1004 - Portland Cement Concrete Mixtures

1004 - Portland Cement Concrete Mixtures

GENERAL

-Reserved-

MATERIALS

All materials used in MDOT’s construction and maintenance projects must be tested and/or approved before incorporation into the project. Materials are approved based upon one of four guidelines:

|

|

|

|---|---|

|

Acceptance |

The material must be sampled, tested, and approved before incorporation into the work. |

|

Tested Stock |

A material stockpile of known quantity is sampled, tested and approved for use before shipment to the project and the supplier/distributor agrees to abide by MDOT’s program. Approved suppliers are found in the Materials Source Guide. |

|

Certified |

A material with a proven track record of meeting specifications and the supplier agrees to MDOT’s program. Approved suppliers are found in the Materials Source Guide. |

|

Qualified Product |

Proprietary materials or products previously evaluated and approved by C&T. Approved materials and products are found on the Qualified Products List in the Materials Source Guide. |

Independent Assurance Testing (IAT) is done by Region materials personnel to verify that the proper procedure and equipment used in sampling and testing is within the guidelines.

Material testing for the project begins with the award of the project. At the pre-construction meeting, the Contractor must give MDOT a copy of the Testing Order listing the materials to be used and their sources.

The Materials Source Guide and the Materials Quality Assurance Procedures Manual contain guidelines and sampling procedures.

Concrete Admixtures

Most MDOT-specified concrete will contain one or more of the following admixtures:

Air Entraining Agents - These agents are used for concrete exposed to freezing and thawing. A calibrated container, interlocked with the batching sequence and in sight of the plant operator, is required when dispensing air entraining agents.

Water Reducers - Water reducers are used in most pavement concrete to reduce the cement content and/or water-cement ratio to achieve the required minimum strength. An interlocking dispenser, similar to that used with air entraining agents, is required.

Water Reducing Retarders - Reducing retarders are seldom used except for bridge deck placement where it may be desirable to place enough concrete to allow the beams to deflect before the concrete has achieved its set. This may help reduce the likelihood of deck cracking or loss of bond between the uncured concrete and the reinforcement and/or shear developers before the concrete has achieved sufficient strength. However, retarders should not be used as a replacement for maintaining the pour sequence specified on the plans.

Non-Chloride Set Accelerators - These are used in full-depth pavement repairs to achieve early opening to traffic in moderate to warm weather. If early opening to traffic is required, every effort should be made to use as little set accelerator as necessary to achieve the required concrete strength. Current MDOT specifications require the Contractor to design the concrete mixture using the least amount of non-chloride set accelerator to achieve the minimum strength at the required opening to traffic time. The Contractor is also required to produce a trial batch and report strength results for each mix design prior to placing concrete. In general, non-chloride set accelerators are not effective toward achieving opening strengths earlier than 12 hours after concrete placement. In addition, if the average air temperature during curing is below 60 degrees, the opening to traffic strength may be further delayed. Batching and dispensing equipment at the plant, similar to that used for air entraining agents, is required.

Only MDOT approved air entraining, water reducing and water reducing retarding, non-chloride accelerating agents are permitted. The Materials Source Guide, issued by C&T, should be consulted for a list of currently approved materials and dosage rates.

Instructions to Concrete Mix Inspector

601.01 - INSTRUCTIONS TO CONCRETE MIX INSPECTOR MATERIALS

It is the responsibility of the concrete mix inspector to ensure that the Contractor or ready mix concrete producer is supplying concrete meeting specification requirements. All concrete testers will be required to possess a Michigan Level 1 Concrete Tester Certification (three year certification). Certification and testing will be conducted at various locations statewide by the Michigan Concrete Association and the Michigan Concrete Paving Association. No other method of qualification will be allowed. To accomplish this, the inspector must:

- Read the requirements in the current edition of the National Ready Mixed Concrete Association (NRMCA) - Quality Control Manual, Plant Certification Check List. Copies of the checklist are available in the Region or TSC office.

- Verify the plant has been inspected and certified by a private inspection agency meeting the requirements of the NRMCA certification program, or has been accepted for use by the Region materials personnel as a noncertified automated plant, or approved manual plant.

- Have the proper equipment to check the concrete mixture for slump, air content and temperature.

- Check to see that truck mixers, agitators or nonagitating hauling units meet the requirements of the NRMCA.

