File list

Jump to navigation

Jump to search

This special page shows all uploaded files.

| Date | Name | Thumbnail | Size | User | Description | Versions |

|---|---|---|---|---|---|---|

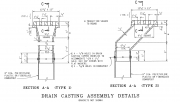

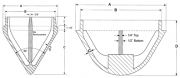

| 08:21, 9 April 2014 | Fig717-01.png (file) |  |

154 KB | Greenes2 | Drain Casting Assembly Details from Standard Plan Series B101 | 1 |

| 08:20, 9 April 2014 | Fig711-07.png (file) |  |

110 KB | Greenes2 | Bridge Barrier Railing, Aesthetic Parapet Tube | 1 |

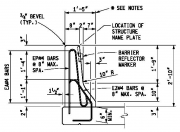

| 08:19, 9 April 2014 | Fig711-06.png (file) |  |

28 KB | Greenes2 | Bridge Barrier Railing, Thrie Beam Retrofit (Open Parapet Type Bridge Railing) | 1 |

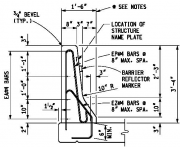

| 08:18, 9 April 2014 | Fig711-05.png (file) |  |

17 KB | Greenes2 | Bridge Barrier Railing, Thrie Beam REtorfit (R4 Type Bridge Railing) | 1 |

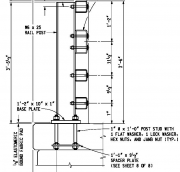

| 08:17, 9 April 2014 | Fig711-04.png (file) |  |

41 KB | Greenes2 | Bridge Barrier Railing, 4 Tube | 1 |

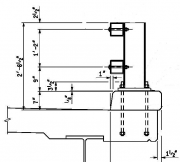

| 08:16, 9 April 2014 | Fig711-03.png (file) |  |

52 KB | Greenes2 | Bridge Barrier Railing, 2 Tube | 1 |

| 08:16, 9 April 2014 | Fig711-02.png (file) |  |

28 KB | Greenes2 | Bridge Barrier Railing Type 5 | 1 |

| 08:15, 9 April 2014 | Fig711-01.png (file) |  |

30 KB | Greenes2 | Bridge Barrier Railing Type 4 | 1 |

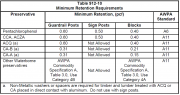

| 08:14, 9 April 2014 | Fig709-05.png (file) |  |

161 KB | Greenes2 | Table 912-10 Preservation retention requirements. MDOT 2012 Standard Specifications for Construction. | 1 |

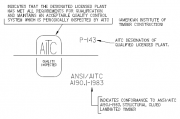

| 08:12, 9 April 2014 | Fig709-04.png (file) |  |

23 KB | Greenes2 | Inspection Stamp for Glulam Lumber | 1 |

| 08:11, 9 April 2014 | Fig709-03.png (file) |  |

518 KB | Greenes2 | Stress laminated deck system showing typical components. USDA-FPL-GTR-125 | 1 |

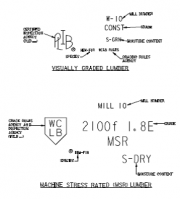

| 08:06, 9 April 2014 | Fig709-02.png (file) |  |

19 KB | Greenes2 | Typical Lumber Grading Marks | 1 |

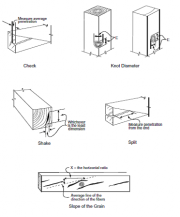

| 08:06, 9 April 2014 | Fig709-01.png (file) |  |

40 KB | Greenes2 | Timber and Lumber Terminology | 1 |

| 16:58, 7 April 2014 | Letter - Procedures for Review of Contractor Claims.png (file) |  |

