Difference between revisions of "Pavement Markings"

HolvenstotC1 (talk | contribs) m |

HolvenstotC1 (talk | contribs) m |

||

| Line 207: | Line 207: | ||

should be considered rather than just allowing the existing markings to deteriorate over time. | should be considered rather than just allowing the existing markings to deteriorate over time. | ||

| − | At highway-railroad, at-grade crossings on abandoned rail lines and at railroad grade crossings with covered rail, it will no longer be necessary to install the railroad grade crossing pavement markings. Existing highway-railroad, at-grade crossing pavement markings should be removed at these types of crossings. According to the Michigan Vehicle Code 257.669 (3) | + | At highway-railroad, at-grade crossings on abandoned rail lines and at railroad grade crossings with covered rail, it will no longer be necessary to install the railroad grade crossing pavement markings. Existing highway-railroad, at-grade crossing pavement markings should be removed at these types of crossings. According to the Michigan Vehicle Code 257.669 (3) 'abandoned railroad track' means a railroad track which meets all of the following requirements: |

* The track has been abandoned pursuant to federal law. | * The track has been abandoned pursuant to federal law. | ||

| Line 298: | Line 298: | ||

'''Interchanges:''' Interchanges are handled in the same manner as intersections, apart from diverging diamond interchanges (DDIs). At a DDI, MDOT is not only responsible for maintaining the stop bar, crosswalk, and turning guide line markings at both signalized intersections, but will also maintain all special markings between the two signalized intersections. | '''Interchanges:''' Interchanges are handled in the same manner as intersections, apart from diverging diamond interchanges (DDIs). At a DDI, MDOT is not only responsible for maintaining the stop bar, crosswalk, and turning guide line markings at both signalized intersections, but will also maintain all special markings between the two signalized intersections. | ||

| + | |||

| + | '''Roundabouts:''' At roundabouts with trunkline, MDOT will maintain all markings within the circulatory roadway (including the entry yield lines) and all markings on trunkline approach legs. Where lane use arrows specific to the roundabout are placed on local legs approaching the roundabout, MDOT will maintain the special markings out to the furthest set of lane use arrows/legends. The respective local agency is responsible for all other markings on their legs. | ||

'''On-Street Parking:''' If on-street parking is either being put in or affected as part of an MDOT project, MDOT will be responsible for the initial striping. Maintenance of the on-street parking markings is the responsibility of the local agency. | '''On-Street Parking:''' If on-street parking is either being put in or affected as part of an MDOT project, MDOT will be responsible for the initial striping. Maintenance of the on-street parking markings is the responsibility of the local agency. | ||

| Line 303: | Line 305: | ||

===[[#Contract Cycle|Contract Cycle]]=== | ===[[#Contract Cycle|Contract Cycle]]=== | ||

| − | Every year, approximately 85 percent of the long line markings on MDOT roads are restriped, totaling nearly | + | Every year, approximately 85 percent of the long line markings on MDOT roads are restriped, totaling nearly 150 million feet of material. |

In addition, approximately 25 percent of special markings on MDOT roads are replaced each year. | In addition, approximately 25 percent of special markings on MDOT roads are replaced each year. | ||

| − | |||

| − | |||

Most Regions replace special markings on a 4 year cycle. When using cold plastic, the material can be placed two layers thick (initial application plus an overlay 4 years later) before requiring full removal. Polyurea does not need full removal but requires the existing material surface to be scarified prior to placing the next. | Most Regions replace special markings on a 4 year cycle. When using cold plastic, the material can be placed two layers thick (initial application plus an overlay 4 years later) before requiring full removal. Polyurea does not need full removal but requires the existing material surface to be scarified prior to placing the next. | ||

| − | There can be some variation in the size of both types of contracts from year to year based a few different factors. Long line contracts can vary due to the size of the | + | There can be some variation in the size of both types of contracts from year to year based a few different factors. Long line contracts can vary due to the size of the year's construction program and the replacement of aging durables. |

Special marking contracts vary due to whether markings need full removal and replacement or just overlay. An allowance for callback work is added to each contract to account for replacement of materials that unexpectedly need to be replaced or were in inadvertently left out. | Special marking contracts vary due to whether markings need full removal and replacement or just overlay. An allowance for callback work is added to each contract to account for replacement of materials that unexpectedly need to be replaced or were in inadvertently left out. | ||

===[[#Contact Development|Contact Development]]=== | ===[[#Contact Development|Contact Development]]=== | ||

| − | Contract templates are being developed for both types of contracts to promote consistency between the Regions. Contracts are not plan based but instead are completed as log projects. A statewide pavement marking database for both long lines and special markings maintained in Microsoft Access is housed in | + | Contract templates are being developed for both types of contracts to promote consistency between the Regions. Contracts are not plan based but instead are completed as log projects. A statewide pavement marking database for both long lines and special markings maintained in Microsoft Access is housed in MDOT's ProjectWise program. |

'''Role overview (Region vs. Lansing Responsibilities)''' | '''Role overview (Region vs. Lansing Responsibilities)''' | ||

| − | Regions maintain their own log information and prepare contract documents and then submit to Lansing Pavement Marking | + | Regions maintain their own log information and prepare contract documents and then submit to Lansing Pavement Marking unit. The logs are submitted for review and compilation in late October or early November, and the contract documents are submitted to Lansing for review prior to submission to Specifications and Estimates. |

'''Schedule''' | '''Schedule''' | ||

| − | In late summer/early fall, Lansing Pavement Marking Area develops rough contract cost estimates for all 14 contracts (7 regions, 2 contracts each) and then divides the projects into 3 lettings (February, March and April) based on roughly equal total cost per letting. Lansing then programs projects in Jobnet and sends emails to regions with information needed to start developing their contracts. Information included in these emails includes job number, miscellaneous notes, pay item unit | + | In late summer/early fall, Lansing Pavement Marking Area develops rough contract cost estimates for all 14 contracts (7 regions, 2 contracts each) and then divides the projects into 3 lettings (February, March and April) based on roughly equal total cost per letting. Lansing then programs projects in Jobnet and sends emails to regions with information needed to start developing their contracts. Information included in these emails includes job number, miscellaneous notes, pay item unit prices, etc. Regions then begin to develop their contracts in order to prepare for reviews with Lansing. Projects are programmed 5 years out, with the fifth and furthest year being programmed annually. |

{{top}} | {{top}} | ||

| Line 334: | Line 334: | ||

====[[#Annual Long Line Products|Annual Long Line Products]]==== | ====[[#Annual Long Line Products|Annual Long Line Products]]==== | ||

| − | Approximately 85% of | + | Approximately 85% of MDOT's roadways are restriped each year, and this is accomplished through the use of two materials: waterborne and sprayable thermoplastic. Both of these products are considered 1-year or "maintenance" products and do not have a long life expectancy. |

| − | Waterborne is a water-based paint and is the most economical product available. It is also environmentally friendly, containing no Volatile Organic Compounds ( | + | Waterborne is a water-based paint and is the most economical product available. It is also environmentally friendly, containing no Volatile Organic Compounds (VOCs). Waterborne is a spec book material that can be applied between May 1st and October 15th when the ambient temperature is 50 degrees or higher. Standard placement is at a film thickness of 15 mils, and can be achieved via striping trucks, hand application, or hand carts. Dry time varies with temperature and humidity, but is generally only a matter of minutes. Night application is not feasible due to the moisture present. |

