Difference between revisions of "707 - Structural Steel"

| (74 intermediate revisions by 5 users not shown) | |||

| Line 4: | Line 4: | ||

<center><span STYLE="font: 40pt arial;">'''Structural Steel Construction'''</span></center> | <center><span STYLE="font: 40pt arial;">'''Structural Steel Construction'''</span></center> | ||

| − | |||

| − | ==[[#GENERAL|GENERAL]]== | + | ==[[#GENERAL DESCRIPTION|'''GENERAL DESCRIPTION''']]== |

| − | |||

| − | + | ===General Overview=== | |

| − | + | Structural steel construction involves the fabrication, handling, erection, bolting and welding of steel members used in structural applications. Most structural steel for Department projects is comprised of bridge elements – plate girders and rolled beams, intermediate and end diaphragms, connection plates and stiffeners, cover plates, beam bearings, pin and hanger assemblies and foundation piling. All these elements can be further defined as primary or secondary members, per 707.01 of the MDOT Standard Specifications for Construction. Structural steel may be in the form of plate, rolled or bent shapes, hollow structural shapes, tube railing, steel deck grating, modular expansion joints, bars and pins, etc. Structural Steel also includes other highway appurtenances such as sign and lighting support structures, tower lighting units, mast arm traffic signal supports, and bridge mounted signs. | |

| − | + | The Structural Fabrication Unit (SFU) is responsible for implementing the Department’s quality assurance program for fabricated materials required to be accepted based on “Fabrication Inspection” per the MDOT - Materials Quality Assurance Procedures (MQAP) Manual or per a project special provision. The SFU serves as the Department’s structural fabrication expert and provides recommendations to design and construction staff regarding plan details, specifications, shop inspection, and field inspection. The SFU also performs technical reviews of shop fabrications and field construction related documents required to be submitted for review and approval. It is important to note that MDOT utilizes consultants to perform fabrication inspection and project management while the SFU provides fabrication engineering and program management. | |

| − | + | The SFU adheres to MDOT’s Structural Fabrication Quality Manual (SFQM). The purpose of the SFQM is to provide the SFU and their consultants with information on implementing MDOT’s QA program for fabricated materials required to be accepted based on “Fabrication Inspection”. | |

| − | The | + | The SFQM can be found on the SFU Website |

| − | + | A supplier wishing to perform fabrication of main and secondary bridge members and highway structures (specified in 707 or special provision) must be certified by the American Institute of Steel Construction (AISC) in accordance with 707.01B of the MDOT SSC. | |

| − | + | ===Definitions and Terms=== | |

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| − | |||

| − | + | ===Contractor Prequalification=== | |

| + | <span style="color: red"> -Reserved- </span> | ||

{{top}} | {{top}} | ||

| − | |||

| − | + | ====Plant Certification Requirements==== | |

| + | <span style="color: red"> -Reserved- </span> | ||

{{top}} | {{top}} | ||

| − | |||

| − | |||

| − | |||

| − | + | ==[[#MATERIALS|'''MATERIALS''']]== | |

| − | + | ===Description of Materials Used=== | |

| + | All structural field welding will be done by the Shielded Metal Arc Welding (SMAW) process using E7018 electrodes unless the special provision requires a different electrode (e.g. structural steel with a yield stress greater than 50ksi or steels with higher carbon contents may need to be welded with an electrode with special alloys). | ||

{{top}} | {{top}} | ||

| + | ===Pictures of Materials=== | ||

| − | + | [[File:707-1.jpg|800px|thumb|center|'''Figure 707-1''']] | |

| + | {{top}} | ||

| − | |||

| − | + | ==[[#EQUIPMENT|'''EQUIPMENT''']]== | |

| − | + | ===Description of Equipment Used=== | |

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| + | ===Equipment Specifications=== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| + | ===Pictures of Equipment=== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| − | |||

| − | |||

| − | + | ==[[#PRECONSTRUCTION|'''PRECONSTRUCTION''']]== | |

| − | + | ===Submittals and Shop Drawings=== | |

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| − | + | ===Permits=== | |

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| − | + | ===Qualified Products List (QPL)=== | |

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| − | + | ===Plant Inspections=== | |

| + | <span style="color: red"> -Reserved- </span> | ||

{{top}} | {{top}} | ||

| − | == | + | ===Contractor Submitted Plans/Procedures=== |

| − | + | <span style="color: red"> -Reserved- </span> | |

| − | |||

| − | === | ||

| − | |||

| − | |||

{{top}} | {{top}} | ||

| − | === | + | === Fabrication Notification === |

| − | + | ==== Prefabrication Meeting ==== | |

| + | The SFU, or consultant working on behalf of the SFU, will conduct a prefabrication meeting with the fabricator when deemed necessary. Prefabrication meetings facilitate effective quality control and quality assurance and are conducted prior to the start of fabrication. The SFU (or consultant representative), quality assurance inspector (QAI), and quality control inspector (QCI) must be present, whereas the engineer and contractor should be present to ensure a team effort to facilitate accurate and timely construction. | ||

| − | + | ==== Inspection Facilities ==== | |

| + | Shop inspection includes the time from verifying materials used for fabrication through loading for shipping to the construction site. Structural steel used for MDOT projects shall conform to 707.02 of the MDOT SSC and structural steel elements that require fabrication inspection can be located in the Materials Acceptance Requirements Table located in the MDOT - Materials Quality Assurance Procedures (MQAP) Manual. Material and fabrication inspection requirements may also be located in a special provision for the product. | ||

| − | + | Fabrication inspection of structural steel shall be in accordance with section 2.3 and 2.4 of the SFQM. | |

| − | + | The SFU utilizes Inspection Test Plans (ITPs) to supplement the inspection procedures of the SFQM and other supporting QA documents by tabulating the progression of QA inspections and tests required by MDOT as part of its acceptance of structural steel fabricated members. The following ITPs are located on the SFU Website - MDOT - Structural Fabrication: | |

| − | + | *Structural Steel ITP Level 1: Main load carrying members, typically characterized by full time inspection frequency and sample size | |

| + | *Structural Steel ITP Level 2: Secondary members and ancillary products, typically characterized by reduced inspection frequency and sample size. | ||

| − | + | ==== QAI Authority ==== | |

| − | + | <span style="color: red"> -Reserved- </span> | |

| − | |||

{{top}} | {{top}} | ||

| + | === Acceptance === | ||

| − | + | In general, MDOT utilizes consultants to provide fabrication inspection and project management; however, the Structural Fabrication Unit will randomly perform fabrication inspection and project management on select projects for various reasons. The consultant QAI will perform fabrication inspection on behalf of MDOT at structural steel fabrication facilities nationwide. Once fabrication is complete and the elements are ready to be shipped to the project site, the QAI will stamp the elements as well as the shipping documents “Approved for Use”. See Figure 707.1. The consultant then submits all fabrication documentation to the “MDOT Inbox” folder in ProjectWise. | |

| + | |||

| + | Figure 707.1: "Approved For Use" Stamp (MDOT) | ||

| − | + | Visual Inspection (VI) acceptance of structural steel delivered to the project site shall be performed by the engineer in accordance with section 2.3.7.B.2 and 2.4.7.B.2 of the SFQM and section 1.06 of the MQAP Manual. Structural steel elements must not be shipped from the fabricator to the project or contractor’s yard without approval by the QAI. | |

| + | The Engineer reserves the right to reject any delivered structural steel products that show visual signs of damage, or does not meet specification requirements in accordance with section 105 of the MDOT SSC. The Engineer must notify the SFU of any structural steel products arriving on site that do not meet the specification requirements. | ||

