Chapter 4 -Drainage

Supplement to Chapter 4

Sections in MDOT Drainage Manual

The following list includes sections moved from the Road Design Manual to sections within the MDOT Drainage Manual. Some topics listed, remain in the Road Design Manual but are supplemented by discussions in the MDOT Drainage Manual.

| TOPIC | LOCATION IN MDOT DRAINAGE MANUAL |

|---|---|

| Chapter 2 – Legal Policy and Procedures | |

| Glossary | Glossary |

| General Procedures | Section 2.5.1 |

| Legal Precedent to Discharge Surface Water | Section 2.5.2 |

| Types of Right of Way Easements or Conveyance for Drainage | Section 2.5.3 |

| Drainage Considerations | Section 2.5.4 |

|

Section 2.5.4.1 |

|

Section 2.5.4.2 |

|

Section 2.5.5 |

|

Section 2.5.6 |

|

Section 2.5.7 |

|

Section 2.5.8 |

| Chapter 7 – Road Storm Drainage Systems | |

| General | Sections 7.1, 7.3.9, and 7.4.8.3 |

|

|

|

Section 7.4.1 |

|

Section 7.4.2 |

|

Section 7.4.8.4 |

|

Sections 7.2, 7.4.9.1, and 7.4.8.4 |

|

Sections 7.4.9.7, 3.4.3, 3.4.1.4, and Table 3-1 |

| Rainfall-Frequency Zones | Appendix 3-B |

| Rainfall-Intensity-Duration Tables | Appendix 3-B |

| Solving Manning’s Formula | Section 7.4.8.2 and Table 7-5 |

| Design Factors for Storm Sewers | Section 7.3.2 |

| Steps in the Design of Storm Sewers using Rational Method | Sections 7.4.9.7 and 7.4.8.2 |

|

Table 7-9 |

|

Section 7.4.8.2 |

| Factors in Locating Catch Basins or Inlets | Section 7.4.5 |

| Factors in Locating Manholes | Section 7.4.7.1 |

| Numbering Drainage Structures | Section 7.4.7.3 |

| Access Manholes to Storm Sewers | Section 7.4.7.2 |

|

Section 7.4.7.2 |

|

Section 7.4.7.3 |

|

Section 7.4.7.3 |

| Storm Sewer Pipe Classification and Usage Guidelines | Section 7.4.8.1 |

| Jacked-in-Place Sewers | Section 7.4.8.1 |

| Storm Sewer Soil Borings | Section 7.4.8.1 |

| Storm Sewer Pipe-Curved | Section 7.4.8.5 |

| Chapter 2 – Legal Policy and Procedures Chapter 8 – | |

| Acceptable Drainage Outlets | Sections 8.1.1 and 2.2.1 |

| Unacceptable Drainage Outlets | Section 8.1.1 |

| Retention/Detention Systems | Section 8.3.1 |

| Design Guidelines to Reduce Impacts of Nonpoint Source Pollution on Receiving Waters | Sections 8.3.2 and 9.3.3 |