76 KB | Greenes2 | Letter-Procedures for Review of Contractor Claims | 1 |

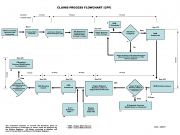

| 16:57, 7 April 2014 | IM11-07 CPF.png (file) |  |

59 KB | Greenes2 | Claims Process Flow Chart | 1 |

| 14:24, 19 March 2014 | Flowchart 602-09.png (file) |  |

41 KB | Greenes2 | Figure 602-9 Pavement Coring for Acceptance Flow Chart | 1 |

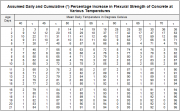

| 14:12, 19 March 2014 | Table 602 % increase strength.png (file) |  |

27 KB | Greenes2 | Table 602 % increase strength.png | 1 |

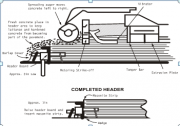

| 13:37, 19 March 2014 | Fig 602-08.png (file) |  |

33 KB | Greenes2 | Figure 602-8 Header Board Placement | 1 |

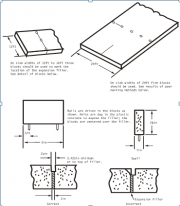

| 13:36, 19 March 2014 | Fig 602-07.png (file) |  |

40 KB | Greenes2 | Figure 602-7 Transverse Expansion Joints | 1 |

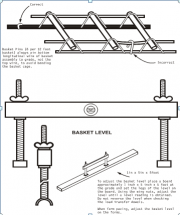

| 13:36, 19 March 2014 | Fig 602-06.png (file) |  |

47 KB | Greenes2 | Figure 602-6 Basket Pin and Basket Level | 1 |

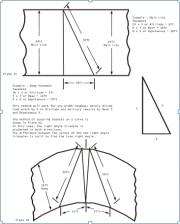

| 13:35, 19 March 2014 | Fig 602-05.png (file) |  |

39 KB | Greenes2 | Figure 602-5 Positioning Dowel Basket Assemblies | 1 |

| 09:56, 19 March 2014 | Fig 718-9.png (file) |  |

249 KB | Greenes2 | Figure 9. Improper concrete placement | 1 |

| 09:56, 19 March 2014 | Fig 718-8.png (file) |  |

298 KB | Greenes2 | Figure 8. Rebar cage being lowered into complete shaft | 1 |

| 09:55, 19 March 2014 | Fig 718-7.png (file) |  |

150 KB | Greenes2 | Figure 7. Rebar cage spacers | 1 |

| 09:55, 19 March 2014 | Fig 718-6.png (file) |  |

59 KB | Greenes2 | Figure 6. Soft rock core barrel | 1 |

| 09:55, 19 March 2014 | Fig 718-5.png (file) |  |

76 KB | Greenes2 | Figure 5. Muck bucket bottom | 1 |

| 09:54, 19 March 2014 | Fig 718-4.png (file) |  |

124 KB | Greenes2 | Figure 4. Muck bucket | 1 |

| 09:54, 19 March 2014 | Fig 718-3.png (file) |  |

98 KB | Greenes2 | Figure 3. Single flight rock auger | 1 |

| 09:54, 19 March 2014 | Fig 718-2.png (file) |  |

270 KB | Greenes2 | Figure 2. Double flight earth auger | 1 |

| 09:53, 19 March 2014 | Fig 718-1.png (file) |  |

189 KB | Greenes2 | Figure 1. Typical drill rig set up | 1 |

| 14:00, 18 March 2014 | 103 Figure 1.jpg (file) |  |

56 KB | Greenes2 | Figure 1 – Approval Thresholds for contract revisions | 1 |

| 12:16, 3 February 2014 | Fig 705-6.png (file) |  |

56 KB | Greenes2 | Figure 6. Typical conical pile pile points | 1 |

| 12:16, 3 February 2014 | Fig 705-5.png (file) |  |