- Cast strength specimens, as needed, for quality assurance.

Plant Site Review

Before the concrete supplier starts to deliver concrete to the project, the inspector should check the plant site. Plants cannot adopt a standard layout because their layout depends on the site and method of materials delivery and storage. However, they can observe certain fundamental principles, especially for the handling and stockpiling of aggregate materials.

The stockpiles should be far enough apart to avoid contaminating one material with another.

While it is not a requirement, if the base for the stockpiles and roadways for the trucks are built with well-compacted granular material, it will ease the Contractor’s operations and reduce rejection of aggregates due to contamination with foreign materials.

Contamination Sources

Trucks usually deliver aggregate materials to the plant and deposit them at the base of the stockpiles. From there, they are cast into the stockpiles by a , or a front-end loader. This introduces two possible sources of contamination with foreign material.

- If the trucks haul over muddy roads or across clay areas, the dual tires may carry large quantities of clay or mud into the stockpile area.

- If the operator becomes careless in building the stockpile and gouges the bucket into the earth under the base, contaminated material may be introduced into the stockpile. Make frequent inspections of the stockpile operations.

Materials contaminated during stockpiling or charging of the bins must be removed and changes made to the operation to prevent further contamination.

Maintaining Moisture in Stockpiles

If blast-furnace slag coarse aggregate is being used in the concrete, the Contractor should continuously water the slag stockpile while it is being built and maintained. This is especially important during periods of hot weather and low relative humidity. If dry slag coarse aggregate is permitted to be introduced into the concrete mixture during batching, it will absorb excessive amounts of mix water, thus, increasing the potential for early-age uncontrolled random cracking of the pavement.

NRMCA Plant Certification

Portable and stationary concrete batch plant facilities supplying Portland cement concrete (PCC) must be certified and meet NRMCA requirements. Portable concrete batch plant facilities must be recertified on an annual basis at the start of production. After each move, the Contractor must perform a verification inspection of the plant following the NRMCA plant certification checklist.

Documentation that the batch plant meets NRMCA certification requirements must be provided to the Engineer prior to batching concrete. A certified scale company must certify scales after each move.

A waiver of NRMCA certification will be permitted if it is determined that no NRMCA-certified facility is within 25 miles (40 km) of the project limits. Batching facilities meeting the requirements of a fully automated plant, and approved by Region materials personnel, will then be permitted.

If a NRMCA, or a certified or approved automated plant is not available, then a waiver of automation will be permitted and a manual plant may be used with the Engineer’s approval.

Every plant, regardless of certification or approval status, must have a current scale check report on file. The five page Concrete Plant Equipment Inspection Report, Form 580 (Figure 601-1) should be on file at the TSC (with corrections documented for any deficiencies noted) for plants receiving waiver of NRMCA certification. NRMCA certified plants must display their current Certificate of Conformance on-site, and furnish the Department with a photocopy to be on file at the TSC.

Documentation

Concrete Tickets

The Contractor/concrete producer will have computer-generated delivery tickets from plants certified by NRMCA.

|

| |

|---|---|

|

|

Name of concrete producer |

|

|

Plant designation where batched. |

|

|

Ticket serial number |

|

|

Truck Number |

|

|

Contractor name |

|

|

MDOT job NumberDate and time the batch was loaded. |

|

|

Grade of concrete |

|

|

Certification executed by the producer stating that all materials have been tested and approved, or certified as meeting MDOT’s specifications. Plants dedicated to only one project are excluded from this requirement. |

|

|

An automated printout of actual batch weights will accompany each delivery ticket. |

|

|

Cubic Yards of Concrete |

|

|

Delivery Date |

|

|

Batch Loading Time |

|

|

Maximum allowable on-site addition of water |

|

|

Extra water added on site |

|

|

Contractor signature or initials |

|

Type and name of admixtures with amount batched | |

Provide a space on each ticket for the engineer to sign. Tickets need to be signed by the street or structure inspector only when, in the Engineer’s opinion, a signature is needed to document elapsed times, concrete grades or other specification requirements.

Concrete tickets for Superstructure Concrete

Verify and record discharge time on tickets and sign all concrete delivery tickets. Include any testing results (air, temperature and slump) on the ticket

Exposed Concrete

The following items may be accepted on the basis of conventional field testing (slump, air and strength) and only intermittent plant observation will be required, as deemed necessary by the Engineer:

- Curb and gutter, valley gutter and sidewalk.