| − | + | The Engineer must reject fabricated structural steel products that are delivered to the project site without being stamped and without a stamped Bill of Lading. Note, only large structural steel products will be individually stamped whereas packaged structural steel products (containers of fasteners, pallets of diaphragms/ bridge sign connections, etc.) will be stamped on the outside of the package in multiple locations. It is very important that the Engineer verify packaged materials prior to their use to avoid the possibility of nonconforming products being used for the project. | |

| − | + | The Engineer shall contact the SFU immediately whenever a structural steel product or Bill of Lading arrives to the project site without an approval stamp. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | The Engineer shall make stockpile payments for fabricated structural steel products in accordance with section 109 of the MDOT SSC. See subsection 2.3.6 and 2.4.6 of the SFQM for SFUs responsibilities with stockpile payment. These materials can be stored at the fabrication facility or at the construction site. If stored at the construction site, the materials shall be inspected by the Engineer as stockpiling occurs since the approval stamp ink could wash away over time. If the approval stamp(s) appear to be fading away, the Engineer shall mark the accepted structural steel products in a more permanent method. | |

| − | + | The Engineer should contact the SFU with any questions regarding the acceptability of structural steel products shipped to the project site. The SFU will review all proposed correction(s) to structural steel products not meeting specification requirements prior to approval. | |

| − | + | ==== Fracture Critical Members ==== | |

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| + | ==== Furnishing and Fabricating ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| + | ==== Direction of Rolling ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

{{top}} | {{top}} | ||

| + | ==== Identification ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | ==== | + | {{top}} |

| + | ==== Workmanship ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| + | ==== Lifting Materials ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

{{top}} | {{top}} | ||

| + | ==== Distortion and Shrinkage ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | ==== | + | {{top}} |

| + | ==== Straightening and Repair of Damaged Material ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| − | + | ==== Dimensional Tolerances ==== | |

| − | + | <span style="color: red"> -Reserved- </span> | |

{{top}} | {{top}} | ||

| − | ==== | + | ==== Cambering ==== |

| + | On wide flange beam and plate girder spans, the normal sag which occurs when the beam is loaded is necessary to be offset by either fabricating a camber in a beam or thickening the concrete haunch over the beams. Sometimes a combination of both is used. Also, beams may not be true to line and variances in elevation have to be provided for. Therefore, a convenient method of establishing the finished grade before casting concrete is desirable. | ||

| − | + | The superstructure plans for steel bridges may show a construction camber diagram sketch and another indicating top of screed elevations with slab thickness ordinates. | |

| + | Plan camber of structural steel beams is built into the member with a small tolerance permitted as shown on the plans. The fabrication is checked by the QAI shop inspector working on behalf of the SFU to see that the members are fabricated to the tolerance permitted. The camber in the shop is usually measured with the beam on its side. Estimated reduction in camber is then tabulated on the plans to cover camber loss due to the weight of the member, forms and reinforcing steel; welding of stud shear connectors; and the deflection from the weight of the concrete deck. | ||

| + | It is the Contractor's responsibility to erect the beams within the permitted camber tolerance. Any correction work to obtain this camber is the Contractor's responsibility. Any proposed corrective work should be reviewed by the SFU before approving. | ||

| + | When camber varies from the plan, it may be possible to adjust haunches and/or top of slab grades to allow for discrepancies. | ||

| + | For deck replacement projects, slab and screed elevations are based on the beam camber returning to its original position. Given the inherent variability of construction, this scenario is not always the case. Therefore, beams shall be surveyed after deck removal, and the results compared to the original camber diagram to determine if slab and screed grade adjustments are required. | ||

{{top}} | {{top}} | ||

| − | ==== | + | ==== Fit of Stiffeners ==== |

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| + | ==== Shop Welding ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| + | ==== Nondestructive Testing of Bridge Welds ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| + | ==== Nondestructive Testing of Structural Steel Welds ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

{{top}} | {{top}} | ||

| + | ==== Splices and Connections ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | ==== | + | {{top}} |

| + | ==== Assembly ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| + | ==== Pins and Link Plates ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| + | ==== Bushings for Pins and Link Plates ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| + | ==== Bearings and Bearing Surfaces ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| + | ==== Finished Members ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| + | ==== Correction of Errors or Defects ==== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

{{top}} | {{top}} | ||

| − | + | ==== Galvanizing Structural Steel ==== | |

| − | === | + | <span style="color: red"> -Reserved- </span> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | < | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | < | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

{{top}} | {{top}} | ||

| − | === | + | ===Handling and Storing Materials === |

| + | |||

| + | Once the structural steel has been VI and accepted, the inspector should verify that the material is properly stored prior to installation. Below is a list of items the inspector should check regarding storage of structural steel elements: | ||

| + | *Padding must be used to prevent paint damage when chains or cables are used to brace or erect structural steel. The padding will minimize coating damage and resulting corrosion due to handling operations. | ||

| + | *Structural steel members should be stored on adequate supports (dunnage comprised of wood, carpet, or other suitable padding) to preserve its shape and quality. No part of the structural steel shall come in direct contact with the ground. | ||

| + | *Structural steel members are to be stored in an upright position and should be thoroughly braced to avoid overturning, which may damage the member itself, adjacent members or material, or injure personnel in the immediate vicinity. | ||

| + | *Structural steel members should be so arranged that depressions, troughs, and similar "moisture traps" are eliminated and the blocking should be high enough so that the steel members don't meet the ground or sit in ponded water or mud. This will keep the structural steel dry and free of corrosion until it is erected. | ||

| + | *Structural steel related items such as bearings, bridge railing, sign structures and tower lighting units should also be protected from damage, dirt, and corrosion. | ||

| + | *Structural steel hardware (bolts, nuts and washers, etc.) must be stored in sealed containers that will keep them free of dirt and moisture until the point they are installed. The inspector must reject any hardware that shows signs of corrosion or dirt prior to installation. | ||

| − | + | === Shipping === | |

| − | + | <span style="color: red"> -Reserved- </span> | |

| − | |||

| − | |||

| − | |||

{{top}} | {{top}} | ||

| − | + | ==[[#CONSTRUCTION|'''CONSTRUCTION''']]== | |

| − | |||

| − | |||

| − | |||

| − | |||

| + | ===Construction Requirements/Procedures/Installation Methods=== | ||

| + | {{top}} | ||

| + | ==== Erection ==== | ||

{{top}} | {{top}} | ||

| + | ===== Methods and Equipment ===== | ||

| + | The inspector should review and understand the erection plan and the location and orientation of match-marked pieces. These markings are usually placed on the end of a member and will be erected with this marking in the same location as shown on the erection diagram. | ||

| − | ==== | + | ===== Bearings ===== |

| + | Placement of masonry plates is the first step in the erection process. These plates are placed on the concrete bridge seats of abutments and piers as shown in the contract the plans. The inspector shall: | ||

| + | *Check concrete surfaces for flatness at bearing locations. All high spots shall be ground so that full bearing under each plate is achieved. | ||

| + | *Verify plates for warpage. | ||

| + | *Check bearing of each individual plate by applying pressure to corners of the plate. | ||

| + | *Verify use of elastomeric sheets under masonry plates if designated on the contract plans. | ||

| + | *Verify low spots under edges of plates are not filled with grout. This thin layer of grout may not bond resulting in deterioration from loading and weathering cycles. | ||

