.4 | 1.5 | |||

| 660 | 1.3 | 1.4 | 1.5 | ||||

| 495 | 1.4 | 1.5 | |||||

| 330 | 1.5 | ||||||

7.01.11E Other Controlling Factors

For free access highways, the clear zone should ideally be the same as for controlled access highways, but often this is impossible as it would require complete reconstruction of the highway, and destruction of the existing roadside features. Clear zone may often be restricted by drives, intersections, ditches, narrow R.O.W., and other features. While it may be argued that the dynamics of a vehicle running off the road are no different on a free access road than they are on a limited access facility, it remains as a fact of life that there will always be obstacles of some description on free access roads - mailboxes, driveway embankments, trees, buildings, etc. Enormous numbers of these obstacles occur on the trunkline system.

Continued efforts should be made to reduce these obstacles as finances permit, even though some cannot be removed without great difficulty, because of socio-environmental considerations, e.g., mature shade trees in a west-facing front yard. However safety considerations should overrule, and if need be, even these mature shade trees may have to be removed.

The designer should note that the presence of an up-slope significantly reduces the clear zone width required. It is therefore seldom necessary to remove a tree or to shield an obstacle that is located at the top of a cut-slope if the elevation of the top of slope is approximately 5'-0" to 6'-0" higher than the edge of pavement. These situations should always be checked, however.

7.01.12 Types of Guardrail Used in Michigan

There are nine standard types of steel beam guardrail in addition to cable barrier found on Michigan highways. The term "Current Use" means "currently proposed for use", not necessarily what may be found existing in the field.

7.01.12A Type A (Standard Plan R-60-Series)

Description: W-beam attached directly to posts, Terminal End Shoes on ends. 12'-6" post spacing, 28" height to top of rail.

Current Use:

- Cul-de-sacs

- Limited to locations not exposed to through traffic.

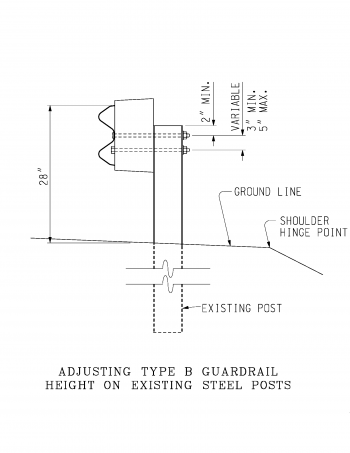

7.01.12B Type B (Standard Plan R-60-Series)

Description: W-beam guardrail, 8" offset blocks. 6'-3" post spacing, 28" height to top of rail.

Current Use:

- Basic type for all free access trunklines.

- On local roads when part of a state trunkline project.

7.01.12C Type BD (Standard Plan R-60-Series)

Description: Type B with W-beam on both sides of the post, 8" offset blocks.

Current Use:

- Limited use in medians on free access highways when median barrier is recommended.

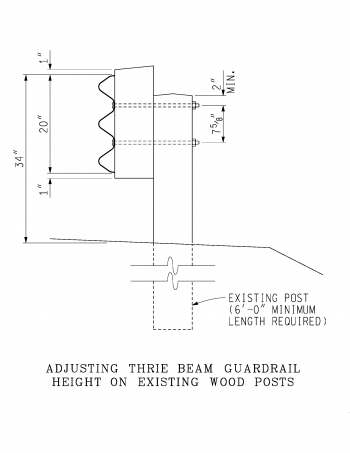

7.01.12D Type T (Standard Plan R-60-Series)

Description: Offset thrie beam rail, 8" offset blocks, 6'-3" post spacing, 34" height to top of rail.

Current Use:

- Standard guardrail for new freeway construction (including ramps).

- Updating existing freeways and ramps when the entire run of guardrail is being removed and replaced.

7.01.12E Type TD (Standard Plan R-60-Series)

Description: Similar to Type T except beam elements and offset blocks are installed on both sides of the post.

Current Use:

- In freeway medians over 30' wide when median barrier is recommended. Used to update existing freeway medians when there is a significant length of guardrail being replaced or where none was constructed initially, but barrier is now recommended.

7.01.12F Type MGS-8 (Standard Plan R-60-Series)

Description: W-beam guardrail meeting MASH criteria, 8" offset blocks, standard 6'-3" post spacing, and 31" height to top of rail. Beam element splices occur between standard 6'-3" post spaces.

Current Use:

- Standard MASH-compliant guardrail for all freeways (including ramps) and free access roadways. After December 31, 2017, it is anticipated that Type MGS guardrail systems will be required for new guardrail installations on all freeways (including ramps) and free access roadways.

7.01.12G Type MGS-0 (Standard Plan R-60-Series)

Description: W-beam guardrail meeting MASH criteria with no offset blocks, backup plates at all post locations, standard 6'-3" post spacing, and 31" height to top of rail. Beam element splices occur between standard 6'-3" post spaces.

Current Use:

- MASH-compliant guardrail for all freeways (including ramps) and free access roadways where space is limited and a narrow guardrail system with no offset blocks is desired. MGS-0 should be limited to locations where space is restricted and the installation of a narrow guardrail system with no offset blocks is preferred. After December 31, 2017, it is anticipated that Type MGS guardrail systems will be required for new guardrail installations on all freeways (including ramps) and free access roadways.

7.01.12H Type MGS-8D (Standard Plan R 60 Series)

Description: Type MGS-8 with W-beam guardrail and 8" offset blocks on both sides of the post.

Current Use:

- In all roadway medians, freeway and free access, when median guardrail is recommended and a MASH-compliant guardrail system is desired. After December 31, 2017, it is anticipated that Type MGS guardrail systems will be required for new guardrail installations on all freeways (including ramps) and free access roadways.

7.01.12I Type MGS-0D (Standard Plan R 60 Series)

Description: Type MGS-0 guardrail with W beam and backup plates on both sides of the post.

Current Use:

- In all roadway medians, freeway and free access, when a MASH-compliant median guardrail is desired, and where space is limited and a narrow guardrail system with no offset blocks is preferred. Type MGS 0D should be limited to locations where space is restricted and a narrow median guardrail system with no offset blocks is preferred. After December 31, 2017, it is anticipated that Type MGS guardrail systems will be required for new guardrail installations on all freeways (including ramps) and free access roadways.