Sprayable thermoplastic is a granular material that is heated to more than 400 degrees Fahrenheit until it is liquefied and placed on the pavement. Sprayable thermoplastic is a spec book material that can be applied between April 15th and November 15th when the ambient temperature is 50 degrees or higher. Standard placement is at a film thickness of 30 mils, which results in a final thickness of 40 mils once beads are applied. Sprayable thermoplastic is two or more times the cost of waterborne, but has the advantages that it dries (cools) in less than one minute and can be placed at night. This makes it the preferred material for high traffic areas where material tracking is a concern, or where traffic restrictions force night placement. The downside is that placement can only be done with striping trucks (not by hand or cart) due to the temperature and pressure requirements to place the material. | Sprayable thermoplastic is a granular material that is heated to more than 400 degrees Fahrenheit until it is liquefied and placed on the pavement. Sprayable thermoplastic is a spec book material that can be applied between April 15th and November 15th when the ambient temperature is 50 degrees or higher. Standard placement is at a film thickness of 30 mils, which results in a final thickness of 40 mils once beads are applied. Sprayable thermoplastic is two or more times the cost of waterborne, but has the advantages that it dries (cools) in less than one minute and can be placed at night. This makes it the preferred material for high traffic areas where material tracking is a concern, or where traffic restrictions force night placement. The downside is that placement can only be done with striping trucks (not by hand or cart) due to the temperature and pressure requirements to place the material. | ||

| Line 350: | Line 350: | ||

Lesser Used Products: | Lesser Used Products: | ||

| − | * '''Methyl Methacrylate,''' or MMA, is another plural component durable liquid. It is relatively new to MDOT and while it is a highly durable and plow-resistant material, it is challenging to work with and requires specialized equipment that most contractors do not have. It can be placed in a thin spray like polyurea, extruded thick like thermoplastic, or structured in a | + | * '''Methyl Methacrylate,''' or MMA, is another plural component durable liquid. It is relatively new to MDOT and while it is a highly durable and plow-resistant material, it is challenging to work with and requires specialized equipment that most contractors do not have. It can be placed in a thin spray like polyurea, extruded thick like thermoplastic, or structured in a "splatter" pattern to provide wet-night visibility. MMA is able to bond well to both asphalt and concrete surfaces. The Pavement Marking Engineer should be contacted prior to specifying this material for longitudinal markings in a project. |

* '''Multipolymer''' is a new class of material being developed, and is in many ways a hybrid between thermoplastic and MMA. | * '''Multipolymer''' is a new class of material being developed, and is in many ways a hybrid between thermoplastic and MMA. | ||

| Line 358: | Line 358: | ||

:* Endurablend is a cement-based pavement marking material which is sprayed down at a thickness of 60 mils. Endurablend may be tinted any color. It is used for both longitudinal and special markings. | :* Endurablend is a cement-based pavement marking material which is sprayed down at a thickness of 60 mils. Endurablend may be tinted any color. It is used for both longitudinal and special markings. | ||

| − | =====[[#Wet | + | =====[[#Wet Reflective|Wet Reflective]]===== |

| − | Wet | + | Wet reflective refers to the ability for a pavement marking to be seen at night and in the rain, and is a difficult property to maintain. Both liquid and preformed pavement markings can be wet-reflective. |

| − | Any liquid pavement marking material can be made wet-reflective through the addition of large beads or elements to the standard glass bead application | + | Any liquid pavement marking material can be made wet-reflective through the addition of large beads or elements to the standard glass bead application. Addition of the wet reflective optics adds approximately $0.10 per foot to the material installation cost, so they are typically only used with durable pavement markings or freeway lane lines. There is some difficulty with thin-applied products holding the larger beads and elements, so it is highly recommended to recess the materials for added protection from snowplows. |

| − | Preformed materials with wet | + | Preformed materials with wet reflective properties have specialized glass beads that provide the wet reflectivity embedded in the surface of the material during the manufacturing process. Preformed tape is the most commonly used of the wet reflective preformed materials, but it is significantly more expensive than liquid wet reflective products so the use is limited. The tape provides arguably better wet reflectivity in the first several years of service life, but over time the wet reflective coating of the product begins to wear out. |

[[File:Shadow Marking.JPG|400x250 px|thumb|left|Shadow Marking]] | [[File:Shadow Marking.JPG|400x250 px|thumb|left|Shadow Marking]] | ||

=====[[#Shadow/Contrast|Shadow/Contrast]]===== | =====[[#Shadow/Contrast|Shadow/Contrast]]===== | ||

| − | + | "Shadow" and "contrast" refer to two methods of helping white pavement markings stand out against light-colored pavement surfaces, such as new concrete. | |

| − | Shadow markings are used to emphasize lane line markings and consist of a non-reflective black | + | Shadow markings are used to emphasize lane line markings and consist of a non-reflective black "tail" marking placed on the downstream side of each skip. The black markings are readily visible in the daytime against pale pavements, but are not reflective since the white markings will show up well at night (plus black wouldn't reflect well). The standard lengths for shadow markings are 6 foot after each broken lane line skip and 2 foot after any lane drop dotted line skips. See Pavement Marking Standard [https://mdotjboss.state.mi.us/TSSD/getCategoryDocuments.htm?categoryPrjNumbers=1403856,1403857,1403858,1403859,1403860&category=Pavement%20Markings PAVE-906] for additional information. |

Contrast markings are used to emphasize symbols and legends, and consist of either a black border around all sides of the white marking or a black box behind the marking. Contrast can also refer to lane line markings with black borders on both sides, but this application is not to be used since it cannot be maintained with current striping practices. | Contrast markings are used to emphasize symbols and legends, and consist of either a black border around all sides of the white marking or a black box behind the marking. Contrast can also refer to lane line markings with black borders on both sides, but this application is not to be used since it cannot be maintained with current striping practices. | ||

| Line 377: | Line 377: | ||

* '''Polyurea''' is a plural component liquid, which means it is comprised of a base and a catalyst that are combined during application. This is the same material used for durable longitudinal markings, and is still applied at a thickness of 20 mils. A hand cart is used for line-style markings, while stencils and squeegees are needed to apply arrows and legends. This material holds up well to shearing forces, but the placement time is longer than cold plastic so mobility concerns should be considered.: | * '''Polyurea''' is a plural component liquid, which means it is comprised of a base and a catalyst that are combined during application. This is the same material used for durable longitudinal markings, and is still applied at a thickness of 20 mils. A hand cart is used for line-style markings, while stencils and squeegees are needed to apply arrows and legends. This material holds up well to shearing forces, but the placement time is longer than cold plastic so mobility concerns should be considered.: | ||

| − | * '''Cold Plastic''' is a preformed material similar to the durable wet-reflective tape, but is less expensive and does not have the wet-reflective coating. Glass beads that provide retroreflectivity are embedded in surface of material during manufacture process,and the product is supplied in rolls from the manufacturer that can be cut with a knife by hand or stamped using a die to create specific shapes. A liquid primer is typically applied before the material is placed, but cold plastic installs very quickly. The | + | * '''Cold Plastic''' is a preformed material similar to the durable wet-reflective tape, but is less expensive and does not have the wet-reflective coating. Glass beads that provide retroreflectivity are embedded in surface of material during manufacture process,and the product is supplied in rolls from the manufacturer that can be cut with a knife by hand or stamped using a die to create specific shapes. A liquid primer is typically applied before the material is placed, but cold plastic installs very quickly. The material's weakness is that it is prone to tearing and failing under shearing forces, such as vehicle turning locations. |

| Line 392: | Line 392: | ||

* '''Preformed Thermoplastic''' is a preformed material that comes to the site in sheets or shapes and after being laid on the pavement is torched until molten to create the bond with pavement. The torching and cooling time results in a fairly long application time for this product, but it has some unique properties such as being able to be multicolor and in any shape. Like extruded thermoplastic this material does very well on asphalt surfaces but does not bond well to concrete, however a primer can help. This product is commonly used for accessible symbols and route shields. | * '''Preformed Thermoplastic''' is a preformed material that comes to the site in sheets or shapes and after being laid on the pavement is torched until molten to create the bond with pavement. The torching and cooling time results in a fairly long application time for this product, but it has some unique properties such as being able to be multicolor and in any shape. Like extruded thermoplastic this material does very well on asphalt surfaces but does not bond well to concrete, however a primer can help. This product is commonly used for accessible symbols and route shields. | ||

| − | |||

| − | |||

| − | |||

====[[#Other|Other]]==== | ====[[#Other|Other]]==== | ||

| Line 439: | Line 436: | ||

==[[#'''Recessing'''|'''Recessing''']]== | ==[[#'''Recessing'''|'''Recessing''']]== | ||

| − | Recessing consists of | + | Recessing consists of grooving the pavement surface and then applying permanent marking material within the groove. The optimal depth of the groove is slightly deeper than the thickness of the material. Recessing the material below the surface provides protection from snow plows and, to a certain degree, from vehicle tire wear. The groove remains in the pavement after the initial material has reached its life span and can have new material applied within it. |

| Line 477: | Line 474: | ||

[pattern], [cycle] | [pattern], [cycle] | ||

| − | Patterns include: solid, double solid, broken, solid and broken, and dotted. Cycle is indicated for broken, solid and broken, and dotted lines in the form: [length] | + | Patterns include: solid, double solid, broken, solid and broken, and dotted. Cycle is indicated for broken, solid and broken, and dotted lines in the form: [length]' mark, [length]' gap |