| − | + | Masonry plates and expansion rockers will be match-marked to the centerline of bearing line previously marked on the concrete bearing surface by the instrument crew. If masonry plates are not center marked, the inspector shall establish these marks on each unit. In doing this, locate the match line by using anchor bolt holes as the center. When erecting each unit, these marks will match the centerline of bearing lines previously placed on the bridge seat. On projects where sole plates are welded to the bottom flange of WF-beams or plate girders, it will be necessary to shift the entire beam to align marks. | |

| − | + | At the time of erection, machine-finished bearing surfaces will be coated with a lubricant suitable for bearings in accordance with 707.03.E.4 | |

| + | When considering suspended span ends, the required opening should be maintained at the moving end. It makes little difference what the opening is under a field welded stay plate because it should not move. Where the plans call for expansion joints at independent backwalls, a check should also be made at the backwalls to verify enough beam end clearance to accommodate the maximum expansion. Expansion rocker tilt shall be determined by the Offset Dimension for Rocker Tilt chart (see Figure 707.5). | ||

| + | |||

| − | + | [[File:707-3.png|800px|thumbnail|center|'''Figure 707-3 – Sample Steel Fabrication Memo''']] | |

| − | + | {{top}} | |

| − | + | ===== Falsework ===== | |

| + | Falsework is a form of temporary support and may be required in the erection of steel for some projects. Often it is required at beam splices, usually on long spans or when special erection procedures are called for. Contractors shall submit working drawings and design calculations for falsework in accordance with 707.03.E.3 of the MDOT SSC. Approval does not relieve the Contractors responsibility for design adequacy. | ||

| + | The inspector should ensure that the falsework is assembled as shown on the approved drawings and that all bolted and welded connections are properly completed. | ||

| + | Assembling | ||

| − | + | As wide flange beams and plate girders are erected, sufficient horizontal stabilization must be provided for each beam to prevent the beam from tipping over due to construction or wind loading. Common methods for achieving horizontal stabilization are listed below. This is an important phase of erection and may prevent serious accidents and damage to steel beams caused by high winds or crane booms striking erected sections. | |

| − | + | *Bolting beams to piers or abutments | |

| − | + | *Placing diaphragms as the erection progresses | |

| − | + | *Placing falsework | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Give particular attention to cantilevered center spans. End diaphragms and lateral bracing on skewed bridges will be placed as erection progresses to ensure proper fit or to determine assembly problems at the earliest phase possible. These members are, in effect, control members and must be placed in proper sequence. Inspectors should insist that skewed diaphragms be placed at the time each girder is set and before any final bolting of intermediate diaphragms. If the fabrication and design are correct, all the steel should fit. At no time should already connected diaphragms or bracing be disconnected to allow for easier fit up of successive elements as this could result in the erected elements becoming unstable. | |

| + | Flame cutting is not allowed to bring members and connections into proper alignment. | ||

| − | + | If reaming is required to bring members and connections into proper alignment, it must be approved by the Engineer. Reaming is the process of using specialized tools to enlarge previously drilled holes in the steel elements. Excessive reaming could result in smaller edge distances and will allow more movement than the connection may have been designed for. | |

| − | + | Excessive pressure should not be used to force members into place, particularly when assembling diaphragms. Sweep can be forced into the main member when the length of the diaphragm is off as little as ½” . This sweep can develop across the structure to form a large sweep. When the bridge components do not appear to assemble correctly, a careful check must be made to determine if the pieces are properly match-marked. | |

| − | |||

| − | + | {{top}} | |

| − | < | + | ===== Misfits ===== |

| − | + | <span style="color: red"> -Reserved- </span> | |

| − | |||

| − | + | {{top}} | |

| − | + | ===== High-Strength Bolted Connections ===== | |

| − | + | See Field Manual for Structural Bolting located on the MDOT - Structure Construction website for information on bolted field splices. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | All field splice plates should be shipped in the assembled and drilled position, except that they are moved back one-half joint. The plates are brought forward on the beams to their final position. Occasionally, ironworkers inadvertently take the plates off, thus creating considerable difficulties. All plates, including the flanges, are required to be match-marked and it should be possible to determine the location and orientation of each plate. The fabrication plants CNC drill some parts of the girders to use as templates then do a laydown assembly. During this assembly, they will use the templates to match drill the other parts of the connection and match mark the parts. The match-marking scheme used should be shown on the approved shop drawings. If the plate hole alignment is difficult to achieve and they appear to require reaming, a mismatch should be suspected. | |

| − | + | If minor hole misalignment occurs, the Engineer will be consulted regarding corrective measures to be used. Often the main splice plates on girder splices appear to be slightly out of alignment. When this occurs, the plates need to be inverted or rotated according to the match-marking. Never ream on main girder splice plates, as the connection is design to be slip critical. | |

| − | + | The inspector shall observe reaming operations to ensure the correct size reamer is being used. Also, holes will be reamed perpendicular to the member faces and all burrs will be removed. Members should be tightly clamped together to prevent metal chips from getting between surfaces. | |

| − | |||

| − | + | The joint should be straight edged or string lined during the final bolting operation and adjustments made as required in grade or alignment to ensure straightness at the splice. | |

| − | + | The slope of surfaces of bolted parts in contact with the bolt head and nut shall not exceed 1:20 with respect to a plane normal to the bolt axis. Where an outer face of the bolted parts has a slope of more than 1:20, a smooth beveled washer will be used to compensate for the lack of parallelism. | |

| − | |||

| − | |||

| − | + | Prior to assembling, all joint surfaces, including those under the bolt head, nut, or washer must be free of oil, grease, burrs, dirt, or other foreign material that would prevent the solid seating of the parts. On shop painted steel, a carefully controlled coating of zinc rich primer has been applied to all faying (i.e., contact or friction) surfaces. These surfaces would have been masked during subsequent coating applications per subsection 716.03.B.2 of the MDOT SSC. Ensure no other coating is applied to these surfaces prior to bolting. | |

| + | When making bolted attachments to existing structural steel, the contact surfaces on the old steel should be blast cleaned and prime coated with zinc rich paint as specified in section 715 of the MDOT SSC. | ||

| − | + | Pre-Installation bolt tension verification shall be performed for high strength bolt assemblies to verify the Turn of Nut (TON) pretensioning method results in the required minimum bolt tension. This test is performed in a tension calibrator (typically a Skidmore) to ensure contractors have sufficient knowledge and ability to perform TON in accordance with the MDOT SSC. Pre-Installation bolt tension verification shall be performed in accordance with 707.03.E.6.b of the MDOT SSC. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Proper marking for high strength bolt connections tensioned by the TON method is shown in Figure 707.06. | |

| − | |||

| − | |||

| − | + | [[File:707-6.jpg|800px|thumbnail|center|'''Figure 707-6 Typical Turn of Nut Marking System''' ]] | |

| − | | | ||

| − | |||

| − | + | {{top}} | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ===== Field Welding ===== | |

| − | + | Field welding will be performed according to subsection 707.03.E.7 of the MDOT Standard Specifications for Construction and the current American Welding Society (AWS) Bridge Welding Code D1.5. All field welding must be completed in accordance with Form 0395 - AASHTO / AWS D1.5 Field Welding Plan which has been approved by the Structural Fabrication Unit. Field welding is not allowed unless shown on the plans or authorized by the Engineer. | |

| − | + | All structural field welding will be done by the Shielded Metal Arc Welding (SMAW) process using E7018 electrodes. Gas Metal Arc Welding (GMAW) and other gas shielded processes are prohibited. Submerged Arc Welding (SAW) and Flux Cored Arc Welding (FCAW) may be allowed for field welding when approved by the Engineer. | |