|

Section 8.4.1 |

|

Section 8.4.4 |

| Storm Water Runoff Detention Basin Design Guides | Section 8.4.1 |

|

Section 8.4.1.1 |

|

Section 8.4.3 |

| Chapter 4 – Natural Channels and Roadside Ditches | |

| Roadway Drainage Ditches | Sections 4.4.3.2.1 and 4.4.3.2.3 |

| Standard Ditches | Section 4.4.3.2.2 |

|

Section 4.4.3.2.2 |

|

Section 4.4.3.2.2 |

|

Section 4.4.3.2.2 |

|

Section 4.4.3.2.2 |

|

Section 4.4.3.2.2 |

| Chapter 3 – Hydrology Chapter 5 – Culverts | |

| MDOT and FHWA Requirements | Section 5.3.2 |

| Roadway Culvert Size Determination | Sections 5.3.3 and 5.3.4 |

| Culvert Pipe Class Designations | Section 5.3.2.1 |

| Culvert Usage Guidelines | Section 5.3.2.2 |

| Permit Requirements for Roadway Culverts | Section 5.3.3 |

|

Section 5.3.4 |

|

Section 5.3.4 |

| Determining Culvert Sizes | Section 5.3.4 |

| Estimating Peak Flows for Culverts | Section 5.3.4 |

|

Section 3.4.4 and Appendix 3C |

|

Section 3.4.1 |

| Hydraulic Analysis Data and Soil Borings on Plans | Appendix 6-B |

| Culvert Extensions and Replacements | Section 5.3.6 |

|

Section 5.3.4 |

|

Section 5.3.6 |

|

Section 5.3.6 |

| Bedding and Filling Around Pipe Culverts | Section 5.3.7 |

| Corrugated Structural Plate Pipe and Pipe Arches | Section 5.3.4 |

| End Treatment for Culverts | Section 5.3.5 |

|

Section 5.3.5.1 |

|

Section 5.3.5 and Table 5-1 |

| C.S.P. to Concrete Culvert Adapter | Section 5.3.6 |

| Outlet Headwalls | Section 5.3.5.1 |

| Downspout Headers | Section 5.3.5.1 |

| Concrete Slab Culverts | Section 5.3.5.2 |

| Lining of Culverts | Section 5.5.3 |

4.01 GENERAL INFORMATION

4.01.01 References

- Computing Flood Discharges for Small Ungaged Watersheds, MDEQ, (rev. 2008)

- Concrete Pipe Design Manual, American Concrete Pipe Association, (June 2000)

- Concrete Pipe Handbook, American Concrete Pipe Association, (January 1988)

- Hydrology, Section 4, National Engineering Handbook, Soil Conservation Service

- MDOT Drainage Manual, Current Edition

4.01.03 General Procedures

See Drainage Manual Section 2.5.1.

At the time the line and grade of new roadways or the extent and limits of a widening or reconstruction project are determined, a careful engineering study and design must be made concurrently for surface and subsurface drainage. Highway drainage design involves two basic operations: estimating peak flows of runoff and designing a conveyance system.

Detailed hydrologic and hydraulic design guidelines are presented in the MDOT Drainage Manual. For specific information contact the Design Engineer - Hydraulics.

4.02 STORM SEWER DESIGN

4.02.15 Sewer Bulkheads

Only sewer bulkheads larger than 12" in diameter will be measured for payment. The cost of placing sewer bulkheads 12" in diameter and less will not be paid for separately but payment for the work will be considered as having been included in the contract unit prices bid for other contract items. The sewer bulkhead location should be shown on the plans

4.02.18 Storm Sewer Under Structures

Storm sewers within the stress influence of the footings shall be protected by concrete encasement or other approved methods. If the designer has any question about which the stress influence lines in a particular structure, he should contact the Geotechnical Services Unit of Construction Field Services Division.

4.02.20 Jacked-in-Place Sewers

See Drainage Manual Section 7.4.8.1.

At times it may be necessary to install sewer pipe by jacking or tunnel¬ing methods. A sewer installed by jacking or tunneling may be considered a special design, therefore a request to determine the design of the pipe should be made to the Design Engineer - Municipal Utilities. However, some general jacking information for designers is listed below.

- The smallest practical pipe size that can be jacked is 36" in diame¬ter. However, a smaller size pipe may be inserted inside a jacked casing and the void outside the sewer filled with a flowable fill.

- Concrete pipe is to be specified when jacking a storm sewer.

- If circumstances require jacking a pipe smaller than 36", a C76 Wall Class 5 pipe shall be specified.

- Jacking a storm sewer will normally be more economical than an open trench installation when either the fill height exceeds approximately 16' or maintaining traffic is beneficial. The situation should be reviewed at The Plan Review Meeting and a recommendation provided to the designer.

- Jacking will usually continue on a 24-hour-per-day operation due to the pipe's tendency to set up if the jacking operation is inter¬rupted for more than a few hours

- Jacking is usually done from the low side up grade to allow water to drain out during the jacking operation. However, it may also be done by jacking down grade, which allows for better control of the pipe grade due to the weight of the pipe.

- Pipe that is being jacked is subjected to vertical loads from the weight of earth and horizontal loads from the jacking pressure. The resultant vertical earth load on a horizontal plane at the top of the bore is a function of the weight of earth above the bore minus the upward friction forces, minus the cohesion of the soil along the limits of the prism above the bore.

- The vertical load from the weight of earth and possible live load will determine the class of pipe to be specified.

- The cross-sectional area of the concrete pipe is adequate to resist axial compression from jacking, and unless unusual circumstances exist, little or no gain is accomplished in increasing crushing resistance by specifying a higher class of concrete pipe than required for vertical loads.