21 KB | Greenes2 | Figure 5. Typical HP section pile points | 1 |

| 12:16, 3 February 2014 | Fig 705-4.png (file) |  |

77 KB | Greenes2 | Figure 4. Typical helmet and cushion configuration | 1 |

| 12:15, 3 February 2014 | Fig 705-3.png (file) |  |

30 KB | Greenes2 | Figure 3. Typical nylon hammer cushions | 1 |

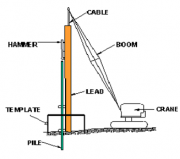

| 12:15, 3 February 2014 | Fig 705-2.png (file) |  |

22 KB | Greenes2 | Figure 2. Typical pile driving equipment set up | 1 |

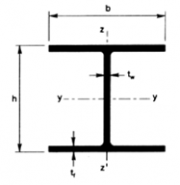

| 12:14, 3 February 2014 | Fig 705-1.png (file) |  |

8 KB | Greenes2 | Figure 1. Typical HP shape | 1 |

| 16:30, 29 January 2014 | Fig 704-8.png (file) |  |

1.21 MB | Greenes2 | Figure 704-8: Typical cofferdam bracing with walers and struts | 1 |

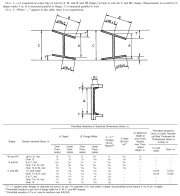

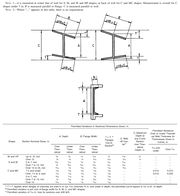

| 12:39, 29 January 2014 | 714 Fig 5.png (file) |  |

902 KB | Greenes2 | Figure 5. ASTM A6 permitted variations in sectional dimensions | 1 |

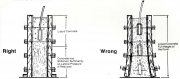

| 12:21, 29 January 2014 | 714 Fig 7.png (file) |  |

586 KB | Greenes2 | Figure 7. Proper vibrating techniques in deep forms | 1 |

| 12:21, 29 January 2014 | 714 Fig 6.png (file) |  |

1.07 MB | Greenes2 | Figure 6. ASTM A6 permitted variations in straightness | 1 |

| 12:20, 29 January 2014 | 714 Fig 5.jpg (file) |  |

1.17 MB | Greenes2 | Figure 5. ASTM A6 permitted variations in sectional dimensions | 1 |

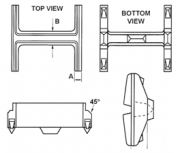

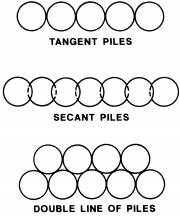

| 12:12, 29 January 2014 | 714 Fig 4.png (file) |  |

32 KB | Greenes2 | Figure 4. Typical pile wall layouts | 1 |

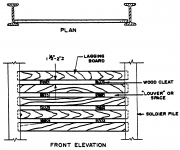

| 12:11, 29 January 2014 | 714 Fig 3.png (file) |  |

40 KB | Greenes2 | Figure 3. Typical soldier pile wall section | 1 |

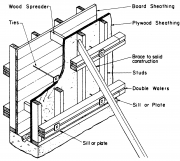

| 12:10, 29 January 2014 | 714 Fig 2.png (file) |  |

65 KB | Greenes2 | Figure 2. Typical formwork components | 1 |

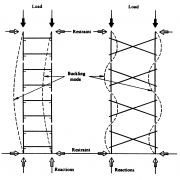

| 12:10, 29 January 2014 | 714 Fig 1.png (file) |  |

42 KB | Greenes2 | Figure 1. Shoring tower buckling modes | 1 |

| 16:10, 18 December 2013 | HMA2.jpg (file) |  |

50 KB | Greenes2 | Cover Photo 2 for 501 | 1 |

| 16:08, 18 December 2013 | HMA1.jpg (file) |  |

93 KB | Greenes2 | Cover Photo 1 for 501 | 1 |

| 16:04, 18 December 2013 | HMA1.png (file) |  |

19 KB | Greenes2 | Cover Photo 1 for 501 | 1 |

| 10:54, 8 November 2013 | 704-7.JPG (file) |  |

423 KB | Rinarda | 1 |