| + | Proper storage and use of electrodes is critical. Care must be taken to ensure no moisture is picked up in the coating of the electrodes as this can add hydrogen to the coating and cause discontinuities in the weld. Electrodes exposed to the atmosphere upon removal from drying or storage ovens (see Figure 707.11) or hermetically sealed containers (see Figure 707.12) must be used within two hours, or re-dried at a minimum temperature of 500° F for a minimum of two hours. Electrodes can only be re-dried once, and any electrode that becomes wet cannot be re-dried. Electrodes taken from a hermetically sealed container or drying oven that are not going to be used within two hours should be stored in a portable oven, also known as a “hot box” (see Figure 707.13), at a minimum temperature of 250° F. The welder should take out only as many electrodes from the hot box as can be used within that two hour period of time. | ||

| + | |||

| + | [[File:Fig707.11.png|800px|thumbnail|center|'''Figure 707-11 Drying and Storage Oven''']] | ||

| − | + | [[File:Fig707.12.png|800px|thumbnail|center|'''Figure 707-12 Hermetically Sealed Electrode Containers''']] | |

| − | + | [[File:Fig707.13.png|800px|thumbnail|center|'''Figure 707-13 Hotboxes for Electrode Storage''']] | |

| − | |||

| − | |||

| − | + | The first step in making a sound weld is to make sure the joint is correctly cleaned and then preheated prior to welding. Cleaning the joint can be accomplished by using a stiff wire brush. All surfaces to be welded must be free from all loose or thick scale, slag, rust, moisture, grease, or other contaminants. Mill scale that can withstand a vigorous wire brushing, or anti-spatter compound may remain prior to welding. | |

| − | + | The pieces to be joined should be checked for flatness, straightness and dimensional accuracy. Likewise, alignment, root opening, fit-up and joint preparation should be examined. Finally, process and procedure variables should be verified, including electrode size and type and equipment settings. These variables should be listed in the weld procedure (WPS). | |

| + | Preheating is the required practice of providing localized heat to the weld zone. The preferred method of preheating is by the use of a manual torch and the required preheat temperature varies based on the thickness of the base metal (see Table 707.6). Preheat shall be applied for a distance of 3 inches in all directions from the weld joint and should be verified by the welder using a temperature indicating stick. Bridge welding is not permitted when the ambient temperature is below 40 degrees Fahrenheit. | ||

| + | |||

| + | [[File:Table707.6.png|900px|thumbnail|center|'''Table 707-6 Minimum Preheat Temperatures''']] | ||

| − | + | Welds should be cleaned between every pass and after the final pass. A finished weld should have a clean appearance. Cleaning is typically accomplished by using a stiff wire brush in conjunction with a chipping hammer to remove slag and splatter. The grinder is also a very common and useful tool for cleaning. Grinders are to be used with care to avoid doing more harm than good to both finished welds and the base metal. | |

| − | + | Once the welding has been completed the welds must be tested for acceptability according to subsection 707.03.E.7.e of the MDOT Standard Specifications for Construction. The contractor is responsible for the non-destructive testing of the welds. Personnel qualified as Level II or Level III in accordance with the American Society for Nondestructive Testing (ASNT), Recommended Practice No. SNT-TC-1A must perform all the testing and provide a copy of their qualification to the inspector. If welds are found to be unacceptable, the welds must be repaired and retested. Consult the Structural Fabrication Unit of Bridge Field Services with any questions regarding non-destructive testing. | |

| − | + | Shear developers are used to provide a composite section between the concrete deck and the steel beams supporting it. They are in the form of steel studs and are welded to beam flanges at the spacing shown on the plans. This composite section generally allows the designer to reduce the beam size required, as a portion of the deck is considered part of beam, thus increasing its moment of inertia. Shear developers, such as studs, are a certified product and must be selected from the Qualified Products List. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Shear developers shall be welded in accordance with 707.03.E.7.h of the MDOT SSC. | |

| − | + | See Field Manual for Structural Welding located on the [https://www.michigan.gov/mdot/0,4616,7-151-87728_87844_87846---,00.html MDOT - Structure Construction website] for more information on structural welding. | |

| − | + | New operators may have a tendency to tip the studs slightly, increasing the chances of producing defective welds. Also, they sometimes do not hesitate long enough to allow the weld metal to cool. | |

| + | When the welding operation is delayed due to rain, the flange surface must be dry before commencing welding and any connection ferrules which were dampened due to the rain must be replaced with dry ones. | ||

| − | + | Prior to the welding operation, The Engineer and Contractor should discuss the procedure that will be used to repair all studs that lack a full 360° fillet if present. The Contractor can repair defective studs by manually adding fillet weld material to each stud that lacks a full 360° fillet using E7015, E7016, or E7018 electrodes, or by welding new studs adjacent to the defective ones. | |

| + | Studs are tested by ringing with a hammer. To test the studs, the inspector should allow cooling before testing. The first two studs welded will be bent to a 30 degree angle without breaking the weld. If the weld breaks, repairs will be made and the next set of studs tested along with the studs that were repaired. The rest of the studs on that beam can then be checked for proper welding. Sufficient tests should be made to ensure proper procedures are being followed (bend over additional studs). If a weld defect is found, the stud may be bent to an angle of 15 degrees away from the defect. If no weld break occurs, the stud is acceptable. No welding will be done when the temperature of the base material is below 32 °F (0C) or when the surface is wet or exposed to rain or snow. | ||

| − | + | All welders performing work for MDOT must be endorsed through MDOT’s Welder Qualification or Certification Program, which can be located on the [https://www.michigan.gov/mdot/0,4616,7-151-87728_87844_87846_91594---,00.html SFU website - MDOT - Structural Fabrication]. Welders must already meet American Welding Society qualification requirements. MDOT’s endorsement is a verification of the welder’s ability and has a specific period of effectiveness. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | The Project Engineer will contact the SFU to arrange for welder qualification testing if the Contractor does not currently have a Department qualified welder available. The Engineer reserves the right to require a confirming qualification test during work progression. | |

| − | |||

| − | The | ||

| − | |||

| − | |||

| − | |||

| − | + | Field welders must be qualified in the welding process, position, method, electrode classification, base metal type, and the maximum electrode diameter actually being used to perform the work. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Welders qualified using a 3/8” thick test plate are allowed to weld material up to 1” in thickness but if the welder is tested using a 1” thick test plate, they are not limited in the thickness of material they can weld. | |

| − | |||

| − | |||

| − | |||

| − | + | ===Safety=== | |

| + | <span style="color: red"> -Reserved- </span> | ||

{{top}} | {{top}} | ||

| + | ===Productivity information/charts=== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | === | + | {{top}} |

| + | ===Items of Note=== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| − | + | ===Layout / Survey=== | |

| − | + | <span style="color: red"> -Reserved- </span> | |

| − | |||

| − | |||

| − | |||

| − | < | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | {{top}} | |

| − | |||

| − | |||

| − | + | ==[[#INSPECTION & TESTING|'''INSPECTION & TESTING''']]== | |

| − | | | ||

| − | |||

| − | + | ===Inspection Procedures=== | |

| − | + | <span style="color: red"> -Reserved- </span> | |

| − | < | ||

| − | + | {{top}} | |

| − | + | ===Special Attention Areas=== | |

| − | + | <span style="color: red"> -Reserved- </span> | |

| − | < | ||

| − | + | {{top}} | |

| − | + | ===QA/QC Tests=== | |

| − | + | <span style="color: red"> -Reserved- </span> | |

| − | |||

| − | < | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | {{top}} | |

| − | + | ===Lab Testing / Field Testing=== | |

| − | + | <span style="color: red"> -Reserved- </span> | |

| − | |||

| − | < | ||

| − | |||

| − | |||

| − | |||

| − | + | {{top}} | |

| + | ===Rejection/Remedial Actions=== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| + | {{top}} | ||

| + | |||

{{top}} | {{top}} | ||

| − | + | ==[[#MEASUREMENT, DOCMENTATION & PAYMENT|'''MEASUREMENT, DOCMENTATION & PAYMENT''']]== | |

| − | + | ===Measurement=== | |

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| + | ===Documentation Requirements=== | ||

| + | <span style="color: red"> -Reserved- </span> | ||

| − | + | {{top}} | |

| − | + | ===Basis of Payment=== | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ====[[#Stockpile Payment|Stockpile Payment]]==== | |

| − | + | See subsection 109.04 of the Standard Specifications for Construction for stockpile payment requirements. Additionally, see subsection [http://www.michigan.gov/documents/mdot/MDOT_MQAP_Manual_5_Section_D_307110_7.pdf 4.05.07 (Structural Steel) or 4.06.06 (Lighting, Signal and Sign Support Structures)] of the MQAP manual for QAI’s responsibilities for verifying stockpile payment. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