Callouts for special markings are shown in the following format: | Callouts for special markings are shown in the following format: | ||

PAVT MRKG, [material], [pay item name or similar description] | PAVT MRKG, [material], [pay item name or similar description] | ||

| − | When a special marking type appears on the same plan sheet multiple times, it is acceptable to label a single instance of each type and add | + | When a special marking type appears on the same plan sheet multiple times, it is acceptable to label a single instance of each type and add "(TYP)" at the end of the callout rather than label each instance separately. Recessing of longitudinal lines or special markings must be indicated in the callouts or via a general note on each plan sheet. Quantities are to be shown per plan sheet. If there are no pavement marking plan sheets or the plan sheets do not cover all markings, such as when using Witness, Log, place the quantities not associated with a pavement marking plan sheet on the Miscellaneous Quantities plan sheet under the heading "Permanent Pavement Markings". |

MDOT Road Design Manual, Section 1.02.18 | MDOT Road Design Manual, Section 1.02.18 | ||

| Line 489: | Line 486: | ||

* Removal of Cure Compound: The use of curing compound with new concrete creates a surface that pavement markings, temporary or permanent, will not adhere to. Ensure that pay item quantities are included for removal of curing compound for any markings placed on new concrete, unless the markings will be recessed as this removes the affected pavement surface. | * Removal of Cure Compound: The use of curing compound with new concrete creates a surface that pavement markings, temporary or permanent, will not adhere to. Ensure that pay item quantities are included for removal of curing compound for any markings placed on new concrete, unless the markings will be recessed as this removes the affected pavement surface. | ||

| − | * '''Correct Delineator Pay Items:''' The pay item for "Delineator, Reflective Sheeting, [size], [color]" is a piece of retroreflective sheeting material that is applied to a flexible delineator post; pay item "Post, Flexible, Delineator". The pay items "Delineator Reflector | + | * '''Correct Delineator Pay Items:''' The pay item for "Delineator, Reflective Sheeting, [size], [color]" is a piece of retroreflective sheeting material that is applied to a flexible delineator post; pay item "Post, Flexible, Delineator". The pay items "Delineator Reflector" are installed on rigid delineator posts; pay item "Post, Delineator". |

* '''Special Emphasis Style Crosswalks:''' Special emphasis, or "continental" style crosswalks should be used anytime a crosswalk intersects a free flow movement of traffic. This could include designated midblock crossings, free flow freeway entrance/exit ramps, entrances and exits to a roundabout. More information on midblock crosswalks can be found in this [[link to section|section]] | * '''Special Emphasis Style Crosswalks:''' Special emphasis, or "continental" style crosswalks should be used anytime a crosswalk intersects a free flow movement of traffic. This could include designated midblock crossings, free flow freeway entrance/exit ramps, entrances and exits to a roundabout. More information on midblock crosswalks can be found in this [[link to section|section]] | ||

| Line 527: | Line 524: | ||

===[[#Materials|Materials]]=== | ===[[#Materials|Materials]]=== | ||

| − | Post-mounted delineators may be either rigid or flexible installations. Rigid installations consist of a reflective element bolted to a ground-driven steel U-channel post. In the past round plastic | + | Post-mounted delineators may be either rigid or flexible installations. Rigid installations consist of a reflective element bolted to a ground-driven steel U-channel post. In the past round plastic "button" reflectors were used for such installations, but MDOT has moved to using rectangular reflectors that are in essence miniature signs (sign sheeting on aluminum panels). Flexible installations consist of reflective sheeting applied to a ground-driven flexible post, often a plastic or fiberglass, which is selected from the Qualified Products List. |

Standard guardrail and concrete barrier reflectors are fairly generic items and must conform to the requirements defined in the spec book. | Standard guardrail and concrete barrier reflectors are fairly generic items and must conform to the requirements defined in the spec book. | ||

| Line 549: | Line 546: | ||

====[[#Non-Freeway|Non-Freeway]]==== | ====[[#Non-Freeway|Non-Freeway]]==== | ||

Non-freeway shoulder rumble strips should be used on all rural, 2-lane, 4-lane, and divided trunk line roadways where the posted speed is 55 mph and the paved shoulder is at least 6 feet wide. | Non-freeway shoulder rumble strips should be used on all rural, 2-lane, 4-lane, and divided trunk line roadways where the posted speed is 55 mph and the paved shoulder is at least 6 feet wide. | ||

| − | Non-freeway shoulder rumble strips consist of | + | Non-freeway shoulder rumble strips consist of a recessed sine wave pattern with a 14-inch wavelength placed in a cyclical pattern of 48 feet of grooving followed by a 12-foot gap. This gap is to accommodate the movement of bicyclists on and off of the shoulder through the rumble strips. Non-freeway shoulder rumble strips are placed at a 12 inch offset from the painted edge line and are gapped for several roadway features, including intersections, commercial driveways, and bridges. |

===[[#Centerline|Centerline]]=== | ===[[#Centerline|Centerline]]=== | ||

| − | Centerline rumble strips should be used on all rural 2-lane and 4-lane trunk line roadways (in both passing and non-passing zones) where the posted speed is 55 mph and the lane plus paved shoulder width beyond the centerline corrugation is greater than | + | Centerline rumble strips should be used on all rural 2-lane and 4-lane trunk line roadways (in both passing and non-passing zones) where the posted speed is 55 mph and the lane plus paved shoulder width beyond the centerline corrugation is greater than 13" in width. |

Centerline rumble strips consist of grooves on an alternating 1-foot/2-foot on-center pattern installed along the centerline of the roadway. They are gapped for several roadway features, including intersections, commercial driveways, and bridges. | Centerline rumble strips consist of grooves on an alternating 1-foot/2-foot on-center pattern installed along the centerline of the roadway. They are gapped for several roadway features, including intersections, commercial driveways, and bridges. | ||

| − | Centerline rumble strips have not been in use as long as shoulder rumble strips, but have proven to be a highly effective safety feature. A two-phase research project done on | + | Centerline rumble strips have not been in use as long as shoulder rumble strips, but have proven to be a highly effective safety feature. A two-phase research project done on MDOT's statewide (all eligible trunkline routes) implementation found a 51% reduction in fatal centerline-crossing crashes after the installation of centerline rumble strips. |

| + | |||

| + | ===[[#Edgeline|Edgeline]]=== | ||

| Line 610: | Line 609: | ||

* '''How do we replace durable markings as they wear out?''' | * '''How do we replace durable markings as they wear out?''' | ||

| − | + | In general, it is not financially feasible to replace worn out durable markings with new durable markings. Instead when a durable marking reaches the end of its service life that section of roadway is added back into the annual restriping contracts, and the durable marking will be painted over with either waterborne or sprayable thermoplastic. Recently small durable projects have been programmed in with the annual restriping projects that allow replacement of some aged durables in-kind. Projects are programmed for 2 Regions per year and rotate. | |

{{top}} | {{top}} | ||

Latest revision as of 09:49, 13 October 2021

Overview

Functions and Limitations

Markings on highways and on private roads open to public travel have important functions in providing guidance and information for the road user. Major marking types include pavement and curb markings, delineators, colored pavements, channelizing devices, and islands. In some cases, markings are used to supplement other traffic control devices such as signs, signals, and other markings. In other instances, markings are used alone to effectively convey regulations, guidance, or warnings in ways not obtainable by the use of other devices. Markings have limitations. Visibility of the markings can be limited by snow, debris, and water on or adjacent to the markings. Marking durability is affected by material characteristics, traffic volumes, weather, and location. However, under most highway conditions, markings provide important information while allowing minimal diversion of attention from the roadway.