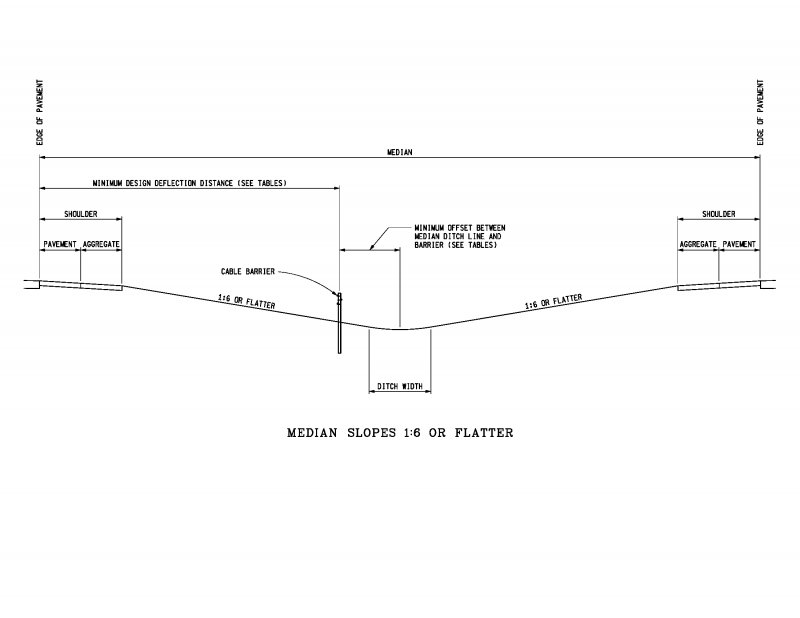

7.01.12J Cable Barrier

(See Section 7.01.55C)

Description: Three or four steel cables mounted on steel posts, anchored and tensioned.

Current Use:

- Medians where crash history indicates cross median crashes and rigid barrier is not warranted.

- Special situations where up to 90 degree impacts can be expected and larger deflections can be tolerated.

7.01.13 Curved Beam Elements

Curved steel beam elements having a radius of 150' or less must be shop bent. Designers should try to be as accurate as possible when specifying a radius for curved rail, as it is time consuming and expensive returning elements to the shop for re-bending. When shop bent rail will be required, the following note should be included on the plans: "Shop bent curved guardrail elements shall not be ordered until the radius has been field verified by the Engineer."

7.01.14 Guardrail Surface Finish

7.01.14A Galvanized

For a short time in the early to mid-1950's, the first steel W-beam guardrail was not galvanized and therefore had to be painted. Subsequently, galvanized beam elements were supplied and have been used ever since except, of course, for the use of weathering steel. The galvanizing coating is considered to have a service life of at least 25 years under average conditions before exhibiting significant rusting. Some of the earlier accepted galvanized rails were "pre-galvanized" and had very thin zinc coatings. These have rusted at a considerably premature age. From that time, a heavier galvanizing was applied by hot dip method after forming. This exhibited good durability. The industry asked for reconsideration of the pre-galvanized method in 1995. The Construction Field Services Division performed a study to determine the weather resistance of pre-galvanized rail. The results of an accelerated weathering simulation were acceptable. The specifications now allow for either method of galvanizing.

7.01.14B Unpainted Corrosion-Resistant

Atmospheric corrosion resistant guardrail (sometimes referred to as "weathering" or "rusty steel" guardrail) was first installed in Michigan, at 3 test sites, in 1963. It was adopted as standard by the Department in late 1971. If galvanized beam was desired, and it was in certain locations where visibility was especially needed, then it had to be specified on the plans and in the pay item. The theory behind the development of this material was that, being uncoated, it would oxidize rather quickly to a uniform brown color, the chemistry of the steel causing the surface rust to be dense and adherent. After the initial surface rust had formed, it was thought that further oxidation would proceed very slowly as the oxides would form a protective coating, making painting unnecessary. Initially, the buffered endings were galvanized, but in 1976 it was decided to specify corrosion resistant steel for them as well. In early 1980 a moratorium was placed on the use of weathering steel, requiring all new guardrail be galvanized according to the former requirements. The moratorium was prompted by the discovery that, when chloride contamination occurred, oxidation of the metal did not slow up after the initial rusting, and crevice corrosion accelerated the attack on the overlapped surfaces. Concerns were expressed that the useful life of the rail would be considerably less than that originally anticipated. The moratorium led to a permanent discontinuation of the use of weathering steel.

7.01.14C Corrosion-Resistant Guardrail Replacement Policy

The Engineering Operations Committee, meeting on January 20, 1989, decided that all existing corrosion resistant, or "rusty steel", guardrail encountered on proposed Interstate resurfacing or reconstruction projects should be removed and replaced as part of the project. On projects involving bridges only, the nominal provisions of the approach guardrail anchorage shall be replaced if the rail elements are rusty steel. Where guardrail at the bridge approaches is part of a more extensive installation, the decision to replace will be made on the merits of the specific project. See Section 7.01.44 for upgrading local roads.

7.01.15 Guardrail Terminals

The following guardrail terminal details are in current use for new construction and where specified for updating:

7.01.15A Guardrail Approach Terminal, Type 1B (Standard Plan R-61-Series)

Current Use:

- On approach end of Guardrail, Type B, Type MGS-8, and Type MGS-0, on one-way roadways.

- On both ends of Guardrail, Type B, Type MGS-8, and Type MGS-0, on two-way roadways.

7.01.15B Guardrail Approach Terminal, Type 1T (Standard Plan R-61-Series)

Current Use:

- On approach end of Guardrail, Type T, on one-way roadways.

- On both ends of Guardrail, Type T, on two-way roadways.

7.01.15C Guardrail Approach Terminal, Type 2B (Standard Plan R-62-Series)

Current Use:

- Same as Type 1B when grading limits prohibit proper offset for Type 1B.

7.01.15D Guardrail Approach Terminal, Type 2T (Standard Plan R-62-Series)

Current Use:

- Same as Type 1T when grading limits prohibit proper offset for Type for 1T.

7.01.15E Guardrail Departing Terminal, Type B (Standard Plan R-66-Series)

Current Use: 1. Departing end of Guardrail, Type B, on one-way roadways. 2. Departing end of Guardrail, Type B, on two-way roadways when located outside the clear zone.

7.01.15F Guardrail Departing Terminal, Type T (Standard Plan R-66-Series)

Current Use:

- Departing end of Guardrail, Type T, on one-way roadways.

- Departing end of Guardrail, Type T, on two-way roadways when located outside the clear zone.

7.01.15G Guardrail Departing Terminal, Type MGS (Standard Plan R-66-Series)

Current Use:

- Departing end of Guardrail, Type MGS 8 and MGS-0, on one way roadways.

- Departing end of Guardrail, Type MGS 8 and MGS-0, on two way roadways when located outside the clear zone.

7.01.16 Guardrail Attachment to Bridges and Walls

The following guardrail anchorage details are in current use for new construction and where specified for upgrading and are detailed on Standard Plans R-67-Series, B-22-Series, B-23-Series:

7.01.16A Guardrail Anchorage, Bridge, Detail T-1 Standard Plan R-67-Series)

Current Use: (Two uses detailed)

- Use when connecting Guardrail, Type T, Type MGS-8 or Type MGS-0 to Bridge Barrier Railing, Type 4, 2 Tube, 4 Tube, or aesthetic parapet tube without expansion at backwall.

- Use when connecting Guardrail, Type T, Type MGS-8 or Type MGS-0 to Bridge Barrier Railing, Type 4, 2 Tube, 4 Tube, or aesthetic parapet tube with expansion at backwall.

7.01.16B Guardrail Anchorage, Bridge, Detail T-2 Standard Plan R-67-Series)

Current Use:

- Use when connecting Guardrail, Type B to Bridge Barrier Railing, Type 4, 2 Tube, 4 Tube, or aesthetic parapet tube without expansion at backwall.