{{top}} | {{top}} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

[[Category:Construction Manual]] | [[Category:Construction Manual]] | ||

| + | [[Category: Division 7]] | ||

| + | [[Category: Section 707]] | ||

| + | [[Category:New CM Format]] | ||

Latest revision as of 13:23, 5 September 2024

GENERAL DESCRIPTION

General Overview

Structural steel construction involves the fabrication, handling, erection, bolting and welding of steel members used in structural applications. Most structural steel for Department projects is comprised of bridge elements – plate girders and rolled beams, intermediate and end diaphragms, connection plates and stiffeners, cover plates, beam bearings, pin and hanger assemblies and foundation piling. All these elements can be further defined as primary or secondary members, per 707.01 of the MDOT Standard Specifications for Construction. Structural steel may be in the form of plate, rolled or bent shapes, hollow structural shapes, tube railing, steel deck grating, modular expansion joints, bars and pins, etc. Structural Steel also includes other highway appurtenances such as sign and lighting support structures, tower lighting units, mast arm traffic signal supports, and bridge mounted signs.

The Structural Fabrication Unit (SFU) is responsible for implementing the Department’s quality assurance program for fabricated materials required to be accepted based on “Fabrication Inspection” per the MDOT - Materials Quality Assurance Procedures (MQAP) Manual or per a project special provision. The SFU serves as the Department’s structural fabrication expert and provides recommendations to design and construction staff regarding plan details, specifications, shop inspection, and field inspection. The SFU also performs technical reviews of shop fabrications and field construction related documents required to be submitted for review and approval. It is important to note that MDOT utilizes consultants to perform fabrication inspection and project management while the SFU provides fabrication engineering and program management.

The SFU adheres to MDOT’s Structural Fabrication Quality Manual (SFQM). The purpose of the SFQM is to provide the SFU and their consultants with information on implementing MDOT’s QA program for fabricated materials required to be accepted based on “Fabrication Inspection”.

The SFQM can be found on the SFU Website

A supplier wishing to perform fabrication of main and secondary bridge members and highway structures (specified in 707 or special provision) must be certified by the American Institute of Steel Construction (AISC) in accordance with 707.01B of the MDOT SSC.

Definitions and Terms

-Reserved-

Contractor Prequalification

-Reserved-

Plant Certification Requirements

-Reserved-

MATERIALS

Description of Materials Used

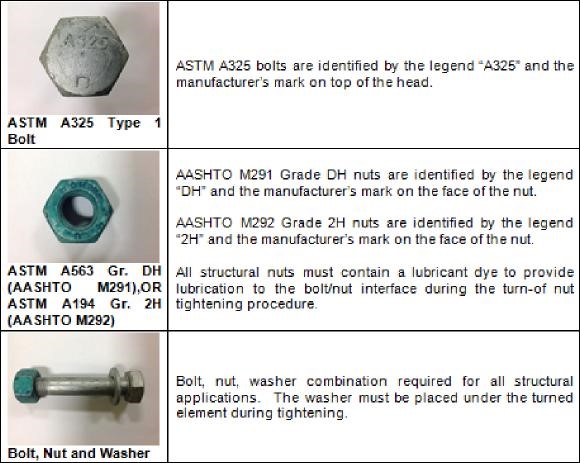

All structural field welding will be done by the Shielded Metal Arc Welding (SMAW) process using E7018 electrodes unless the special provision requires a different electrode (e.g. structural steel with a yield stress greater than 50ksi or steels with higher carbon contents may need to be welded with an electrode with special alloys).

Pictures of Materials

EQUIPMENT

Description of Equipment Used

-Reserved-

Equipment Specifications

-Reserved-

Pictures of Equipment

-Reserved-

PRECONSTRUCTION

Submittals and Shop Drawings

-Reserved-

Permits

-Reserved-

Qualified Products List (QPL)

-Reserved-

Plant Inspections

-Reserved-

Contractor Submitted Plans/Procedures

-Reserved-

Fabrication Notification

Prefabrication Meeting

The SFU, or consultant working on behalf of the SFU, will conduct a prefabrication meeting with the fabricator when deemed necessary. Prefabrication meetings facilitate effective quality control and quality assurance and are conducted prior to the start of fabrication. The SFU (or consultant representative), quality assurance inspector (QAI), and quality control inspector (QCI) must be present, whereas the engineer and contractor should be present to ensure a team effort to facilitate accurate and timely construction.

Inspection Facilities

Shop inspection includes the time from verifying materials used for fabrication through loading for shipping to the construction site. Structural steel used for MDOT projects shall conform to 707.02 of the MDOT SSC and structural steel elements that require fabrication inspection can be located in the Materials Acceptance Requirements Table located in the MDOT - Materials Quality Assurance Procedures (MQAP) Manual. Material and fabrication inspection requirements may also be located in a special provision for the product.

Fabrication inspection of structural steel shall be in accordance with section 2.3 and 2.4 of the SFQM.

The SFU utilizes Inspection Test Plans (ITPs) to supplement the inspection procedures of the SFQM and other supporting QA documents by tabulating the progression of QA inspections and tests required by MDOT as part of its acceptance of structural steel fabricated members. The following ITPs are located on the SFU Website - MDOT - Structural Fabrication:

- Structural Steel ITP Level 1: Main load carrying members, typically characterized by full time inspection frequency and sample size

- Structural Steel ITP Level 2: Secondary members and ancillary products, typically characterized by reduced inspection frequency and sample size.

QAI Authority

-Reserved-

Acceptance

In general, MDOT utilizes consultants to provide fabrication inspection and project management; however, the Structural Fabrication Unit will randomly perform fabrication inspection and project management on select projects for various reasons. The consultant QAI will perform fabrication inspection on behalf of MDOT at structural steel fabrication facilities nationwide. Once fabrication is complete and the elements are ready to be shipped to the project site, the QAI will stamp the elements as well as the shipping documents “Approved for Use”. See Figure 707.1. The consultant then submits all fabrication documentation to the “MDOT Inbox” folder in ProjectWise.

Figure 707.1: "Approved For Use" Stamp (MDOT)

Visual Inspection (VI) acceptance of structural steel delivered to the project site shall be performed by the engineer in accordance with section 2.3.7.B.2 and 2.4.7.B.2 of the SFQM and section 1.06 of the MQAP Manual. Structural steel elements must not be shipped from the fabricator to the project or contractor’s yard without approval by the QAI. The Engineer reserves the right to reject any delivered structural steel products that show visual signs of damage, or does not meet specification requirements in accordance with section 105 of the MDOT SSC. The Engineer must notify the SFU of any structural steel products arriving on site that do not meet the specification requirements.