- Soil borings are required when storm or culvert pipe is installed by jacking or tunneling. Contact, coordination, and follow up with the Region/TSC Soils Engineer as described in the following section is important in reducing potential risks to the operation.

4.02.21 Storm Sewer Soil Borings

The plans and specifications do not automatically provide for the additional work required to install sewers through areas of unstable soils. Therefore, soil borings must be obtained and shown on the plans to identify where remedial treatment is necessary. Corrective treatment usually means undercutting and backfilling. Also, in areas having a high water table, a well point system may sometimes be considered. The designer should use the following procedures.

- The need for soil borings should be discussed at the scope verification meeting. The Project Manager should provide the Region/TSC Soils Engineer with any necessary information for locating proposed sewer lines. The Region/TSC Soils Engineer will then provide the Project Manager with pertinent soils data and recommendations.

- Follow up requests to be sure soil borings are received. The complete boring data shall be made part of the plans and proposal. The data report will include the log of borings, the complete shear report, the weight and moisture report, as well as a plot of the shear strength. The report by the Geotechnical Services Unit, Construction Field Services Division can be reproduced on a plan sheet.

- When unstable soils are encountered, the Designer and the Geotechnical Services Unit, Construction Field Service Division engineers should confer to determine the best method of correction.

- Estimated quantities for the correction should be included in the plans.

- Where unstable soil conditions, or obstructions other than rock, require excavation of the sewer trench below the elevation shown on the plans, such excavation shall be made to the dimensions authorized by the Engineer. The pay item "Trench Undercut and Backfill" is used to pay for this excavating and backfilling of the trench with a specified aggregate up to the bottom of the trench elevation on the plans. Many jobs will include short runs of relatively shallow depth sewers where undercutting is unnecessary, therefore, the designer will have to make some judgement when requesting soil borings.

4.02.22 Storm Sewer Pipe - Curved

See Drainage Manual Section 7.4.8.5.

Curved pipe, if necessary, needs to be reviewed and approved by the Design Engineer - Municipal Utilities.

4.03 DRAINAGE OUTLETS

4.03.04 Design Guidelines to Reduce Impacts of Nonpoint Source Pollution on Receiving Waters

See Drainage Manual Sections 8.3.2 and 9.3.3.

Recent legislation and regulatory policies has necessitated that MDOT reevaluate the design practices used to control the pollutants contained in stormwater runoff from state highways. MDEQ, EPA, or FHWA may require the inclusion of stormwater runoff control measures as a precondition for obtaining state and federal environmental clearance. Environmental regulations have increased emphasis on water quality and nonpoint source pollution. Stormwater Best Management Practices (BMP) will be greatly expanded and required on future projects. For example, as part of the National Pollutant Discharge Elimination System (NPDES) Permit applications required from the Water Quality Act of 1988, it will be necessary to provide locations of soil erosion control measures on the design plans (see MDOT Soil Erosion and Sedimentation Control Manual). The design engineers and region personnel must provide copies of the plans with site specific control measures along with other NPDES construction permit application information to the Geotechnical Services Unit, Construction Field Services Division. Please reference Sections 2.05 and 10.04.04B.

The following general guidelines for controlling the pollution contained in stormwater runoff are applicable to virtually all highway situations. There are a number of low-cost drainage design principles and practices that have significant potential for reducing pollutant loads from highway stormwater runoff. These relatively low-cost principles and practices can be incorporated into existing highway design procedures. They are intended to be used wherever practicable and without the necessity of identifying a specific highway runoff contaminant problem. The principal concepts that should be considered when designing highway systems include:

- Reduce direct discharges - Eliminate direct discharges of highway stormwater runoff to receiving waters (including groundwater) wherever practicable. Highway stormwater runoff should be routed through one or a combination of effective stormwater management measures including: vegetation, detention, infiltration, or wetland systems prior to discharge to receiving waters.

- When possible, drains along bridge decks over open water should be eliminated.

- Reduce runoff velocity - Reducing the runoff velocity to a non-erosive level decreases the transport of sediment and encourages sedimentation, especially bedload. The bedload contains larger soil particles that slide, roll or bounce along the channel bottom. The methods for reducing the runoff velocity include reducing gradients, installing velocity reduction devices (such as: check dams, drop structures, baffles, sediment basins and diversions), and by using vegetative controls (grassed waterways, overland sheet flow etc.).