7.01.16C Guardrail Anchorage, Bridge, Detail T-3 Standard Plan R-67-Series)

Current Use:

- Use when connecting Guardrail, Type B to Bridge Barrier Railing, Type 5 without expansion at backwall.

7.01.16E Guardrail Anchorage, Bridge, Detail T-5 Standard Plan R-67-Series)

Current Use: (Two uses detailed)

- Use when connecting Guardrail, Type B to Bridge Barrier Railing, Type 4 with expansion at backwall.

- Use when connecting Guardrail, Type B to Fillerwalls.

7.01.16F Guardrail Anchorage, Bridge, Detail T-6 Standard Plan R-67-Series)

Current Use:

- Use when connecting Guardrail, Type T to Fillerwalls.

7.01.16G Guardrail Anchorages, Bridge, Detail A-1 (Standard Plans B-22-Series and B-23-Series)

Current Use:

- Use when connecting Guardrail, Type T to Bridge Railing, Thrie Beam Retrofit.

7.01.16H Guardrail Anchorages, Bridge, Detail A-2 (Standard Plans B-22-Series and B-23-Series)

Current Use:

- Use when connecting Guardrail, Type B to Bridge Railing, Thrie Beam Retrofit.

7.01.16I Need for Additional Expansion

The Guardrail Anchorage, Bridge details on Standard Plan R-67-Series will accommodate thermal deck movement up to about 4". If the expected thermal deck movement will exceed 4", the Road designer should consult with the Bridge designer to decide the method for providing the additional expansion required in the guardrail.

7.01.17 Strength Requirements of Steel Beam Guardrail

The Standard Specifications reference material requirements for steel beam guardrail and associated hardware to AASHTO Specification M 180, which requires 70,000 psi tensile strength in the base metal.

Crash testing of roadside safety devices, such as guardrail and other barriers, is standardized according to procedures outlined in National Cooperative Highway Research Program Report 350 (NCHRP 350) and the Manual for Assessing Safety Hardware (MASH), respectively.

MASH contains the current guidelines for testing and evaluating roadside safety devices, thereby superseding NCHRP 350. As of January 1, 2011, newly tested or modified roadside safety devices must be evaluated using MASH criteria. However, all safety hardware accepted prior to adoption of MASH using NCHRP 350 criteria may remain in place and may continue to be manufactured and installed. As a result, it is acceptable to install new roadside safety devices that meet NCHRP 350 or MASH. MDOT-approved roadside safety hardware not accepted under NCHRP 350 or MASH with no suitable alternatives may remain in place and may continue to be installed.

There are up to six test levels in NCHRP 350 and MASH, respectively, depending on the feature being evaluated. All six test levels apply to longitudinal barriers. Test levels 2 and 3 apply to breakaway features and test levels 1, 2, and 3 apply to crash cushions and end treatments.

Fundamentally, guardrail is intended to redirect the impacting vehicle, not stop it. Energy absorption and vehicle deceleration are the functions of an impact attenuator (or a Type 2 terminal, under certain conditions). For this reason, 25 degrees is the maximum angle used in testing for guardrail strength.

The designer will occasionally encounter situations where a broad area must be shielded. These may be areas wide enough to allow a vehicle to exceed 25 degrees in approach angle and too wide to make an impact attenuator feasible. These situations must be studied. The solution will usually involve guardrail placed in a curving configuration or the use of cable barrier if there is room for the deflection that is characteristic of a cable barrier.

| NCHRP 350 Test Level |

Vehicle | Impact Conditions | |

| Nominal Speed (km/h) |

Nominal Angle (deg) | ||

| 1 | 2000P (2000 kg pick up truck) | 50 | 25 |

| 2 | 2000P (2000 kg pick up truck) | 70 | 25 |

| 3 | 2000P (2000 kg pick up truck) | 100 | 25 |

| 4 | 8000S (8000 kg single unit truck) | 80 | 15 |

| 5 | 3600V (3600 kg tractor van trailer) | 80 | 15 |

| 6 | 3600T (3600 kg tractor tanker-type trailer) | 80 | 15 |

| MASH Test Level |

Test Vehicle Designation and Type |

Impact Conditions | ||

| Vehicle Weight KG (lbs) |

Speed km/h (mph) |

Angle Degrees | ||

| 1 | 1,100C (Passenger Car) 2,270P (Pickup Truck) |

1,100 (2,420) 2,270 (5,000) |

50 (31) 50 (31) |

25 25 |

| 2 | 1,100C (Passenger Car) 2,270P (Pickup Truck) |

1,100 (2,420) 2,270 (5,000) |

70 (44) 70 (44) |

25 25 |

| 3 | 1,100C (Passenger Car) 2,270P (Pickup Truck) |

1,100 (2,420) 2,270 (5,000) |

100 (62) 100 (62) |

25 25 |

| 4 | 1,100C (Passenger Car) 2,270P (Pickup Truck) 10,000S (Single Unit Truck) |

1,100 (2,420) 2,270 (5,000) 10,000 (22,000) |

100 (62) 100 (62) 90 (56) |

25 25 15 |

| 5 | 1,100C (Passenger Car) 2,270P (Pickup Truck) 36,000V (Tractor-Van Trailer) |

1,100 (2,420) 2,270 (5,000) 36,000 (79,300) |

100 (62) 100 (62) 80 (50) |

25 25 15 |

| 6 | 1,100C (Passenger Car) 2,270P (Pickup Truck) 36,000T (Tractor-Tank Trailer) |

1,100 (2,420) 2,270 (5,000) 36,000 (79,300) |

100 (62) 100 (62) 80 (50) |

25 25 15 |

7.01.18 Suggested Shy Line Offset Values

Shy line offset is the distance from the edge of traveled way in which a roadside object will not be perceived as an obstacle or result in the driver reducing speed or changing the vehicle's path of travel.

| Design Speed (mph) |

Shy Line Offset (LS) (ft) |

| 80 | 12 |

| 75 | 10 |

| 70 | 9 |

| 60 | 8 |

| 55 | 7 |

| 50 | 6.5 |

| 45 | 6 |

| 40 | 5 |

| 30 | 4 |

7.01.19 Suggested Runout Lengths for Barrier Design

Runout length is the distance from the object being shielded to the point the vehicle is assumed to depart from the roadway.

| Traffic Volume (ADT) veh/day | ||||

| Over 10,000 | Over 5000 - 10,0000 |

1000 - 5000 | Under 1000 | |

| Design Speed (mph) |

Runout Length LR (ft) |

Runout Length LR (ft) |

Runout Length LR (ft) |

Runout Length LR (ft) |

| 70 | 360 | 330 | 290 | 250 |

| 60 | 300 | 250 | 210 | 200 |

| 50 | 230 | 190 | 160 | 150 |

| 40 | 160 | 130 | 110 | 100 |

| 30 | 110 | 90 | 80 | 70 |

7.01.20 Guardrail Deflection

Being flexible barriers, both steel beam guardrail and cable guardrail are expected to deflect under impact. This deflection is a result of deformation of the beam element or stretching of the steel cable, fracturing of the post (if wood) or bending of the post (if steel), and lateral displacement of the post in the soil. It is therefore necessary that room for deflection be provided between the back of the rail system (back of posts) and the object or area being shielded. For design purposes, use the chart at the end of this section for the expected deflections of the various barrier systems.