2011 MMUTCD, Section 3A.01

Initiatives

Sinusoidal Rumble Strips

Sinusoidal rumble strips, or "mumble strips", are a rolling sine wave pattern that is slightly recessed into the pavement surface. Sinusoidal rumble strips provide adequate sound and vibration to the driver but produce less exterior noise than traditional rumble strips. Different patterns are currently installed in Minnesota, Pennsylvania and California. MDOT installed and evaluated pilot projects in all Regions, and has now made sinusoidal rumble strips the standard for non-freeway shoulders. Sinusoidal rumble strips are an option for other installations provided the locations meet the criteria in Section 6.05.11 of the Road Design Manual.

Statewide Rumble Strip Installation and Research

From 2008-2010, MDOT performed a statewide installation of centerline rumble strips on all appropriate non-freeway roads posted 55 mph. The research project that followed took place in two phases. Phase I studied the impacts of rumble strips on driver behavior and Phase II studied the impact of rumble strips on crashes. A significant finding of phase II is that centerline rumble strips resulted in a 51 percent reduction in fatal centerline-crossing lane departure crashes. Both reports can be found here:

RC-1575 - Impact of Non-Freeway Rumble Strips - Phase 1

RC-1627 - Evaluation of Non-Freeway Rumble Strips - Phase II

Pavement Marking Research Project

A pavement marking research project evaluated current pavement marking practices in Michigan and other states to identify best practices for increased program efficiency. The research project concluded in Spring of 2017. Recommendations from the research project are being evaluated for implementation.

Innovative Materials

As new materials are developed, MDOT seeks to evaluate them for cost effectiveness, durability, wet night retroreflectivity, and speed of installation. It is important to evaluate both products that are competitors to existing products and brand-new products that have never been tried in the state before. An example of a material that has been recently tested in Michigan is multipolymer cement (Endurablend).

Wrong-Way Movement Treatments

PAVE-926 was created to help address wrong way movements at partial cloverleaf interchanges. The standard shows optional and required pavement marking and delineator treatments.

Wet Reflective Freeway Lane Lines

In 2018 MDOT experimented with placing wet reflective optics in maintenance (1-year) materials on 2 freeway routes with the annual restriping projects. After observing improved wet night visibility on those routes application of wet reflective optics was expanded all lane lines on freeway routes, for both maintenance and construction placement.

Six Inch Freeway Lane Lines

Beginning with the 2020 annual restriping projects (2021 for construction projects), all freeway lane lines will be increased in width from 4" to 6".

Six Inch Non-Freeway Markings

Beginning with the 2021 annual restriping projects (2022 for construction projects), all non-freeway white lane lines will be increased in width from 4" to 6" (any 8" will go to 12").

Beginning in 2022 and spanning over 3 years for conversion (2-3 Regions per year), non-freeway yellow lines will be increased in width from 4" to 6".

Longitudinal Markings

Types

The general functions of longitudinal lines shall be:

A. A double line indicates maximum or special restrictions

B. A solid line discourages or prohibits crossing (depending on specific application)

C. A broken line indicates a permissive condition, and

D. A dotted line provides guidance or warning or a downstream change in lane function.

The widths and patterns of longitudinal lines shall be:

A. Normal line - 4 to 6 inches wide.

B. Wide line - at least twice the width of a normal line.

C. Double line - two parallel lines separated by a discernible space.

D. Broken line - normal line segments separated by gaps

E. Dotted line - noticeably shorter line segments separated by shorter gaps than used for a broken line. The width of the dotted line extension shall be at least the same as the width of the line it extends.

2011 MMUTCD Section 3A.06

- Information regarding patterns and widths of longitudinal markings used on MDOT roads can be found in the most recent version of PAVE-905.

Applications

Longitudinal markings are line type markings that delineate travel lanes and are parallel to vehicle travel direction. They are various widths and can be solid or dashed at various lengths. All lines on MDOT roads are retroreflective with the exception of off-street parking markings, such as for rest areas, roadside parks, and parking/carpool lots.

Centerline pavement markings are yellow markings used to delineate the separation of traffic that is moving in opposite directions on an undivided roadway. MDOT uses 4-inch wide markings for centerlines, increasing to 6-inch width statewide by 2025, and the different patterns convey passing and no passing zones to the different directions of traffic. When placed over a centerline rumble strip the centerline markings become known as a rumble stripe and gain some wet-night reflectivity. Even with rumble strips present, centerline markings can be recessed for added durability.

Edgeline pavement markings delineate the right or left edge of a roadway and identify the extents of the pavement to be used for vehicular travel. On divided highways, one-way streets, and ramps, the left edgeline is to be yellow. The righthand edgeline should always be white. The edgelines should be 6-inch width on MDOT roadways, while many local agencies use 4-inch width.

Lane Line pavement markings are white markings that delineate the separation of traffic moving in the same direction. 6-inch lane lines are located between adjacent lanes traveling in the same direction, and also a thru lane and an exit or entrance lane. Lane lines can also be 12-inch width for drop and weave lanes, as shown in PAVE-925 and PAVE-940.

Gore pavement markings are 12-inch wide white markings that define the neutral area between thru traffic and merging/diverging traffic, such as at a freeway ramp.

Parking Area pavement markings are 4-inch wide markings that define parking stalls and buffers in a parking area, such as a rest area, carpool lot, or roadside park. Parking area markings are done with waterborne and are unique in that they do not require glass beads, and therefore are not retroreflective. MDOT's standards for parking area pavement markings are defined in PAVE-956, which includes a chart to determine how many accessible spaces are needed. When designing for accessible stalls, and for parking areas as a whole, it is important to note the following:

- 1 of every 6 accessible spaces must be a van accessible space, with a minimum of 1

- Accessible stalls (car and van) should be 12 feet wide when measured to the center of the pavement marking lines

- If the accessible route (e.g. – sidewalk) is located in front of the parking space, install wheel stops to keep vehicles from reducing the clear width of the accessible route below 36 inches

- All accessible stalls must have an adjacent access aisle (“buffer†in our standard)

- Two vehicles may share an access aisle located between them

-

- Access aisles adjacent to accessible car stalls must be a minimum of 5 feet wide

-

- Access aisles adjacent to accessible van stalls must be a minimum of 8 feet wide

-

- Access aisles may be located on either side of the parking space except for angled van parking spaces, which must have access aisles located on the passenger side of the parking spaces

- Pavement markings for accessible stalls shall be white

-

- Blue may be used to supplement as shown in the standard, but cannot be used as a standalone color

References/Resources:

- ADA Compliance Brief: Restriping Parking Spaces

- ADA Design Guide: Restriping Parking Lots

Special Markings

Types

Special markings (also referred to as "transverse markings") include shoulder markings, word and symbol markings, arrows, stop lines (stop bars), yield lines, crosswalk lines, speed measurement markings, speed reduction markings, speed hump markings, parking space markings, and others. Special markings are generally white but in certain cases may match the color of the nearest edge line or include contrasting colors. (Based on 2011 MMUTCD, Section 3B.15)

Applications

The applications of special pavement markings are more varied than those for longitudinal pavement markings. Special markings can be used to guide, warn, or regulate both vehicular and pedestrian traffic. Some of the special markings used in Michigan and their appropriate uses are detailed below.

Stop Bar Markings indicate the point behind which vehicles are required to stop in compliance with a traffic control signal. They may also be used in conjunction with stop signs, but it is not MDOT standard to do so unless an intersection requires additional emphasis. Stop bars on MDOT trunkline are 24 inches in width, but many local agencies use 18-inch width on their roadways.

Yield Lines come in two designs and are used to indicate the point behind which vehicles are required to yield in compliance with a "Yield" sign or a "Yield Here to Pedestrians" sign. While not frequently used in Michigan the lines comprised of triangles (also known as "shark teeth") are installed in advance of unsignalized midblock pedestrian crossings that span more than two lanes. The other type of yield line is present at the entry to the circular roadway of a roundabout and consists of 12-inch wide striping in a pattern of 3 feet of marking followed by 3 feet of gap.