Typically, the sediment pollutant load is transported along the pavement, curbs, and shoulders, as suspended solids or absorbed in suspended solids in stormwater runoff. Therefore, pollutant reduction measures are usually intended to reduce the volume of particulates available for transport by runoff or to filter and settle out suspended solids.

4.03.04A Vegetative Controls

Vegetative controls that include grassed channels, vegetated waterways, filter strips, and overland flow, work by reducing the velocity of the surface flow or channel flow allowing sediment and suspended solids to settle out. Since many of the sediments contain absorbed pollutants, these pollutants in the runoff may be reduced substantially prior to entering adjacent waterways, if the velocity of runoff is slowed over an adequate length of vegetation. These systems also take advantage of soil absorption capabilities.

Vegetated controls can be applied wherever suitable land area is available. Vegetative controls are adaptable to a variety of site conditions, are flexible in design and layout, and are the least costly management procedure. Vegetative controls can be used as sole management measures or in conjunction with secondary measures (detention basins, infiltration systems).

Drainage design should include provisions for maximum use of vegetative controls. A length of approximately 200' has been shown to be very effective in pollutant removal; however, any length is helpful. Pollutant removal using vegetative control is consistently high, particularly for suspended solids and heavy metals. The vegetation acts to reduce runoff velocity, enhancing sedimentation and filtration of suspended solids, increasing infiltration, and allowing a greater opportunity for absorption and uptake by plants.

4.03.04B Detention Basins

See Drainage Manual Sections 8.4.1 and 8.4.3.

Detention basins are those basins without a permanent pool to receive runoff inflow and a positive outflow structure. Settling of suspended materials is the primary pollutant removal action, although some biological removal of nutrients also occurs. The concept of temporarily storing stormwater runoff is a fundamental approach to stormwater management and may be used to achieve both flood control and pollutant reduction benefits.

Detention basins can be utilized in areas:

- where suitable depressions occur or can be constructed, and where acceptable inflow and outflow conditions can be achieved. Also from a cost standpoint, the basin should be placed where the least amount of earth moving is required and still obtain the necessary basin volume;

- where soils are able to provide a stable embankment;

- where storage and the required surface area of detention basins for pollution abatement area are adequate to retain the runoff from a specified storm event (i.e., 10 year, 25 year, etc.) of the contributing drainage area.

Potentially, detention basins can be highly effective in pollutant removal. Differences in basin performance are attributed to the size of the basin relative to the connected drainage area and local storm characteristics. Results of Nationwide Urban Runoff Program (NURP, EPA 1982) research indicated that biological processes in the permanent pool produced significant reductions in soluble nutrients, in addition to the physical settling of particles. See Drainage Manual Section 8.4.1.

4.03.04C Infiltration Systems

See Drainage Manual Section 8.4.4.

Infiltration systems are a method in which surface runoff is temporarily contained and allowed to infiltrate or percolate in the soil, utilizing the sediment layers as a mechanism to filter out pollutants. Infiltration systems involve systems which infiltrate runoff after it has been collected (infiltration basins, drainage wells, deep infiltration wells, shallow infiltration wells, shallow infiltration pits and trenches).

Infiltration systems can easily be adapted to fit the requirements of highway, railroad, and airport systems, i.e., shaped into deep-sided linear basins, constructed in borrow areas, or linked in a series of small basins. Infiltration systems are primarily applied in cases in which right-of-way is a limiting factor, and where the soil is relatively permeable and the groundwater table is not too close to the point of discharge.

Little data are available concerning pollutant removal efficiencies of infiltration systems. Theoretically, since there is no outflow unless the storage capacity is exceeded, pollutant removal efficiencies, in terms of stormwater runoff approaches 100 percent. True pollutant removal efficiencies however, depend on specific requirements. Designers must consider the following:

- soil/subsoils that are moderately to highly permeable. A percolation test and/or gradation may be needed. Contact the Region/TSC Soils Engineer for assistance.

- groundwater table is approximately 5' below the bottom of the storage area. The location of the ground water table may be provided by the Region/TSC Soils Engineer.

- runoff inflow is relatively free of suspended solids. Designers can use either a two cell system or a vegetated ditch with a minimum length of 200'.

- there is sufficient storage for the runoff during infiltration period (see Design Engineer - Hydraulics).