The Engineer must reject fabricated structural steel products that are delivered to the project site without being stamped and without a stamped Bill of Lading. Note, only large structural steel products will be individually stamped whereas packaged structural steel products (containers of fasteners, pallets of diaphragms/ bridge sign connections, etc.) will be stamped on the outside of the package in multiple locations. It is very important that the Engineer verify packaged materials prior to their use to avoid the possibility of nonconforming products being used for the project.

The Engineer shall contact the SFU immediately whenever a structural steel product or Bill of Lading arrives to the project site without an approval stamp.

The Engineer shall make stockpile payments for fabricated structural steel products in accordance with section 109 of the MDOT SSC. See subsection 2.3.6 and 2.4.6 of the SFQM for SFUs responsibilities with stockpile payment. These materials can be stored at the fabrication facility or at the construction site. If stored at the construction site, the materials shall be inspected by the Engineer as stockpiling occurs since the approval stamp ink could wash away over time. If the approval stamp(s) appear to be fading away, the Engineer shall mark the accepted structural steel products in a more permanent method.

The Engineer should contact the SFU with any questions regarding the acceptability of structural steel products shipped to the project site. The SFU will review all proposed correction(s) to structural steel products not meeting specification requirements prior to approval.

Fracture Critical Members

-Reserved-

Furnishing and Fabricating

-Reserved-

Direction of Rolling

-Reserved-

Identification

-Reserved-

Workmanship

-Reserved-

Lifting Materials

-Reserved-

Distortion and Shrinkage

-Reserved-

Straightening and Repair of Damaged Material

-Reserved-

Dimensional Tolerances

-Reserved-

Cambering

On wide flange beam and plate girder spans, the normal sag which occurs when the beam is loaded is necessary to be offset by either fabricating a camber in a beam or thickening the concrete haunch over the beams. Sometimes a combination of both is used. Also, beams may not be true to line and variances in elevation have to be provided for. Therefore, a convenient method of establishing the finished grade before casting concrete is desirable.

The superstructure plans for steel bridges may show a construction camber diagram sketch and another indicating top of screed elevations with slab thickness ordinates. Plan camber of structural steel beams is built into the member with a small tolerance permitted as shown on the plans. The fabrication is checked by the QAI shop inspector working on behalf of the SFU to see that the members are fabricated to the tolerance permitted. The camber in the shop is usually measured with the beam on its side. Estimated reduction in camber is then tabulated on the plans to cover camber loss due to the weight of the member, forms and reinforcing steel; welding of stud shear connectors; and the deflection from the weight of the concrete deck.

It is the Contractor's responsibility to erect the beams within the permitted camber tolerance. Any correction work to obtain this camber is the Contractor's responsibility. Any proposed corrective work should be reviewed by the SFU before approving. When camber varies from the plan, it may be possible to adjust haunches and/or top of slab grades to allow for discrepancies. For deck replacement projects, slab and screed elevations are based on the beam camber returning to its original position. Given the inherent variability of construction, this scenario is not always the case. Therefore, beams shall be surveyed after deck removal, and the results compared to the original camber diagram to determine if slab and screed grade adjustments are required.

Fit of Stiffeners

-Reserved-

Shop Welding

-Reserved-

Nondestructive Testing of Bridge Welds

-Reserved-

Nondestructive Testing of Structural Steel Welds

-Reserved-

Splices and Connections

-Reserved-

Assembly

-Reserved-

Pins and Link Plates

-Reserved-

Bushings for Pins and Link Plates

-Reserved-

Bearings and Bearing Surfaces

-Reserved-

Finished Members

-Reserved-

Correction of Errors or Defects

-Reserved-

Galvanizing Structural Steel

-Reserved-

Handling and Storing Materials

Once the structural steel has been VI and accepted, the inspector should verify that the material is properly stored prior to installation. Below is a list of items the inspector should check regarding storage of structural steel elements:

- Padding must be used to prevent paint damage when chains or cables are used to brace or erect structural steel. The padding will minimize coating damage and resulting corrosion due to handling operations.

- Structural steel members should be stored on adequate supports (dunnage comprised of wood, carpet, or other suitable padding) to preserve its shape and quality. No part of the structural steel shall come in direct contact with the ground.

- Structural steel members are to be stored in an upright position and should be thoroughly braced to avoid overturning, which may damage the member itself, adjacent members or material, or injure personnel in the immediate vicinity.

- Structural steel members should be so arranged that depressions, troughs, and similar "moisture traps" are eliminated and the blocking should be high enough so that the steel members don't meet the ground or sit in ponded water or mud. This will keep the structural steel dry and free of corrosion until it is erected.

- Structural steel related items such as bearings, bridge railing, sign structures and tower lighting units should also be protected from damage, dirt, and corrosion.

- Structural steel hardware (bolts, nuts and washers, etc.) must be stored in sealed containers that will keep them free of dirt and moisture until the point they are installed. The inspector must reject any hardware that shows signs of corrosion or dirt prior to installation.

Shipping

-Reserved-

CONSTRUCTION

Construction Requirements/Procedures/Installation Methods

Erection

Methods and Equipment

The inspector should review and understand the erection plan and the location and orientation of match-marked pieces. These markings are usually placed on the end of a member and will be erected with this marking in the same location as shown on the erection diagram.

Bearings

Placement of masonry plates is the first step in the erection process. These plates are placed on the concrete bridge seats of abutments and piers as shown in the contract the plans. The inspector shall:

- Check concrete surfaces for flatness at bearing locations. All high spots shall be ground so that full bearing under each plate is achieved.

- Verify plates for warpage.

- Check bearing of each individual plate by applying pressure to corners of the plate.

- Verify use of elastomeric sheets under masonry plates if designated on the contract plans.

- Verify low spots under edges of plates are not filled with grout. This thin layer of grout may not bond resulting in deterioration from loading and weathering cycles.

Masonry plates and expansion rockers will be match-marked to the centerline of bearing line previously marked on the concrete bearing surface by the instrument crew. If masonry plates are not center marked, the inspector shall establish these marks on each unit. In doing this, locate the match line by using anchor bolt holes as the center. When erecting each unit, these marks will match the centerline of bearing lines previously placed on the bridge seat. On projects where sole plates are welded to the bottom flange of WF-beams or plate girders, it will be necessary to shift the entire beam to align marks.