It should be noted that the above deflection distances are not well-defined values, and that deflections may vary for different soil types and moisture content, thawed or frozen ground, different types of anchorages, and differing lengths of installation. If specific site conditions are such that it is predictable that greater deflection values may occur, and space for deflection is restricted, then shorter post spacing or deeper embedment of posts should be considered. Shorter post spacing is only effective, however, if the full effect of proper post embedment is realized. See Section 7.01.41D, "8'-0" Posts". See also Section 5.5.2, 2011 AASHTO Roadside Design Guide.

| Guardrail | Post Spacing |

Deflection |

| Type T | 1'-6¾†| 1'-2" |

| Type T | 3'-1½†| 1'-8" |

| Type T | 6'-3" | 2'-0" |

| Type C | 6'-3" | 2'-0" |

| Type B | 3'-1½†| 2'-0" |

| Type B | 6'-3" | 3'-0" |

| 3-Cable | 8'-0" | 8'-0" |

The Zone of Intrusion (ZOI) is the region measured above and behind the face of a barrier system where an impacting vehicle or any major part of the system may extend during an impact. For a typical TL-3 system, the ZOI extends between 18" and 30" behind the traffic side face of the barrier. Where practical, the designer should keep objects out of this area. See Section 5.5.2, 2011 AASHTO Roadside Design Guide, for additional ZOI guidance.

7.01.21 Guardrail Strength Transitions

Sudden and significant changes in lateral stiffness of a barrier system may cause an impacting vehicle to pocket, if it proceeds from a weaker system to a stronger system. A gradual modification of the deflection characteristics of the barrier is therefore needed. This may be achieved by closer post spacing, heavier barrier elements, larger posts or a combination of these. Illustrated below is a typical transition from Guardrail, Type B to a concrete barrier, filler wall, or barrier railing. The 2011 AASHTO, Roadside Design Guide (page 7-15) advocates that the transition length between joining barrier types should be approximately 10 to 12 times the difference in dynamic deflection. For a difference in deflection of 12", the transition stiffening length should occur in one effective beam element length or 12'-6". See Section 7.01.20 for dynamic deflections.

7.01.22 Minimum Guardrail Lengths and Gaps

A free-standing section of guardrail (one not attached to a bridge or other structure) should be at least 100' in length. Greater lengths are recommended; lesser lengths maybe acceptable under low speed conditions. A gap of less than approximately 200' between barrier installations should be avoided. Usually this will require filling in the gap with connecting barrier. An exception would be the unique situation where an approach and trailing ending, separated by a gap, can be buried in a cut slope, and the consequences of a vehicle encroaching on the cut slope would be less than hitting the guardrail filling the gap.

7.01.23 Function of Guardrail Components

It is essential that the designer understand the function of the various components of a guardrail system and some of the principles underlying barrier design details.

Beam height - The 28" top of rail height of single beam systems is a compromise between satisfying the conflicting demand of meeting the centers of gravity of heavier, higher cars and of smaller, lower cars. The use of a second beam element (Type C), or of a wider beam element (Type T), permits the 32" and 34" top of rail heights that cover a broader range of center of gravity heights.

Offset block - Serves two principal purposes, 1) locates beam farther from the post to minimize the possibility of wheel snagging on the post and pocketing in the guardrail, and 2) maintains top of rail height momentarily longer as the post rotates backward under impact, reducing the probability of the vehicle vaulting over the rail. (See page 5-16, 2011 AASHTO, Roadside Design Guide)

Round washer - Provides an even bearing surface around holes that are often field-drilled and rough.

Post bolt washer - To prevent the head of the post bolt from pulling through the beam element. Recent recommendations, nationally, have been to delete the washer, on new construction, to allow the rail to strip off the posts and thus not go down under impact. Washers are now recommended only on the end post of the SRT, or on the end post in a Departing End Terminal.

Rail splice - Splices, of course, are unavoidable. They should be at least as strong as the rail itself; all eight connection bolts (twelve in thrie beam) are needed to distribute the load throughout the rail section. Lapped splices are usually such that the outer rail overlaps in the downstream direction, to prevent vehicle snagging.

7.01.24 Accommodation of Expansion

Provision must be made for the movement of guardrail beam elements caused by thermal expansion and contraction. The movement in rail elements is accomplished by means of oblong slots at the splices. Additional expansion at structures is obtained by means of longer slots in the Special End Shoes and Thrie Beam Expansion Section illustrated on Standard Plan R-67-Series (see Section 7.01.16I).

7.01.25 Guardrail Approach Terminals

Crashworthy end treatments are critical to guardrail installations. An approach terminal is designed to redirect an impacting vehicle and to reduce the occurrences of a vehicle being penetrated, rolled, or vaulted in an end on hit. The following section describes the characteristics and uses of approved standard treatments.

7.01.25A Type 1 Terminals

Type 1 Guardrail Approach Terminals are flared gating terminals. This is the preferred design when grading limits allow for the appropriate 4'-0" offset of the terminal end from the tangent extension of the standard line of guardrail run. When the Type 1 terminal is called for on plans by reference to Standard Plan R-61-Series, the contractor may use one of two terminal options. Descriptions of the current approved options are described in this section.

7.01.25A1 Slotted Rail Terminal (SRT)

The SRT was adopted by the Department in 1995 when FHWA mandated the discontinued use of the BCT. It subsequently became the first guardrail terminal to pass the NHCRP Report 350 crash test criteria.

The concept of a slotted rail terminal consists of longitudinal slots cut into the W-beam rail element to control the location of dynamic buckling thus reducing the potential for impact or penetration of the occupant compartment by the buckled rail element.

The SRT was originally intended as a retrofit or replacement for the BCT ending.

The SRT uses many of the same components used in the BCT. It also uses features common to other end treatments such as the yoke and strut and controlled release terminal (CRT) posts. The parabolic flare of the SRT is identical to that of the BCT, simplifying the retrofit of existing terminals.

7.01.25A2 Flared Energy Absorbing Terminal FLEAT)

FLEAT was adopted in 1998 after it passed NCHRP Report 350 crash testing. Among other reasons, it was chosen as an alternate for the SRT because of the similarities in the components and installation configuration of the two systems. In addition to these similarities to the SRT and other flared terminals, the FLEAT includes an energy absorbing impact head. Unlike the SRT, the 4'-0" offset of the FLEAT is a straight taper rather than a parabolic flare.

7.01.25A3 Minimum Offset)

The Type 1 Terminal is designed to have a minimum offset of 4'-0", measured from the tangent line of the guardrail run. Whenever conditions allow, the line of guardrail designed in advance of the terminal should be flared to further increase the total offset of the terminal from the traveled lane. On curved roadways the offset is measured from the circular extension of the standard rail alignment along the curve.

Sometimes on certain minor trunklines and a great number of local roads, the end post may have to be placed on the slope beyond the shoulder hinge point, in which case care should be taken that the terminal end shoe and the steel sleeves are not left "high" nor placed too low.