4.03.04D Wetland Treatments

Wetlands systems, man-made or natural, can be used as a runoff pollutant-removal mechanism through sediment retention and vegetation uptake. Due to the variation in highway quality and each wetland's ability to withstand impacts, treatment capacity and effectiveness is best evaluated on a site-by-site basis and coordinated with the Project Planning Division.

Overall pollutant removal effectiveness is dependent on type of wetland, geographic location, climate, and hydrologic parameters. However, the literature indicates wetlands can provide a highly effective management measure and studies have shown that removal of nutrients, moderate amounts of suspended solids, Biochemical Oxygen Demand (BOD), and heavy metals were consistently high. These systems are limited, in that heavy amounts of sediments in the runoff water can adversely affect detention and pollution removal characteristics, and therefore wetland systems are not recommended solely for soil erosion and sedimentation control practices.

4.05 DESIGN CRITERIA FOR ROADWAY CULVERTS

4.05.02 Culvert Pay Lengths

Concrete pipe 24" diameter and above is available in commercial lengths of 8'. When installing new culverts or extending existing culverts, the length quantities should be based on available commercial lengths.

4.05.08 Estimating Peak Flows for Culverts

The hydrologic analysis required for culverts can use either the method described in the Michigan Department of Environmental Quality paper entitled Computing Flood Discharges For Small Ungaged Watersheds, (Drainage Manual Appendix 3-C) referred to as the MDEQ SCS Method, or the Rational Method. All cross culverts must be designed for the 50-year flow and checked against the 100-year flood flow.

4.05.08A MDEQ’s Soil Conservation Service (SCS) Method

Reference Drainage Manual Section 3.4.4 and Appendix 3-C.

The MDEQ SCS Method is based on Section 4, Hydrology, from the SCS National Engineering Handbook. It is an acceptable method to be used for drainage areas of less than 20 square miles. Assistance on determining estimated peak flows can be obtained from the Design Engineer - Hydraulics.

4.05.08B The Rational Method for Estimating Peak Flows for Culverts

Reference Drainage Manual Section 3.4.1 and Table 3-1.

If the area is less than 20 acres and the flow to the culvert crossing is low or inter¬mittent, the more simplified Rational Method may be used for design.

4.05.10 Hydraulic Analysis Data and Soil Borings on Plans

See Drainage Manual Appendix 6-B.

If either the size or location of the culvert are changed, the Road Design Unit must obtain new approval from the Design Engineer - Hydraulics. A plan sheet should be included in all projects showing the project drainage (see Section 1.02.03). All drainage structures should be accompanied by a tabulation of drainage data shown on the Drainage Map. For drain¬age areas equal to or greater than two square miles, or design discharge in excess of 500 cfs, the tabular form illustrated below is required and can be obtained from the Design Engineer – Hydraulics. For all other culverts, the tabulation must include the design flood frequency discharge and the drainage area.

Soil borings must be requested from the Geotechnical Services Unit for any new or extended culverts that have the following sizes or equivalent area:

- Pipe culverts equal to or greater than 60†diameter

- Box and slab culverts equal to or greater than 4’ x 4’

For culverts smaller than these sizes, the soil borings must be requested from the Region/TSC Soils and Materials Engineer (see Section 14.25). All soil borings and related information must be shown on the plans.

SAMPLE TABULATION FOR DRAINAGE AREAS ≥ 2 square miles OR DISCHARGE > 500 cfs

| SUMMARY OF HYDRAULIC ANALYSIS | |||||||

|---|---|---|---|---|---|---|---|

| EXISTING CONDITION | PROPOSED CONDITION | ||||||

| FLOOD DATA | DISCHARGE (cfs) |

WATER SURFACE ELEV. AT U/S FACE OF STRUCTURE (ft) |

VELOCITY AT D/S FACE (fps) |

WATER SURFACE ELEV. AT U/S FACE OF STRUCTURE (ft) |

VELOCITY AT D/S FACE (fps) |

EWATERWAY AREA (ft2) AT D/S FACE |

CHANGE IN WATER SURFACE ELEV ___ feet U/S OF PROPOSED STRUCTURE (ft) |

| 50-YEAR | |||||||

| 100-YEAR | |||||||

| 500-YEAR | |||||||

- NOTES:

- The drainage area contributory to this crossing is _______square miles.