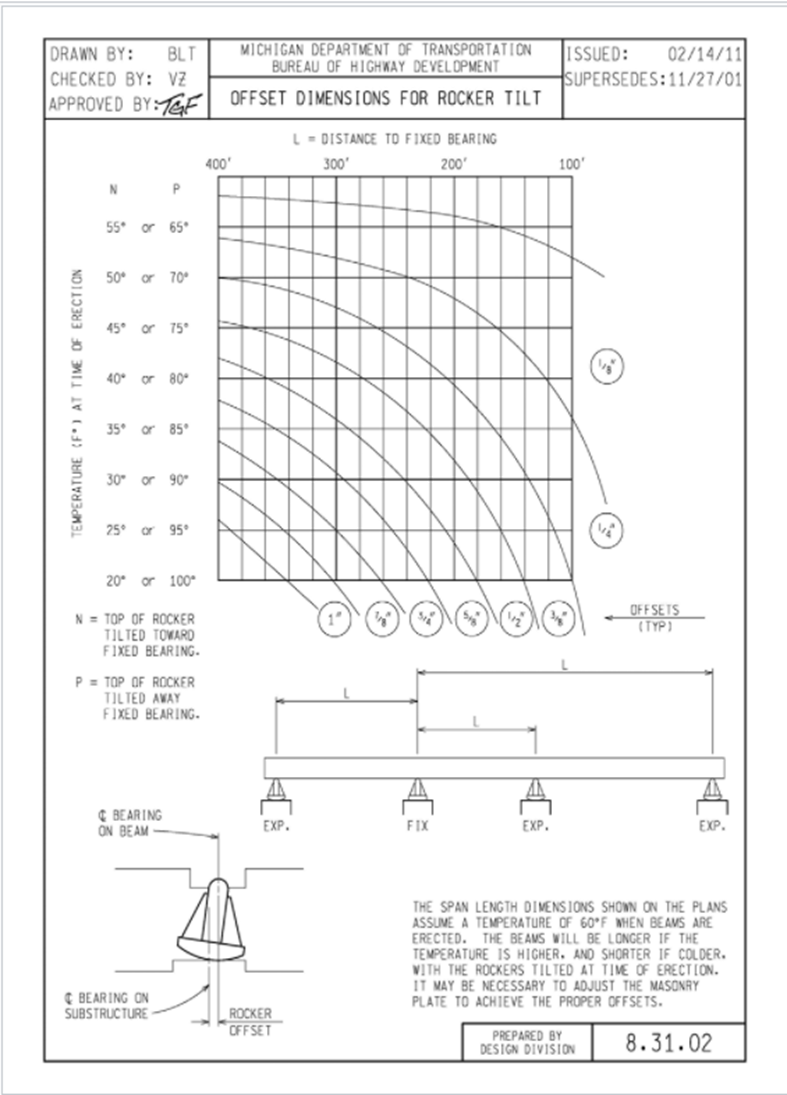

At the time of erection, machine-finished bearing surfaces will be coated with a lubricant suitable for bearings in accordance with 707.03.E.4 When considering suspended span ends, the required opening should be maintained at the moving end. It makes little difference what the opening is under a field welded stay plate because it should not move. Where the plans call for expansion joints at independent backwalls, a check should also be made at the backwalls to verify enough beam end clearance to accommodate the maximum expansion. Expansion rocker tilt shall be determined by the Offset Dimension for Rocker Tilt chart (see Figure 707.5).

Falsework

Falsework is a form of temporary support and may be required in the erection of steel for some projects. Often it is required at beam splices, usually on long spans or when special erection procedures are called for. Contractors shall submit working drawings and design calculations for falsework in accordance with 707.03.E.3 of the MDOT SSC. Approval does not relieve the Contractors responsibility for design adequacy.

The inspector should ensure that the falsework is assembled as shown on the approved drawings and that all bolted and welded connections are properly completed. Assembling

As wide flange beams and plate girders are erected, sufficient horizontal stabilization must be provided for each beam to prevent the beam from tipping over due to construction or wind loading. Common methods for achieving horizontal stabilization are listed below. This is an important phase of erection and may prevent serious accidents and damage to steel beams caused by high winds or crane booms striking erected sections.

- Bolting beams to piers or abutments

- Placing diaphragms as the erection progresses

- Placing falsework

Give particular attention to cantilevered center spans. End diaphragms and lateral bracing on skewed bridges will be placed as erection progresses to ensure proper fit or to determine assembly problems at the earliest phase possible. These members are, in effect, control members and must be placed in proper sequence. Inspectors should insist that skewed diaphragms be placed at the time each girder is set and before any final bolting of intermediate diaphragms. If the fabrication and design are correct, all the steel should fit. At no time should already connected diaphragms or bracing be disconnected to allow for easier fit up of successive elements as this could result in the erected elements becoming unstable. Flame cutting is not allowed to bring members and connections into proper alignment.

If reaming is required to bring members and connections into proper alignment, it must be approved by the Engineer. Reaming is the process of using specialized tools to enlarge previously drilled holes in the steel elements. Excessive reaming could result in smaller edge distances and will allow more movement than the connection may have been designed for. Excessive pressure should not be used to force members into place, particularly when assembling diaphragms. Sweep can be forced into the main member when the length of the diaphragm is off as little as ½” . This sweep can develop across the structure to form a large sweep. When the bridge components do not appear to assemble correctly, a careful check must be made to determine if the pieces are properly match-marked.

Misfits

-Reserved-

High-Strength Bolted Connections

See Field Manual for Structural Bolting located on the MDOT - Structure Construction website for information on bolted field splices.

All field splice plates should be shipped in the assembled and drilled position, except that they are moved back one-half joint. The plates are brought forward on the beams to their final position. Occasionally, ironworkers inadvertently take the plates off, thus creating considerable difficulties. All plates, including the flanges, are required to be match-marked and it should be possible to determine the location and orientation of each plate. The fabrication plants CNC drill some parts of the girders to use as templates then do a laydown assembly. During this assembly, they will use the templates to match drill the other parts of the connection and match mark the parts. The match-marking scheme used should be shown on the approved shop drawings. If the plate hole alignment is difficult to achieve and they appear to require reaming, a mismatch should be suspected.

If minor hole misalignment occurs, the Engineer will be consulted regarding corrective measures to be used. Often the main splice plates on girder splices appear to be slightly out of alignment. When this occurs, the plates need to be inverted or rotated according to the match-marking. Never ream on main girder splice plates, as the connection is design to be slip critical. The inspector shall observe reaming operations to ensure the correct size reamer is being used. Also, holes will be reamed perpendicular to the member faces and all burrs will be removed. Members should be tightly clamped together to prevent metal chips from getting between surfaces.

The joint should be straight edged or string lined during the final bolting operation and adjustments made as required in grade or alignment to ensure straightness at the splice.

The slope of surfaces of bolted parts in contact with the bolt head and nut shall not exceed 1:20 with respect to a plane normal to the bolt axis. Where an outer face of the bolted parts has a slope of more than 1:20, a smooth beveled washer will be used to compensate for the lack of parallelism.

Prior to assembling, all joint surfaces, including those under the bolt head, nut, or washer must be free of oil, grease, burrs, dirt, or other foreign material that would prevent the solid seating of the parts. On shop painted steel, a carefully controlled coating of zinc rich primer has been applied to all faying (i.e., contact or friction) surfaces. These surfaces would have been masked during subsequent coating applications per subsection 716.03.B.2 of the MDOT SSC. Ensure no other coating is applied to these surfaces prior to bolting. When making bolted attachments to existing structural steel, the contact surfaces on the old steel should be blast cleaned and prime coated with zinc rich paint as specified in section 715 of the MDOT SSC.

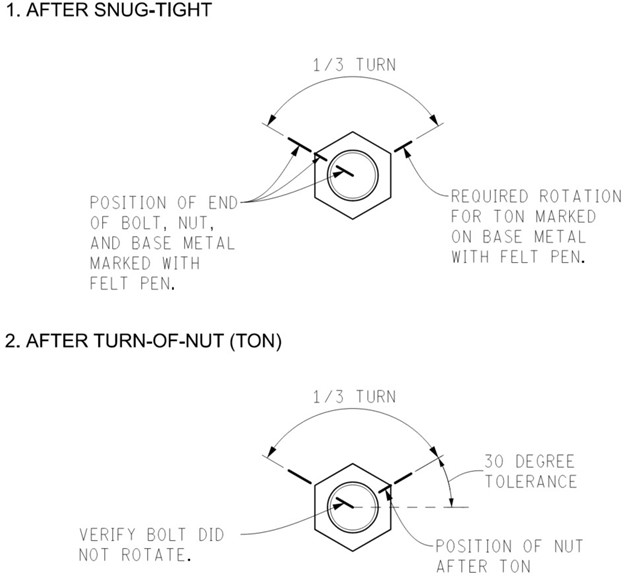

Pre-Installation bolt tension verification shall be performed for high strength bolt assemblies to verify the Turn of Nut (TON) pretensioning method results in the required minimum bolt tension. This test is performed in a tension calibrator (typically a Skidmore) to ensure contractors have sufficient knowledge and ability to perform TON in accordance with the MDOT SSC. Pre-Installation bolt tension verification shall be performed in accordance with 707.03.E.6.b of the MDOT SSC.