7.01.25B Type 2 Terminals

Type 2 terminals are tangent, energy absorbing terminals. They are used when proper grading cannot be achieved to accommodate the 4'-0" offset called for with the Type 1 terminals. When the Type 2 terminal is called for on plans by reference to Standard Plan R-62-Series, the contractor may use one of two terminal options. Descriptions of the currently approved options are described in the following sections.

7.01.25B1 Extruder Terminal (ET)

The ET was installed experimentally by the Department in 1993 and was used occasionally when special situations called for a non flared terminal. In 1995 the ET became the first non-flared terminal to meet the NCHRP Report 350 crash test criteria. Frequent use of the ET led to its upgraded status as a standard plan in 1997. It features an impact head that, when hit head on, flattens the guardrail beam element as the head translates down the terminal rail. The flattened rail is then extruded away from the impacting vehicle.

7.01.25B2 Beam Eating Steel Terminal (BEST)

At the same time the ET was originally approved as a standard, the BEST was chosen as an approved alternate option. It’s status as a standard was short lived when the SKT (see succeeding section) replaced it months after its adoption. The BEST featured an impact head that shredded and flattened the rail before extruding it. The developers and patent holders of the BEST discontinued marketing and production of this product shortly after they developed and patented the SKT.

7.01.25B3 Sequential Kinking Terminal (SKT)

The SKT was successfully crash tested in 1997 and adopted by the Department as a standard Type 2 terminal alternate in 1998, replacing the BEST. The materials and configuration of the SKT were more compatible with the ET. Like the FLEAT, its impact head includes a deflector plate that produces sequential kinks in the beam element before extruding it away from the impacting vehicle.

7.01.25B4 Minimum Offset

The original intent of the Type 2 terminals was to provide endings that required no offset. This was the orientation used in the crash tested system. It was later determined by the FHWA that a 12" offset would be acceptable without further testing. This minimal offset was adopted in Standard Plan R-62-Series in order to minimize the number of nuisance accidents that may occur when the impact head was located close to or encroaching on the shoulder.

7.01.25C Function of the Various Guardrail Terminal Components

It is important that designers, as well as construction and maintenance personnel, understand the function of the components that make up Guardrail terminals:

Bearing plate - Distributes the forces in the cable to the wooden end post and steel sleeve. The slotted bearing plate design featured in the SRT, allows the bearing plate to separate from the cable upon breaking of the wooden end post.

Terminal End Shoe - This feature of the SRT absorbs some of the impact forces, spreading them over a wider area, to reduce the potential for the end of the beam element to penetrate the vehicle passenger compartment.

Impact head - The impact head or extruder head absorbs energy in an end on hit. Like the terminal end shoe, it spreads the forces over a wider area.

In addition, the rail element passes through the head and is extruded away from the impacting vehicle. The FLEAT and the SKT head contains a deflector plate that creates sequential kinks in the rail as it passes through. The ET head flattens the rail as it passes through. The bending or flattening dissipates energy while preventing rail penetration into the vehicle.

Cable - For downstream impacts, transfers tensile forces from the beam to the base of the end post, allowing the full redirective strength of the rail system to be developed at the third post. For ending impacts the cable is released and serves no purpose.

Channel Strut - This strut and yoke distributes the load from the tensioned cable between the first and second post. The strut also contributes to the collapse of the second post during an end on impact.

Controlled release terminal (CRT) post - CRT posts are 6" x 8" wood posts with two 3½†diameter holes drilled through the post. One hole is placed at the ground line and the other 1'-4" below the ground, to facilitate fracture of the post during end-on impacts.

Holes in the two end posts - These holes are used to weaken the end posts and to allow them to break off close to the ground, when the guardrail ending is struck by an end impacting vehicle. The guardrail ending will likely collapse, thereby reducing spearing and vaulting. The holes have no function for downstream impacts.

Pipe Insert - No function for ending impacts. For downstream impacts, distributes vertical component of forces in the cable to the post.

Slotted Rail Element (SRT) - The first two panels of rail in the SRT are slotted to provide controlled dynamic buckling. Rail buckling in the SRT is controlled by the length and location of the slots. The controlled buckling of the rail element reduces the potential for the rail to directly impact or penetrate the vehicle occupant compartment.

Slot guard (SRT) - Slot guards are installed on the SRT at the downstream end of each set of rail slots. It prevents the bumper or other parts of the impacting vehicle from intruding into and extending the slots.

Soil plate - Inhibits movement of the post in the soil; aids in keeping the post from pulling out of the ground.

Steel sleeves - For ending impacts, reduces tendency for the post to rotate in the soil; aids in resisting movement so the post will break off at the weakening hole. For downstream impacts, distributes loads from the post to the soil.

7.01.25D Guardrail Full Strength Point

When a standard guardrail terminal is used, the length of need is calculated to a point where the guardrail run develops the full strength of the system. This point on the approach end is considered to be the third post from the end (page 5-51, 2011 AASHTO, Roadside Design Guide).

7.01.25E Clear Area Behind Guardrail Terminals

When determining the length of need of a guardrail run, the designer should verify that there will be no obstacle behind or to the behind side of a guardrail terminal that would prevent gating.

This is especially true with the Type 1 terminal since it is specifically designed to gate.

The area behind should be traversable for the vehicle after it passes through the terminal. The minimum recovery area behind and beyond a terminal should be an obstacle free area approximately 75' long and 20' wide. If it appears that the area behind will not be traversable, then the guardrail run will probably have to be extended to a point where the area behind the terminal is clear.

7.01.25F Burying Ending in a Backslope

Occasionally high cut slopes adjacent to the traveled roadway do not provide sufficient clear area behind a Type 1 terminal to allow gating.

The designer should consider terminating the guardrail inside the backslope. The designer or project manager can obtain a special detail for this treatment from the Design Standards Unit.

7.01.25G Slope Under Guardrail Terminals

The area under the terminal should be graded to a 1:10 slope or flatter from the edge of the traveled lane to the shoulder hinge point (2'-0" behind the face of the post). See the appropriate guardrail approach terminal Standard Plans for grading details.

7.01.29 Guardrail Flare

When designing guardrail, the designer should take advantage of opportunities to flare the installation. This reduces the required length of need. It also places the guardrail terminal farther from the traveled lane, thus reducing the potential for nuisance hits.

7.01.29A Flare Rate

Historically, 1:15 has been the preferred flare rate for guardrail in Michigan. Other maximum flare rates for semi-rigid barriers are listed on page 5-48 of the 2011 AASHTO, Roadside Design Guide and on Standard Plan R-59-Series according to design speed. Flatter flare rates listed by AASHTO for barrier inside the shy line should only be used where it will not increase the length of the guardrail run.

7.01.29B Uniform Flare from Structures

Guardrail may need to be flared inward to meet the bridge barrier railing of bridges with narrow shoulders. When the guardrail length at a structure is increased, such as for an embankment, a uniform guardrail flare rate (not flatter than 1:30) may be substituted for the combined short parallel section and the two flared sections. The Illustration below shows this situation on a left approach rail. When the shielded area in advance of the bridge rail is a steep embankment, the length of need is determined as outlined in Standard Plan R-59-Series. A uniform flare can then be constructed from the end of the tangent length of barrier at the bridge rail (L1) to the first post of the guardrail terminal at offset distance “zâ€.