- The water surface and/or energy grade elevations shown on the above hydraulic table are to be used for comparison purposes only and are not to be used for establishing a regulatory floodplain. The elevations may be used provided they are verified with the Land and Water Management Division, Michigan Department of Environmental Quality.

4.05.12 Bedding and Filling Around Pipe Culverts

Reference Drainage Manual Section 5.3.7.

The bedding and filling around pipe culverts is done according to Standard Plan R-82-Series upon which the Culvert Class-Depth-Usage Table is based. This type of installation is referred to as a “Positive Projecting Embankment Conduit†for a concrete pipe. The following information describes other types of installations for concrete pipe. However, when special designs or installations are required, a design request should be made to the Bridge Design Section.

4.05.12A Trench Installation

When the culvert pipe is placed in a narrow trench and covered with earth, the backfill will tend to settle downward. This downward movement or tendency for movement of the backfill within the trench above the conduit is retarded by frictional forces along the sides of the trench that act upward and help support the backfill. As this type of installation applies normally to a sewer-type installation and our standard plans and specifications do not restrict the trench width for a culvert, this type of installation is not normally considered in design.

4.05.12B Positive Projecting Conduits

Positive projecting pipes are installed in shallow bedding with the top of the conduit projecting above the surface of the natural ground or compacted fill at the time of installation and then covered with earth fill. Culverts placed in wide trenches also are included with this classification. This classification is the basis for our Standard Plan R-82-Series.

4.05.12C Negative Projecting Embankment Conduit

Negative projecting embankment culvert pipes are installed in relatively shallow trenches of such depth that the top of the pipe is below the level of the natural ground surface or compacted fill at the time of installation and then covered by earth fill, the height of fill being greater than the depth of trench. As with a trench installation, the load on the pipe is reduced by frictional forces along the sides of the trench. This may reduce the ASTM class of concrete pipe required; however, a request to Bridge Design for a design will be required before reducing pipe class.

4.05.12D Induced Trench Conduit

The induced or imperfect trench installation is used when it is necessary to relieve or reduce the load on a concrete pipe under a high fill. The culvert is initially installed as a positive projecting pipe. When the embankment fill has been placed to an elevation of two to three times the diameter of the culvert above natural ground, a trench is excavated over the culvert and backfilled with compressible material simulating a negative projecting installation. As this is a special design, the design and details for this type of construction are to be requested from Bridge Design.

4.05.19 Precast Concrete Box Culverts

Precast box culverts are available in numerous sizes state-wide. The designer should contact a local supplier to verify that a particular size is available. The supplier, in some instances, may be willing to furnish a larger size if his available forms do not match the required size. Precast box culverts offer the advantage of rapid installation and are competitively priced with cast-in-place box culverts for new construction or culvert extensions.

Precast concrete box culverts are called for by size, as specified in the Standard Specifications for Construction. It should be noted on the plans that the box culvert shall meet the specified ASTM requirements for HS25 loading. If the culvert is located under a railroad crossing, consult the Design Engineer – Municipal Utilities. When the culvert requires headwalls, details must be obtained from the Design Engineer – Municipal Utilities.

When extending box culverts, adhesive anchored bolts shall be used to tie the new construction to the existing.

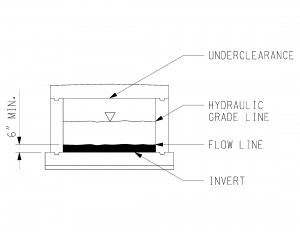

The invert of a box culvert is to be set 6†below the normal flow line. This elevation is to be referred to as the invert elevation on the details to avoid confusion with the flow line of the waterway that appears on the profile.

4.05.20 Lining Culverts

Reference Drainage Manual Section 5.5.3.

When a culvert has structural deterioration, it may be possible to line the culvert instead of replacing it. Caution must be used by the designer and a hydraulic analysis should be done to determine the potential hydraulic impacts of inserting the liner. The analysis should cover the range of flows passed by the culvert.

Lining may be in the form of inserting plastic pipe and grouting the annulus or insertion of a resin-impregnated flexible liner. Installation is covered by appropriate Special Provision, e.g. “In Place Culvert Rehabilitation, Liner.†The installation of a liner may be allowed for the following conditions:

- The culvert is a cross culvert that acts as an equalizer between two bodies of water (e.g. between two wetlands).