- Concrete dividers, medians and glare screens.

- Culvert head walls, spillways and paved ditches.

- Nonproduction base course.

- Slope paving and headers.

- Temporary pavements and nonproduction pavement patching.

- Sign and light standard foundations.

Batch weights will be set up from an approved mix design. The concrete delivery tickets will contain the same information required for production projects, including certification that the materials used in the concrete are State tested or certified as meeting specification requirements. A NRMCA certified plant should be used the Standard Specifications for Construction using Form 580 (Figure 604-1).

Yield checks are optional, as overruns may be expected with small pours, and they may not provide correlative information.

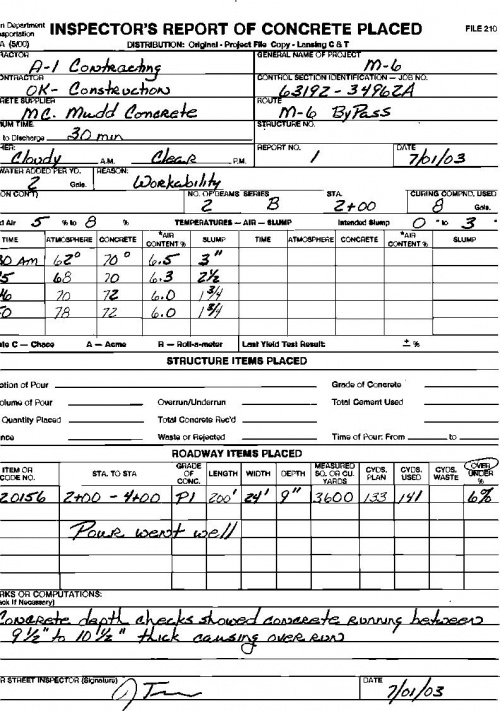

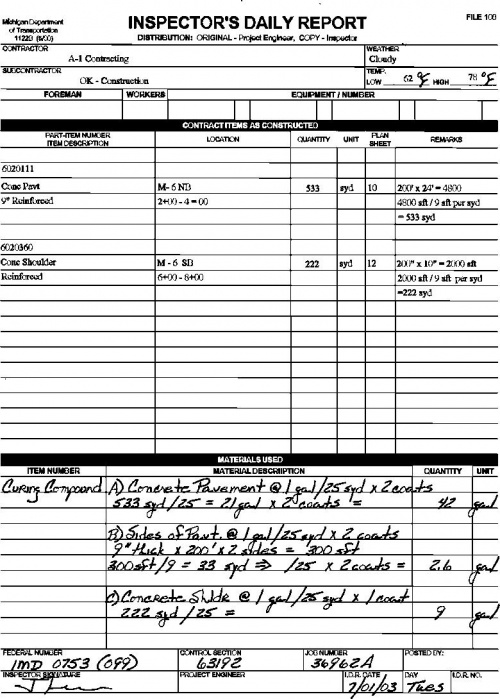

Documentation - The individual pours may be summarized on Inspector’s Report of Concrete Placed, Form 1174A (Figure 601-6) and submitted weekly, or more frequently, as judgment dictates. The report is intended to be a source document and history which will provide information on slump, air, etc. in the event the pour should develop some deficiency. Form 1174A should have the wording “Random Plant Inspection” printed in a prominent place to indicate that a continuous plant inspection was not observed. Any pay quantities should be reported on Daily Work Report (DWR), Form 1122B (Figure 601-7).

Nonexposed Concrete

Concrete without plant inspection and with limited field testing, as approved by the Engineer, may be used with the following concrete items:

- Manhole, catch basin and inlet foundations.

- Sign, signal and light bases.

- Fence post and guardrail anchors.

- Conduit and sewer encasement.

- Thrust blocks.

- Other nonexposed items designated in the plans or proposal such as tremie seals, mud mats or subfootings.

Substructure concrete above the subfooting and water main encasement are not to be considered in this category but must have complete reporting and inspection.