7.01.30 Guardrail at Embankments

As a general rule, a barrier should be placed to protect a vehicle from going down an embankment only if the barrier itself is the least severe of the two features. Such a comparison must of necessity be very subjective because of the many variables involved. The Department generally follows the criterion that, if the fill slope is 1:3 or flatter, no barrier is required. For slopes of 1:3 or flatter, the height of fill does not increase severity.

The economics of earthwork obviously dictate that all slopes cannot be 1:6, regardless of fill height. As the fill becomes higher, more consideration must be given to steepening the slopes, which in turn may call for a decision relative to placing a barrier.

Slopes intended to be traversable, i.e., one flat enough that a barrier can be omitted but still perhaps 1:3, should be relatively free of discontinuities that might "trip up" a vehicle. Plans should note that half-buried boulders and large rocks should be removed as part of the final trimming operation.

7.01.30A Height-Slope Guidelines

7.01.30B Location on Fill Sections (New Construction)

The following shoulder sections with guardrail are shown to clarify and standardize the location of guardrail. Divided highway sections illustrate guardrail on left and right shoulders of each roadway.

** The 2’ offset from face of guardrail to edge of shoulder should not be used if the paved shoulder width is at least 12’.

7.01.30C Maximum Height of 1:2 Slope Without Barrier

Barrier is not warranted on 1:2 fill slopes up to about 5' height. See Section 7.01.30A, Height-Slope Guidelines.

7.01.30D Flattening Slopes to Eliminate Guardrail

On limited access projects, guardrail may be eliminated if the fill slopes are flattened to 1:4 or flatter. In order to eliminate guardrail on free access projects, the fill slope should also be flattened to 1:4 or flatter, unless additional R.O.W. would be required. If there are no obstacles or severe inclined slopes within the clear zone or at the toe of the fill slope, a 1:3 slope or flatter may then be considered.

7.01.30E Length of Barrier at Embankments (New Construction)

When determining the length of barrier required to shield an embankment slope (does not apply to barn roof sections), the designer must first determine the beginning of the 1:4 slope and where the slope steepens to 1:3. Using Standard Plan R-59-Series, which shows flared installations, the limits of the endings can be determined. Field personnel should check the length and slope rate of the fill section and make any necessary adjustments; sometimes the length will be adequate, but it may be necessary to "slide" the barrier one way or the other to fit actual conditions.

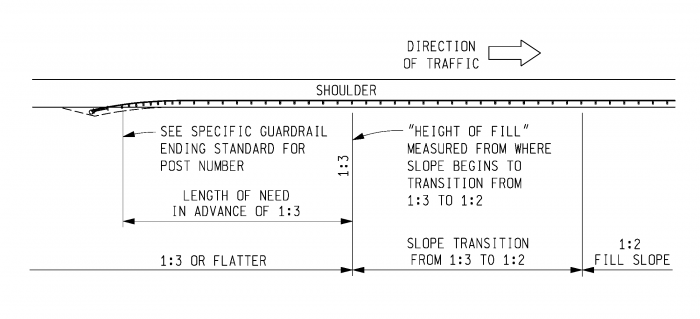

7.01.30F Length of Barrier at Embankments(Upgrading Projects)

When a flared guardrail installation is not feasible and a parallel guardrail installation must be used, the following chart and diagram should be used to determine the length of barrier needed in advance of a 1:3 slope.

| GUARDRAIL AT EMBANKMENTS (PARALLEL INSTALLATIONS) | ||||

|---|---|---|---|---|

| HEIGHT OF FILL AT 1:3 (ft) |

LENGTH OF NEED IN ADVANCE OF 1:3 (ft) | |||

| OVER | TO | 70 mph | 60 mph | 50 mph |

| 5 | 10 | 147 | 121 | 100 |

| 10 | 12 | 197 | 171 | 122 |

| 12 | 14 | 235 | 205 | 153 |

| 14 | 16 | 269 | 238 | 179 |

| 16 | 18 | 296 | 262 | 198 |

| 18 | 20 | 316 | 280 | 212 |

| 20 | 22 | 331 | 294 | 223 |

| 22 | 24 | 343 | 305 | 231 |

| 24 | 25 | 349 | 309 | 235 |

7.01.30G Placing Beam Guardrail on a Downslope

Usually the greater the distance from the roadway that a barrier can be placed, the less chance there is of it being struck and less barrier length will be needed to shield the object. However, placing a barrier on a downslope close to the shoulder hinge point (approximately 12'-0" or less) introduces the potential for the barrier to be less effective because of the tendency for a vehicle, leaving the shoulder, to vault over it. The following guidelines therefore apply:

- Beam guardrail may be placed on a slope, beyond the shoulder point, if the slope is 1:10 or flatter.

- Generally, a 1:10 or flatter slope should not be constructed specifically to locate the barrier farther out.

- Usually, the placement of guardrail on a 1:6 slope is not recommended. There has been one crash test where guardrail was placed on a 1:6 slope, 18 feet off the shoulder point that satisfactorily redirected a vehicle. However, a flatter slope is more desirable. The placing of guardrail on 1:6 slopes should be confined to the applications specified in Section 7.01.32F.

7.01.30H Guardrail Placed near Intersecting Streets and Driveways

An intersecting street or driveway located near a roadside object or feature may prevent installation of the full length of barrier required along the main road. An example of this would be a bridge on a main road with an intersecting driveway located near the bridge.

The preferred solution is to close or relocate the intersecting street or driveway in order to install the full length of barrier required along the main road. A crash cushion or other impact attenuating devices may be used to shield a fixed object such as a bridge railing end, however, this may not provide the length of need required to shield other roadside objects or features in the vicinity.

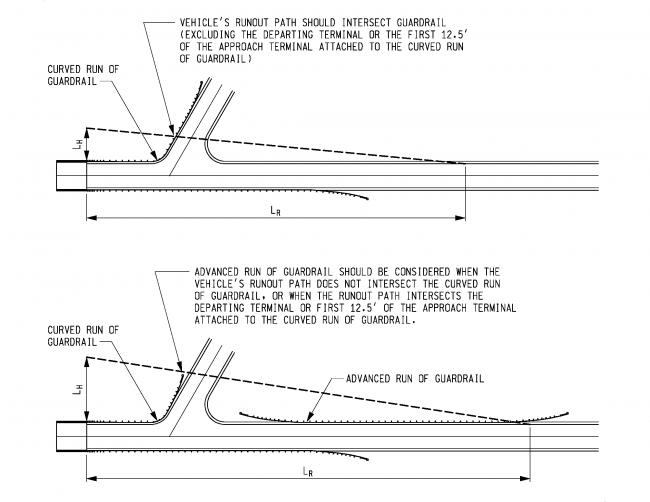

When closing or relocating the intersecting driveway or street is not feasible, two possible solutions are given in the accompanying sketches. A second guardrail run in advance of the intersecting street or driveway should be considered when the vehicle's runout path does not intersect guardrail, or when the runout path intersects the departing terminal or the first 12.5 feet of the approach terminal attached to the curved run of guardrail. See Special Detail 21 for installing a curved guardrail run near an intersecting street or driveway. Also, graphical design methods are suggested when utilizing the proposed solutions depicted in the accompanying sketches.