- A driveway culvert that is only carrying ditch flow generated from MDOT ROW. For the range of design flows, the water surface elevation upstream of the culvert is contained within the ROW.

- The culvert is a CMP that will not experience inlet control over the range of design flows.

Any questions regarding the hydraulic analysis or potential impacts should be directed to the Design Engineer – Hydraulics.

4.05.21 Drainage Marker Posts

Drainage marker posts are installed to help maintenance personnel locate end sections or headwalls of transverse culverts 36†diameter or less and on all underdrain outlet endings. Drainage marker posts are to be placed outside the shoulder hinge lines and should not be used in medians except on spread roadways. Drainage marker posts shall be at least 6’ long and shall conform to the delineator or steel line posts that are specified in the current standard specifications.

4.06 UNDERDRAINS

4.06.01 Purpose of Underdrains

Current methods of installing underdrains are shown on Standard Plan R-80-Series. In order to protect a roadway surface from early deterioration, a stable base must be built for the roadway. Water in subbase materials weakens the foundation soils, therefore a good roadway requires good drainage. Underdrains intercept and remove seepage from the subbase, eliminating springy or bad subsoil conditions. Underdrains are used on both enclosed and daylighted drainage systems.

The various underdrains either capture and drain the water trapped below the pavement surface or intercept seepage water before it enters the space below the pavement and then convey the seepage to either an outlet ditch or a storm sewer system.

4.06.02 Bank Underdrains

Bank underdrains are sometimes placed in the back slopes to intercept seepage planes before they reach the roadway to minimize erosion or sloughing. Two basic methods of installing bank underdrains are shown on the standard plan. One method backfills the trench with a granular material and wraps the underdrain pipe with a geotextile. The other method envelopes both the open-graded material and the underdrain pipe by lining the trench with a geotextile.

4.06.03 Subgrade and Subbase Underdrains

Subgrade underdrains are meant to drain both the subbase and subgrade under the pavement. Currently, two methods of constructing subgrade underdrains are shown on the standard plan. One method lines the trench with a geotextile that envelopes both the open-graded material and the underdrain pipe. The other method uses granular material and wraps the underdrain pipe with a geotextile.

The subbase underdrain is meant to drain only the subbase. The flow line of the underdrain is normally a maximum of 10†below the top of the subgrade. The underdrain pipe is wrapped with a geotextile.

4.06.04 Open-Graded Underdrains

Four methods of installing open-graded underdrains are shown on the standard plan. All four have an open-graded material immediately below the pavement surfacing. Their purpose is to drain quickly any water that enters through joints or cracks in the pavement and to minimize the amount of water entering the subbase material. Two of the methods use underdrain pipe and two use the Prefabricated Drainage System (PDS).

4.06.05 Underdrain Outlets & Outlet Endings

Underdrain outlets are used to connect underdrains to the outlet endings. To resist crushing from heavy construction and maintenance vehicles and to insure positive flow, rigid PVC or corrugated steel pipe shall be used for underdrain outlets.

Currently three approved outlet endings are shown on Standard Plan R-80-Series. Other designs may be used when approved by the Engineer.

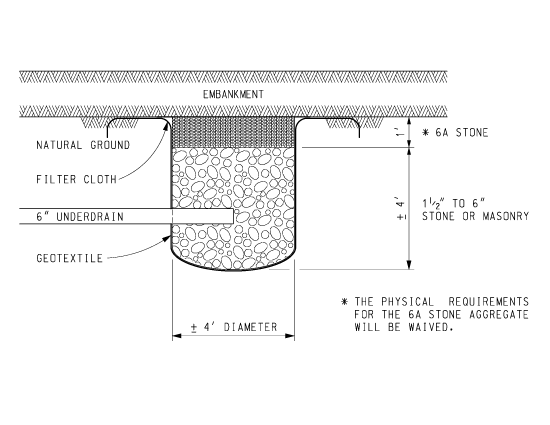

4.06.06 Stone Baskets

Stone baskets are used to drain springs that occur below the roadway. The stone basket is constructed by making an excavation at the spring head 4’ in diameter and approximately 5’ below the bottom of embankment. A geotextile shall be placed in the excavated hole and backfilled with 1½†to 6†stone or masonry, and a 1’ thick layer of 6A stone. A 6†diameter underdrain is used to dissipate water from the stone basket. The location of the stone basket should be shown on the typical cross section and the following sketch detailed in the construction plans.