Crosswalk Markings provide guidance for pedestrians who are crossing roadways by defining and delineating their path and can also serve to alert motorists of the pedestrian crossing. Standard crosswalk markings used at signalized or stop-controlled intersection legs consist of two parallel 6-inch lines placed transverse to the flow of vehicular traffic. Special emphasis crosswalk markings consist of 12-inch bars placed parallel to vehicular traffic and separated by a 24-inch space. Special emphasis markings are used over the standard crosswalk markings at midblock crossing locations, established school crossings, and where pedestrians must cross vehicular traffic that does not stop. See "Guidance for Installation of Pedestrian Crosswalks on Michigan State Trunkline Highways" on the MDOT Traffic & Safety website for more information.

On-Street Parking Markings delineate vehicle parking spaces along the sides of a through roadway. The most common layout for the parking spaces is parallel parking, where the vehicles remain facing in the direction of thru traffic. The options for parallel parking layouts are detailed in PAVE-955. On-street parking markings can also be perpendicular to the direction of thru traffic or placed at an angle between parallel and perpendicular. One version of angle parking, known as back-in angle parking, is detailed in PAVE-957. Unlike parking lot markings, on-street parking markings must be retroreflective. The markings can be placed with any of the available pavement marking materials except sprayable thermoplastic, which requires a large truck for placement.

Guide Lines

Guide lines are special markings used at dual turn locations as well as offset intersections. They may also be used as option edge line extensions across intersections. Markings should be dotted (2' mark/4' gap) or solid, and must be at least as wide as the line being extended. The color placed should match the color of the line being extended.

- Dotted turning guide lines must be cold plastic

- Solid turning guide lines should be sprayable thermoplastic

- Dotted thru guide lines may be cold plastic or sprayable thermoplastic

- Solid thru guide lines should be sprayable thermoplastic

For additional guidance regarding guide lines, see PAVE-907.

Optical Speed Bars

Optical Speed Bars are white transverse markings on both sides of the lane that are placed at decreasing spacing in the direction of travel to give drivers the sense that they are traveling at a higher rate of speed to encourage slowing down. Previous installations in Michigan include EB I-94, Exit 12 (Sawyer Rd) in Sawyer and WB US-10 Business Route at M-20 in Midland.

Location Criteria:

- In advance of a location with an advisory speed, such as a severe horizontal or vertical curve or other roadway feature drivers must always decelerate in advance of, like a roundabout

- The desired reduction in speeds has not been achieved by the installation of warning signs and/or other traffic control devices

Optical speed bars should not be used on long tangent sections of roadway or in areas frequented mainly by local or familiar drivers, (e.g., school zones).

Installation Requirements:

- Optical speed bars shall be white on both sides of the lane

- Longitudinal pavement markings (center, edge, or lane lines) must be present on both sides of the lane

- Longitudinal spacing between optical speed bars reduces in the direction of travel

- Install with special marking materials (not waterborne or sprayable thermoplastic)

Word and Symbol Markings can be helpful to road users in some locations by supplementing signs and providing additional emphasis for important regulatory, warning, or guidance messages, because the markings do not require diversion of the road user’s attention from the roadway surface. These include legends, arrows, accessible symbols, route shield markings, and more. Most arrows and legends are detailed in the current version of Pavement Marking Standard PAVE-900.

Shared Lane "Sharrow" Markings are used on state trunkline non-freeways within urban areas that designate bicycle routes and are marked using the bicycle symbol with chevrons. They are only used on roadways that have a speed limit of 35 mph or lower and are not used on shoulders or in designated bicycle lanes. These shared lanes are used for the following reasons:

- Routing the bicyclists to avoid on-street parking and the potential of impacting an open door of a parked vehicle.

- Assisting bicyclists with lateral positioning in lanes that are too narrow for a motor vehicle and a bicycle to travel safely side by side within the same traffic lane.

- Forewarn road users of the location bicyclists are most likely to occupy within the traveled lane.

- Promote safe passing of bicyclists by motorized vehicles.

- Reduce the incidence of wrong-way bicycling.

Guidance for placing shared lane markings can be found in PAVE-961.

Railroad Grade Crossing Markings consist of an "X", the letters RR, and transverse lines. For payment the transverse lines are considered separate from the rest of the symbol and are paid for under the stop bar pay items. Railroad markings are placed in each approach lane on all paved approaches to a highway-rail crossing where signals or automated gates are located, and at all other crossings where the posted highway speed is 40 mph or greater.

These markings may be omitted where the posted speed is less than 40 mph, or in urban areas if an engineering study indicates that other devices installed provide suitable warning and control. The volumes of highway and train traffic should also be considered when determining whether markings may be omitted. Such crossings will have low volumes and are likely to be passive (no signals or gates). A Diagnostic Study Team Review (DSTR) or an engineering study may be done to satisfy the needs of the Michigan Manual on Uniform Traffic Control Devices (MMUTCD) as noted above. The Region/TSC Traffic and Safety Representative should discuss possible locations for omitting railroad grade crossing pavement markings with the MDOT Railroad Safety Inspector. If the decision is made to omit railroad grade crossing pavement markings at a location, the prompt removal of the existing markings should be considered rather than just allowing the existing markings to deteriorate over time.

At highway-railroad, at-grade crossings on abandoned rail lines and at railroad grade crossings with covered rail, it will no longer be necessary to install the railroad grade crossing pavement markings. Existing highway-railroad, at-grade crossing pavement markings should be removed at these types of crossings. According to the Michigan Vehicle Code 257.669 (3) 'abandoned railroad track' means a railroad track which meets all of the following requirements:

- The track has been abandoned pursuant to federal law.

- The track has been covered or removed.

- All signs, signals and other warning devices are removed.

Aerial Surveillance Markings are white non-reflective transverse markings located on both shoulders of a roadway that enable the Michigan State Police to verify vehicle speeds from the air. Details for these markings can be found in PAVE-911.

Preformed Thermoplastic Route Shields are large markings in the lane that identify lane use ahead of a split or other confusing geometry. Previous installations in Michigan include the SB I-75/US-23 split in Flint and the diverging diamond interchange (DDI) at I-96 and Cascade Rd near Grand Rapids.

Route Shields Southbound I-75 and US-23

Locations:

- Freeways:

- Major splits prone to congestion and/or operating well below posted speeds

- Major splits with a history of driver compliance and/or navigation issues

- Interchanges:

- Prone to congestion and/or operating well below posted speeds and

- Having complex or unusual geometry (ex – DDI interchanges)

- Locations where the Region or TSC Traffic and Safety Engineer determines that installation of the route shield markings would have significant benefit

Design:

- Plans and pay item(s) should identify the required route shield(s)

- Separate pay item per route requiring depiction

- Pavt Mrkg, Preformed Thermopl, (route) Route Shield, __ foot by __ foot

- Shield dimensions dictated by the markings section of the Standard Highway Signs manual

- Use 6' x 15' size for shields installed in non-freeway lanes

- Use 7' x 17' size for two-digit shields installed in freeway lanes

- Use 8' x 20' size for three-digit shields installed in freeway lanes

- Shields may be supplemented by additional special markings

- Secondary shields (option lanes or ahead of a secondary split)

- Lane use arrows

- Legends (TO, ONLY, EAST/WEST/NORTH/SOUTH)

- Limit markings in a single lane to a total of 3 or less including the primary shield (per set)

- Use 80’ longitudinal spacing between all special markings in a single lane

- Route shield special markings are most effective when used in conjunction with overhead signing

- Recommend placement in advance of or between overhead signs to avoid driver overload

- Install two sets of shields (and any supplemental special markings) per direction in advance of the decision point (typically a gore)

- Recommend installing the first set approximately 1 mile in advance of the decision point

General Notes:

- Installation of route shield markings should be discussed and agreed upon with Lansing Traffic and Safety. Not doing so may result in the markings not being maintained by the Region-wide pavement marking contracts

- Preformed thermoplastic is the only material feasible at this time

- Route shield special markings should not be overused due in part to cost but also since the markings may lose their impact if over-installed

Resources:

- TTI Research

Curb/Island Painting

Curb/island painting is pavement marking material, including beads, that is applied to curb and raised island surfaces to provide positive guidance to traffic. Details can be found in the related Previously Approved Special Provisions and PAVE-940.