Site-specific constraints must be taken into consideration when designing guardrail near intersecting streets and driveways. Examples of these constraints include limited intersection sight distance, right-of-way limitations, and the presence of multiple intersecting driveways in close proximity to each other. In addition, the use of excessively short advanced guardrail runs should be avoided. Questions regarding guardrail installations near intersecting streets and driveways should be directed to the Geometric Design Unit of the Design Division.

7.01.31 Shielding Bodies of Water

Warrants for shielding streams or permanent bodies of water are judgement decisions based on location and depth of water and likelihood of encroachment (page 5-9, 2011 AASHTO, Roadside Design Guide). Streams or permanent bodies of water more than 2'-0" in depth will usually require shielding by a barrier if within the clear zone (page 18, 1977 AASHTO, Guide for Selecting, Locating and Designing Traffic Barriers). Barrier may also be required for bodies of water beyond the clear zone if, in the judgement of the designer, there is greater than usual potential for an errant vehicle to enter the water. An exception may be water close to the road for a considerable distance (a causeway is a case in point). In this case, speeds may have been correspondingly reduced because the roadside might be heavily used for recreational access to the water and for fishing. An intermittent barrier leaves many exposed endings to treat and space may not be available for proper flaring of the ends. After all factors are taken into consideration, it may be decided that the disadvantages of a barrier outweigh the advantages.

7.01.32 Barrier at Bridge Approaches (Over and Under)

Besides shielding embankments, the other most common use of a roadside barrier is shielding massive structural components. These fall into two general categories, the overpassing structure (approaches and railings) and the under passing structure (piers, drainage structures, and abutments).

7.01.32A Attachment to Barriers and Closer Post Spacings

Guardrail beam elements fastened to concrete structures should overlap the concrete sufficiently to place the end bolts onto the concrete a minimum of 3'-6". This distance is considered necessary to prevent the concrete from shattering and the bolts from pulling loose under impact.

All of the guardrail anchorage, bridge attachments specified on Standard Plans R-67-Series, B-22-Series and B-23-Series increase in lateral stiffness. This is done to keep an impacting vehicle from displacing the guardrail and pocketing against the rigid bridge structure. The transition for lateral stiffness of guardrail is described in Section 7.01.21. Additionally, Standard Plans B-22-Series and B-23-Series use heavier 10 gage (0.138") thrie beam elements to increase barrier strength.

7.01.32B Relationships Between Bridge Sidewalk and Approach Guardrail

If the bridge approaches are continuously curbed, and the design speed is 40 mph or higher, place the approach guardrail in conjunction with the curb as described in Section 7.01.34. Then carry the rail across the bridge in line with the approach rail, affixed to the sidewalk with metal brackets. If the design speed is 35 mph or less, place the guardrail in general alignment with the bridge railing and connected to it.

If the approaches are not curbed, regardless of traffic speed, place the guardrail at the edge of shoulder, connected to the bridge railing.

7.01.32C Barrier at the Trailing End of Overpassing Structures

Standard Plan R-59-Series does not show guardrail on the trailing end of bridges carrying one-way traffic. This is because, assuming a 15 degree angle of departure, an errant vehicle can be assumed as being in the area where the "approach" fill slope will be 1:3 or flatter. When a slope steeper than 1:3 occurs, shielding may be required.

Where a roadway carries two-way traffic, approach guardrail is provided because the departing end for one direction is the approach end for the other. The designer should determine if the opposite side railing is within the clear zone, measured from the centerline.

If one or more downspout headers are required on the departing end of a one-way bridge, it will be necessary to shield it with guardrail. This guardrail should extend a minimum length of the Guardrail Departing Terminal beyond the last downspout header.

When a major railing or bridge reconstruction project is programmed, existing 12" high approach curbs on the departing ends of one-way bridges should be removed and replaced with a reduced height curb, unless shielding with guardrail will be required. See current Standard Plan R-32-Series for Bridge Approach Curb & Gutter, Detail 1A.

7.01.32D Shielding Requirements at Bridge Underpasses

The clear zone criteria presented in Section 7.01.11 is the primary source of information used in determining whether bridge columns or abutments require shielding. Because a clear zone distance cannot always be determined precisely, it may happen that a fixed object thought to be outside the clear zone may need shielding. When this occurs, the designer must determine a method to shield them. Accepted methods for shielding are specified on the standard plans. If the only requirement is to shield the bridge pier or abutment, the barrier length should be calculated using the information found in Section 7.01.05G.

Current bridges are usually designed with longer spans, so that bridge columns and abutments can be placed outside the clear zone. Even when spans are increased, not all bridge columns and abutments can be located outside clear zones. An example might be where a widened clear zone results from a bridge being located over a curved roadway.

Currently, the approach bridge fill, behind the abutment, is designed to have a 1:6 slope facing oncoming traffic on the road below. However, when the approach slope is not 1:6 or flatter, additional barrier may be required to obtain the required runout length used in the above formula.

7.01.32E Guardrail Median Object Protection

Standard Plan R-56-Series illustrates an enclosed guardrail system for shielding objects such as bridge piers and sign supports in medians 36’ to less than 70’ in width. The system encloses the median objects between two parallel runs of thrie beam guardrail converged and terminated at each end with a Type 3 approach terminal (Standard Plan R-63-Series). This design replaces the past versions of Standard Plan R-56-Series featuring the Minnesota Bullnose design. The current standard also provides details for a direct connection to filler walls. This connection detail requires construction of concrete end walls and reduces the overall guardrail length required.

Standard Plan R-56-Series also details a treatment for shielding the opening between twin-bridge approaches. For wider medians at twin bridge approaches, the guardrail configuration specified on Standard Plan R-59-Series should be used.

7.01.32F Bridge Columns and Foundations in 70’ Medians

Bridge columns and sign support foundations located in the center of 70’ medians were once considered outside the clear zone. Shielding is now required and should be included in any programmed project upgrading.

The treatment for shielding columns and foundations for new construction and reconstruction projects should be according to the enclosed system designs shown on Standard Plan R-56-Series, Guardrail Median Object Protection.

In addition to the enclosed systems discussed in the previous section, an open system is detailed in Standard Plan R-56-Series for other than new construction and reconstruction projects with 70’ medians and existing fill slope rates of 1:6 or flatter. This detail features twin parallel guardrail runs that shield the median objects independently for each direction of traffic. This option offers the advantage of better accessibility for maintenance equipment to service the median or sign foundations. It is intended only for the conditions stated above.