Proper marking for high strength bolt connections tensioned by the TON method is shown in Figure 707.06.

Field Welding

Field welding will be performed according to subsection 707.03.E.7 of the MDOT Standard Specifications for Construction and the current American Welding Society (AWS) Bridge Welding Code D1.5. All field welding must be completed in accordance with Form 0395 - AASHTO / AWS D1.5 Field Welding Plan which has been approved by the Structural Fabrication Unit. Field welding is not allowed unless shown on the plans or authorized by the Engineer.

All structural field welding will be done by the Shielded Metal Arc Welding (SMAW) process using E7018 electrodes. Gas Metal Arc Welding (GMAW) and other gas shielded processes are prohibited. Submerged Arc Welding (SAW) and Flux Cored Arc Welding (FCAW) may be allowed for field welding when approved by the Engineer. Proper storage and use of electrodes is critical. Care must be taken to ensure no moisture is picked up in the coating of the electrodes as this can add hydrogen to the coating and cause discontinuities in the weld. Electrodes exposed to the atmosphere upon removal from drying or storage ovens (see Figure 707.11) or hermetically sealed containers (see Figure 707.12) must be used within two hours, or re-dried at a minimum temperature of 500° F for a minimum of two hours. Electrodes can only be re-dried once, and any electrode that becomes wet cannot be re-dried. Electrodes taken from a hermetically sealed container or drying oven that are not going to be used within two hours should be stored in a portable oven, also known as a “hot box” (see Figure 707.13), at a minimum temperature of 250° F. The welder should take out only as many electrodes from the hot box as can be used within that two hour period of time.

The first step in making a sound weld is to make sure the joint is correctly cleaned and then preheated prior to welding. Cleaning the joint can be accomplished by using a stiff wire brush. All surfaces to be welded must be free from all loose or thick scale, slag, rust, moisture, grease, or other contaminants. Mill scale that can withstand a vigorous wire brushing, or anti-spatter compound may remain prior to welding.

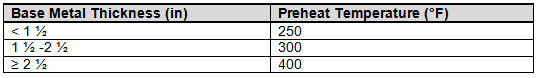

The pieces to be joined should be checked for flatness, straightness and dimensional accuracy. Likewise, alignment, root opening, fit-up and joint preparation should be examined. Finally, process and procedure variables should be verified, including electrode size and type and equipment settings. These variables should be listed in the weld procedure (WPS). Preheating is the required practice of providing localized heat to the weld zone. The preferred method of preheating is by the use of a manual torch and the required preheat temperature varies based on the thickness of the base metal (see Table 707.6). Preheat shall be applied for a distance of 3 inches in all directions from the weld joint and should be verified by the welder using a temperature indicating stick. Bridge welding is not permitted when the ambient temperature is below 40 degrees Fahrenheit.

Welds should be cleaned between every pass and after the final pass. A finished weld should have a clean appearance. Cleaning is typically accomplished by using a stiff wire brush in conjunction with a chipping hammer to remove slag and splatter. The grinder is also a very common and useful tool for cleaning. Grinders are to be used with care to avoid doing more harm than good to both finished welds and the base metal.

Once the welding has been completed the welds must be tested for acceptability according to subsection 707.03.E.7.e of the MDOT Standard Specifications for Construction. The contractor is responsible for the non-destructive testing of the welds. Personnel qualified as Level II or Level III in accordance with the American Society for Nondestructive Testing (ASNT), Recommended Practice No. SNT-TC-1A must perform all the testing and provide a copy of their qualification to the inspector. If welds are found to be unacceptable, the welds must be repaired and retested. Consult the Structural Fabrication Unit of Bridge Field Services with any questions regarding non-destructive testing.

Shear developers are used to provide a composite section between the concrete deck and the steel beams supporting it. They are in the form of steel studs and are welded to beam flanges at the spacing shown on the plans. This composite section generally allows the designer to reduce the beam size required, as a portion of the deck is considered part of beam, thus increasing its moment of inertia. Shear developers, such as studs, are a certified product and must be selected from the Qualified Products List.

Shear developers shall be welded in accordance with 707.03.E.7.h of the MDOT SSC.

See Field Manual for Structural Welding located on the MDOT - Structure Construction website for more information on structural welding.

New operators may have a tendency to tip the studs slightly, increasing the chances of producing defective welds. Also, they sometimes do not hesitate long enough to allow the weld metal to cool. When the welding operation is delayed due to rain, the flange surface must be dry before commencing welding and any connection ferrules which were dampened due to the rain must be replaced with dry ones.

Prior to the welding operation, The Engineer and Contractor should discuss the procedure that will be used to repair all studs that lack a full 360° fillet if present. The Contractor can repair defective studs by manually adding fillet weld material to each stud that lacks a full 360° fillet using E7015, E7016, or E7018 electrodes, or by welding new studs adjacent to the defective ones.

Studs are tested by ringing with a hammer. To test the studs, the inspector should allow cooling before testing. The first two studs welded will be bent to a 30 degree angle without breaking the weld. If the weld breaks, repairs will be made and the next set of studs tested along with the studs that were repaired. The rest of the studs on that beam can then be checked for proper welding. Sufficient tests should be made to ensure proper procedures are being followed (bend over additional studs). If a weld defect is found, the stud may be bent to an angle of 15 degrees away from the defect. If no weld break occurs, the stud is acceptable. No welding will be done when the temperature of the base material is below 32 °F (0C) or when the surface is wet or exposed to rain or snow.

All welders performing work for MDOT must be endorsed through MDOT’s Welder Qualification or Certification Program, which can be located on the SFU website - MDOT - Structural Fabrication. Welders must already meet American Welding Society qualification requirements. MDOT’s endorsement is a verification of the welder’s ability and has a specific period of effectiveness.

The Project Engineer will contact the SFU to arrange for welder qualification testing if the Contractor does not currently have a Department qualified welder available. The Engineer reserves the right to require a confirming qualification test during work progression.

Field welders must be qualified in the welding process, position, method, electrode classification, base metal type, and the maximum electrode diameter actually being used to perform the work.

Welders qualified using a 3/8” thick test plate are allowed to weld material up to 1” in thickness but if the welder is tested using a 1” thick test plate, they are not limited in the thickness of material they can weld.

Safety

-Reserved-

Productivity information/charts

-Reserved-

Items of Note

-Reserved-

Layout / Survey

-Reserved-

INSPECTION & TESTING

Inspection Procedures

-Reserved-

Special Attention Areas

-Reserved-

QA/QC Tests

-Reserved-

Lab Testing / Field Testing

-Reserved-

Rejection/Remedial Actions

-Reserved-

MEASUREMENT, DOCMENTATION & PAYMENT

Measurement

-Reserved-

Documentation Requirements

-Reserved-

Basis of Payment

Stockpile Payment

See subsection 109.04 of the Standard Specifications for Construction for stockpile payment requirements. Additionally, see subsection 4.05.07 (Structural Steel) or 4.06.06 (Lighting, Signal and Sign Support Structures) of the MQAP manual for QAI’s responsibilities for verifying stockpile payment.