Restriping

Responsible Parties

Intersections: MDOT will maintain the stop bar and crosswalk markings on all legs of a signalized intersection with trunkline, and the guide lines at all intersections with trunkline. For all other markings and intersection types, MDOT will maintain the markings on the trunkline legs only and the respective local agency is responsible for their legs.

Interchanges: Interchanges are handled in the same manner as intersections, apart from diverging diamond interchanges (DDIs). At a DDI, MDOT is not only responsible for maintaining the stop bar, crosswalk, and turning guide line markings at both signalized intersections, but will also maintain all special markings between the two signalized intersections.

Roundabouts: At roundabouts with trunkline, MDOT will maintain all markings within the circulatory roadway (including the entry yield lines) and all markings on trunkline approach legs. Where lane use arrows specific to the roundabout are placed on local legs approaching the roundabout, MDOT will maintain the special markings out to the furthest set of lane use arrows/legends. The respective local agency is responsible for all other markings on their legs.

On-Street Parking: If on-street parking is either being put in or affected as part of an MDOT project, MDOT will be responsible for the initial striping. Maintenance of the on-street parking markings is the responsibility of the local agency.

Contract Cycle

Every year, approximately 85 percent of the long line markings on MDOT roads are restriped, totaling nearly 150 million feet of material. In addition, approximately 25 percent of special markings on MDOT roads are replaced each year.

Most Regions replace special markings on a 4 year cycle. When using cold plastic, the material can be placed two layers thick (initial application plus an overlay 4 years later) before requiring full removal. Polyurea does not need full removal but requires the existing material surface to be scarified prior to placing the next.

There can be some variation in the size of both types of contracts from year to year based a few different factors. Long line contracts can vary due to the size of the year's construction program and the replacement of aging durables. Special marking contracts vary due to whether markings need full removal and replacement or just overlay. An allowance for callback work is added to each contract to account for replacement of materials that unexpectedly need to be replaced or were in inadvertently left out.

Contact Development

Contract templates are being developed for both types of contracts to promote consistency between the Regions. Contracts are not plan based but instead are completed as log projects. A statewide pavement marking database for both long lines and special markings maintained in Microsoft Access is housed in MDOT's ProjectWise program.

Role overview (Region vs. Lansing Responsibilities)

Regions maintain their own log information and prepare contract documents and then submit to Lansing Pavement Marking unit. The logs are submitted for review and compilation in late October or early November, and the contract documents are submitted to Lansing for review prior to submission to Specifications and Estimates.

Schedule

In late summer/early fall, Lansing Pavement Marking Area develops rough contract cost estimates for all 14 contracts (7 regions, 2 contracts each) and then divides the projects into 3 lettings (February, March and April) based on roughly equal total cost per letting. Lansing then programs projects in Jobnet and sends emails to regions with information needed to start developing their contracts. Information included in these emails includes job number, miscellaneous notes, pay item unit prices, etc. Regions then begin to develop their contracts in order to prepare for reviews with Lansing. Projects are programmed 5 years out, with the fifth and furthest year being programmed annually.

Materials

Products

Pavement marking materials can be broadly classified into two categories: liquid and preformed. Liquid materials encompass any pavement marking product that is applied as a liquid, although it may be shipped in either liquid or granular form. Liquid products are sprayed, hand-applied, or extruded onto the pavement by use of a striping truck, hand roller, or hand application cart. Preformed materials are solid products that come to the site already formed to the width or shape that will be placed. They are manufactured in sections and supplied either in rolls or packaged flat.

Annual Long Line Products

Approximately 85% of MDOT's roadways are restriped each year, and this is accomplished through the use of two materials: waterborne and sprayable thermoplastic. Both of these products are considered 1-year or "maintenance" products and do not have a long life expectancy. Waterborne is a water-based paint and is the most economical product available. It is also environmentally friendly, containing no Volatile Organic Compounds (VOCs). Waterborne is a spec book material that can be applied between May 1st and October 15th when the ambient temperature is 50 degrees or higher. Standard placement is at a film thickness of 15 mils, and can be achieved via striping trucks, hand application, or hand carts. Dry time varies with temperature and humidity, but is generally only a matter of minutes. Night application is not feasible due to the moisture present. Sprayable thermoplastic is a granular material that is heated to more than 400 degrees Fahrenheit until it is liquefied and placed on the pavement. Sprayable thermoplastic is a spec book material that can be applied between April 15th and November 15th when the ambient temperature is 50 degrees or higher. Standard placement is at a film thickness of 30 mils, which results in a final thickness of 40 mils once beads are applied. Sprayable thermoplastic is two or more times the cost of waterborne, but has the advantages that it dries (cools) in less than one minute and can be placed at night. This makes it the preferred material for high traffic areas where material tracking is a concern, or where traffic restrictions force night placement. The downside is that placement can only be done with striping trucks (not by hand or cart) due to the temperature and pressure requirements to place the material.

Durable Long Line Products

A longitudinal pavement marking material is considered durable if it has an anticipated service life of 3 to 8 years (5 years is typical). MDOT utilizes both liquid and preformed durable products, primarily installing them with significant construction projects. Most common products:

- Polyurea is a plural component liquid, which means it is comprised of a base and a catalyst that are combined during application. Polyurea is the most widely used durable marking material within MDOT, and is applied at a thickness of 20 mils.

- Modified Urethane is another plural component durable liquid, and is very similar to polyurea in terms of application and performance. It will be available in the 2020 spec book.

- Wet Reflective Preformed Tape is a preformed product that provides excellent visibility in a number of scenarios, including nighttime rain events, but is significantly more costly than the other durable products. As a result, its use is typically restricted to lane lines on freeways. It will be available in the 2020 spec book.

Lesser Used Products:

- Methyl Methacrylate, or MMA, is another plural component durable liquid. It is relatively new to MDOT and while it is a highly durable and plow-resistant material, it is challenging to work with and requires specialized equipment that most contractors do not have. It can be placed in a thin spray like polyurea, extruded thick like thermoplastic, or structured in a "splatter" pattern to provide wet-night visibility. MMA is able to bond well to both asphalt and concrete surfaces. The Pavement Marking Engineer should be contacted prior to specifying this material for longitudinal markings in a project.

- Multipolymer is a new class of material being developed, and is in many ways a hybrid between thermoplastic and MMA.

- HPS-8 is a different formulation of thermoplastic which is melted from a granular state like thermoplastic and can be placed with existing thermoplastic machinery. Unlike thermoplastic is able to chemically bond to concrete surfaces and has a higher durability more similar to MMA. It is placed at a thickness of 100 mils, and may be used for either longitudinal or special markings.

- Endurablend is a cement-based pavement marking material which is sprayed down at a thickness of 60 mils. Endurablend may be tinted any color. It is used for both longitudinal and special markings.

Wet Reflective

Wet reflective refers to the ability for a pavement marking to be seen at night and in the rain, and is a difficult property to maintain. Both liquid and preformed pavement markings can be wet-reflective. Any liquid pavement marking material can be made wet-reflective through the addition of large beads or elements to the standard glass bead application. Addition of the wet reflective optics adds approximately $0.10 per foot to the material installation cost, so they are typically only used with durable pavement markings or freeway lane lines. There is some difficulty with thin-applied products holding the larger beads and elements, so it is highly recommended to recess the materials for added protection from snowplows. Preformed materials with wet reflective properties have specialized glass beads that provide the wet reflectivity embedded in the surface of the material during the manufacturing process. Preformed tape is the most commonly used of the wet reflective preformed materials, but it is significantly more expensive than liquid wet reflective products so the use is limited. The tape provides arguably better wet reflectivity in the first several years of service life, but over time the wet reflective coating of the product begins to wear out.

Shadow/Contrast

"Shadow" and "contrast" refer to two methods of helping white pavement markings stand out against light-colored pavement surfaces, such as new concrete. Shadow markings are used to emphasize lane line markings and consist of a non-reflective black "tail" marking placed on the downstream side of each skip. The black markings are readily visible in the daytime against pale pavements, but are not reflective since the white markings will show up well at night (plus black wouldn't reflect well). The standard lengths for shadow markings are 6 foot after each broken lane line skip and 2 foot after any lane drop dotted line skips. See Pavement Marking Standard PAVE-906 for additional information. Contrast markings are used to emphasize symbols and legends, and consist of either a black border around all sides of the white marking or a black box behind the marking. Contrast can also refer to lane line markings with black borders on both sides, but this application is not to be used since it cannot be maintained with current striping practices.