7.01.33 Maintaining Guardrail Strength When One or More Posts Must Be Omitted

7.01.33A Downspout Headers

Standard Plan R-32-Series, under "Notes", advises field personnel to determine the location of proposed guardrail posts prior to locating the spillway or downspout header(s). If this is done, there will be no conflict. There are occasions however, when miscalculation in construction layout or when upgrading guardrail, that an existing downspout header will prevent a post from being placed at the proper spacing. Downspout headers that were constructed prior to 1970 and according to Standard Plan E-4-A-144 series, are an example. These downspouts had deeper throats and were designed to fit 12'-6" post spacing. When a post cannot be properly placed, Standard Plan R-72-Series, "W-Beam Backed Guardrail Installations" should be used.

7.01.33B Wide Culverts

Maintaining the continuity of the barrier strength is also necessary when a run of guardrail spans a wide culvert and the proper embedment of a guardrail post(s) cannot be obtained. When the spanning of a wide culvert requires the omission of one or two posts, Standard Plan R-72-Series, "W-Beam backed Guardrail Installations" should be used. Where no barrier wall exists and the span is over 18'-9", Standard Plan R-73-Series, "Guardrail over Box or Slab Culverts" may be used.

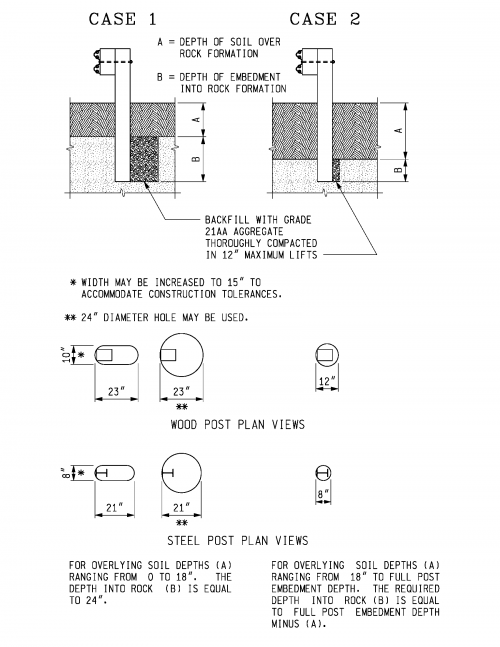

7.01.33C Placing Guardrail in Rock

Rock formations, which occur more frequently in the Upper Peninsula, may prevent the full embedment of guardrail posts. When only a partial embedment of posts can be obtained, backing the guardrail according to the method illustrated in Standard Plan R-72-Series is an option to individually drilling each hole. If the number of post locations in the influence of the rock formation would force the length of the backed guardrail section to exceed that allowed in the standard, the affected posts holes will have to be drilled. If the depth of soil overlying the rock formation is 18" or greater, the hole diameter required for steel posts is 8" (12" for wood) and full post embedment depth is required. If the depth of soil overlying the rock formation is less than 18", the hole diameter required for steel posts is 21" (23" for wood) and a 24" embedment depth into the rock is required. A strong-post W-beam guardrail exhibits better performance if the post is allowed to rotate in the soil. Thus, the post should not be placed in the center of the hole, but at the front, so the backfill is behind the back of the post. This work should be included by special provision.

7.01.33D Guardrail Posts through Paved Surfaces

Guardrail posts embedded into paved surfaces present a problem similar to that of guardrail posts in rock formations. The paved surface will not allow the posts to rotate in their embedment (to distribute vehicle loads through the post into the embedment material) prior to breaking. Thus, an area of pavement around the post know as "leave out" must be omitted to allow the post to rotate. For both steel and wood posts, the size of the leave out should be an area of about 15" x 15" (square or round). The most critical measurement is the distance from the back of post to the back edge of the leave out, which should be a minimum of 7â€. After post installation, patching material is generally placed around the guardrail post in the "leave out" area. This work should be included by special provision.

7.01.33E Additional Blockouts on Guardrail Posts

Double blockouts (16" deep) may be used to increase the post offset to avoid obstacles such as curbs. Except at terminals, there is no limit to the number of posts in a guardrail run that use double blockouts. Under special circumstances, one or two posts in a run of guardrail may employ as many as four blockouts (up to 36") to provide proper clearance. There should be no voids between blockouts when using double or multiple blockouts. Furthermore, for aesthetic reasons, double or multiple blockouts should be installed without creating sudden changes in guardrail alignment.

When using double or multiple blockouts, steps must be taken to prevent the placement of guardrail posts on steep fill slopes beyond the shoulder hinge point. Placing conventional length guardrail posts on steep fill slopes may result in posts having insufficient soil embedment depth, thereby reducing the post's strength to resist overturning. See Section 7.01.41.D, 8'-0" Posts, for guardrail post length requirements when placing guardrail at or near the shoulder hinge line.

7.01.34 Guardrail in Conjunction with Curb

When a vehicle strikes a curb, the trajectory of that vehicle depends upon several variables including the size and suspension characteristics of the vehicle, its speed and angle of impact, and the height and shape of the curb itself. Generally, the use of curb on high speed roadways (design speed greater than 50 mph) is discouraged.

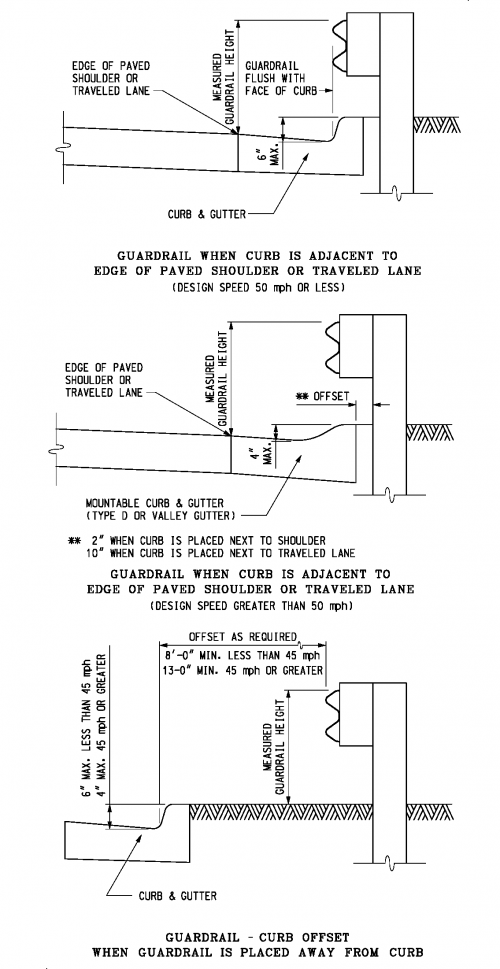

If guardrail/curb combinations are used when design speeds are less than 45 mph, the curb height should be 6" or less, with the face of guardrail being located either flush with the face of curb or at least 8' behind it.

For design speeds of 45 mph or 50 mph, a 6" curb (or less) may be used if the guardrail is located flush with the face of curb. If an offset from the curb is desired, the curb height should be 4" or less with the guardrail being located at least 13' behind the curb.

If guardrail/curb combinations are necessary when the design speed is greater than 50 mph, a mountable curb (Type D curb or valley gutter) should be used, and the curb height should be 4" or less, with the face of guardrail being located flush with the face of curb. .