Documentation: Form 1174 will not be required, but pay quantities will be reported on Form 1174A and the Daily Work Report (DWR), Form 1122. Cylinders/beams, when made, should be reported on Concrete Cylinder/Core Compression Test Results, Form 1160B (Figure 602-2) if cylinders were cast and submitted after strength determination was completed or Report of Modulus of Rupture, Form 1160A (Figure 602-3). Concrete delivery tickets are to state the cement content per cubic yard.

|

DATE | ||

|---|---|---|

|

GENERAL INFORMATION | ||

|

CONTRACTOR’S NAME |

PROJECT NAME | |

|

CONTROL SECTION NO. |

JOB NO. | |

|

PERSONNEL QUALIFICATIONS | ||

|

| ||

|

NAME |

QUALIFICATION | |

|

Possession of one of the following credentials will be considered qualified:

| ||

|

| ||

|

NAME |

QUALIFICATION | |

|

|

| |

|

|

| |

|

Possession of one of the following credentials will be considered qualified:

| ||

|

EQUIPMENT AND FACILITIES | ||

|

| ||

|

SERIAL NO. |

TYPE |

CALIBRATION PROVIDED YES/NO |

|

|

|

|

|

|

|

|

|

Description of curing facilities given |

Acceptable? Yes / No | |

|

Description of how samples will be handled |

Acceptable? Yes / No | |

|

DATE | ||

|---|---|---|

|

| ||

|

SERIAL NO. |

TYPE |

CALIBRATION PROVIDED YES/NO |

|

SAMPLING SYSTEM | ||

|

The special provision for Contractor quality control lists minimal testing required. | ||

|

Yield |

After the start of the first concrete operation for each mix design, determine yield. |

Acceptable? Yes / No |

|

Slump |

At the start of the placement, test first load (subsequent loads, if required). During concrete placement, test for slump at least once per hour. |

Acceptable? Yes / No |

|

Air Entrainment |

At the start of the placement, test first load (subsequent loads, if required). During concrete placement, test for air content at least once per hour. |

Acceptable? Yes / No |

|

Temperature |

At the start of placement, test first load (subsequent loads, if required). During concrete placement, test for temperature at least once per hour. |

Acceptable? Yes / No |

|

Strength |

Determine the strength at least once every 200 yd3 for a specific mix design. A single strength test consists of two cylinders, or two beams. |

Acceptable? Yes / No |

|

ADMINISTRATION | ||

|

| ||

|

PERSON REJECTING CONCRETE |

||

|

WHOM THIS PERSON WILL NOTIFY |

||

|

CONTRACTOR’S REPRESENTATIVE (SIGNATURE) |

||

Concrete Technician’s Checklist

|

|

|

|---|---|

|

|

Aggregates handled to avoid contamination in stockpiles and storage bins. Is base under stockpile? |

|

|

Test slips or certification for all aggregates. Stockpiles must be identified in commercial plants. |

|

|

Certification slips for cement. |

|

|

Up-to-date materials and technology scale check and plant inspection report (should be within the past year, or since last move). Reports should be at the plant. |

|

|

Cement scales are to be checked as requested by the Engineer using standard 50 lb. (22.68 kg) weights, or any other practical combination of weights furnished by the producer. Make sure scale knife edges are clean and centered. |

|

|

Automatic control check performed periodically as requested by the Engineer and reported by plant inspector (Form 1114). |

|

|

Admixture dispensers are to be checked by plant technician daily. A sufficient supply of admixture should be on hand to avoid running out of material. The air-entraining admixture, water reducing admixture or water reducing and retarding admixture dispenser must be interlocked with the batching cycle to stop. Admixtures must be on a department approved list. If non-air entrained cement is used, both a meter and visual indication of admixture must be present. |

|

|

Check for adequate mixing time for the type of mixer used. Truck mixers are to mix at least 70 revolutions at the plant site. |

|

|

Have updated mix design charts for materials used at the plant, and be sure that the proper mix is being used. |

|

|

Stockpiles must be fairly uniform in moisture content. Slag stockpiles mat have to be wet down to obtain uniform moisture. |

|

|

Select coarse aggregate unit weight and average moisture content for fine and coarse aggregate before start of production. |

|

|

Are proper weights set on scales, presets, punch cards or computers? |

|

|

Equipment and facilities available for water/cement ratio test on bridge decks? |

|

|

Arrange for casting, curing and breaking of test beams. |

CONSTRUCTION

-Reserved-

MEASUREMENT AND PAYMENT

-Reserved-