Special Marking Products

The same or similar materials used for longitudinal pavement markings can also be utilized for special pavement markings with the exception of sprayable thermoplastic. Most commonly used:

- Polyurea is a plural component liquid, which means it is comprised of a base and a catalyst that are combined during application. This is the same material used for durable longitudinal markings, and is still applied at a thickness of 20 mils. A hand cart is used for line-style markings, while stencils and squeegees are needed to apply arrows and legends. This material holds up well to shearing forces, but the placement time is longer than cold plastic so mobility concerns should be considered.:

- Cold Plastic is a preformed material similar to the durable wet-reflective tape, but is less expensive and does not have the wet-reflective coating. Glass beads that provide retroreflectivity are embedded in surface of material during manufacture process,and the product is supplied in rolls from the manufacturer that can be cut with a knife by hand or stamped using a die to create specific shapes. A liquid primer is typically applied before the material is placed, but cold plastic installs very quickly. The material's weakness is that it is prone to tearing and failing under shearing forces, such as vehicle turning locations.

Lesser used products:

- Thermoplastic comes in granular or pelletized form and requires heating to molten, after which it is extruded onto the pavement at thicknesses of 90 to 120 mils. Thermoplastic does very well on asphalt surfaces, but does not bond well to concrete.

- Methyl Methacrylate, or MMA, is another plural component durable liquid. It is relatively new to MDOT and while it is a highly durable and plow-resistant material, it is challenging to work with and requires specialized equipment that most contractors do not have. It can be placed in a thin spray like polyurea or extruded thick like thermoplastic. MMA is able to bond well to both asphalt and concrete surfaces.

- Preformed Thermoplastic is a preformed material that comes to the site in sheets or shapes and after being laid on the pavement is torched until molten to create the bond with pavement. The torching and cooling time results in a fairly long application time for this product, but it has some unique properties such as being able to be multicolor and in any shape. Like extruded thermoplastic this material does very well on asphalt surfaces but does not bond well to concrete, however a primer can help. This product is commonly used for accessible symbols and route shields.

Other

In addition to the standard applications of lines, arrows, and legends, pavement marking materials have other uses.

Snowmobile Crossing Protectant

Where snowmobiles are expected to cross a paved roadway surface, a protective coating is applied to the pavement. On asphalt pavements, the material used is a proprietary thermoplastic. This material is similar to the extruded thermoplastic products used for standard pavement markings, but is formulated a bit differently to tailor it to this application. On concrete pavements, two-part epoxy systems are used for the coating. For more information, see the current FUSP.

Thermoplastic Rumble Strips

Thermoplastic rumble strips are transverse, raised rumble strips placed with a proprietary thermoplastic material. This material is similar to the extruded thermoplastic products used for standard pavement markings, but is formulated a bit differently to tailor it to this application. Thermoplastic rumble strips are typically used to alert drivers of an upcoming stop on high-speed (55mph) roadways. They have an advantage over cut-in transverse rumble strips of being visible to drivers (beads are applied to the thermoplastic material) so they are not a surprise when encountered. For additional details on thermoplastic rumble strips, see the 2020 spec book.

Decorative Crosswalks

Decorative crosswalk markings are non-reflective inlaid or surface applied treatments that go between the transverse reflective white lines that mark the crosswalk. The white lines may only be omitted if the crosswalk is adequately lighted in accordance with the MMUTCD. Decorative crosswalk applications give the look of brick or stone pavers, and are limited to colors that do not cause distraction or a degradation of the contrast the white lines present, such as browns, grays, and brick reds. Such treatments can be specified via Special Provision.

Beads/Elements

Glass beads are what give pavement markings their retroreflectivity. The beads are dropped on the surface of liquid markings and are manufactured into the surface of preformed markings. The beads function by bending the light received from vehicle headlights and returning the light back to the drivers, giving pavement markings their nighttime visibility. Glass beads must conform to the requirements of Section 920 of the Standard Specifications for Construction. Larger beads or elements (multi-faceted pieces or clusters of small beads) can be used in addition to the standard beads to add wet-reflective properties to a pavement marking.

Costs

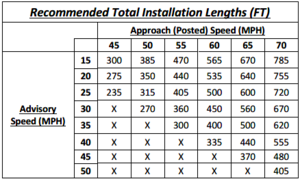

Long line costs vary depending on the quantity of material placed during the striping process. The table below demonstrates how the price of long line changes depending the quantity. During the annual contract, the quantity of material is over 100,000 feet.

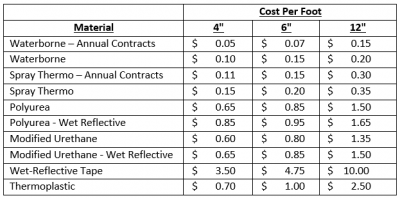

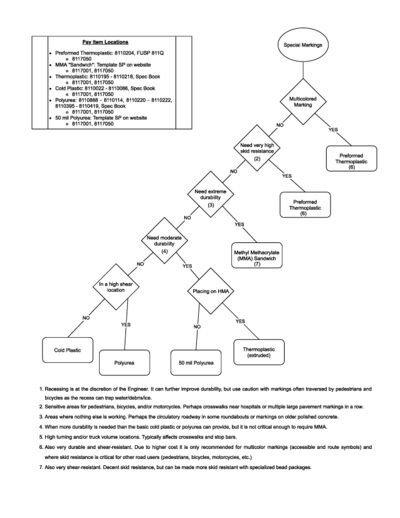

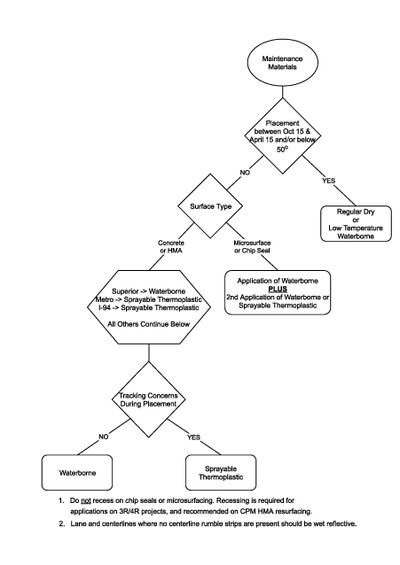

Material Selection

The guidance documents listed here contains flowcharts to assist with material selection for longitudinal lines and special pavement markings.

Recessing

Recessing consists of grooving the pavement surface and then applying permanent marking material within the groove. The optimal depth of the groove is slightly deeper than the thickness of the material. Recessing the material below the surface provides protection from snow plows and, to a certain degree, from vehicle tire wear. The groove remains in the pavement after the initial material has reached its life span and can have new material applied within it.

Longitudinal Markings

Longitudinal recessing applies to edgelines, lane lines, centerlines and gore markings only. Even though crosswalk, stop bar, crosshatch and guide lines are linear style patterns, the equipment necessary for installation differs from that used for longitudinal markings. Recessing longitudinal markings increases longevity of the material as well as helping to increase presence after the winter. Longitudinal recessing will help to increase the life of any material but will not extend the service life of waterborne and sprayable thermoplastic so far as to achieve durable status. It is strongly recommended to recess all durable longitudinal markings. A Design Advisory published in January of 2016 directs roadway designers to include longitudinal recessing on all 3R/4R construction projects with some exceptions, regardless of marking material.

Special Markings

Special marking recessing applies to crosswalks, stop bars, crosshatching, symbols and legends and is done under the transverse recessing pay item. Recessing of special markings helps to address durability concerns including in high turning traffic areas. Be selective as to the installation of recessed special markings as there are concerns that come with its placement. The recess can trap water, ice, and debris which can be problematic for pedestrians, bicycles and motorcycles.

Guide Lines

It is highly recommended to recess guide lines (known as lane line extensions in the MMUTCD) regardless of the material they are constructed out of. There are a couple of reasons for this. Vehicles using the line as a guide for turning cause a shearing motion on the material, and vehicles traveling through the intersection cross over both the turning and thru guide lines. Also, the line is constructed out of relatively small sections of material, making them less durable. Additional information is available in PAVE-907 and the 2020 spec book, with standard pay items available for this work.

Plan Development

Pavement markings, both permanent and temporary, are included in most trunkline projects. The inclusion of pavement markings on the remaining projects will be determined by the Region/TSC. The only type of project not required to include pavement markings (either by contract or by work order) are projects where the existing markings are not altered or obliterated.

MDOT Road Design Manual, Section 7.04.01

Marking Design Formats

Witness, Log

When the roadway will not be geometrically or functionally altered by construction (no addition or removal of turn lanes, no change in passing and no passing zones, no addition or removal of signals, etc.) and the markings should be returned to their pre-construction configuration, marking layout an be addressed through the use of the pay item for Witness, Log (WL). Use of WL requires the Contractor to witness and log any existing pavement markings prior to the markings or pavement being removed. The Engineer should have the opportunity to review the pavement marking layout prior to placement and make any necessary changes, however if changes are anticipated plan sheets should be included in the project documents.

MDOT Road Design Manual, Section 7.04.06

Plans

Standards (Layout by MDOT)

While the applicable pavement marking standard plans should be listed in all contracts with markings, use of solely the standards for pavement marking establishment is only acceptable in a few situations. The standards do not address lane and shoulder widths, turn lane storage lengths, precise stop bar setbacks, and many other variables needed for marking layout, so virtually all projects should include either plan sheets or Witness, Log, Layout. Some of the exceptions to this where referencing the standards would be sufficient are bridge-specific projects (deck and/or approach work) and pavement patching projects, where the Contractor is only being asked to reconnect lines that they can see both ends of.

MDOT Road Design Manual, Section 7.04.06

Plan Formatting

Pavement marking plans show the details of the permanent markings for lane lines, edge lines, and special markings such as: stop bars, directional arrows, turning guide lines, and cross hatching. Pavement marking plans are prepared at a suitable scale that will show individual longitudinal lines and special markings. All markings shall be drawn representative of their patterns and shapes. There must also be a clear differentiation between existing and proposed markings through line styles and/or labeling.

A callout should be shown for each noncontinuous section of a longitudinal line. Callouts for longitudinal lines consist of the following format: PAVT MRKG, [material], [width], [color] [pattern], [cycle]

Patterns include: solid, double solid, broken, solid and broken, and dotted. Cycle is indicated for broken, solid and broken, and dotted lines in the form: [length]' mark, [length]' gap

Callouts for special markings are shown in the following format: PAVT MRKG, [material], [pay item name or similar description]

When a special marking type appears on the same plan sheet multiple times, it is acceptable to label a single instance of each type and add "(TYP)" at the end of the callout rather than label each instance separately. Recessing of longitudinal lines or special markings must be indicated in the callouts or via a general note on each plan sheet. Quantities are to be shown per plan sheet. If there are no pavement marking plan sheets or the plan sheets do not cover all markings, such as when using Witness, Log, place the quantities not associated with a pavement marking plan sheet on the Miscellaneous Quantities plan sheet under the heading "Permanent Pavement Markings".

MDOT Road Design Manual, Section 1.02.18

Commonly Missed Items

- Removal of Cure Compound: The use of curing compound with new concrete creates a surface that pavement markings, temporary or permanent, will not adhere to. Ensure that pay item quantities are included for removal of curing compound for any markings placed on new concrete, unless the markings will be recessed as this removes the affected pavement surface.

- Correct Delineator Pay Items: The pay item for "Delineator, Reflective Sheeting, [size], [color]" is a piece of retroreflective sheeting material that is applied to a flexible delineator post; pay item "Post, Flexible, Delineator". The pay items "Delineator Reflector" are installed on rigid delineator posts; pay item "Post, Delineator".

- Special Emphasis Style Crosswalks: Special emphasis, or "continental" style crosswalks should be used anytime a crosswalk intersects a free flow movement of traffic. This could include designated midblock crossings, free flow freeway entrance/exit ramps, entrances and exits to a roundabout. More information on midblock crosswalks can be found in this section

- Left Turn Roundabout Arrows: Use fishhook style roundabout arrows for all approach arrows showing a left turn movement. Standard arrows are used for all other movements. Standard left turn lane use arrows are used inside the circulatory portion of the roundabout.

- Replace Delineators: Include pay items for new delineators for all 3R/4R road construction projects on divided highways and freeways and anytime guardrail is replaced. Consider inclusion of these items on divided highway and freeway CPM projects depending on the condition of existing devices and the pavement remaining service life.

Construction

Information regarding construction can be found in the appropriate sections of the MDOT Wiki Construction Manual:

Retroreflectivity

Retroreflectivity is the measure of the visibility of pavement markings at night when lit up by headlights. The light is reflected back by glass beads and elements embedded in the marking. The standard unit of retroreflectivity is millicandela / Meter^2/ Lux (mcd/m^2/lux).

Annual Contracts

Retroreflectivity readings are taken each spring to determine how well the pavement markings are performing after winter. Readings are taken on approximately 20% of the pavement markings that were placed with the annual marking contracts in the previous year, plus on any existing durable pavement markings that the Regions would like information for. Annually there is one retroreflectivity contract per Region, with readings taken from April through June and final reports due to MDOT in July. At this time the reports are for information only, but the provided data is useful for MDOT engineers to identify when durable markings have reached the end of their lifespan and should be restriped with an annual product.

Requirements

In the past, retroreflectivity readings were used in conjunction with the annual pavement marking contracts as part of an incentive/disincentive program for the paint contractors. The incentive/disincentive program for striping is no longer in effect and as MDOT does not have any retroreflectivity requirements for aged markings, the retroreflectivity readings taken are for information only at this time. It is anticipated that FHWA will be publishing minimum retroreflectivity values in the future, at which time the retroreflectivity readings will be a necessity to ensure compliance. Regarding the upcoming minimum values, the most current information can be found here.

Delineators

Delineators are retroreflective guidance devices that include roadside (post-mounted), guardrail, and concrete barrier applications. Delineators can be important in supplementing pavement markings as they remain visible when the markings may not, such as when the roadway is wet or covered by snow. Standard delineator applications are addressed in Standard Plan Series R-127, R-60, and R-54.

Application

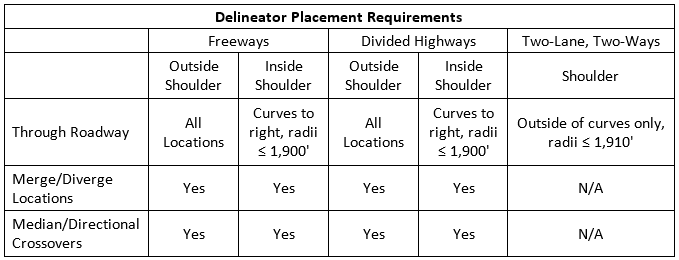

Post-mounted roadside delineators are required in numerous scenarios, which are predominately outlined in the table above. Post-mounted delineators are also required for guardrail installations, weigh stations. Roadside drainage structures (catch basins), and at curbed sections/intersections along 2-lane, 2-way roadways.

Standard guardrail and concrete barrier reflectors are attached directly to the guardrail or barrier and are placed along the length of the run. Where delineation above the standard reflectors is desired due to geometry or crash history, additional products can be specified through Special Provision to provide enhanced visibility.

Materials

Post-mounted delineators may be either rigid or flexible installations. Rigid installations consist of a reflective element bolted to a ground-driven steel U-channel post. In the past round plastic "button" reflectors were used for such installations, but MDOT has moved to using rectangular reflectors that are in essence miniature signs (sign sheeting on aluminum panels). Flexible installations consist of reflective sheeting applied to a ground-driven flexible post, often a plastic or fiberglass, which is selected from the Qualified Products List.

Standard guardrail and concrete barrier reflectors are fairly generic items and must conform to the requirements defined in the spec book. Enhanced delineation products are typically proprietary products or systems. Several competitive options are included in each Special Provision for a given installation type.

Continuous Line Delineation